Preparation method of nano molybdenum disulfide (MoS2) hydrogenation catalyst exposed at high active site

A hydrogenation catalyst, a high-activity technology, applied in physical/chemical process catalysts, molybdenum sulfide, chemical instruments and methods, etc., can solve the problems of no catalyst hydrogenation active sites, low size and stacking degree, etc., and achieves safe synthesis conditions. The effect of increasing active site exposure and high catalytic hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

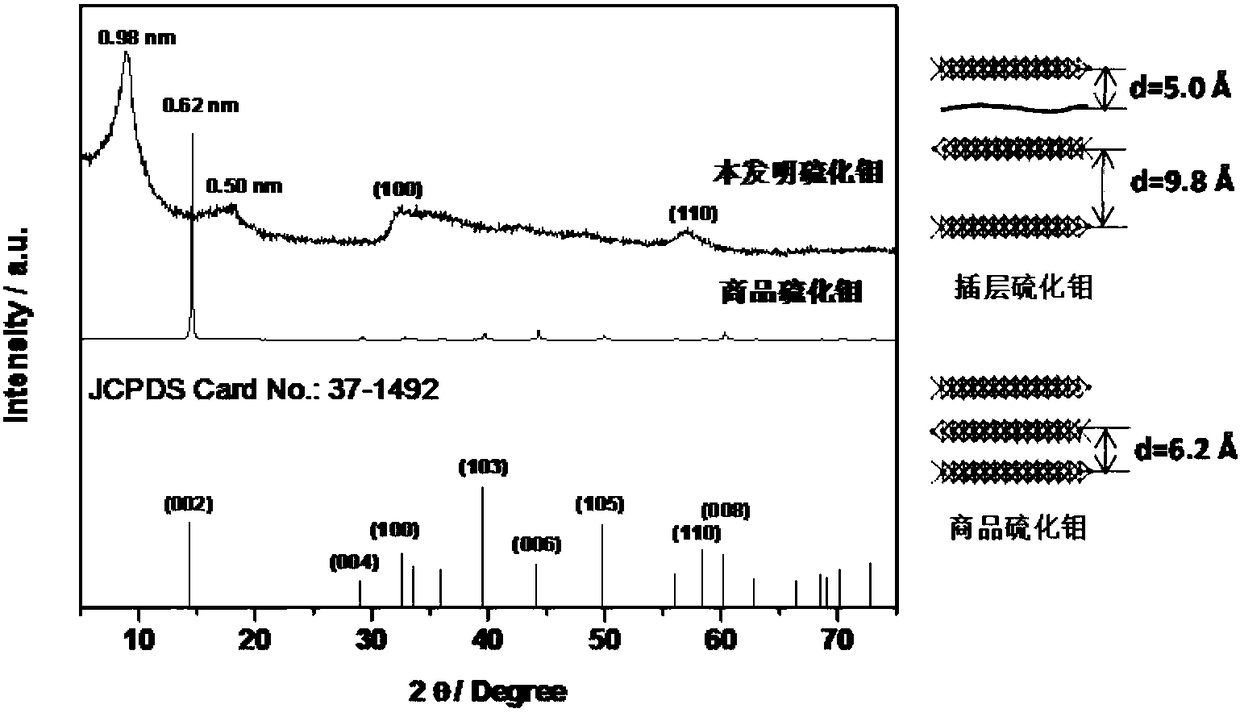

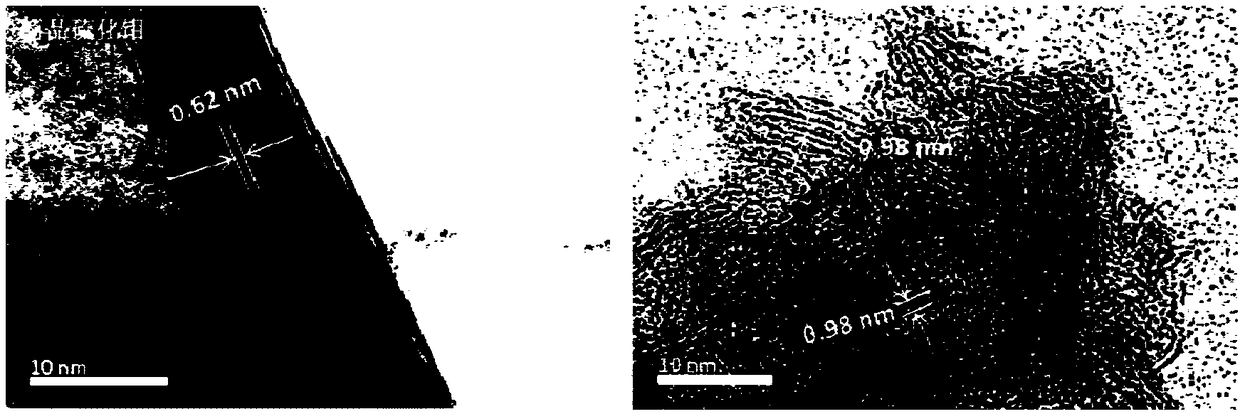

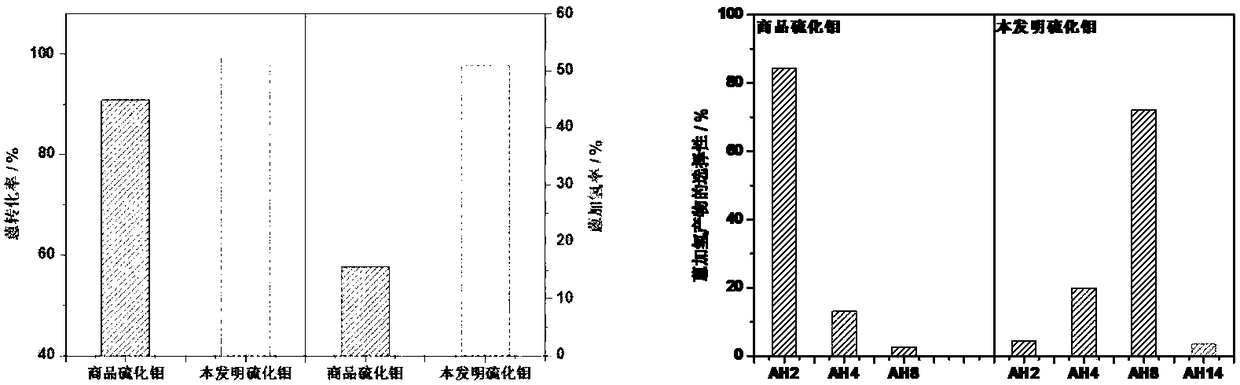

[0026]Disperse 1.62mmol of ammonium heptamolybdate and 4.25mmol of sulfur powder in 50ml of ethylene glycol to form a 0.016M molybdenum source suspension with an S / Mo ratio of 3:1. The ratio of atoms is 7:1. After ultrasonication for 10 minutes, the suspension was fully stirred and transferred to a 100ml hydrothermal kettle, reacted at 180°C for 6 hours, naturally cooled to room temperature, filtered with suction, the precipitate was washed with deionized water and absolute ethanol, and vacuum-dried at 70°C Overnight, collect MoS 2 sample. As a comparison, the commercial MoS 2 Characterization and activity evaluation were performed. The two samples were characterized by XRD and HRTEM, and it was found that the two product components were MoS 2 , but unlike commodity MoS 2 The bulk multilayer stacked structure, the MoS prepared by the present invention 2 With enlarged interlayer, lower packing degree and smaller sheet size (see figure 1 and figure 2 ). The two are use...

Embodiment 2

[0028] Disperse 5mmol of sodium molybdate and 20mmol of sodium sulfide in 50ml of ethylene glycol to form a 0.1M molybdenum source solution with a S / Mo ratio of 4:1, add 10mmol of oxalic acid to make the ratio of Mo atoms to 2:1 . After ultrasonication for 10 minutes, the suspension was fully stirred and transferred to a 100ml hydrothermal kettle, reacted at 160°C for 24 hours, cooled naturally to room temperature, filtered with suction, washed with deionized water and absolute ethanol, and dried in vacuum at 70°C Overnight, collect MoS 2 sample.

Embodiment 3

[0030] Disperse 15mmol of molybdenum oxide and 30mmol of ammonium sulfide in 50ml of diethylene glycol to form a 0.3M molybdenum source solution with an S / Mo ratio of 2:1, and add 15mmol of glucose to make the ratio of Mo atoms to 1:1. After ultrasonication for 10 minutes, the suspension was fully stirred and transferred to a 100ml hydrothermal kettle, reacted at 140°C for 48 hours, cooled naturally to room temperature, filtered with suction, washed with deionized water and absolute ethanol, and dried in vacuum at 70°C Overnight, collect MoS 2 sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com