Collagen protein composite fiber and its producing method

A technology of collagen and composite fibers, which is applied in the direction of fiber chemical characteristics, conjugated artificial filaments, textiles and papermaking, etc., can solve the problems of high production cost, long production cycle and high price, and achieve good hygroscopicity and dyeing performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

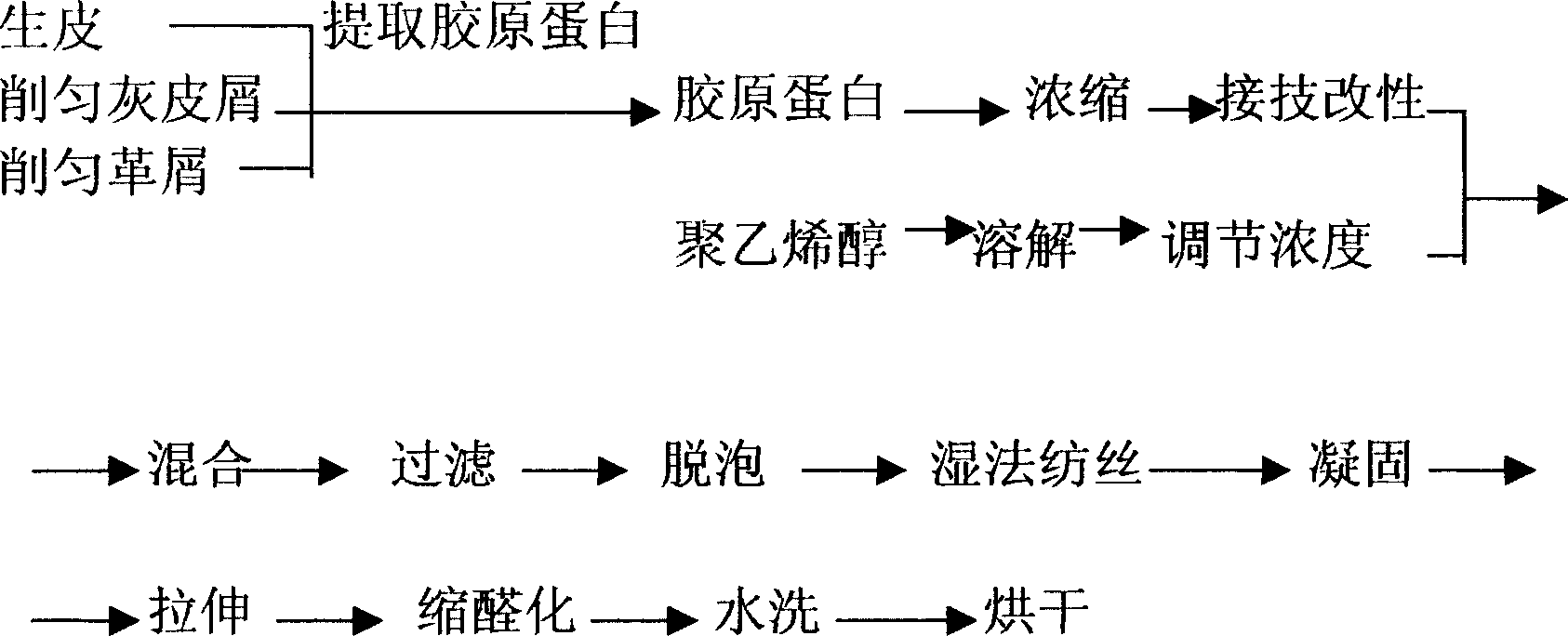

Method used

Image

Examples

Embodiment 1

[0028] Take the rawhide after depilation and liming, put it into the meat on the meat remover, cut it into 2cm×2cm pieces of skin, put it in a drum, wash it with 3 times 35°C water for 15 minutes, drain the water and then wash it again. After pouring out the water in the drum, add 3 times of 35°C clear water, 2% ammonium sulfate and 0.5% of Pyrene, rotate for 40 minutes, discard the water in the drum, and use 3 times of 35°C Wash twice with water and dry, transfer the cleaned leather to the reaction kettle, add 1.5 times of water, gradually raise the temperature to 80°C, and keep warm for 6 hours to gradually dissolve the raw hide, filter, take the filtrate and concentrate to a concentration of 18 %.

[0029] Analyze the collagen solution, transfer it to the reaction kettle, raise the temperature to 60°C, dissolve ammonium persulfate with 10 times the amount of collagen to 1.5% of the collagen content, gradually add it dropwise to the reaction kettle, and simultaneously drop 2...

Embodiment 2

[0033] Take the discarded skin flakes from the tannery's gray skin after peeling, put it in the drum, wash it with 3 times 35 ℃ water for 15 minutes, control the water and wash it again, pour the water in the drum, and then add 3 times 35°C water, use 2% ammonium sulfate of skin weight and 0.5% leveling agent, rotate for 40 minutes, discard the water in the drum, wash with 3 times 35°C water twice and control dry, wash clean Transfer the skin pieces to the reaction kettle, add 3 times of water, gradually heat up to 80°C, and keep warm for 4 hours to gradually dissolve the skin flakes, filter, take the filtrate and concentrate to a concentration of 20%.

[0034] Analyze the collagen solution, transfer it to the reaction kettle, raise the temperature to 68°C, dissolve 0.5% ammonium sulfate with 10 times the amount of collagen, and gradually add it dropwise to the reaction kettle, and simultaneously drop 5% acrylonitrile monomer , After the addition was completed within 30 minute...

example 3

[0037]Take the discarded leather shavings from the wet blue leather of the tannery after shaving, put them in the drum, wash them with 3 times 35°C water for 15 minutes, control the water and then wash them again, and transfer the washed leather shavings to the reaction kettle , add 8 times of water and 5% calcium hydroxide of leather shavings, gradually heat up to 90°C, and keep warm for 4 hours to gradually dissolve the leather shavings, filter, neutralize the pH value to 7± with diluted sulfuric acid solution, and then filter The calcium sulfate precipitate was removed, and the filtrate was concentrated to a concentration of 15%.

[0038] Analyze the obtained collagen solution, transfer it to the reaction kettle, heat up to 75°C, dissolve 1% ammonium sulfate with 10 times the amount of collagen in water, gradually add it dropwise to the reaction kettle, and simultaneously drop 8% acrylamide and After adding 5% methacrylic acid monomer within 30 minutes, keep it warm for 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com