Method for preparing LimMn(XO4)y Lithium ion cell electrode material

A technology for lithium ion batteries and electrode materials, applied in the field of chemical materials, can solve the problems of inability to meet the performance requirements of power lithium ion batteries, harsh process conditions, complicated preparation processes, etc., and achieves easy mass production, cheap raw materials, and easy conditions. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation

[0028] Example 1 Lithium-ion battery LiFePO 4 Preparation of / C nanometer cathode material

[0029] 17.7g LiOH·H 2 O, 164.1g Fe(NO 3 ) 3 ·6H 2 O and 46.5 g NH 3 h 2 PO 4 The aqueous solution was mixed to form a uniform aqueous solution, and then added dropwise to the mixed solution of 58.8g acrylic acid, after stirring evenly, 50mg of 4% initiator aqueous solution ((NH 4 ) 2 S 2 o 8 ), initiate polymerization at 80°C, and then dry the polymer at 120°C to obtain a polymer precursor. The polymer precursor was burned for 3 hours at 700 °C under the protection of argon to obtain the target product LiFePO 4 / C. The product contained -13% carbon.

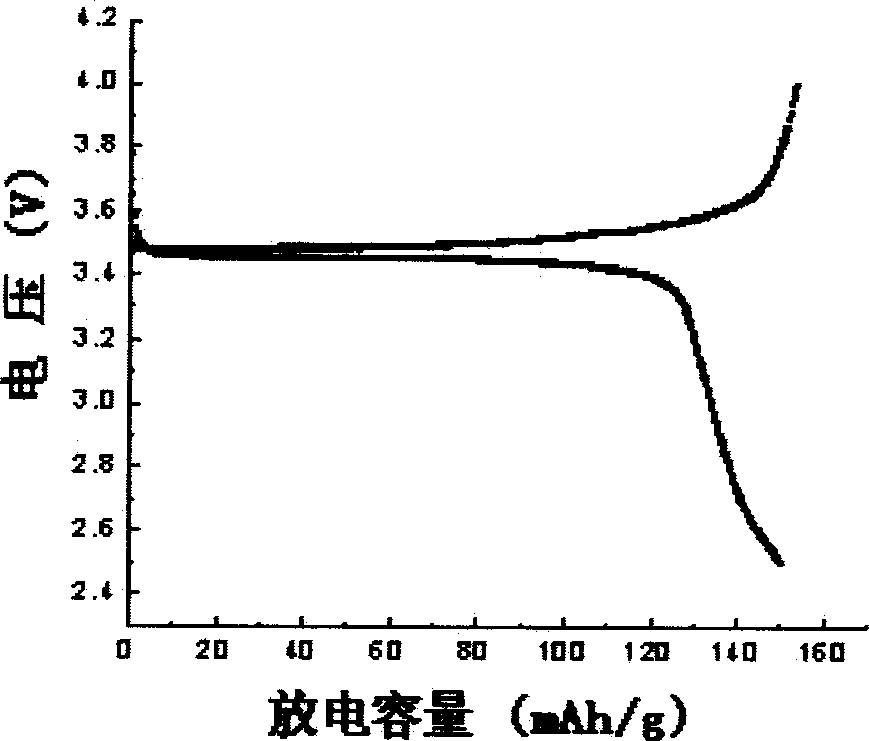

[0030] The resulting LiFePO 4 The TEM image of the / C material shows that the material synthesized by this method has a uniform particle size distribution and a nanometer scale (~70nm). figure 1 The discharge performance of the material as the positive electrode material of lithium-ion bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com