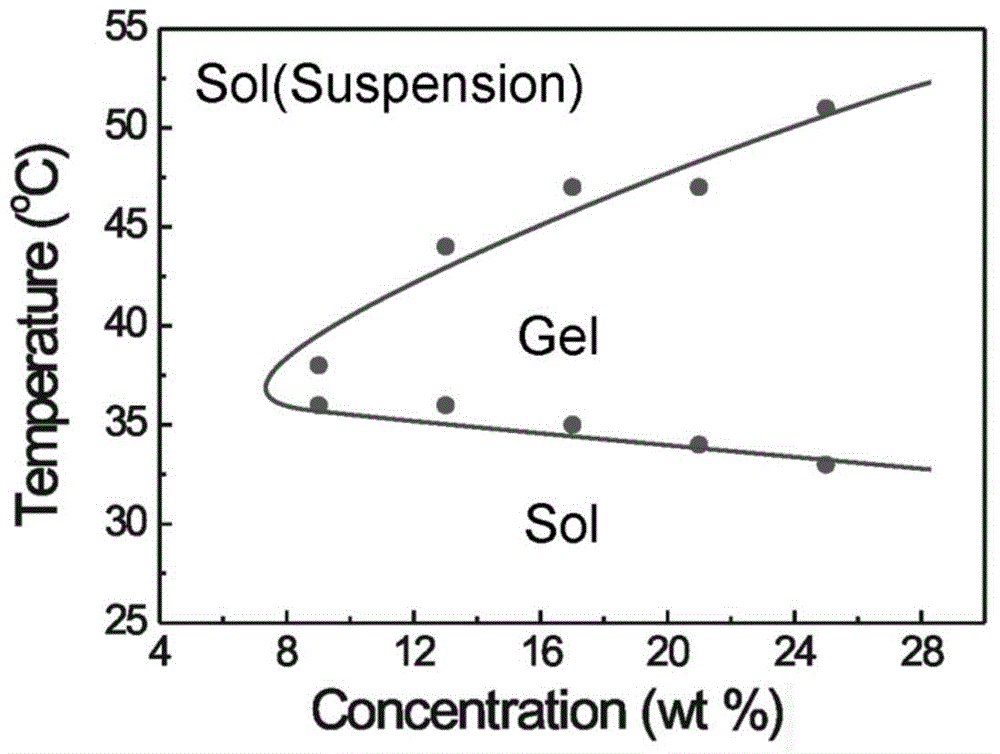

Submucous injection material composed of physical cross-linked hydrogel and application thereof

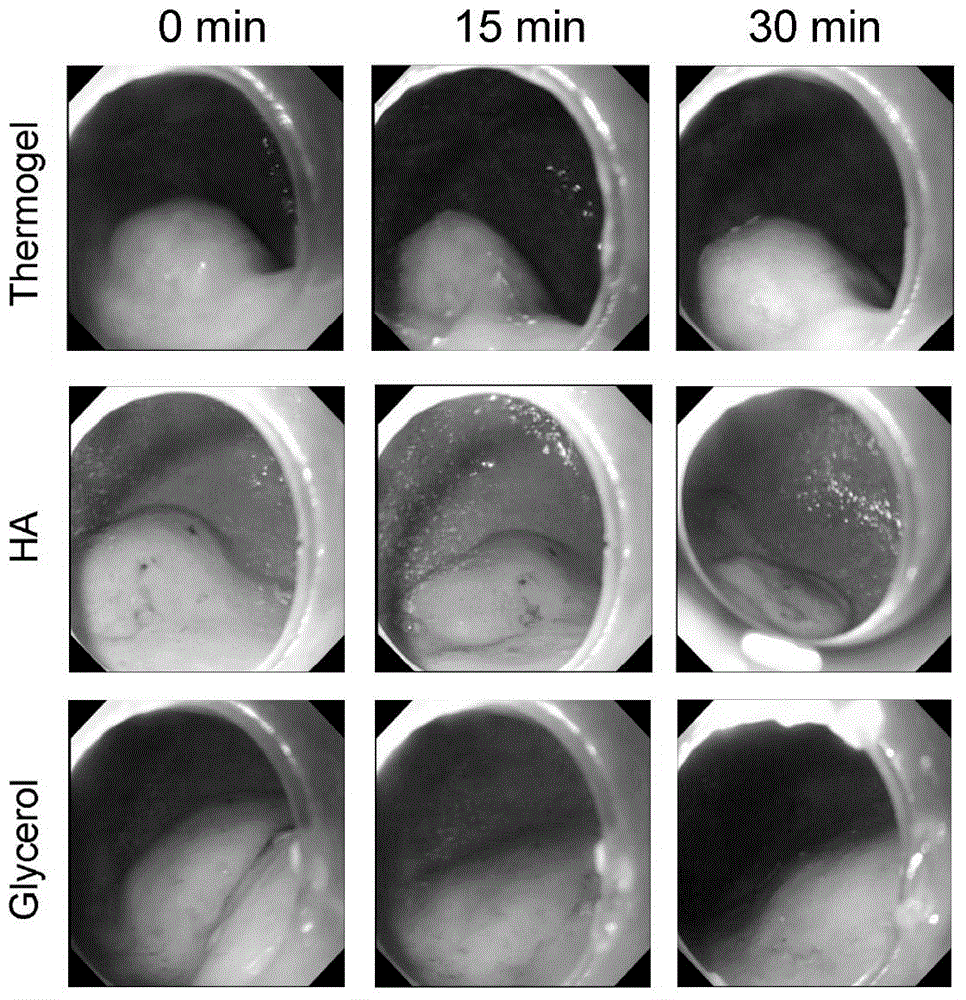

A physical cross-linking and hydrogel technology, which is applied in the field of polymer materials and medical devices, can solve problems such as insufficient bulge height and maintenance time, high price, and application limitations, so as to reduce the difficulty of surgical operations, reduce perforation, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

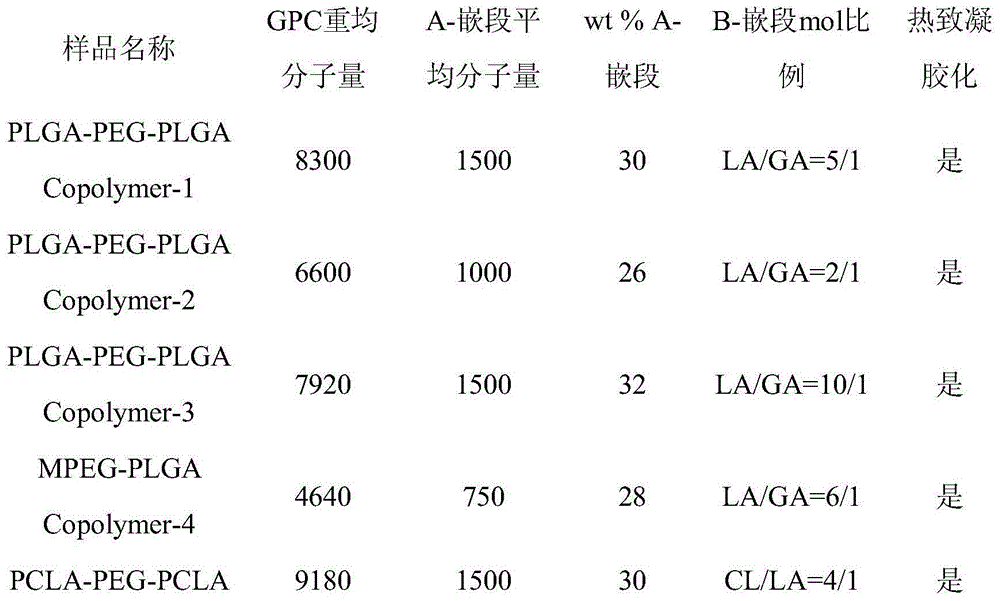

Embodiment 1

[0061] Add 30g of PEG (1500°C) into a 250mL three-neck flask, heat the oil bath to 130°C, and vacuumize for 3h while stirring to remove the residual moisture in the PEG. Then, 56g DL-lactide (LA), 8.9g glycolide (GA) and 0.1wt% stannous octoate (containing a small amount of toluene) were added, and the toluene was removed by vacuuming below 100°C for 30min. Raise the temperature to 150°C, and react for 12 hours under an argon atmosphere after the monomers are completely melted. After the reaction, vacuum filter for 3 hours to remove unreacted monomers and low-boiling products, pour out the reaction product while it is hot, wash with water several times and then freeze-dry to obtain a tri-block copolymer with a yield of about 80%. The number-average and weight-average molecular weight (M n ,M w ) were 6690 and 8300, respectively, and the molecular weight distribution coefficient (M w / M n ) is 1.24. Its water system has the characteristic of heat-induced gelation.

Embodiment 2

[0063] Add 22.5 g of monomethoxy-terminated polyethylene glycol (MPEG750) into a 250 mL three-neck flask, heat the oil bath to 130 ° C, and vacuumize for 3 h while stirring to remove residual moisture in MPEG. Add 45g DL-LA, 6g GA and 0.1wt% stannous octoate (containing a small amount of toluene), and vacuum below 100°C for 30min to remove the toluene. Raise the temperature to 150°C, and react for 12 hours under an argon atmosphere after the monomers are completely melted. After the reaction, vacuum filter for 3 hours to remove unreacted monomers and low-boiling products, pour out the reaction product while it is hot, wash with water several times and then freeze-dry to obtain a diblock copolymer material with a yield of about 75%. The number average and weight average molecular weight (MPEG-PLGA, Copolymer-4) of the BA diblock copolymer (MPEG-PLGA, Copolymer-4) were measured by GPC n ,M w ) were 3570 and 4640, respectively, and the molecular weight distribution coefficient ...

Embodiment 3

[0065] Take 15.0g of PEG (1500) in a 250mL three-neck flask, and vacuumize it for 3h while stirring at 130°C to remove the water contained therein. Add 29.0 g of caprolactone (CL) and 0.3 wt % stannous octoate, and react at 120 ° C for 24 h under an argon atmosphere. After the reaction, vacuum filter for 3 hours to remove unreacted monomers and low-boiling products, and then dissolve the initial product in dichloromethane solution, and diethyl ether precipitates. The yield is about 85%. Measure the number average and weight average molecular weight (M) of the BAB block copolymer (PCL-PEG-PCL, Copolymer-8) by GPC n ,M w ) were 7100 and 9230, respectively, and the molecular weight distribution coefficient (M w / M n ) is 1.30. The copolymer itself has the property of thermally reversible gelation in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com