Method for preparing bismuth vanadate-polyacid gas sensing composite nano-material

A nanocomposite material and gas sensing technology, which is applied in the field of preparation of bismuth vanadate-polyacid gas sensing nanocomposite materials, can solve problems such as poor performance, affecting electron transmission, weakening of gas sensing detection signals, etc. The effect of maintaining sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

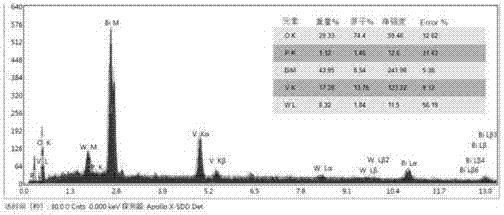

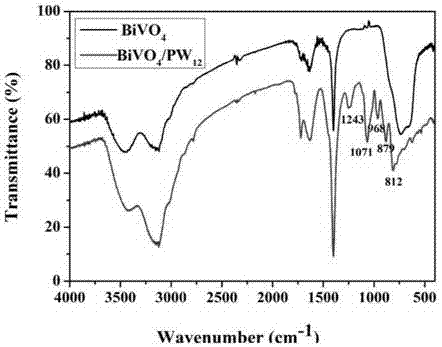

Method used

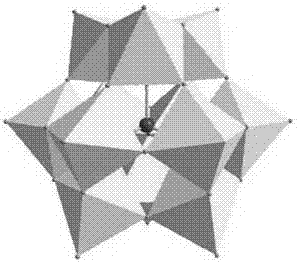

Image

Examples

specific Embodiment 1

[0030] Put the interdigitated electrode with the composite film into the sealed quartz reaction container for testing, one of the gold electrodes of the interdigitated electrode is connected to the working electrode of the electrochemical workstation with a wire, the other gold electrode and the counter electrode and the reference The electrodes are connected. A voltage of 0.1V was applied between the two electrodes, and a stable photocurrent value was obtained under the irradiation of a xenon lamp. When injecting 5ppm, 10ppm, 20ppm, 30ppm and 50ppm nitrogen dioxide gas into the quartz reaction vessel, the current between the two electrodes increases obviously. (see attached Figure 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com