Patents

Literature

33results about How to "Mild working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

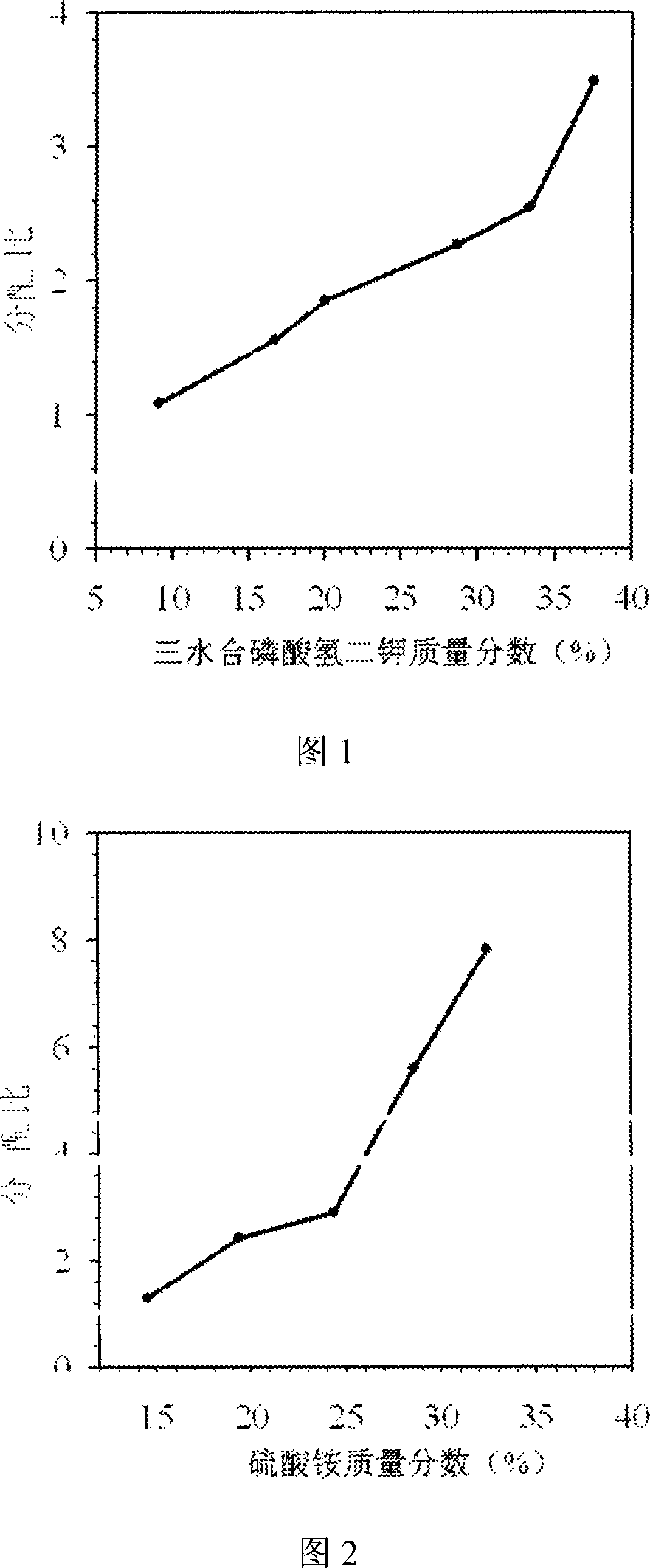

Process of enriching ionic liquid from water solution

InactiveCN1973943AEasy to adjustAchieve multi-level enrichmentLiquid solutions solvent extractionNon-miscible liquid separationEconomic benefitsAqueous solution

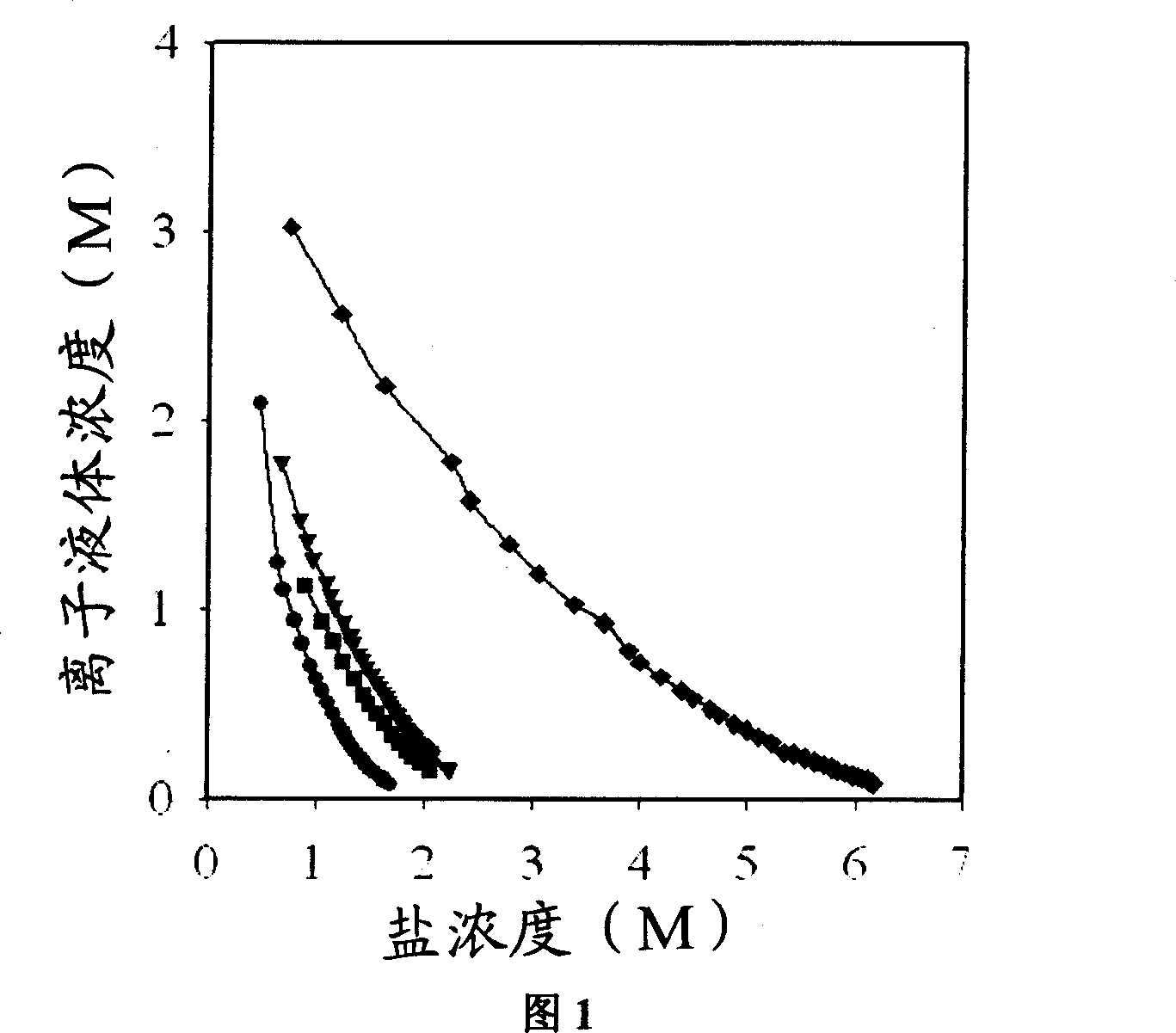

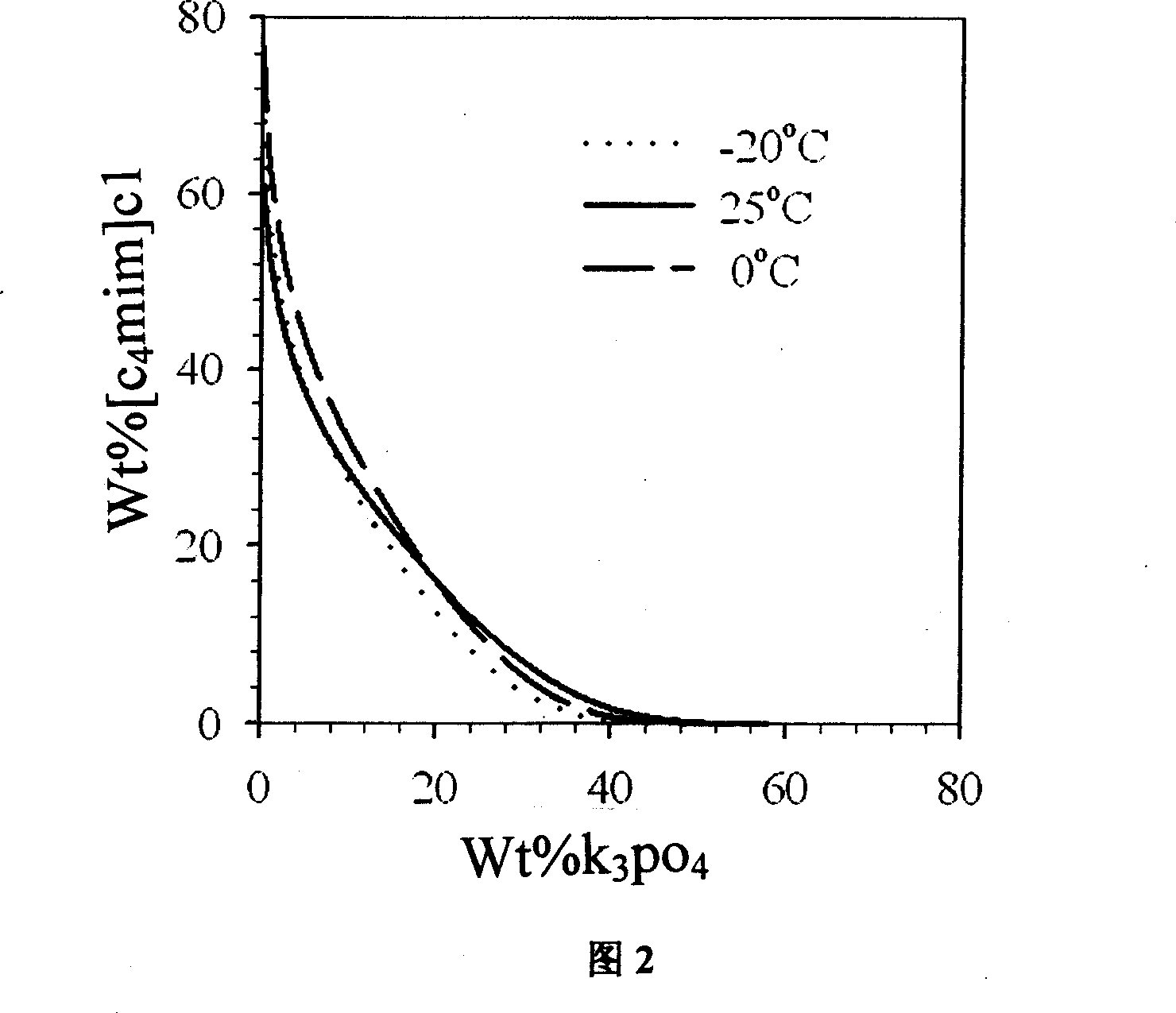

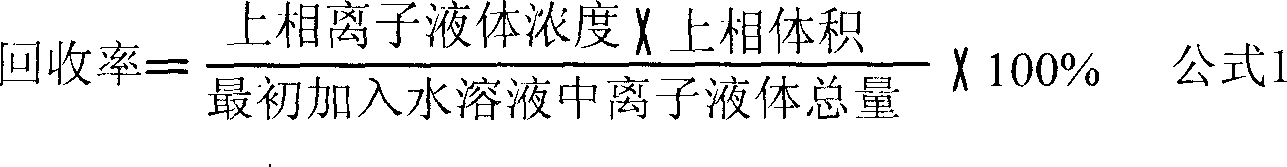

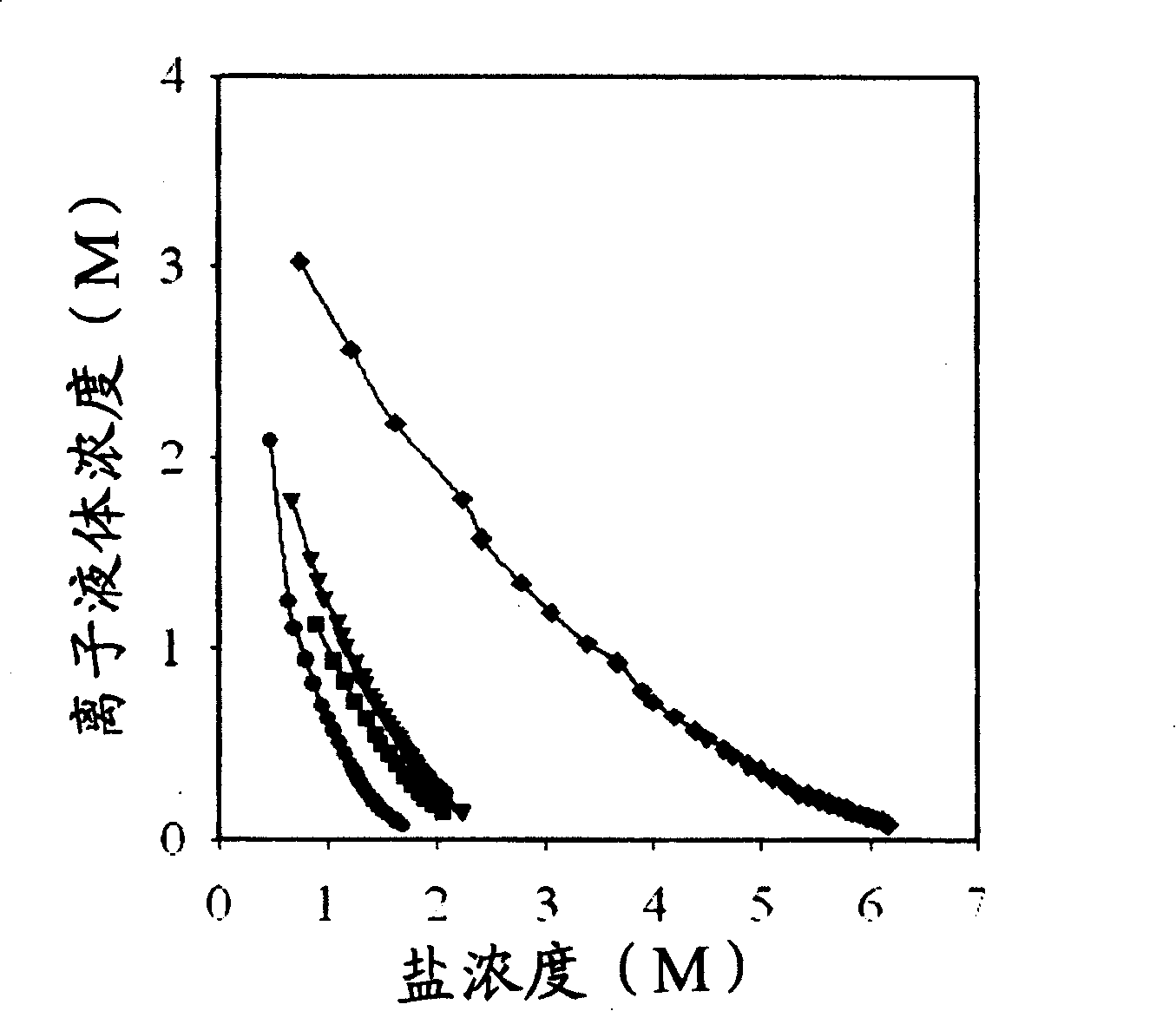

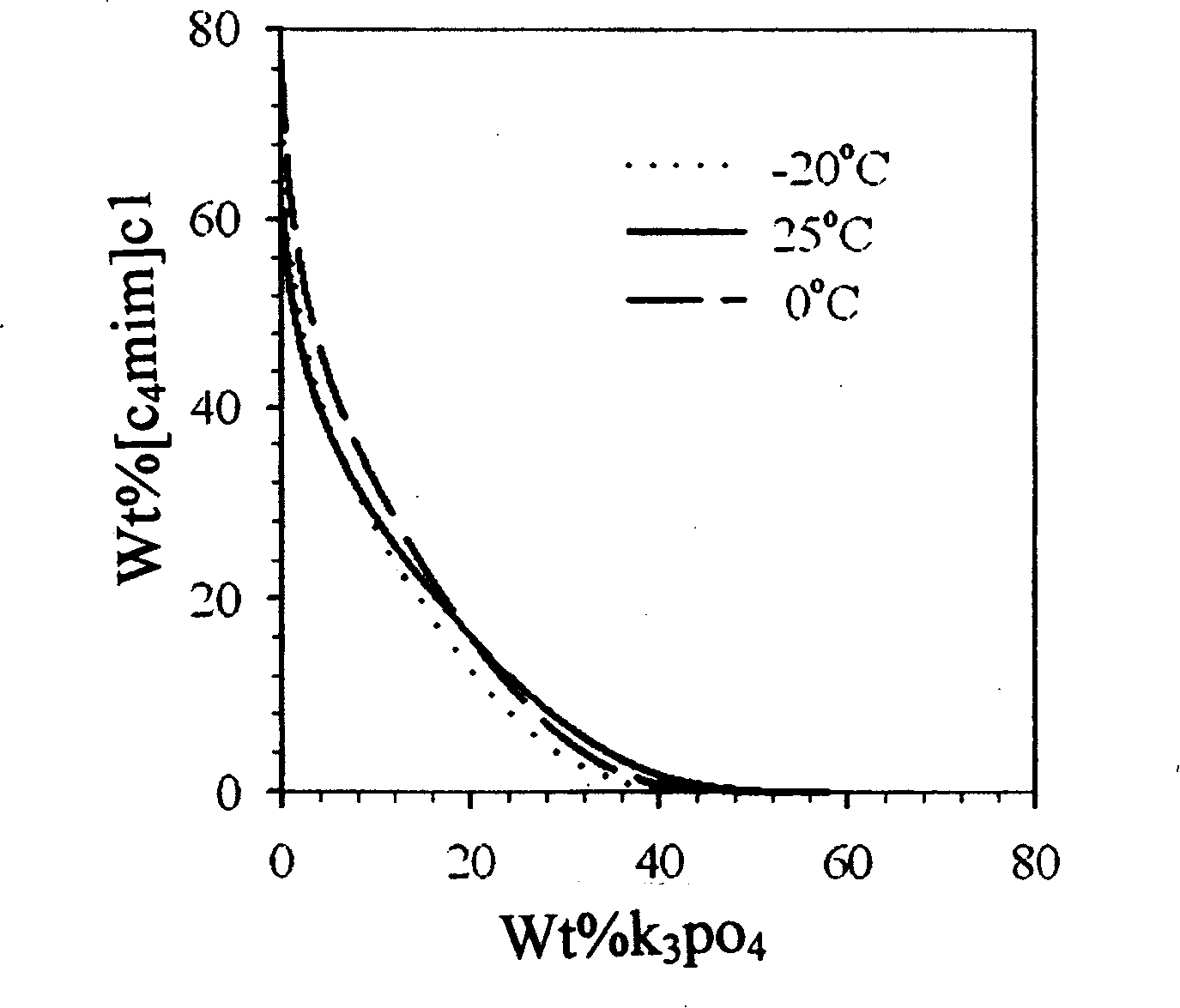

The present invention relates to process of enriching ionic liquid from water solution. Ionic liquid and salt in water solution may form a double water phase system, including the upper rich ionic liquid phase capable of enriching ionic liquid in water solution. By means of lowering the temperature of lower rich salt phase to 0 deg.c to -20 deg.c, a new double water phase system may be formed for further enriching ionic liquid. The present invention can reach total ionic liquid recovering rate up to 95-99 % and required water evaporating quantity only about 10 % of conventional process. The present invention can recover and reuse ionic liquid and salt, and has the advantages of great treating amount, simple apparatus, easy operation, low cost, easy combination of several stages, high economic benefit and environment friendship.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method for extracting tea-seed oil and tea saponin by using biological method

InactiveCN102191124AMitigate the effects of dissolutionLess impuritiesSugar derivativesFatty-oils/fats refiningCentrifugationUltrafiltration

The invention relates to a method for extracting tea saponin and tea-seed oil from tea seed kernels by using a biological method. The amount of each added material is based on the weight of the tea seed kernels, and the method comprises the following steps of: cooking the tea seed kernels, crushing, liquefying and saccharifying, adjusting the pH, and performing centrifugation; for the obtained supernatant oil comprising the main components of fat and oligosaccharide, performing membrane separation to obtain crude oil, and performing alkaline refining de-acidification to obtain refined tea oil; for the subnatant water phase comprising the main components of saponin and protein, adjusting the pH, and then performing centrifugation to obtain crude tea saponin; and performing decontaminating concentration by using an ultrafiltration membrane to obtain refined tea saponin. According to the method, the tea seed kernels are reasonably used to extract the tea-seed oil and the tea saponin at the same time, the process is simple, the operation is safe, high-purity tea oil and saponin are obtained, and simultaneously secondary pollution and a great deal of wastewater cannot be generated.

Owner:武汉普赛特膜技术循环利用有限公司

Extraction and preparation method for licorice effective ingredients

InactiveCN103965152AHigh yield of active ingredientsHigh yieldSugar derivativesSteroidsWater dischargeLicorice acid

The invention relates to an extraction and preparation method for licorice effective ingredients, mainly to a method for simultaneously extracting effective ingredients like glycyrrhizic acid, glycyrrhiza flavonoid and a licorice flavoring agent from licorice. The method comprises the following steps: with glycyrrhizic acid as a raw material, carrying out extraction so as to obtain licorice residue and extract liquid and subjecting the licorice residue to ethanol extraction so as to obtain a crude glycyrrhiza flavonoid product; removing impurities in the licorice extract liquid by using an ultrafiltration membrane device, carrying out concentration by using a nanofiltration membrane device, subjecting a nanofiltration membrane concentrate to acid precipitation and drying a precipitate so as to obtain glycyrrhizic acid; and subjecting a supernatant produced after acid precipitation to concentration with the nanofiltration membrane device and carrying out drying so as to obtain the licorice flavoring agent. The method adopts membrane separation technology for impurity removal and concentration of the extract liquid, so working conditions are mild, product purity and quality are guaranteed, and yield of licorice effective ingredients is high; the method has the advantages of simple production flow, low cost, small pollution, reusability of a nanofiltration membrane filtrate generated in production process, reduction in consumption of raw water and great decrease of waste water discharge.

Owner:武汉普赛特膜技术循环利用有限公司

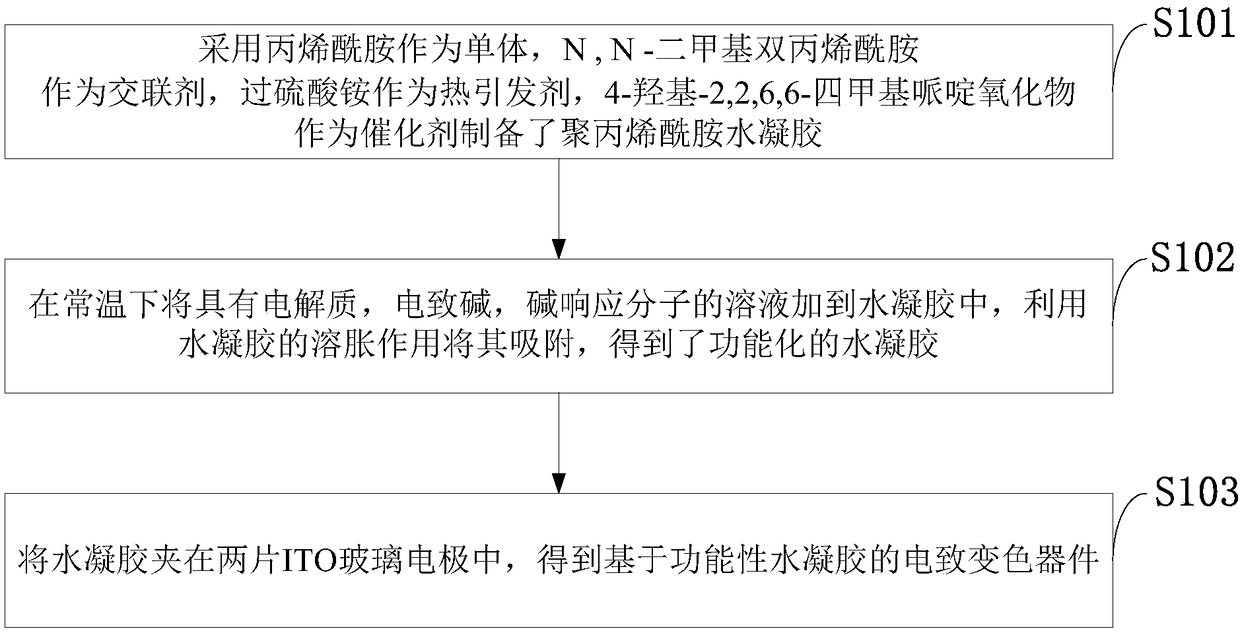

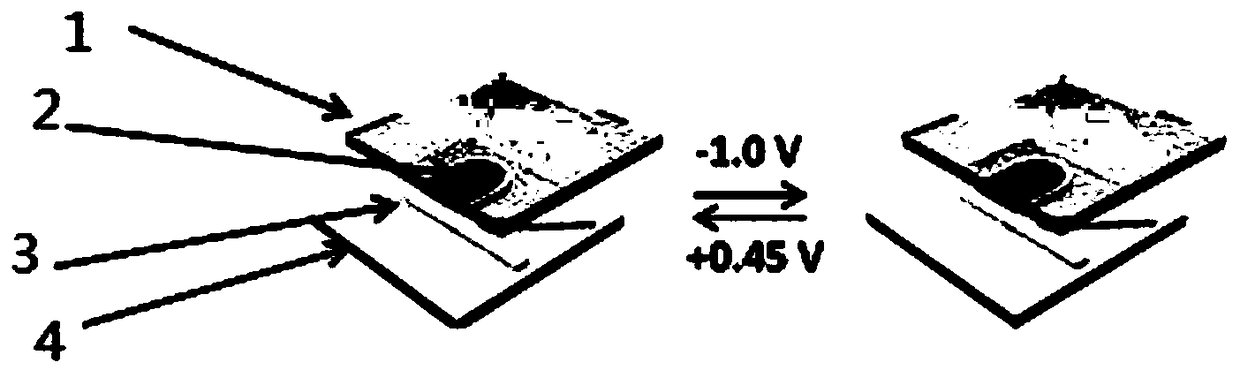

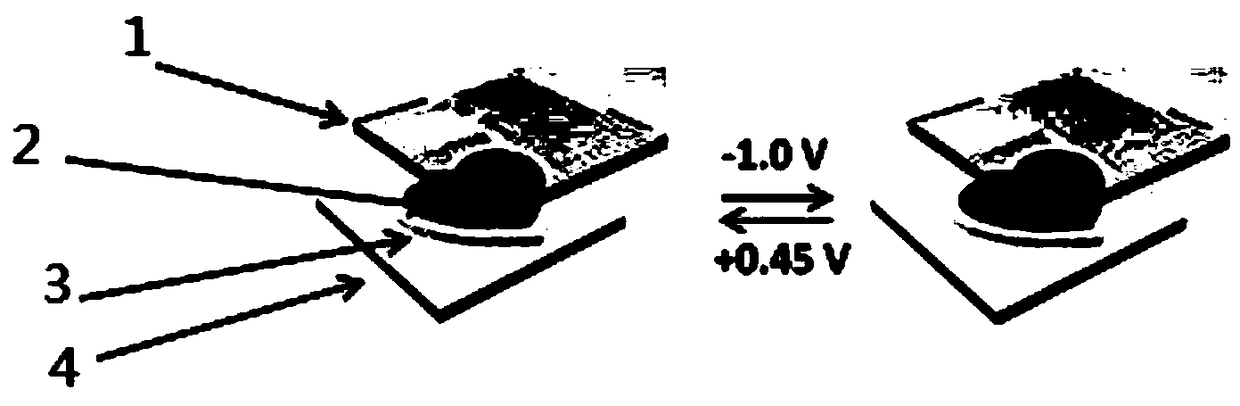

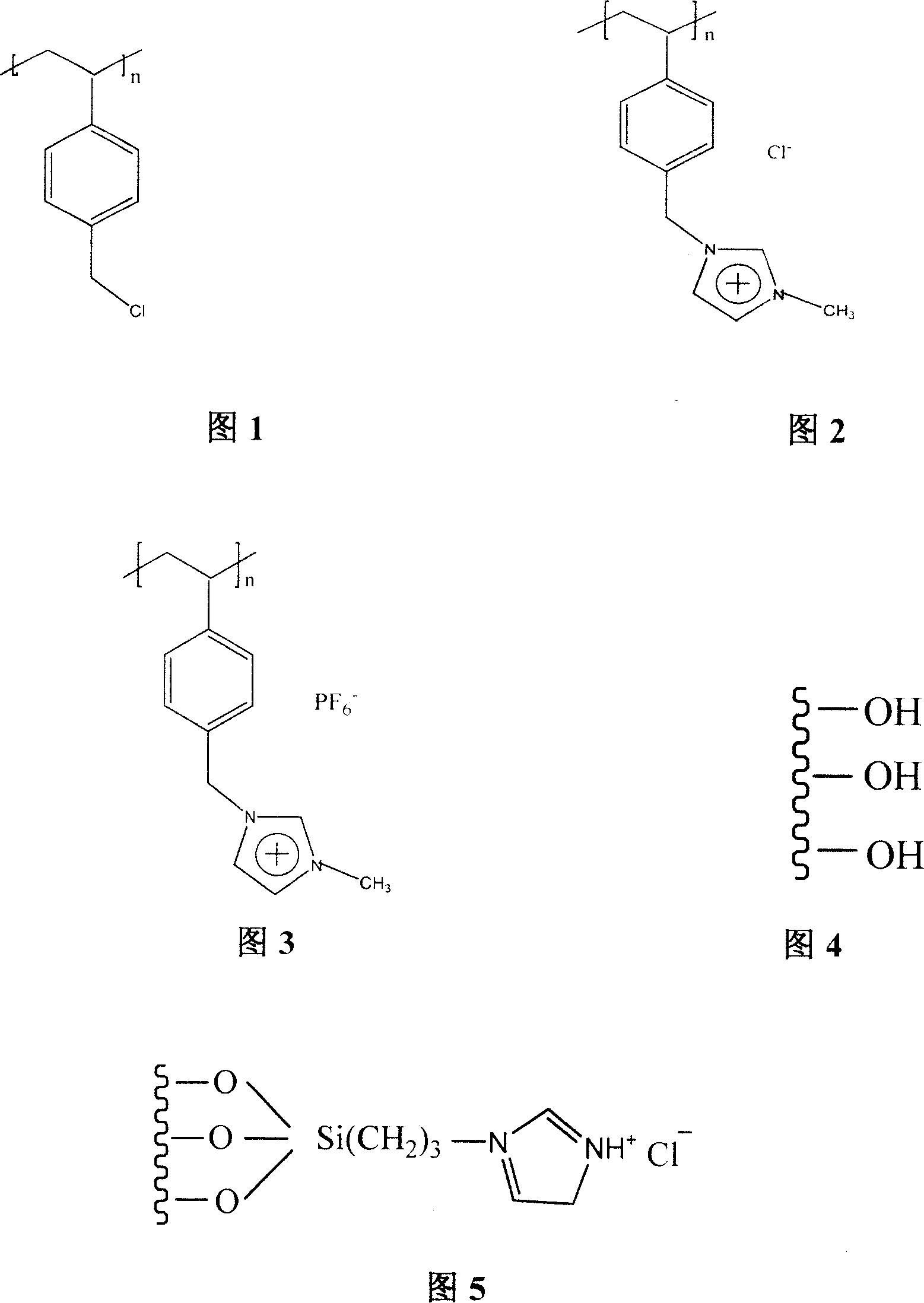

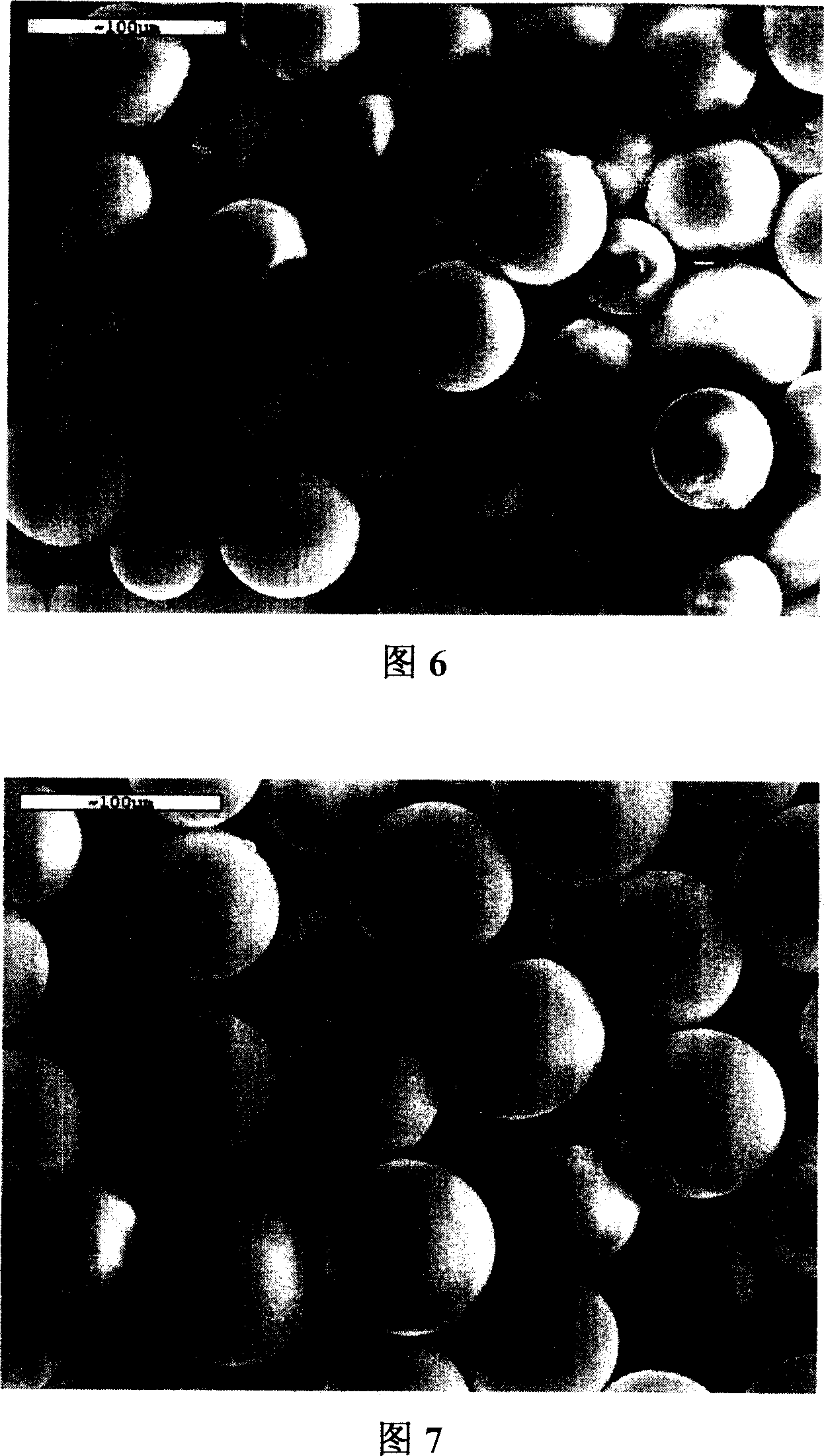

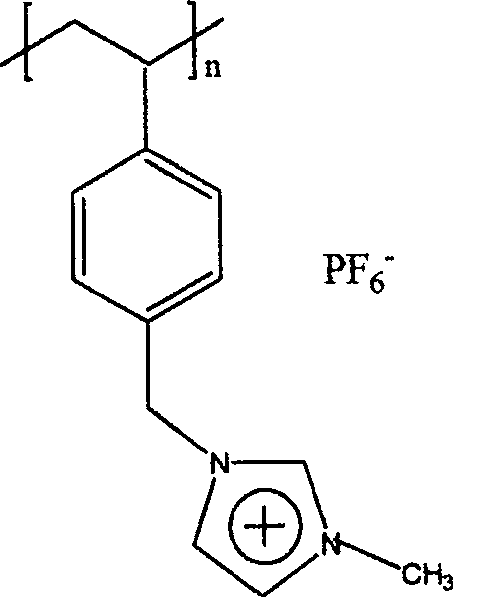

Functional hydrogel-based electrochromic device and preparation method thereof

ActiveCN109143715AExcellent electrochromic propertiesSimple structureNon-linear opticsCross-linkRoom temperature

The invention belongs to the technical field of electrochromic devices, and discloses a functional hydrogel-based electrochromic device and a preparation method thereof. The method comprises the following steps: using acrylamide as a monomer, N,N-dimethylbisacrylamide as a cross-linking agent, ammonium persulfate as a thermal initiator, 4-hydroxy-2,2,6,6-tetramethylpiperidine oxide as a catalyst to prepare polyacrylamide hydrogel; adding a solution having electrolyte, electro-alkali, and base-responsive molecules to the hydrogel at room temperature, and adsorbing the solution by the swelling action of the hydrogel to obtain a functionalized hydrogel; and sandwiching the hydrogel between two ITO glass electrodes to obtain a functional hydrogel-based electrochromic device. The functional hydrogel-based electrochromic device and the preparation method thereof are simple in preparation process, mild in working condition, use water as a solvent to reduce the harm to the human body, which isenvironmentally friendly, good in reproducibility, and very suitable for industrial production.

Owner:上海鼎弈材料科技有限公司

Process for separating superfine particles

The invention relates to a method for separating ultra-fine particles, wherein it adjusts the components of dual-liquid system, or adds extractive to adjust the system which can separate ultra-fine particles into upper phase or lower phase; eccentrically treating two phases to obtain ultra-fine particles. And the inventive system can be repeated used. The invention has simple device and low cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

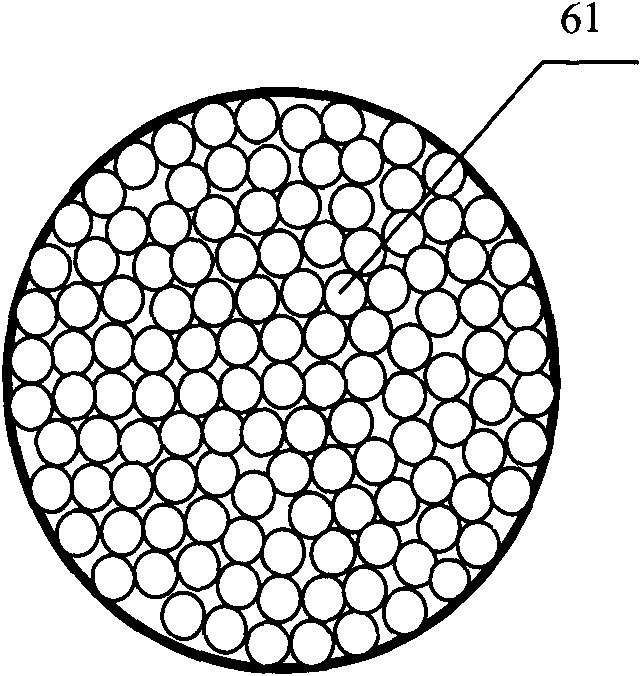

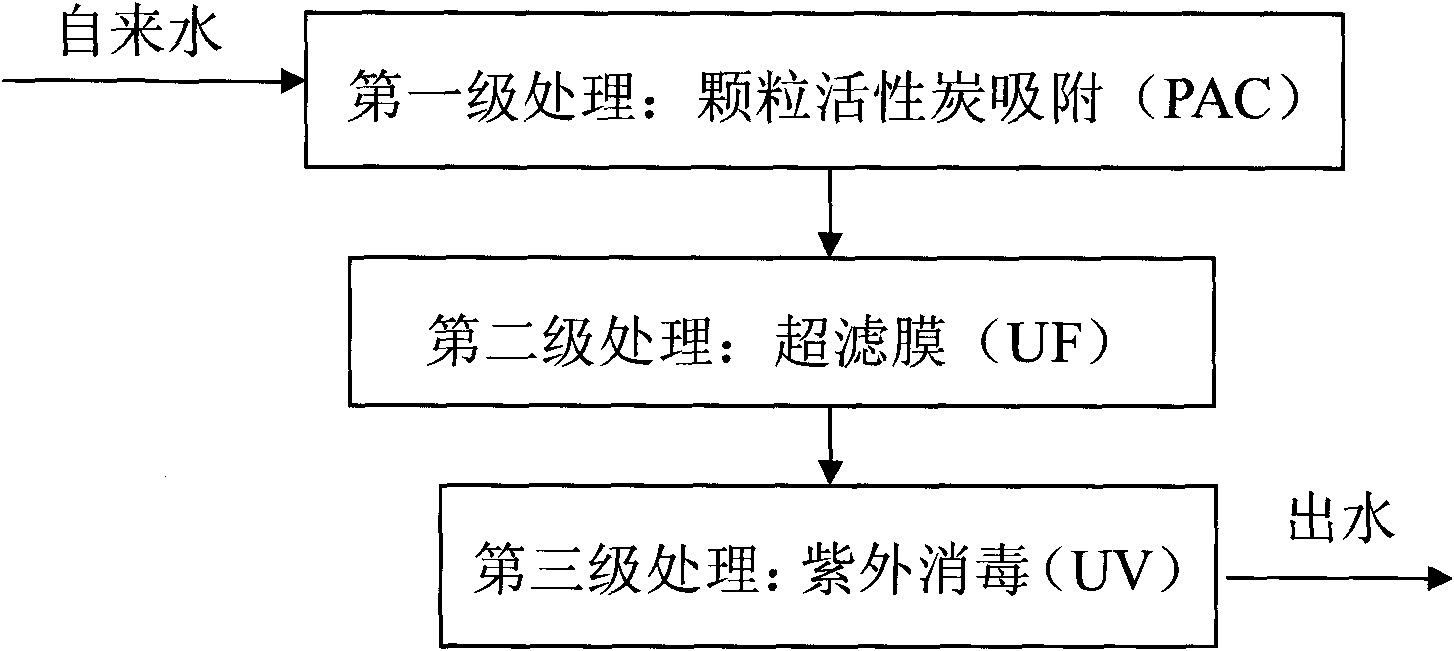

Direct drinking water purifying method and device

InactiveCN101844850AEfficient removalEasy to operate and manageWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisThree stageFiltration

The invention relates to a direct drinking water purifying method and a direct drinking water purifying device. The direct drinking water purifying method comprises three-stage treatment steps, namely active carbon adsorption, ultra-filtration film filtration and ultraviolet sterilization in turn. The direct drinking water purifying device comprises a shell, and a water inlet and a water outlet which are connected on the shell; and the device also comprises a first-stage carbon adsorption treatment device, a second-stage ultra-filtration film treatment device and a third-stage ultraviolet treatment device. The method and the device can effectively solve the problems of poor trace pollutant removing effect, secondary pipeline pollution and the like in the conventional drinking water treatment process through a technique with low energy consumption and low cost.

Owner:TONGJI UNIV

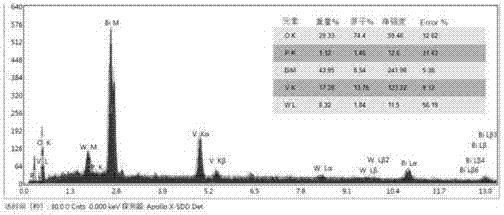

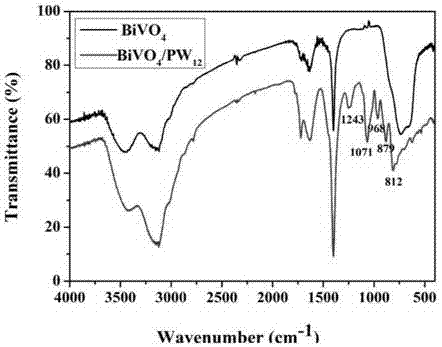

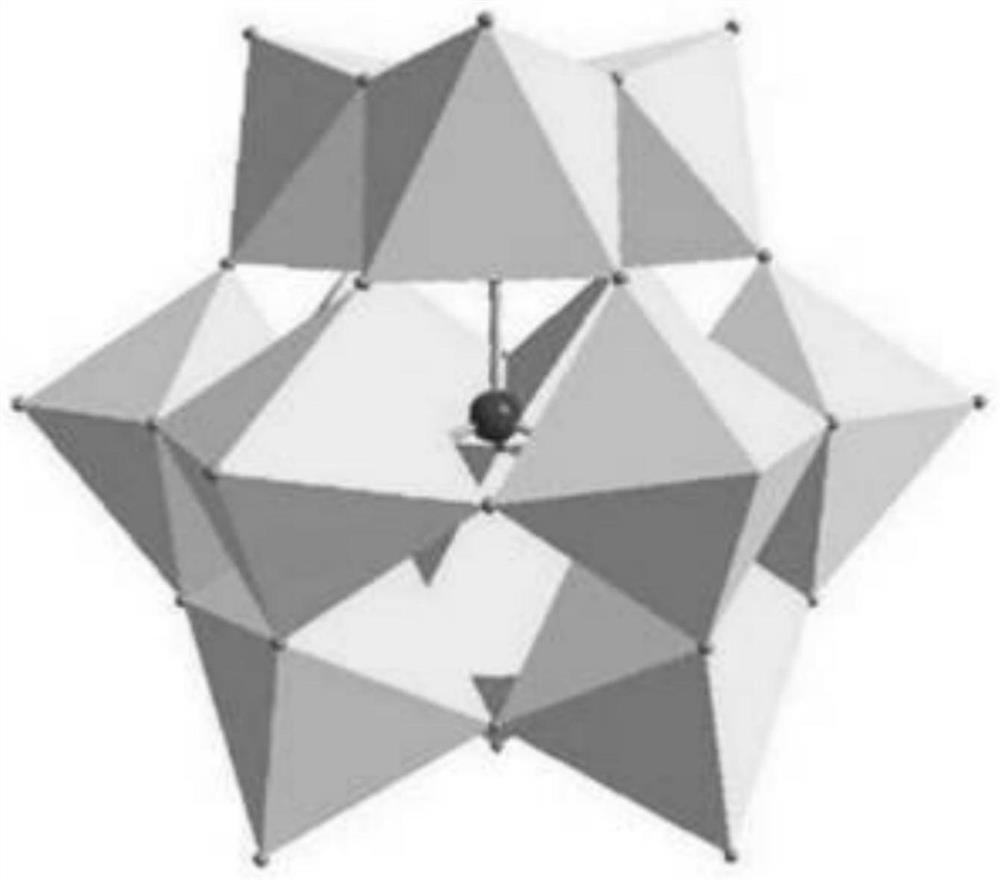

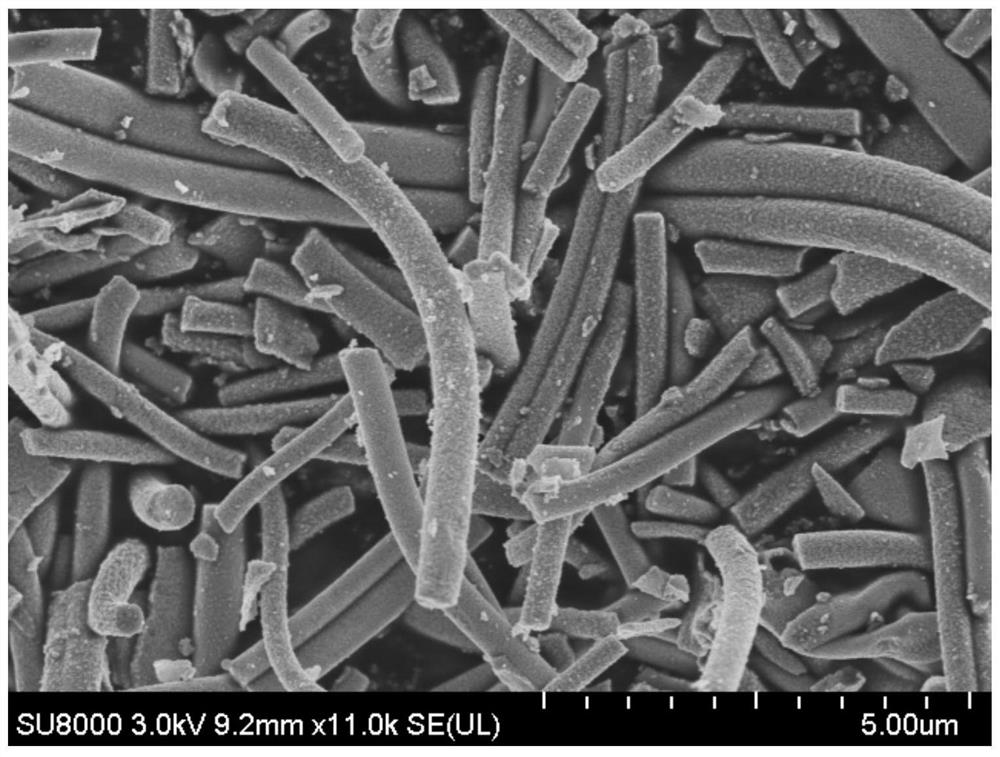

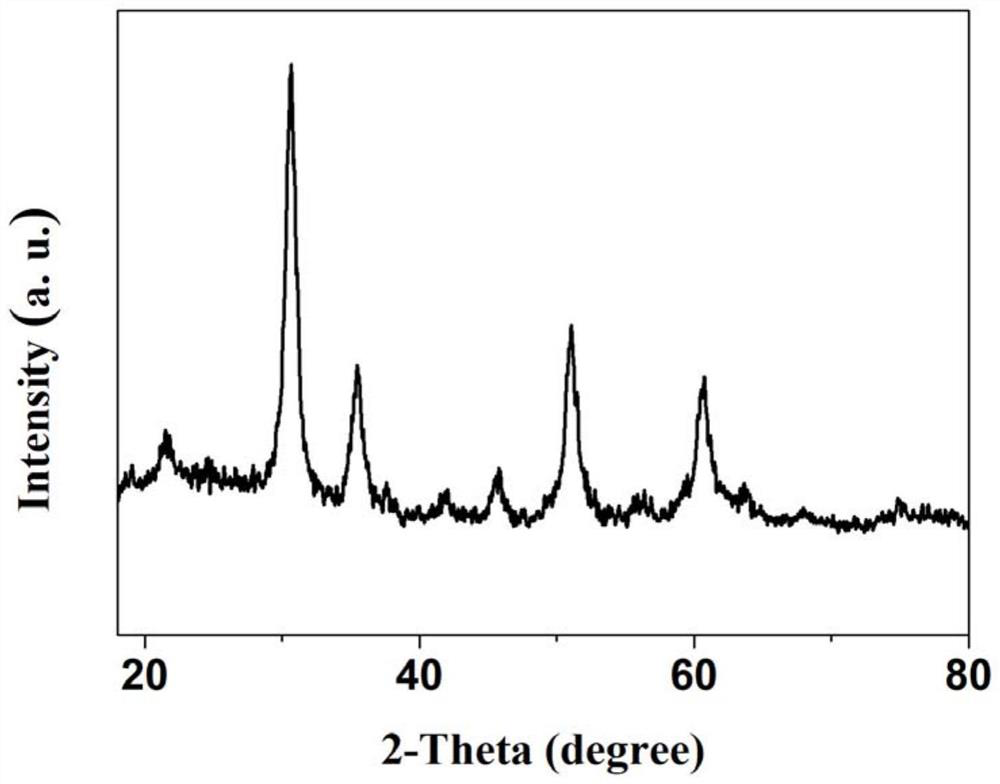

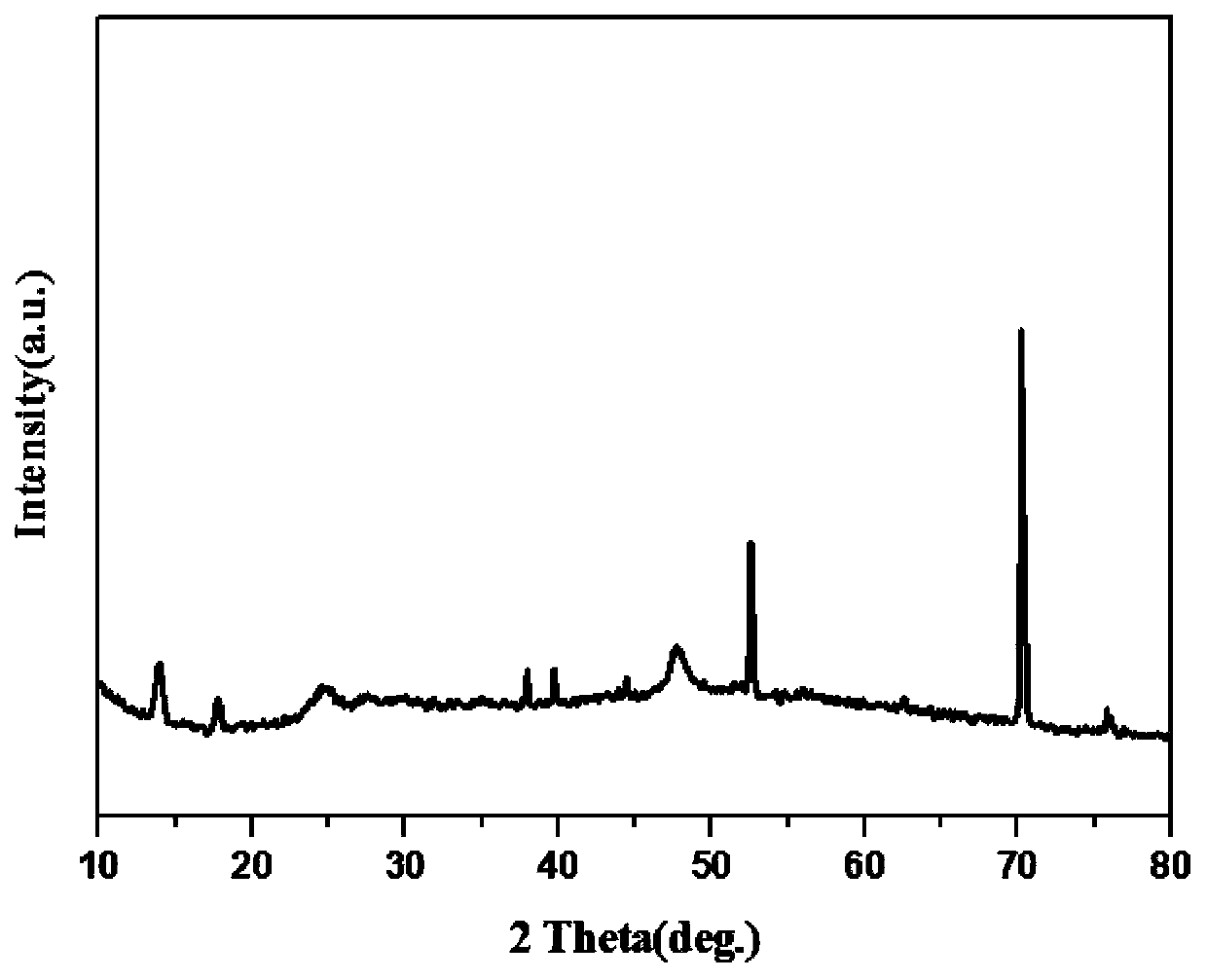

Method for preparing bismuth vanadate-polyacid gas sensing composite nano-material

InactiveCN107064250AMild working conditionsNo need for high temperatureMaterial nanotechnologyNanosensorsNitrogen dioxideBismuth vanadate

The invention provides a method for preparing a bismuth vanadate-polyacid gas sensing composite nano-material. A prepared polyacid modified bismuth vanadate nano-rod composite gas sensitive material can be used in a photoelectric gas sensor. The gas sensitive material is a bismuth vanadate-polyacid composite nano-material which is formed by using a bismuth vanadate nano-rod as a main body and modifying with Keggin-type phosphotungstic acid. In a room temperature environment, under irradiation of a xenon lamp, the sensor has a remarkable sensing detection function for toxic nitrogen dioxide gas. The method for preparing the bismuth vanadate-polyacid gas sensing composite nano-material is simple, has low cost, can be used for effectively detecting low-concentration nitrogen dioxide gas in the air at room temperature, and is applicable to development and production of a novel high-performance gas sensor.

Owner:NORTHEAST NORMAL UNIVERSITY

Method for concentration of lactic acid in fermentation liquor

InactiveCN101172945ACan be designedEasy to adjustCarboxylic compound separation/purificationProduction rateLactic acid fermentation

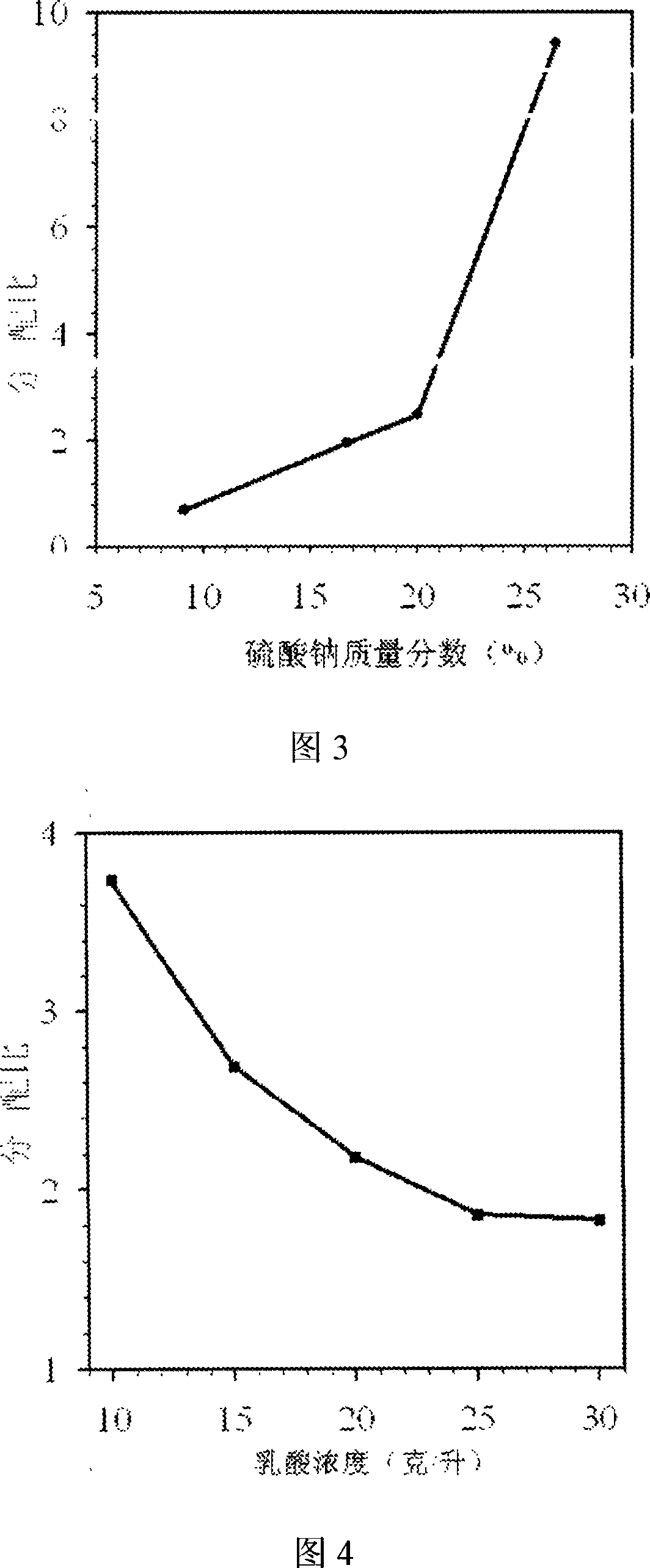

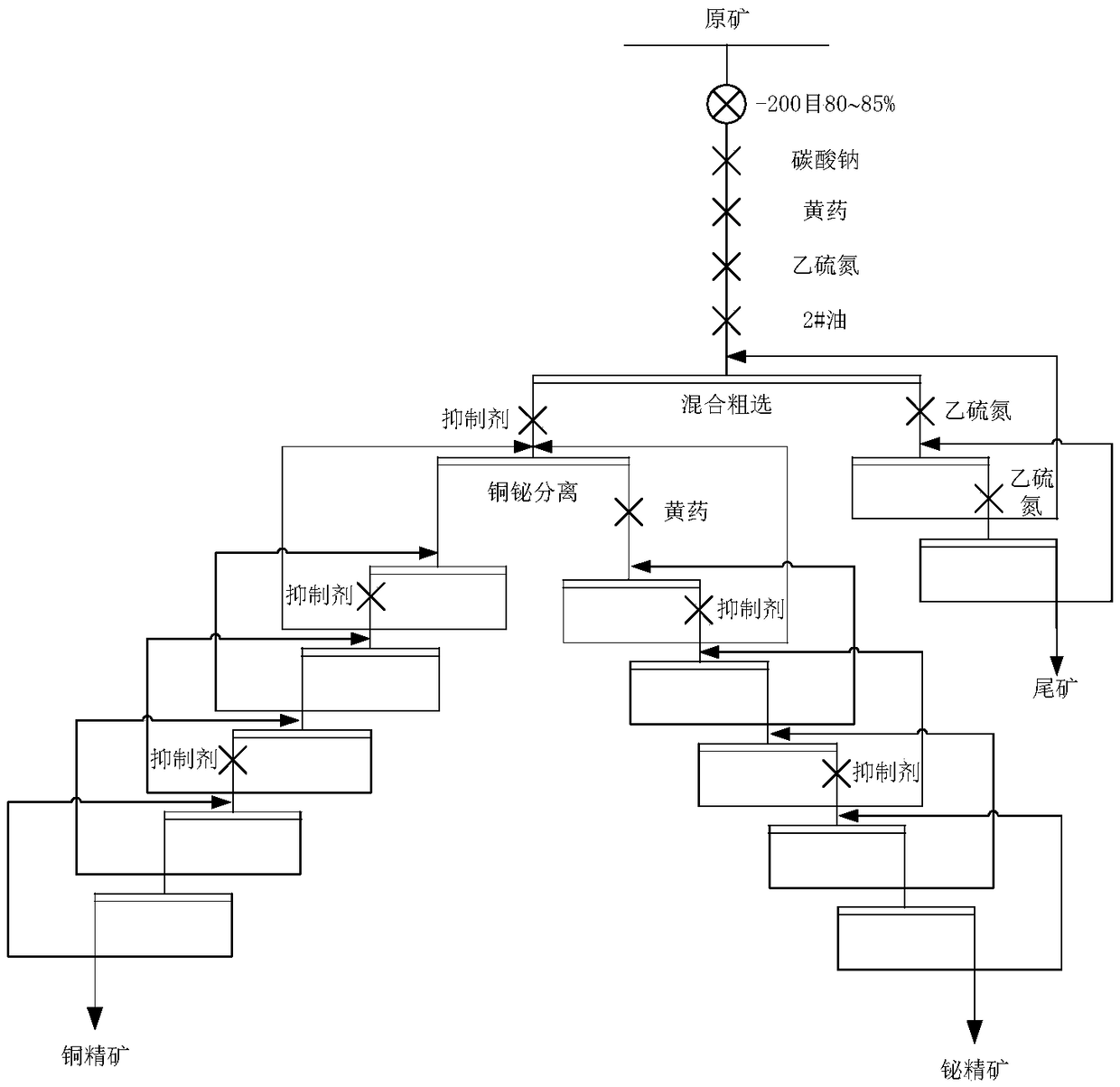

The invention relates to a method for collecting lactic acid from zymotic fluid, and comprises the steps as follows: the proper double aqueous phase system is selected to adjust the distribution of the lactic acid and the lactobacillus in the double aqueous phase system, the lactic acid is distributed at a polymer-rich phase, and the lactobacillus is distributed at a salt-rich phase to achieve the lactic acid collecting. The selected double aqueous phase system is a neutral extracting system close to the PH valve of 5.5 to 6.0 required by zymolysis of the lactic acid, the finished product is separated from the reacting matters. The phase separation provides a reaction power for the zymolysis of the lactic acid, so that the invention is beneficial to improve the productivity of the lactic acid. Moreover, the method disclosed in the invention can be coupled with the zymotic method of the lactic acid to reform the prior separating method of the lactic acid.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for producing purely natural monosodium glutamate by using low-value marine fishes

ActiveCN101984854APrevent oxidationPrevent corruptionFood preparationMonosodium glutamateUltrafiltration

The invention relates to a method for producing purely natural monosodium glutamate by using low-value marine fishes, which comprises the following steps of: adding water in an amount which is 1 to 3 times the weight of low-value marine fishes, and 0.01 to 0.03 weight percent of antioxidant into the low-value marine fishes; raising the temperature to 60 to 80 DEG C, stirring at the pH of 7 to 9 for 1 to 3 hours, adding 0.3 to 0.5 weight percent of alkaline protease and performing enzymolysis at the temperature of between 45 and 60 DEG C and the pH of 7 to 9 for 2 to 4 hours; filtering to remove fish bones and centrifuging to remove fish oil and fish scrap; adding 0.3 to 0.5 weight percent of flavorzyme into filtrate and performing enzymolysis at the temperature of between 45 and 60 DEG C and the pH of 6 to 8 for 2 to 4 hours; heating to 100 DEG C after the enzymolysis is finished, and inactivating for 5 minutes; regulating the pH of enzymolysis liquid to 5 to 6.5 by using citric acid, adding 1 to 3 weight percent of activated carbon, stirring at the temperature of between 60 and 75 DEG C for 2 to 3 hours, centrifuging and filtering; removing impurities from filtrate by using an ultrafiltration membrane of about 2,000Dal and concentrating the filtrate by using a nanofiltration membrane of about 400Dal in turn; and adding 0.1 to 0.3 weight percent of flavor substances and 0.2 to 0.5 weight percent of truffle into concentrated solution, dissolving, uniformly mixing and performing spray drying. The low-value marine fishes are reasonably utilized, the process is simple, secondary pollution is avoided and a large amount of waste water cannot be generated.

Owner:WUHAN AIMIN PHARMA

Comprehensive utilization method of pumpkin

InactiveCN102180991AEasy to separateReduce the burden onMetabolism disorderAntinoxious agentsFreeze-dryingSeparation technology

The invention relates to a comprehensive utilization method of a pumpkin. In the method, added amount of substances is based on weight of the pumpkin; and the pumpkin is taken as a raw material for step-by-step extraction to respectively obtain pumpkin polysaccharide, pectin and pumpkin powder by utilizing a biotechnology and a membrane separation technology. The method comprises the following steps: firstly washing and cutting the pumpkin into blocks, removing seeds, pulping, carrying out water extraction at moderate temperature and centrifugal separation, carrying out acid precipitation on the obtained water extract, concentrating the obtained supernate through a nanofiltration membrane, and spray-drying to obtain the polysaccharide; extracting residues after water extraction by utilizing acid water, carrying out centrifugal separation, removing impurities from the obtained supernate through a microfiltration membrane, concentrating the supernate through a nanofiltration membrane, carrying out acid precipitation on the obtained concentrated solution, carrying out centrifugal separation, and freeze-drying the obtained precipitate to obtain the pectin; spray-drying the supernate to obtain the polysaccharide; and mixing the remaining residues and filtered liquor, grinding by a colloid mill and spray-drying to obtain the pumpkin powder. The comprehensive utilization method has the advantages that effective substances of the pumpkin are fully utilized, and process is simple and feasible, thus being applicable to industrialized production.

Owner:武汉普赛特膜技术循环利用有限公司

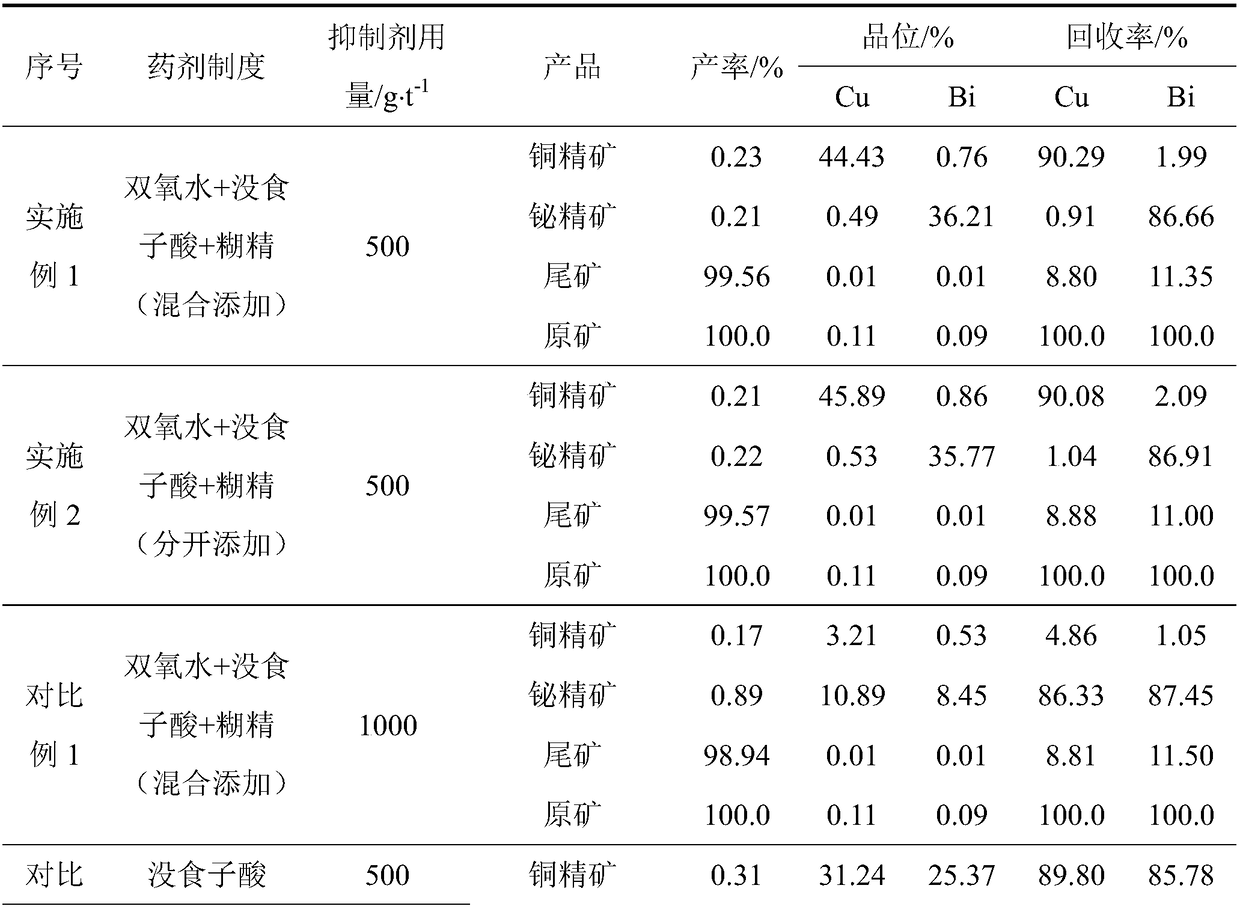

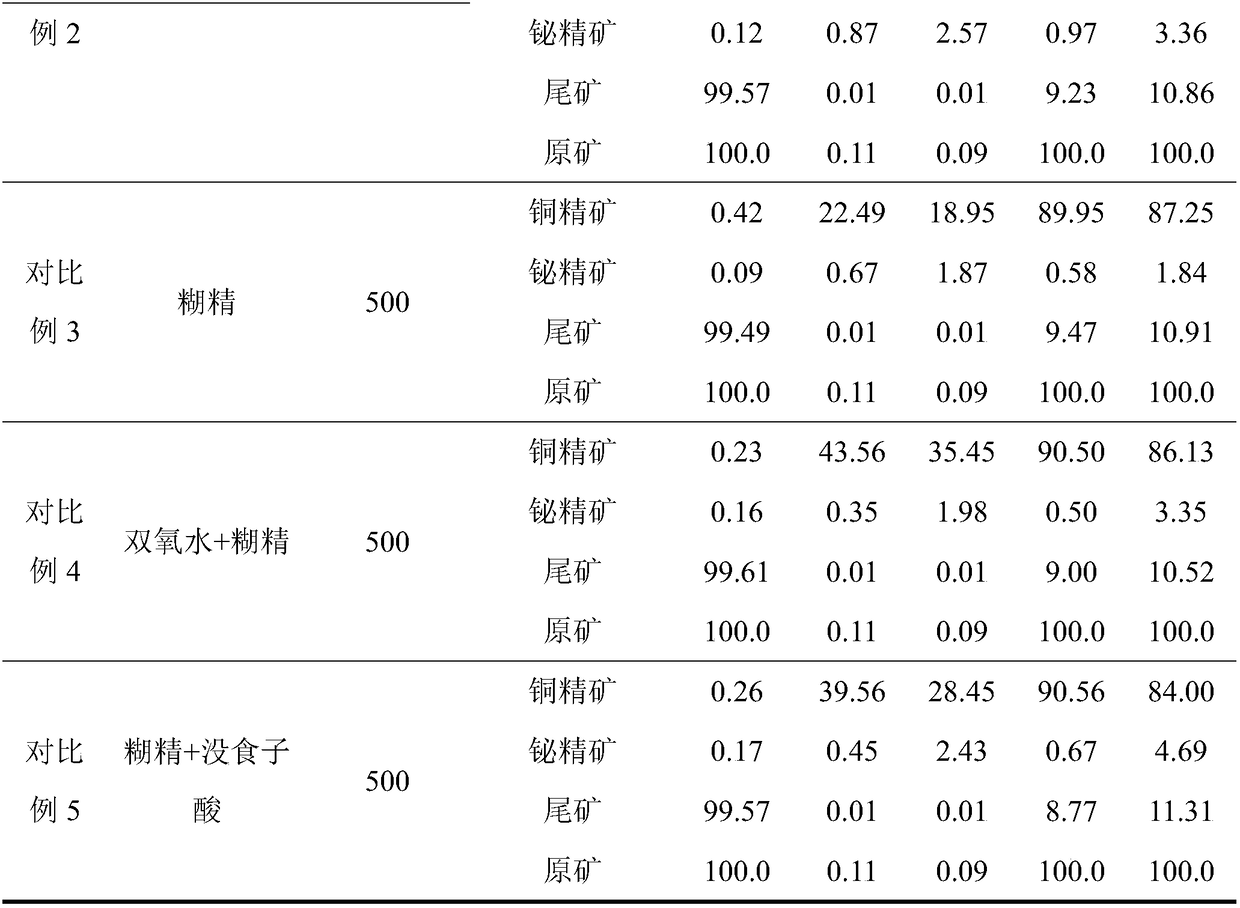

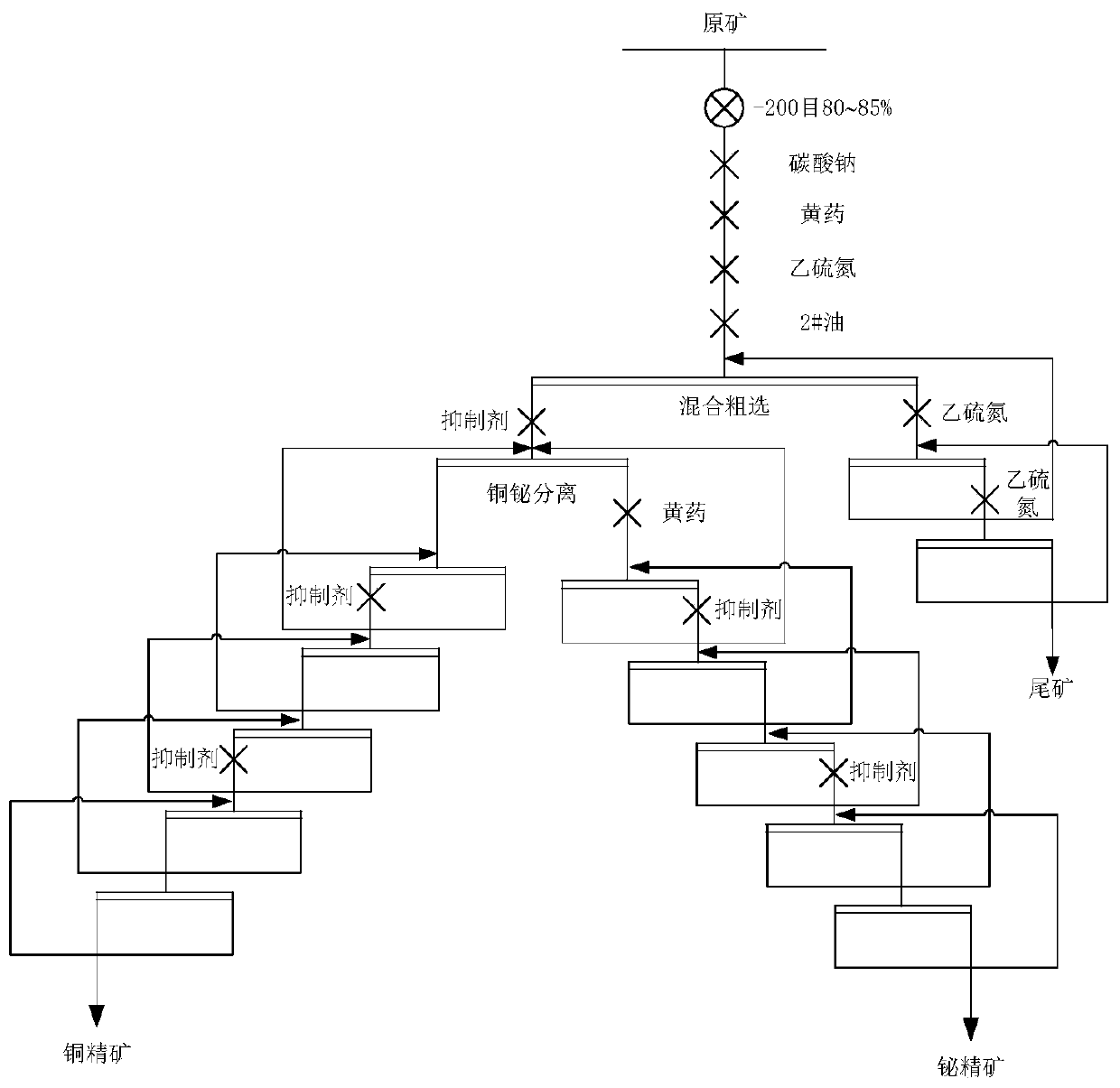

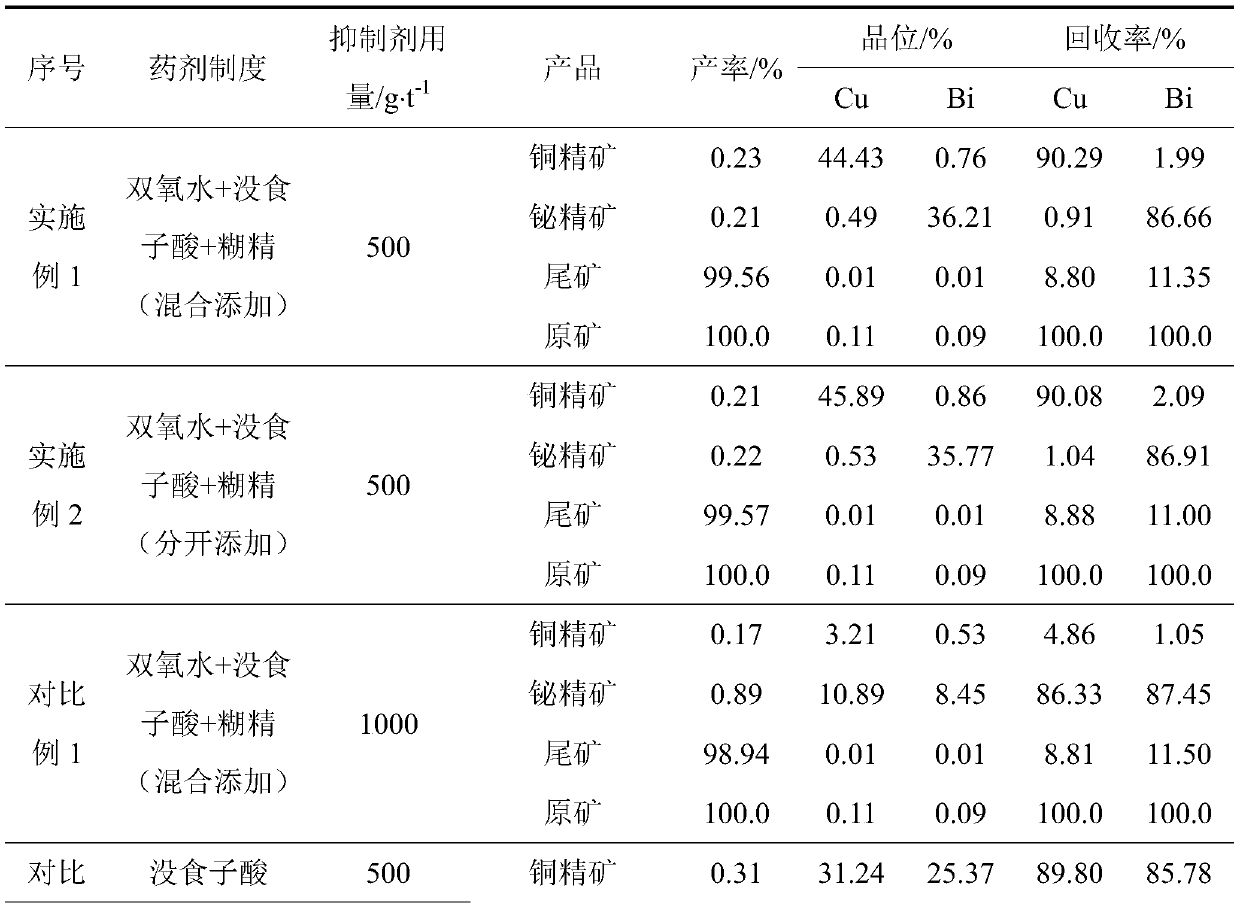

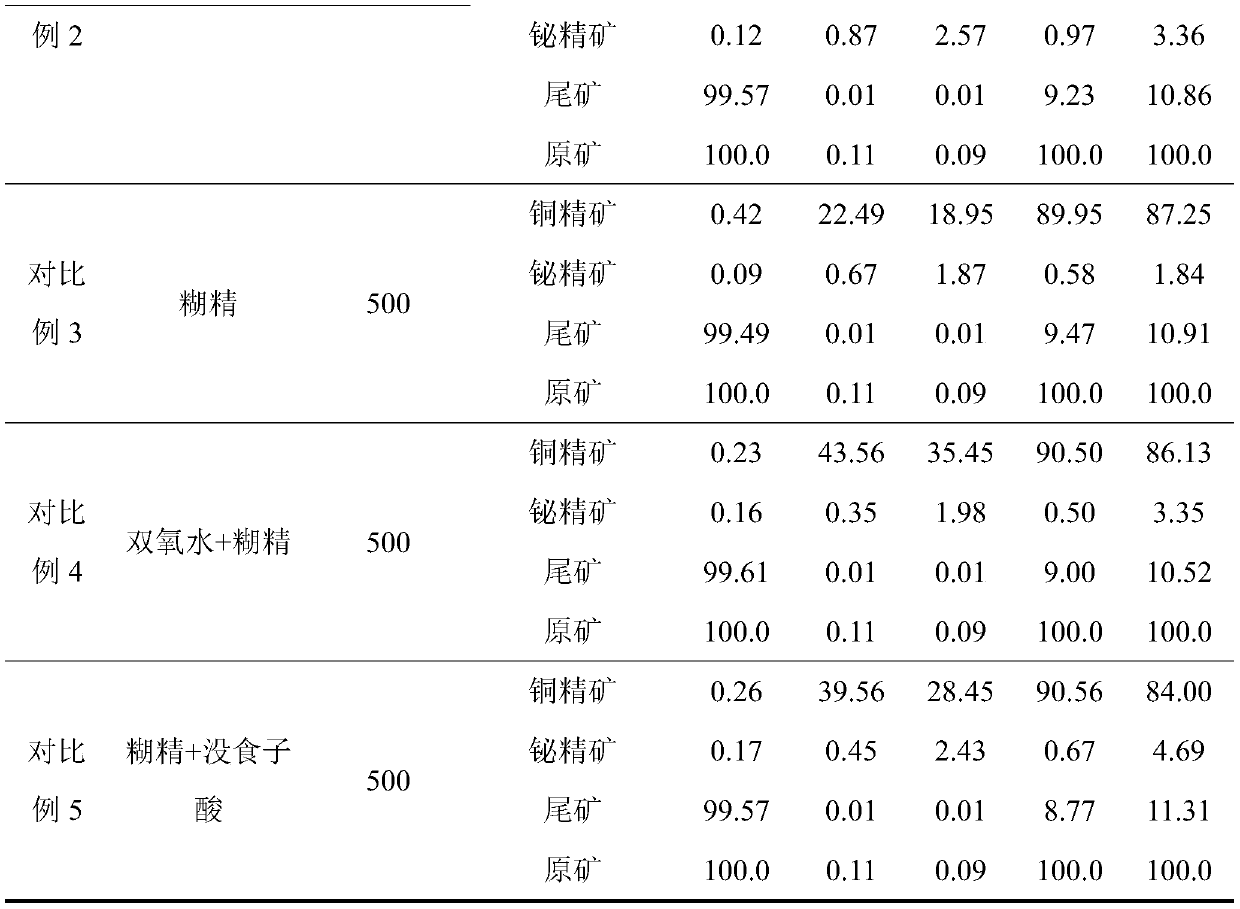

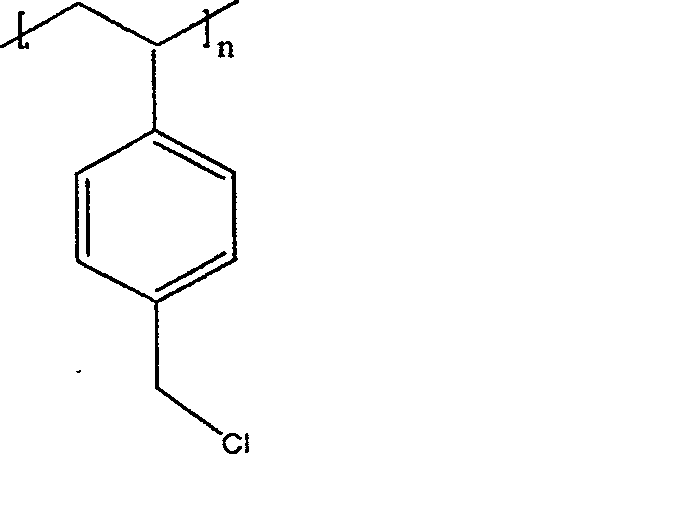

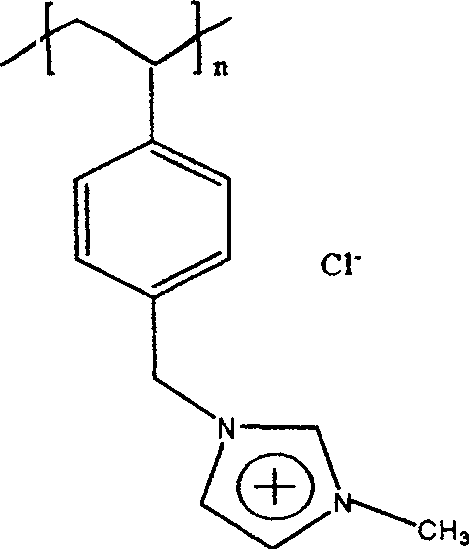

Bismuth sulfide mineral inhibiting agent and application thereof

ActiveCN108620240AImprove adsorption capacityImprove ionic interactionFlotationBismuth sulfideGallic acid ester

The invention discloses a bismuth sulfide mineral inhibiting agent and application thereof. The inhibiting agent comprises the following components in parts by mass: 2-5 parts of hydrogen peroxide, 3-4 parts of gallic acid, and 1-2 parts of dextrin. In a flotation process of sulfide minerals containing bismuth, 50-500 g / t combined inhibiting agent is added in each flotation according to each tonnage of raw ore minerals, so that the inhibition of the sulfide minerals containing bismuth can be realized. The bismuth sulfide mineral inhibiting agent has the advantages of high acting effect, low use level and the like, is free of using such high-consumption medicaments as poisonous cyanides, lime and sodium sulfide to reduce environmental pollution, meanwhile, reduces the beneficiation cost, and improves the sorting index.

Owner:CENT SOUTH UNIV

Preparation method of seafood flavor peptide

The invention relates to a preparation method of seafood flavor peptide. The preparation method comprises the following steps: heating the mixture of raw materials and water; mixing the heated mixture with bacillus, then fermenting the mixture with bacillus to obtain a fermented mixture; carrying out slurry-residue separation and oil-water separation to obtain a fermentation liquor; decolorizing and deodorizing the fermentation liquor, then removing residues and carrying out decarbonizing, and performing refining, concentrating and drying to obtain the flavor peptide. The preparation method disclosed by the invention is wide in raw material resource, low in production cost, mild in working conditions and capable of ensuring the protein content and low salt content of the product.

Owner:上海中科国嘉技术转移有限公司

Process of enriching ionic liquid from water solution

InactiveCN100406092CEasy to adjustAchieve multi-level enrichmentLiquid solutions solvent extractionNon-miscible liquid separationEconomic benefitsAqueous solution

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

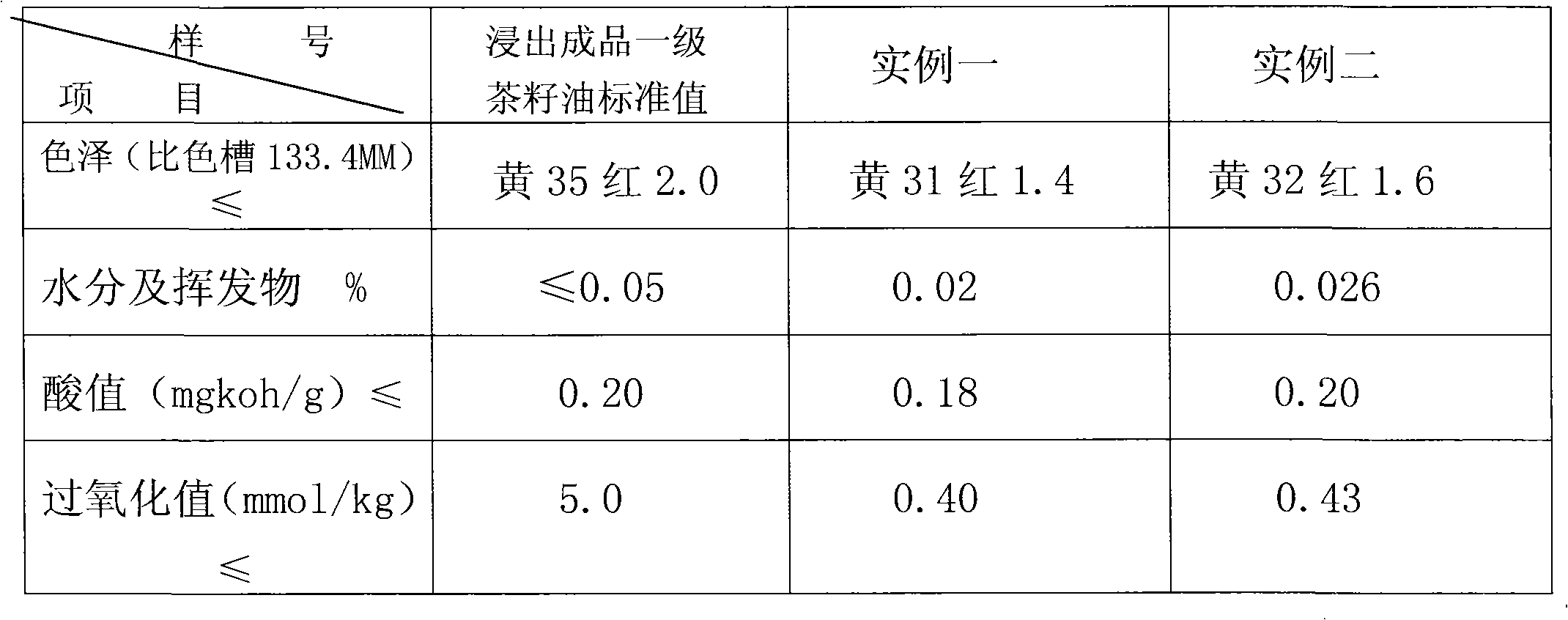

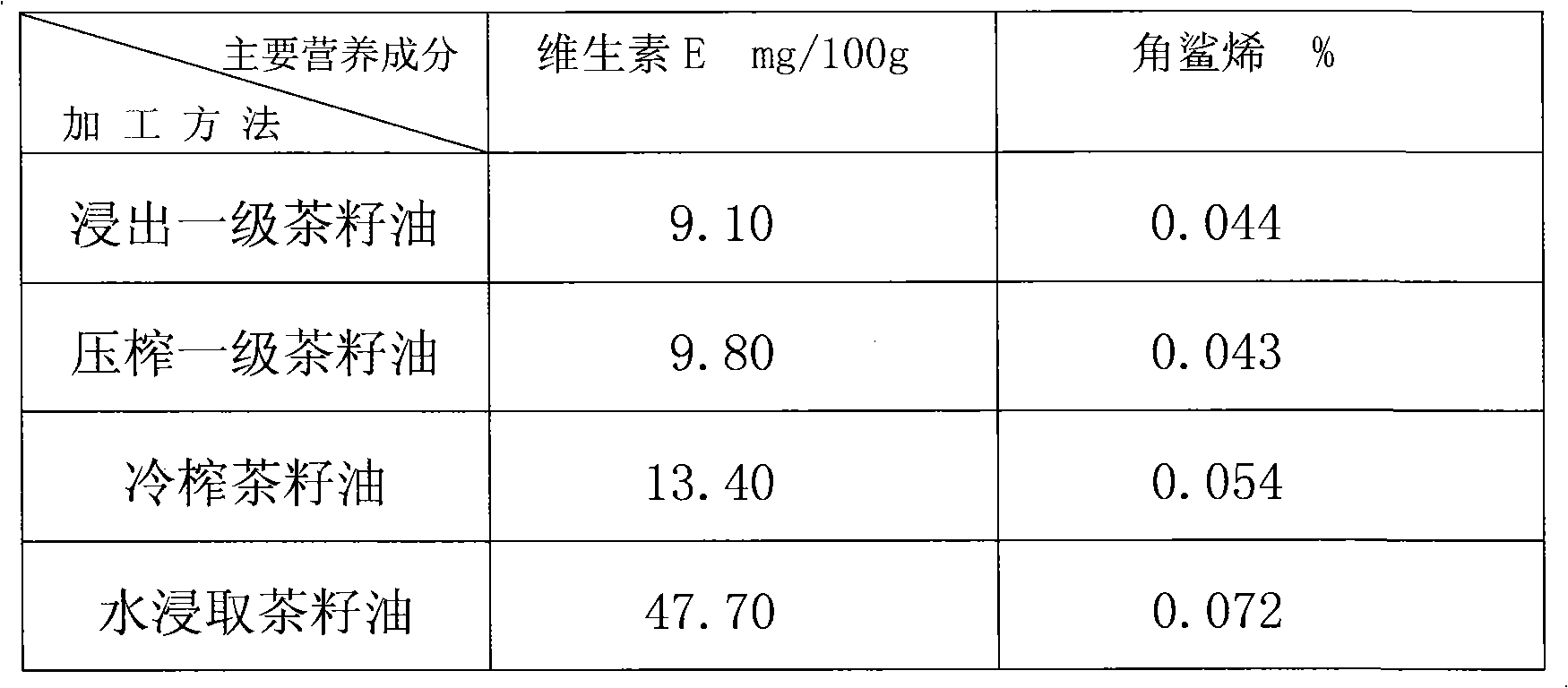

Method for extracting tea seed oil by using water

InactiveCN101775334ANo leachingMild working conditionsFatty-oils/fats productionOrganic solventCamellia oleifera

The invention relates to a method for extracting edible oil from plant seeds, in particular to a method for extracting tea seed oil from tea seeds, the technical scheme comprises the following steps: taking shelled tea seed kernels as raw materials, grinding the shelled tea seed kernels, adding water, mixing, stirring and extracting at a constant temperature, centrifugally separating, and obtaining the finished tea seed oil with oil yield more than or equal to 93%, vitamin E content more than or equal to 47mg / 100g. The method of the invention solves the defects of low oil yield, high temperature, high voltage, residual of organic solvent and more loss of effective constituent in the extracting process of the existing tea seed oil.

Owner:郑小非

Indium oxide-polyacid composite gas sensing material and preparation method thereof

PendingCN112578007AImprove gas sensing performanceMild working conditionsGallium/indium/thallium compoundsFilament/thread formingIndiumNanocomposite

The invention provides an indium oxide-polyacid composite gas sensing material and a preparation method thereof. The prepared polyacid modified indium oxide nanofiber new material can be used for a semiconductor type gas sensor. The material is an indium oxide-polyacid nano composite material formed by taking indium oxide (In2O3) nano fibers as a main body and modifying with Keggin type phosphotungstic acid. In a room temperature environment, the sensor has obvious sensing detection performance on toxic formaldehyde gas. The indium oxide-polyacid composite material provided by the invention issimple in preparation method and very low in cost, can effectively detect low-concentration formaldehyde gas in air at room temperature, and is suitable for development and production of a novel high-performance gas sensor.

Owner:CHANGCHUN UNIV OF SCI & TECH

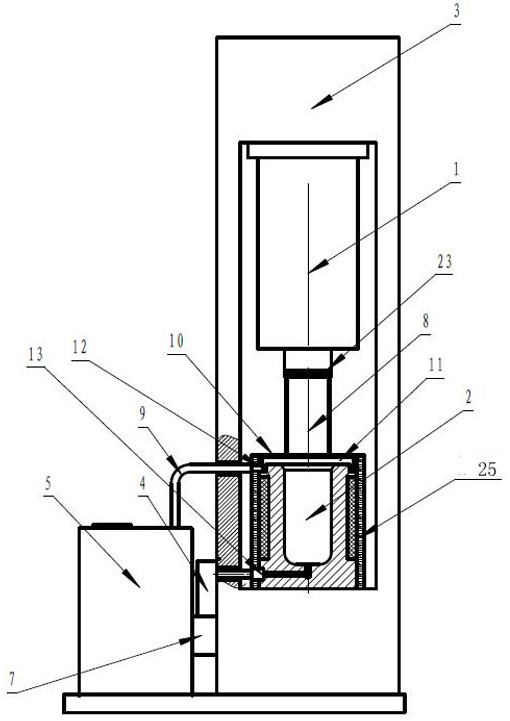

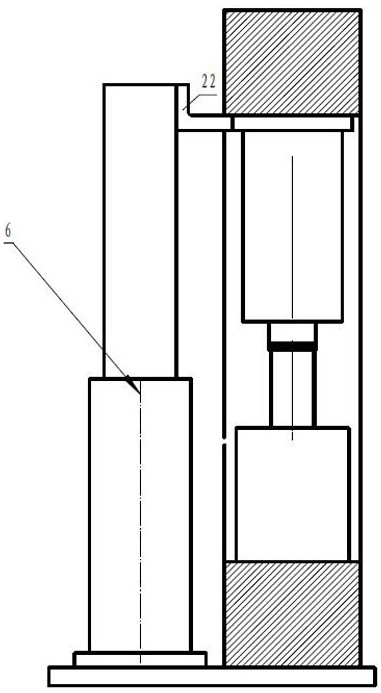

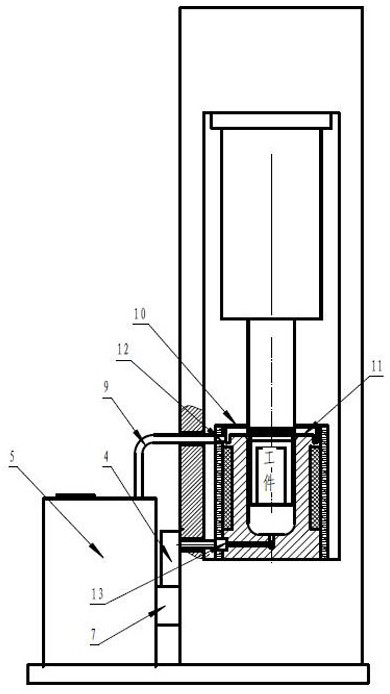

Warm isostatic pressing machine

The invention relates to an isostatic pressing machine, particularly relates to a warm isostatic pressing machine, and solves the problems that an existing warm isostatic pressing machine is complex in structure, low in efficiency, large in energy consumption and poor in working condition. The warm isostatic pressing machine comprises a rack, wherein a pressurizing oil cylinder is installed on an upper beam of the rack, a high-pressure cavity located under the pressurizing oil cylinder is installed on a lower beam of the rack, a piston rod of the pressurizing oil cylinder can be inserted into the high-pressure cavity in a sealed mode, a heat conduction tank is also included and filled with heat conduction oil, an electric heater is arranged in the heat conduction tank, an oil injection hole is formed in the bottom of the high-pressure cavity, an oil return hole is formed in the top of the high-pressure cavity, and the heat conduction tank communicates with the high-pressure cavity through a heat conduction pump, a one-way valve and the oil injection hole by means of a pipeline and further communicates with the high-pressure cavity through an oil return pipe and the oil return hole. The warm isostatic pressing machine is technically characterized in that the mode that the high-pressure cavity of the isostatic pressing machine obtains high pressure is changed into a direct pressurization mode from an injection mode, and defects of an existing warm isostatic pressing machine are overcome.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Method for demulsifying and purifying plant crude oil

InactiveCN103740464AGood flocculation effectRaw materials are easy to getFatty-oils/fats refiningProtein isolateChemistry

The invention relates to a method for demulsifying and purifying plant crude oil. The method comprises the steps of separating in a process of extracting oil through an aqueous enzymatic method or an aqueous dissolving method to obtain a demulsified crude oil; adding PAM to evenly mix, and separating through a film to obtain demulsified, purified and refined oil, wherein the prepared protein isolate can be used as feed. The method is fine in process, simple in steps and capable of making full use of plant protein while obtaining high-purity plant oil.

Owner:HUBEI YIHENG TEA OIL IND SCI & TECH +1

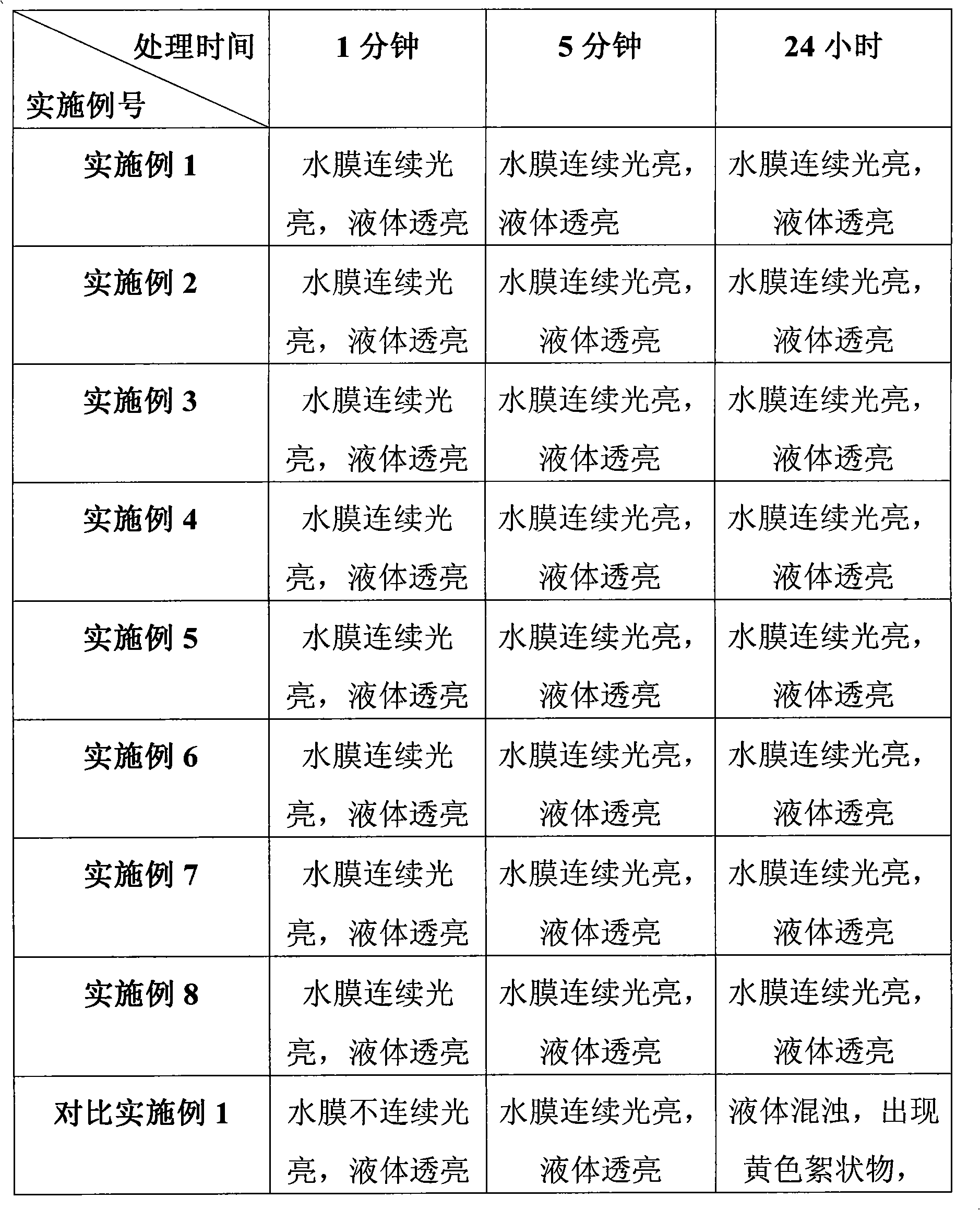

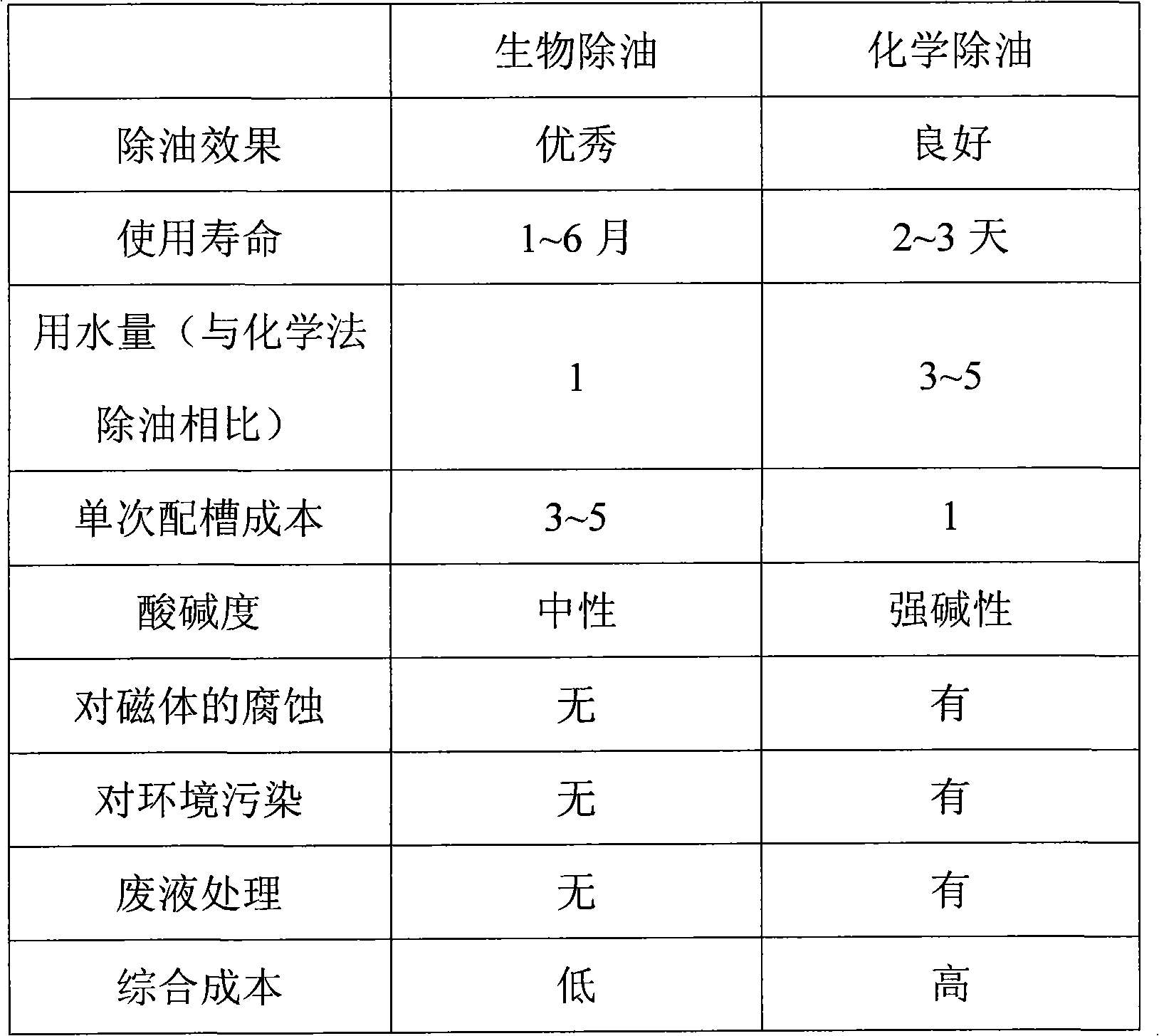

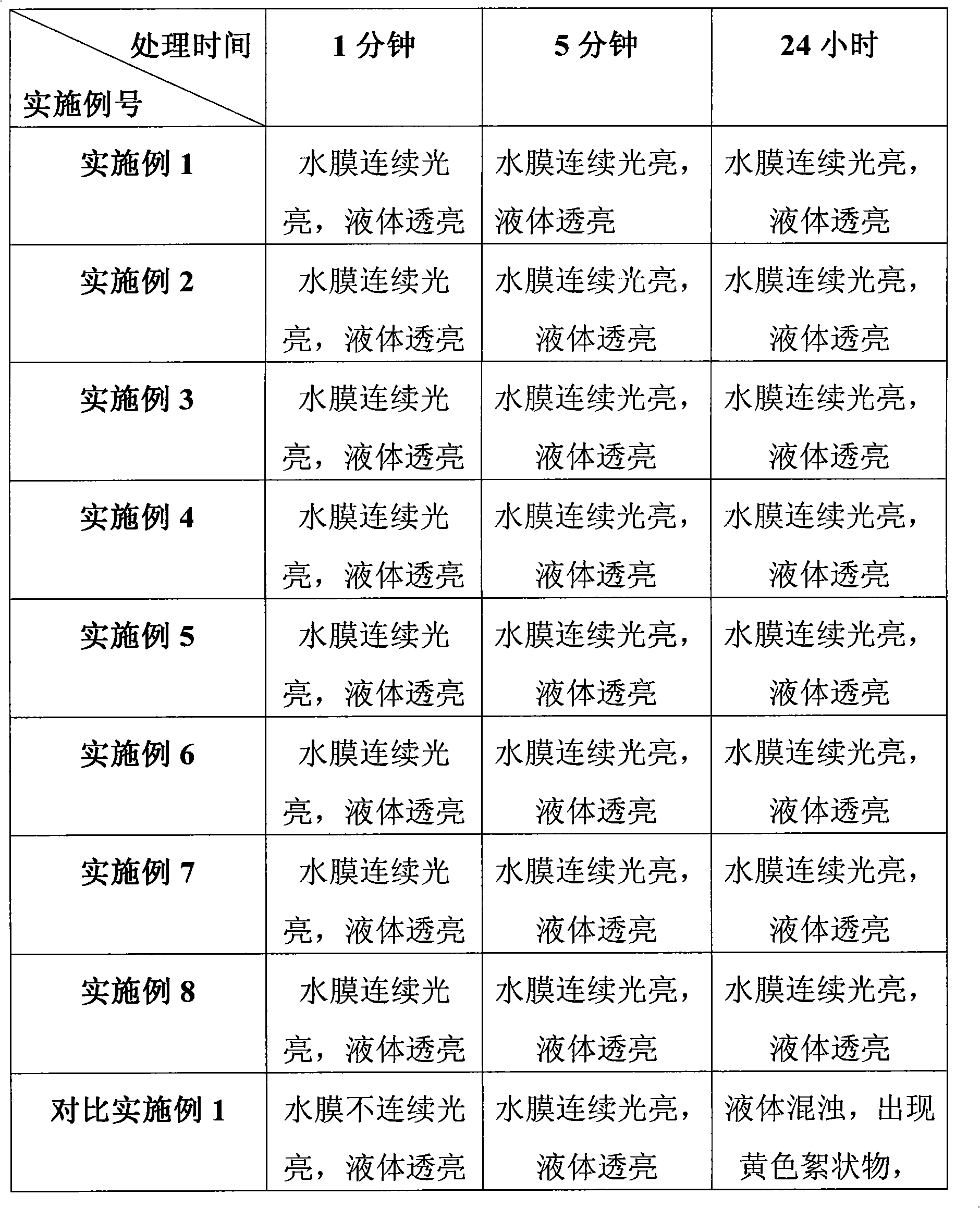

Biological oil removing agent for permanent-magnet materials

ActiveCN102040947AAvoid strong corrosiveAvoid the defect of not being able to completely degrease and degreaseOther chemical processesMagnetic materialsEnvironmental resistancePhosphoric acid

The invention relates to a biological oil removing agent for permanent-magnet materials. The biological oil removing agent is prepared according to the following steps: diluting the biological oil removing agent with water in the volume ratio of 1:(19-99) to obtain a diluent; and regulating the pH value of the diluent to 6.0-9.0 by using two of phosphoric acid, citric acid, sodium citrate and trisodium phosphate, and keeping the temperature of the diluent at 10-40 DEG C for later use. The biological oil removing agent can be used for thoroughly removing oil stains in the permanent-magnet material under the condition of mild pH value without generating substances harmful to the environment. The biological oil removing agent is environment-friendly. Meanwhile, microbes in the biological oil removing agent are cheap and are easy to obtain, and the biological oil removing agent has strong continuous oil removal capability, therefore, the oil removal cost can be greatly lowered by using the biological oil removing agent.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

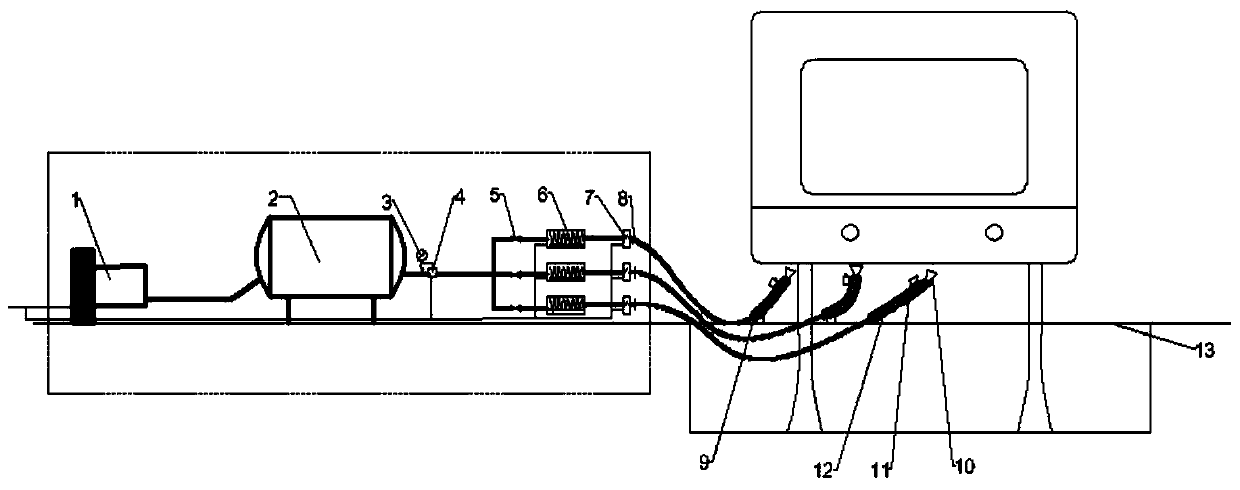

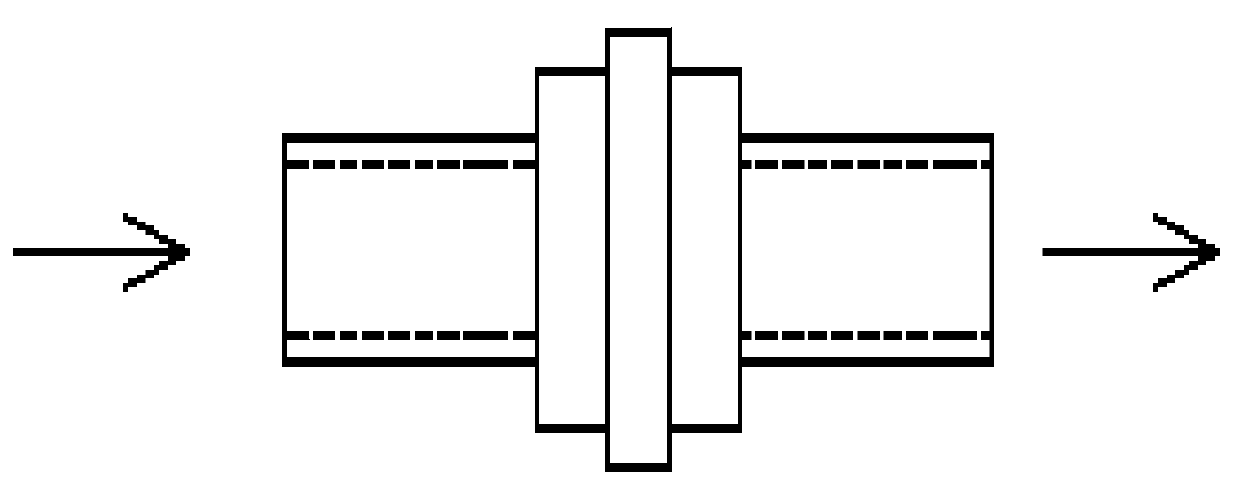

Train de-icing device and method

InactiveCN110103896AMild working conditionsRelieve pressureCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsAutomotive engineeringCold area

The invention provides a train de-icing device and method, belongs to the technical field of train de-icing, and particularly relates to a train de-icing device and method. The problems that existingde-icing technologies for trains have the disadvantages of large energy consumption, high de-icing requirements, great impact force on the trains, low efficiency, and inconvenient operation and control are solved. The train de-icing device comprises an air outlet mechanism, a heating mechanism, an air supplying mechanism, an air supplying header pipe and an air supplying branch pipe. The train de-icing device and method are mainly used for de-icing the bottom and side frozen trains in cold areas.

Owner:HARBIN INST OF TECH

Method of preparing water free isothiazolone

InactiveUS6072056AHigh antibacterial activityHigh acceptanceBiocideOrganic chemistryAqueous solutionOrganic solvent

A method of preparing water free isothiazolone having the steps of obtaining an extract from an aqueous solution containing isothiazolone by using a halogenationed hydrocarbon or nitrated hydrocarbon, removing the halogenationed hydrocarbon or nitrated hydrocarbon from the extract, and adding a organic solvent such as glycol, alcohol and glycol ether provides a water free isothiazolone having a high stability without forming wastes and harmful gas.

Owner:SK CHEM CO LTD

A kind of bismuth sulfide mineral suppressor and application thereof

ActiveCN108620240BImprove adsorption capacityImprove chelation abilityFlotationBismuth sulfideGallic acid ester

The invention discloses a bismuth sulfide mineral inhibiting agent and application thereof. The inhibiting agent comprises the following components in parts by mass: 2-5 parts of hydrogen peroxide, 3-4 parts of gallic acid, and 1-2 parts of dextrin. In a flotation process of sulfide minerals containing bismuth, 50-500 g / t combined inhibiting agent is added in each flotation according to each tonnage of raw ore minerals, so that the inhibition of the sulfide minerals containing bismuth can be realized. The bismuth sulfide mineral inhibiting agent has the advantages of high acting effect, low use level and the like, is free of using such high-consumption medicaments as poisonous cyanides, lime and sodium sulfide to reduce environmental pollution, meanwhile, reduces the beneficiation cost, and improves the sorting index.

Owner:CENT SOUTH UNIV

Method for extracting lithium from high-calcium lithium-containing raw material

PendingCN113998715ALow priceReduce pollutionCalcium/strontium/barium sulfatesChemical industryPhysical chemistryNanofiltration

The invention relates to a method for extracting lithium from a high-calcium lithium-containing raw material, which comprises the following steps: (1) calcium precipitation: adding the calcium-containing lithium-containing raw material into a reaction container, adding a calcium precipitator, stirring to generate calcium sulfate crystals, and carrying out solid-liquid separation to obtain a decalcified lithium-containing mother solution; (2) nanofiltration: carrying out nanofiltration on the decalcified lithium-containing mother liquor obtained in the step (1) through a nanofiltration system to further decalcify and remove other ions greater than or equal to 2 so as to obtain lithium-containing filtrate; and (3) evaporating and concentrating: evaporating and concentrating the lithium-containing filtrate obtained in the step (2) to obtain a lithium-rich concentrated solution. The method has the advantages of simple operation steps, mild working conditions, low energy consumption, safe operation and less environmental pollution; and the whole operation process is carried out according to safe, energy-saving and environment-friendly conditions. The method is suitable for extracting lithium from various calcium-containing and lithium-containing raw materials, is low in production cost, and is particularly suitable for extracting lithium from high-calcium and lithium-containing raw materials.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Process for separating superfine particles

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

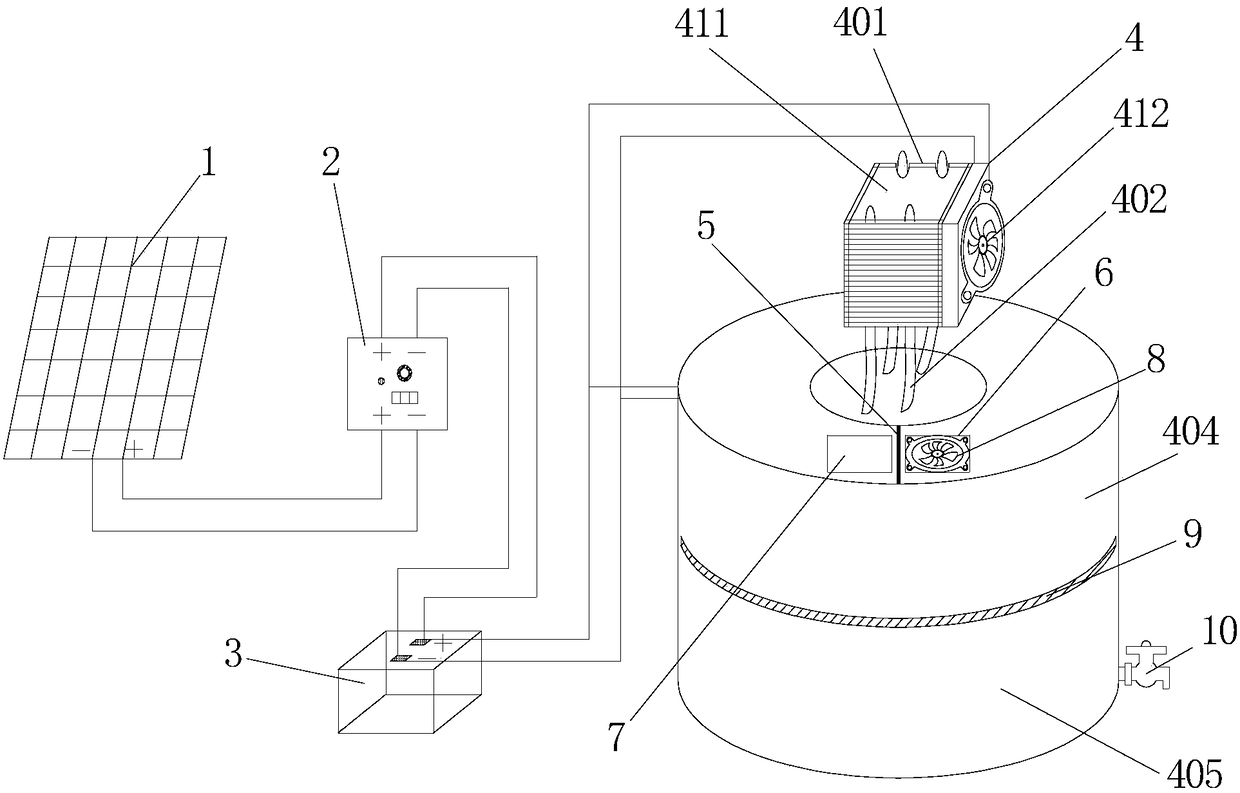

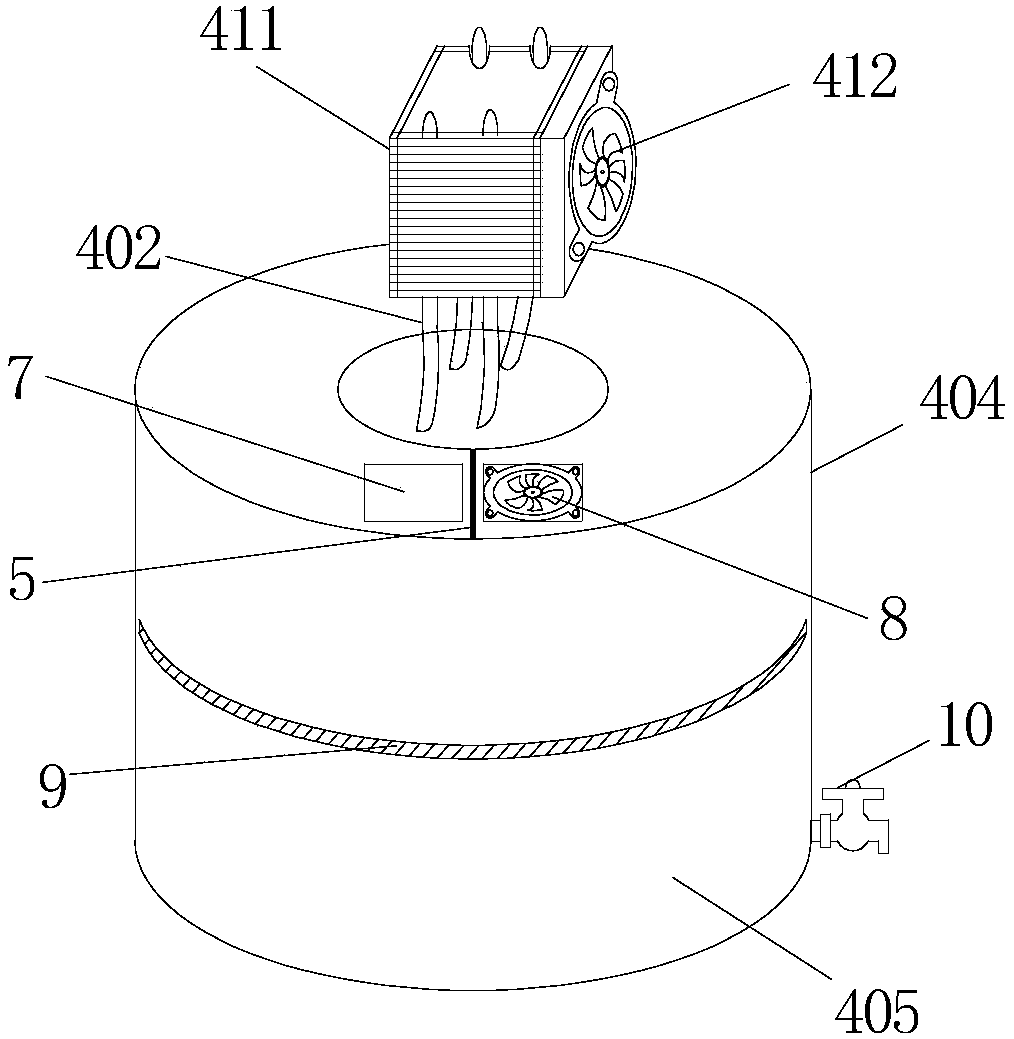

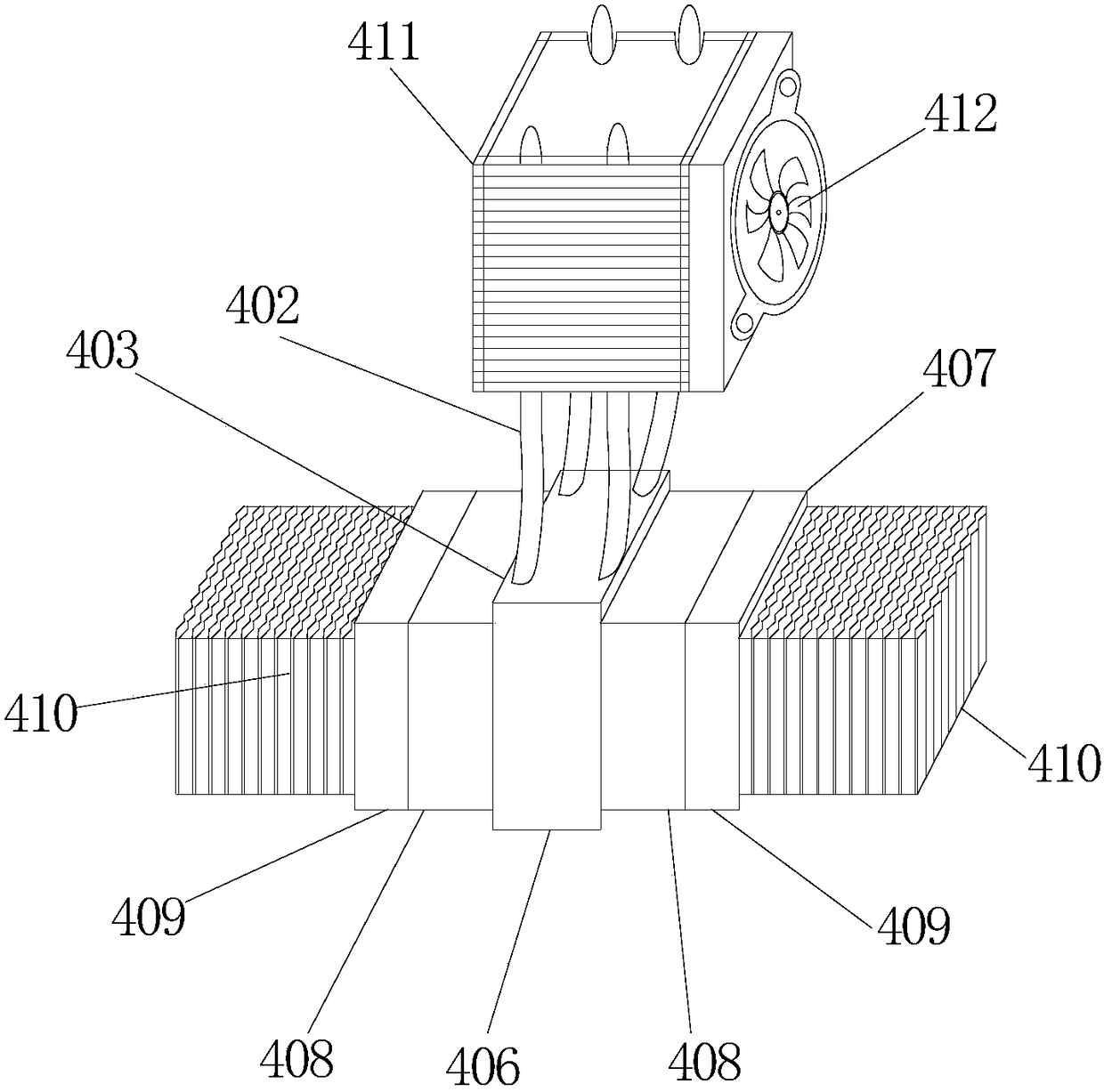

A kind of solar semiconductor refrigeration type water collector

InactiveCN105714878BAchieve self-sufficiencyNo pollution in the processDrinking water installationCold airWater storage tank

Owner:SOUTH CHINA UNIV OF TECH

Biological oil removing agent for permanent-magnet materials

ActiveCN102040947BAvoid strong corrosiveAvoid the defect of not being able to completely degrease and degreaseOther chemical processesMagnetic materialsDiluentPhosphoric acid

The invention relates to a biological oil removing agent for permanent-magnet materials. The biological oil removing agent is prepared according to the following steps: diluting the biological oil removing agent with water in the volume ratio of 1:(19-99) to obtain a diluent; and regulating the pH value of the diluent to 6.0-9.0 by using two of phosphoric acid, citric acid, sodium citrate and trisodium phosphate, and keeping the temperature of the diluent at 10-40 DEG C for later use. The biological oil removing agent can be used for thoroughly removing oil stains in the permanent-magnet material under the condition of mild pH value without generating substances harmful to the environment. The biological oil removing agent is environment-friendly. Meanwhile, microbes in the biological oil removing agent are cheap and are easy to obtain, and the biological oil removing agent has strong continuous oil removal capability, therefore, the oil removal cost can be greatly lowered by using the biological oil removing agent.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

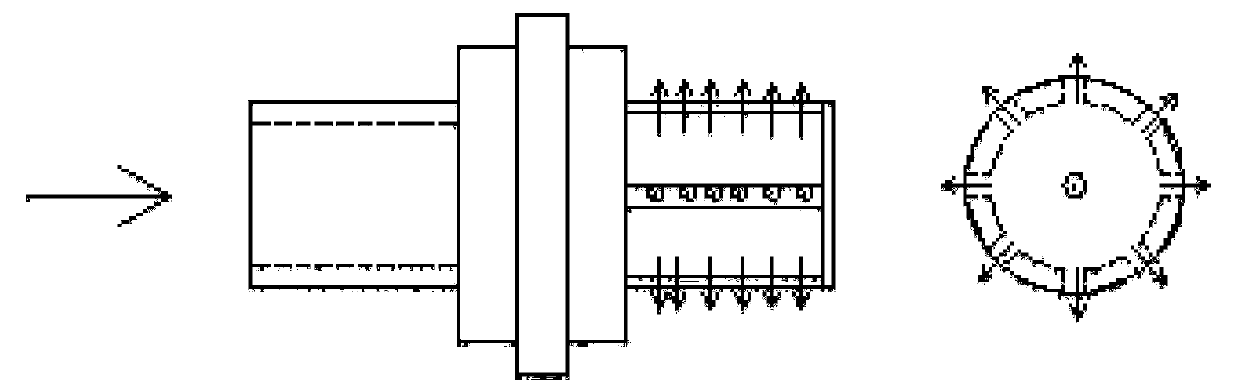

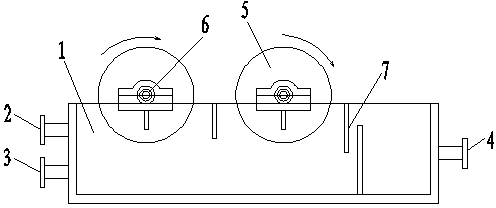

Rotary-type bioreactor

InactiveCN102912126BEasy to assemble and disassembleUniform disassemblyProcess efficiency improvementEngineeringOxygen

The invention discloses a rotary-type bioreactor, comprising a reaction tank, wherein bacterium solution is filled in the reaction tank; a first water inlet and a first water outlet are formed at the left end of the reaction tank; a second water outlet is formed at the right end of the reaction tank; a drum is arranged in the reaction tank; the drum sinks in the bacterium solution, and the interior of the drum is hollow; a hole is formed on the drum, and the aperture of the hole is less than the aperture of a reaction material; and a backflow tube is arranged in the drum; and a hole is formed on the backflow tube. Via the mode aforementioned, the rotary-type bioreactor adopting the scheme has the advantages of being less in pollution, temperate in working condition, short in flow, low in cost, less in investment and the like, and has the characteristic of being wide in mineral applicability in case of being applied to mining metallurgical engineering; oxygen is provided for the bacterium solution via the rotation of the drum so as to directly culture the bacterium solution, and the operation is convenient and fast; the rotary-type reactor performs reaction by means of injecting the bacterium solution, thus avoiding the damages of a shearing force in the normally-used stirring mode on the cells of bacteria, and contributing to the survival of the bacteria; and the reaction of the rotary-type reactor during a rotation process is uniform.

Owner:CHANGZHOU TEXTILE GARMENT INST

Comprehensive utilization method of pumpkin

InactiveCN102180991BEasy to separateReduce the burden onMetabolism disorderAntinoxious agentsSeparation technologyFreeze-drying

The invention relates to a comprehensive utilization method of a pumpkin. In the method, added amount of substances is based on weight of the pumpkin; and the pumpkin is taken as a raw material for step-by-step extraction to respectively obtain pumpkin polysaccharide, pectin and pumpkin powder by utilizing a biotechnology and a membrane separation technology. The method comprises the following steps: firstly washing and cutting the pumpkin into blocks, removing seeds, pulping, carrying out water extraction at moderate temperature and centrifugal separation, carrying out acid precipitation on the obtained water extract, concentrating the obtained supernate through a nanofiltration membrane, and spray-drying to obtain the polysaccharide; extracting residues after water extraction by utilizing acid water, carrying out centrifugal separation, removing impurities from the obtained supernate through a microfiltration membrane, concentrating the supernate through a nanofiltration membrane, carrying out acid precipitation on the obtained concentrated solution, carrying out centrifugal separation, and freeze-drying the obtained precipitate to obtain the pectin; spray-drying the supernate to obtain the polysaccharide; and mixing the remaining residues and filtered liquor, grinding by a colloid mill and spray-drying to obtain the pumpkin powder. The comprehensive utilization method has the advantages that effective substances of the pumpkin are fully utilized, and process is simple and feasible, thus being applicable to industrialized production.

Owner:武汉普赛特膜技术循环利用有限公司

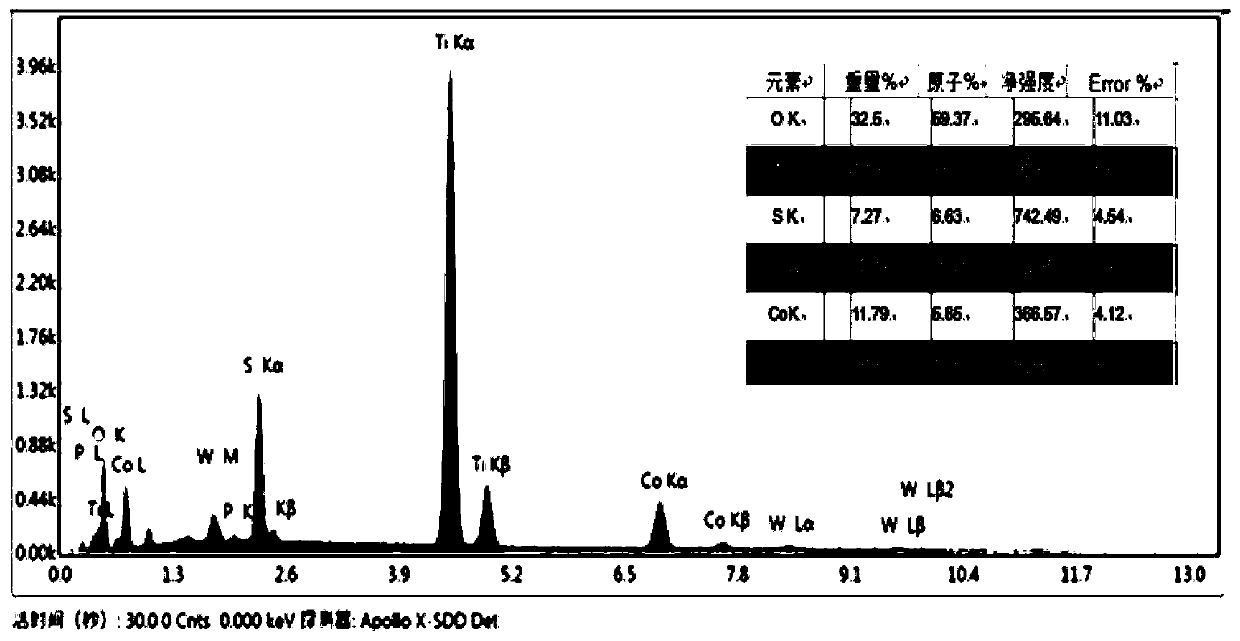

Preparation method of titanium dioxide nanotube array photoelectrochemical oxygen evolution electrode co-modified with polyacid and nine cobalt octasulfide

InactiveCN107012480BPhotoelectrochemical water splitting performance promotionMild working conditionsSurface reaction electrolytic coatingEnergy inputComposite filmDecomposition

The invention provides a preparation method of a polyacid and enneacobalt octasulfide co-modified titanium dioxide nanotube array photoelectrochemical oxygen evolution electrode. The prepared polyacid and enneacobalt octasulfide co-modified titanium dioxide nanotube array composite film photo anode can be used for photoelectrochemical water decomposition and oxygen evolution. The composite film photo anode is the titanium dioxide-enneacobalt octasulfide-polyacid composite film photo anode which is formed by using a titanium dioxide nanotube array as a main body and co-modified by enneacobalt octasulfide and Keggin type phosphotungstic acid. Under indoor temperature environment and irradiation of a xenon lamp, the composite film photo anode has good photoelectrochemical water decomposition performance. The preparation method of the titanium dioxide-enneacobalt octasulfide-polyacid composite film electrode is simple, quite low in cost, capable of achieving efficient and stable photoelectric water decomposition without sacrificing a reagent, a protective layer and a buffer solution, capable of achieving high-efficiency conversion from optical energy to chemical energy and applicable to development and production of the novel photoelectrochemical water decomposition and oxygen evolution electrode.

Owner:NORTHEAST NORMAL UNIVERSITY

A method for demulsifying and purifying vegetable crude oil

InactiveCN103740464BGood flocculation effectRaw materials are easy to getFatty-oils/fats refiningVegetable oilProtein isolate

The invention relates to a method for demulsifying and purifying plant crude oil. The method comprises the steps of separating in a process of extracting oil through an aqueous enzymatic method or an aqueous dissolving method to obtain a demulsified crude oil; adding PAM to evenly mix, and separating through a film to obtain demulsified, purified and refined oil, wherein the prepared protein isolate can be used as feed. The method is fine in process, simple in steps and capable of making full use of plant protein while obtaining high-purity plant oil.

Owner:HUBEI YIHENG TEA OIL IND SCI & TECH +1

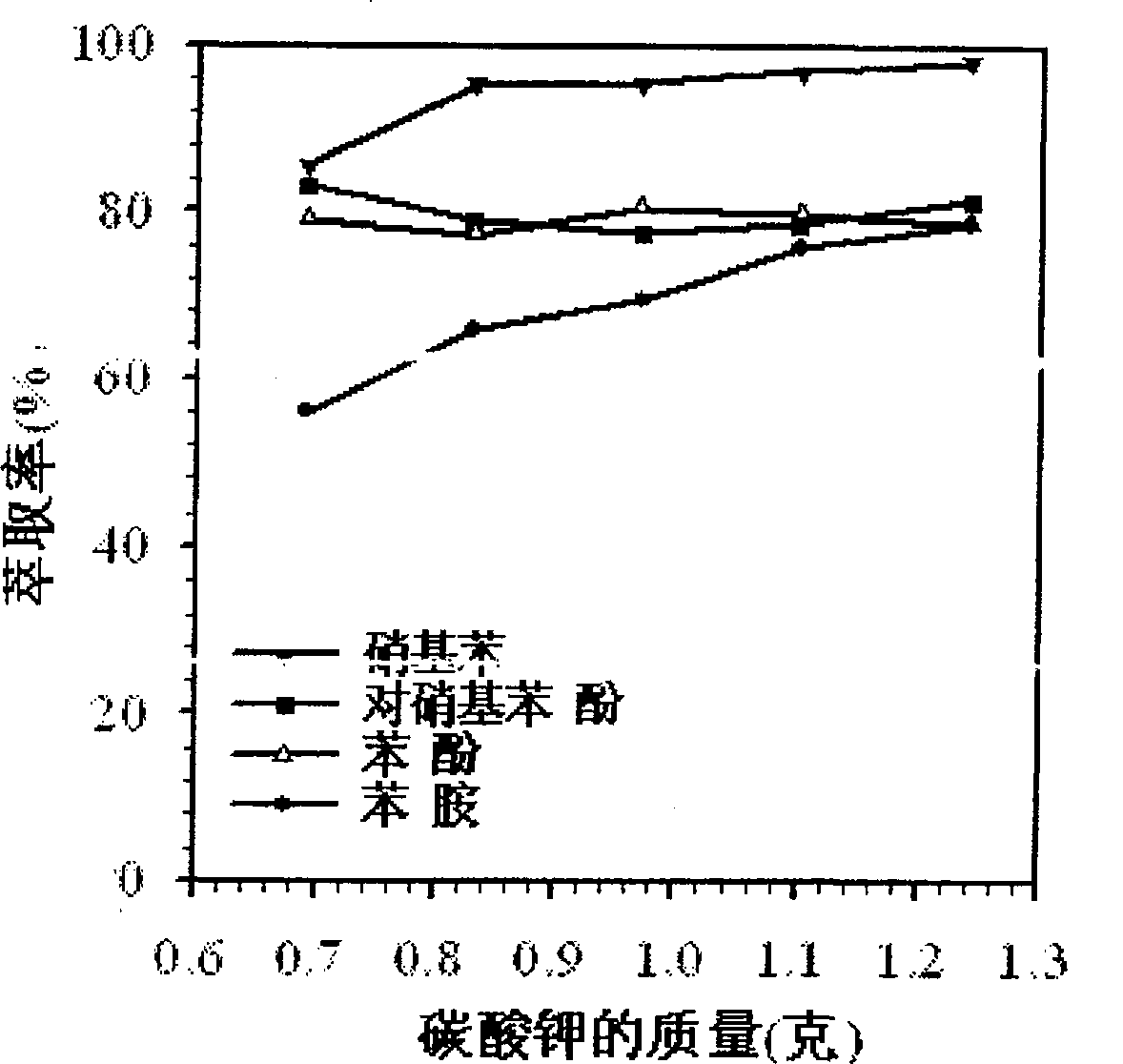

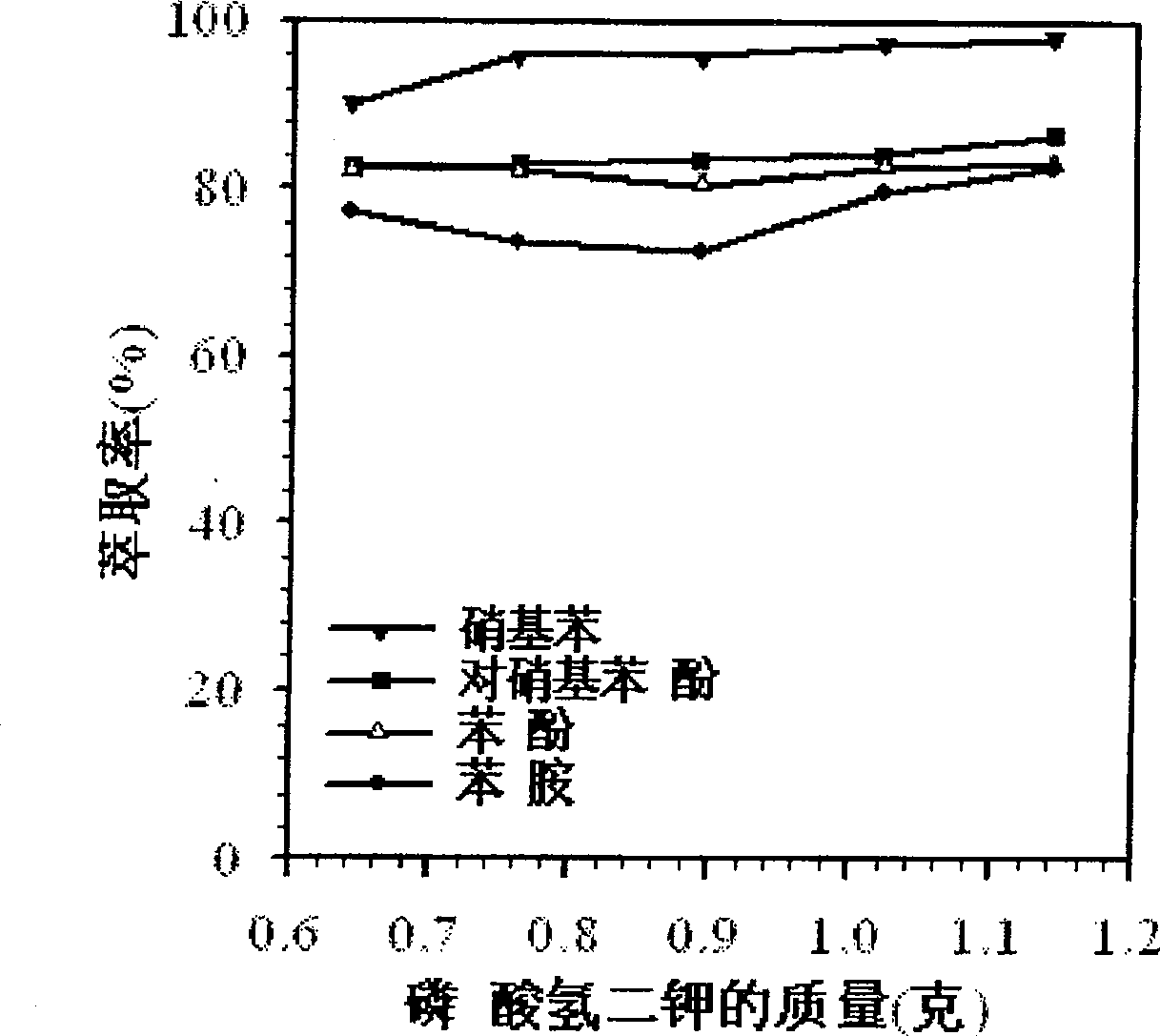

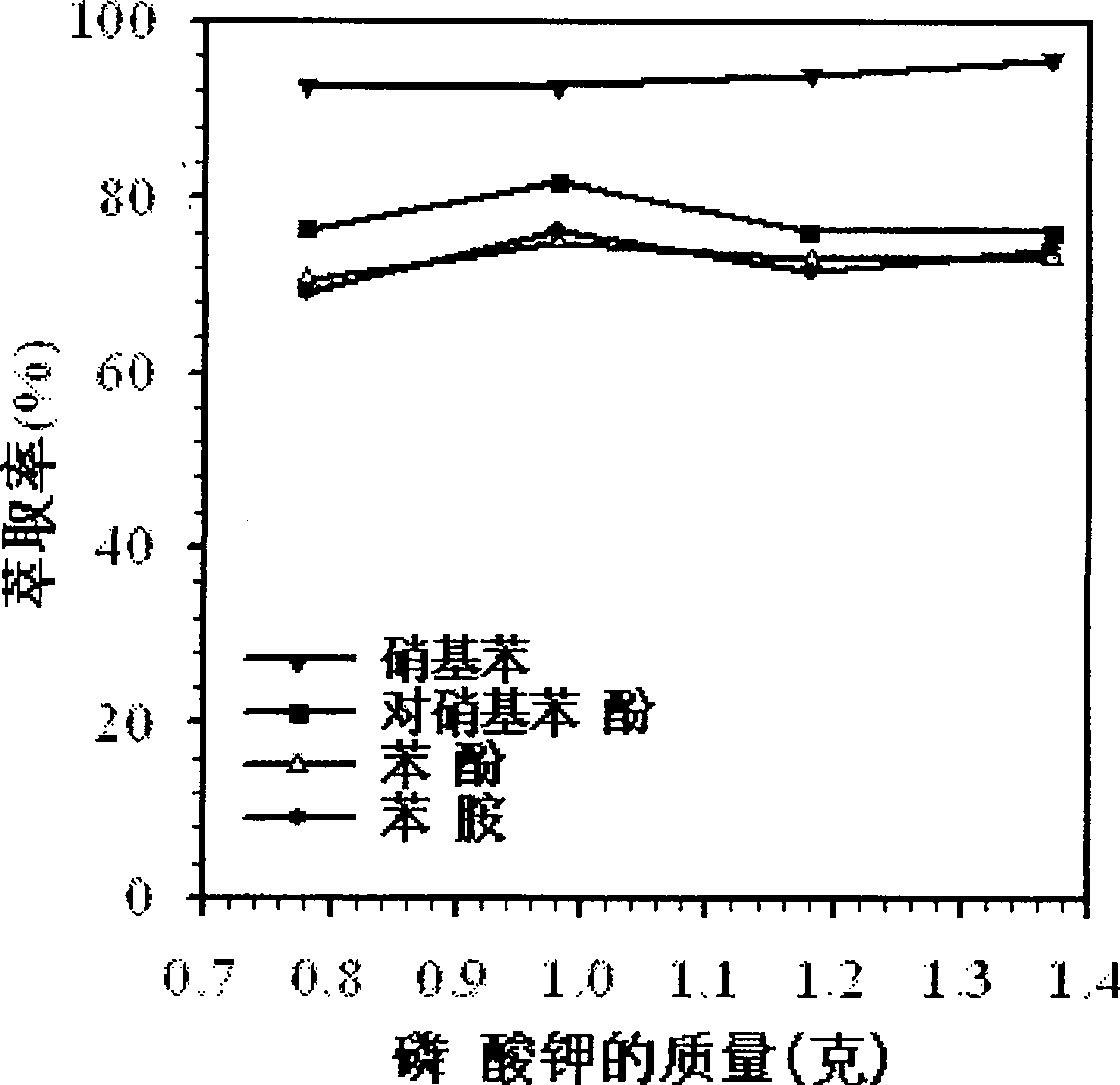

Method for extracting and enriching aromatic compounds in water by double water-phase

InactiveCN100519428CHigh extraction rateNo pollutionLiquid solutions solvent extractionWater/sewage treatment by extractionFencholNitrobenzene

The invention relates to a method for two-phase extraction and enrichment of aromatic compounds in water. A hydrophilic ionic liquid-salt two-phase system is used to extract and recover aromatic compounds in aqueous solution to achieve the purpose of enriching and recovering aromatic compounds from wastewater. The extracted ionic liquid phase can recover aromatic compounds by distillation or vacuum distillation, and the ionic liquid can be enriched and recovered by adding salt for recycling. For general compounds such as p-nitrophenol or phenol, the extraction rate can reach more than 75% after one enrichment, and for some compounds such as nitrobenzene, the extraction rate can reach 90% after one enrichment.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com