Indium oxide-polyacid composite gas sensing material and preparation method thereof

A technology for sensing materials and composite gases, applied in chemical instruments and methods, tungsten compounds, electrochemical variables of materials, etc., can solve problems such as poor performance, affecting electron transmission, weakening of gas sensing detection signals, etc., and achieve gas sensing performance Improved, milder working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

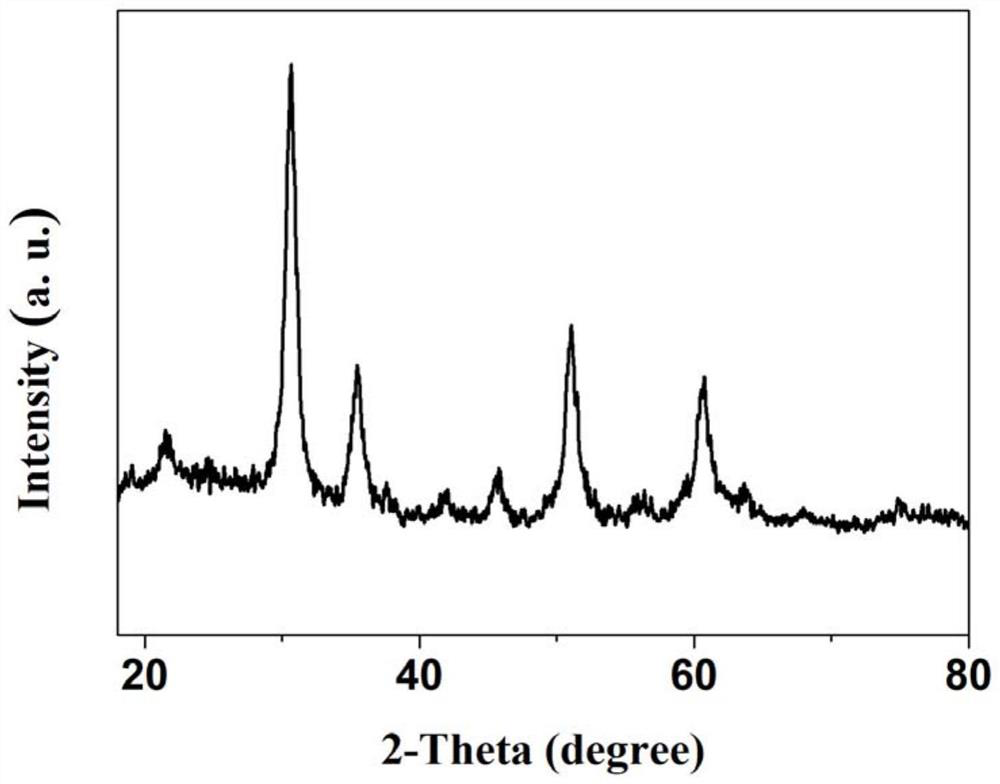

[0032] Put the interdigitated electrode with the composite film into a 1000 ml airtight glass bottle for testing, one of the gold electrodes of the interdigitated electrode is connected to the working electrode of the electrochemical workstation with a wire, the other gold electrode and the counter electrode and the reference connected to the electrodes. A certain voltage is applied between the two electrodes, and a stable current value is obtained at room temperature. When 5ppm, 10ppm, 20ppm, 50ppm and 100ppm formaldehyde gas were injected into the glass bottle, the current between the two electrodes increased significantly.

[0033] (see attached Figure 5 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com