Biological oil removing agent for permanent-magnet materials

A permanent magnet material and degreasing agent technology, applied in the direction of magnetic materials, magnetic objects, other chemical processes, etc., can solve the problems of large oily waste liquid, large degreasing late consumption, and inability to decompose oil stains, etc., to achieve long service life , Degreasing quickly and thoroughly, avoiding strong corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

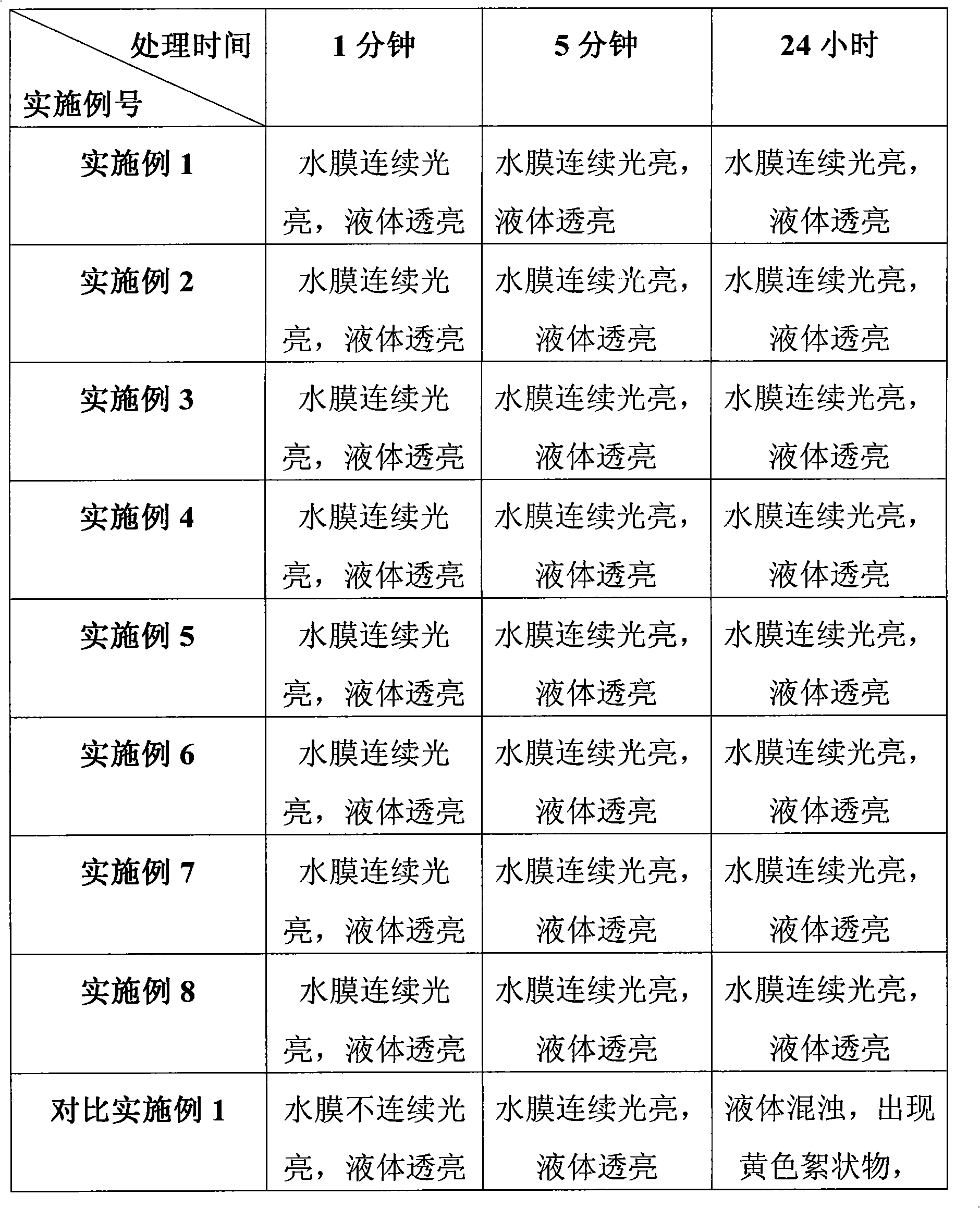

Embodiment 1

[0025] Dilute the biological degreasing agent A08 (provided by Guangzhou Tianzhi Environmental Protection Technology Co., Ltd.) with water at a ratio (volume ratio) of 1:99 to obtain a diluted solution, and then adjust the pH of the diluted solution to 7.0 with phosphoric acid and trisodium phosphate , and keep the temperature of the diluent at around 30°C. Divide the same bonded NdFeB permanent magnet material sample into three parts, put them into the above diluent at the same time, and take one of the above three permanent magnet material samples at the first minute, the fifth minute and the 24th hour. out.

Embodiment 2

[0027] Dilute the biological degreasing agent A08 and water at a ratio (volume ratio) of 1:19 to obtain a diluent, then use citric acid and trisodium phosphate to adjust the pH of the diluent to 9.0, and keep the temperature of the diluent at 10 ℃ or so. Divide the same sintered NdFeB permanent magnet material sample into three parts, put them into the above diluent at the same time, take out one of the above three permanent magnet material samples at the first minute, the fifth minute and the 24th hour respectively .

Embodiment 3

[0029] Dilute the biological degreasing agent A08 and water at a ratio (volume ratio) of 1:24 to obtain a diluted solution, then use citric acid and trisodium citrate to adjust the pH of the diluted solution to 6.0, and keep the temperature of the diluted solution at Around 30°C. Divide the same bonded NdFeB permanent magnet material sample into three parts, put them into the above diluent at the same time, and take one of the above three permanent magnet material samples at the first minute, the fifth minute and the 24th hour. out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com