Green and efficient preparation method of titanium carbide Mxene nanosheet

A nanosheet, titanium carbide technology, applied in titanium carbide, chemical instruments and methods, carbides, etc., can solve the problems of strong corrosion and toxicity of Mxene materials, achieve green and controllable preparation process, high production efficiency, avoid corrosion Sexual and Toxic Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

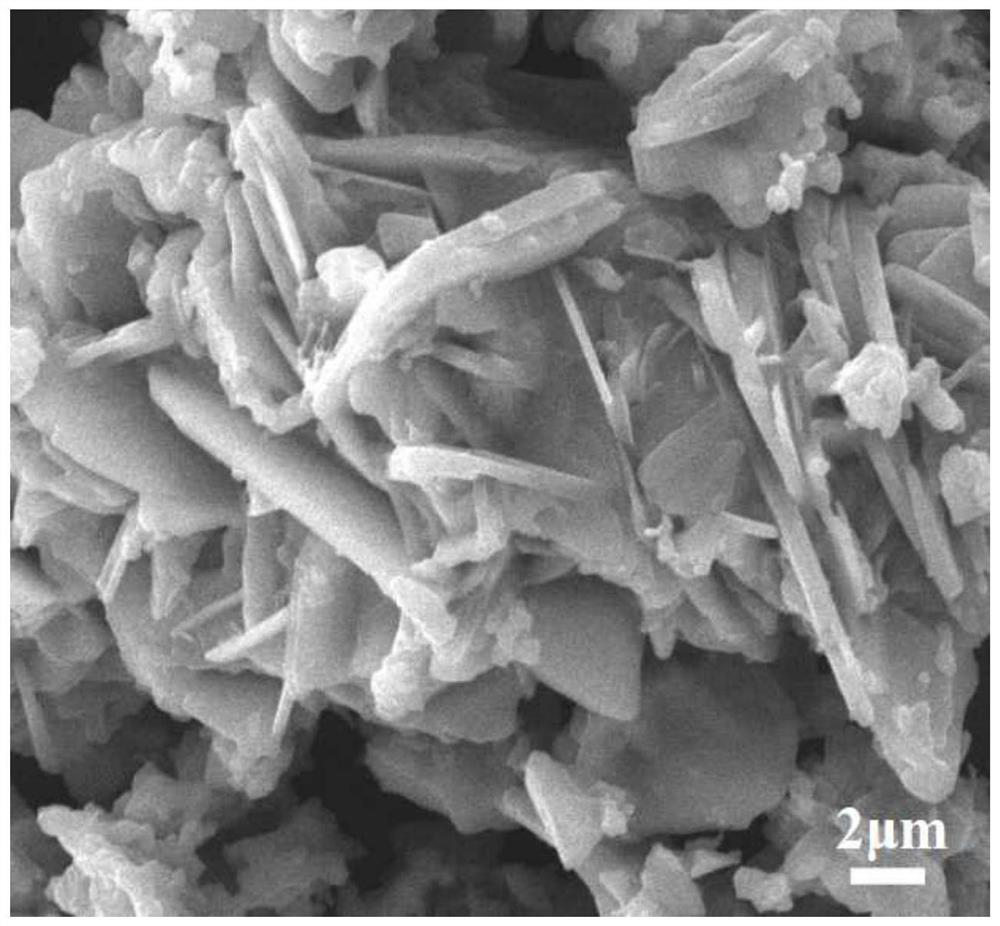

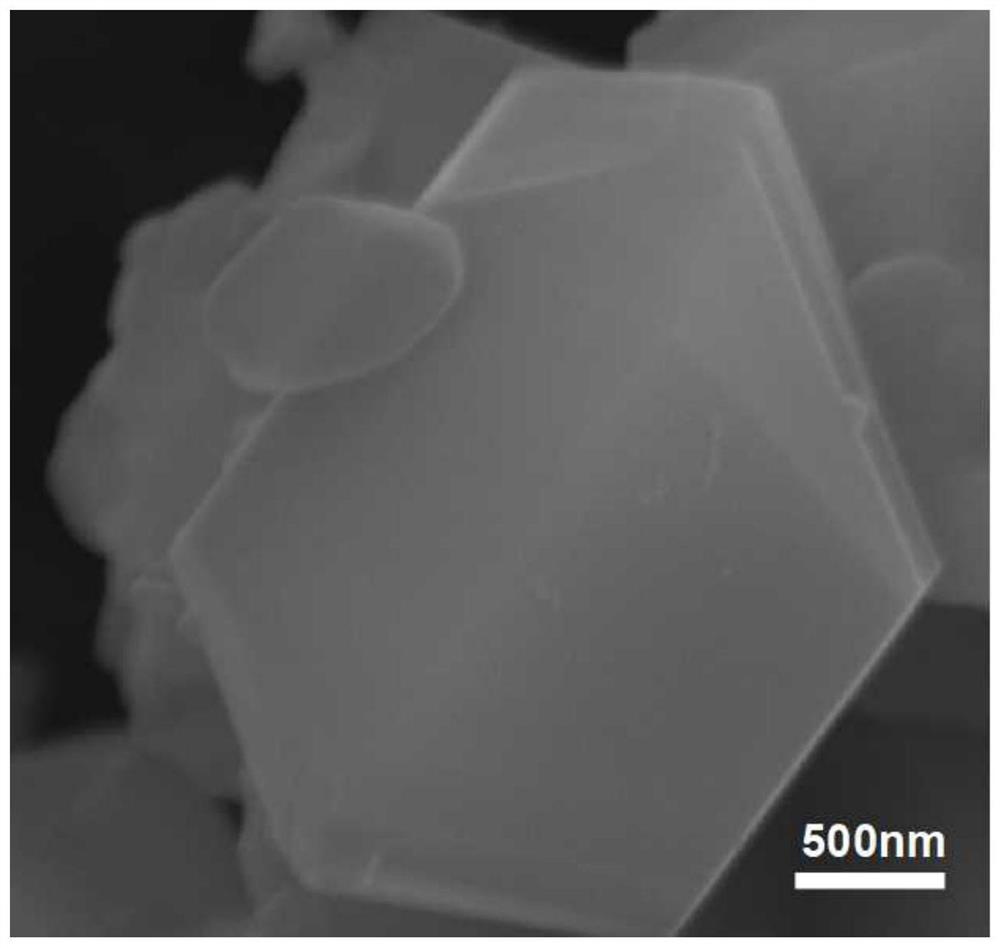

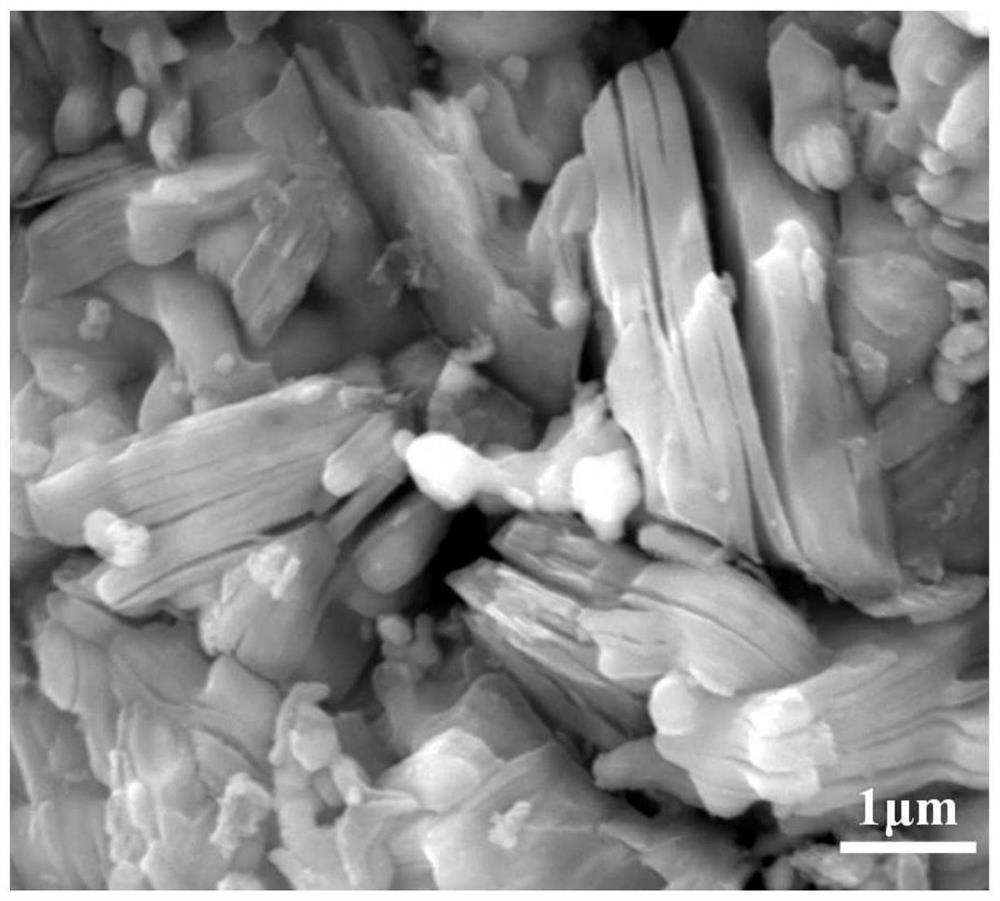

[0019] Specific implementation mode one: a green and efficient preparation method of titanium carbide Mxene nanosheets in this implementation mode is realized according to the following steps:

[0020] 1. Weigh titanium carbide, titanium powder, aluminum powder, sodium chloride and Potassium chloride is mixed and ground, placed in a tube furnace, calcined under an inert atmosphere, the product is washed with deionized water, and then dried in an oven to obtain powder A;

[0021] 2. According to the molar ratio (0.5~1):(1~5):(1~5):(1~5), weigh the above powder A, nickel chloride hexahydrate, potassium chloride and sodium chloride in sequence and mix them Grinding, placing in a tube furnace, calcining under an inert atmosphere, washing the product with deionized water, and then drying in an oven to obtain powder B;

[0022] 3. According to the mass volume ratio of 1g: (60-200) mL, mix the above powder B with ferric chloride solution, wash with deionized water after magnetic sti...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the inert atmosphere in step 1 is argon or nitrogen; the temperature of the calcination is 1000° C. to 1400° C., and the calcination time is 3 to 5 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that the number of deionized water washing in step 1 is 2 to 5 times. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com