Nanometer colloid particle, preparation method, cleaning agent containing nanometer colloid particle and cleaning method

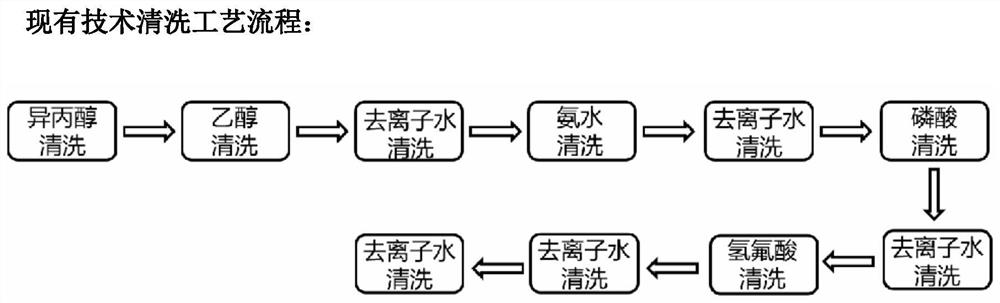

A technology of nano-colloid and cleaning agent, which is applied to cleaning methods and utensils, cleaning methods using liquids, detergent compositions, etc., can solve problems such as difficulty in meeting cleaning and process requirements, cumbersome cleaning method steps, and complex components, etc. Achieve the effect of eliminating the use of harmful chemicals, excellent surface cleaning effect with ultra-high cleanliness, and reducing the use of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

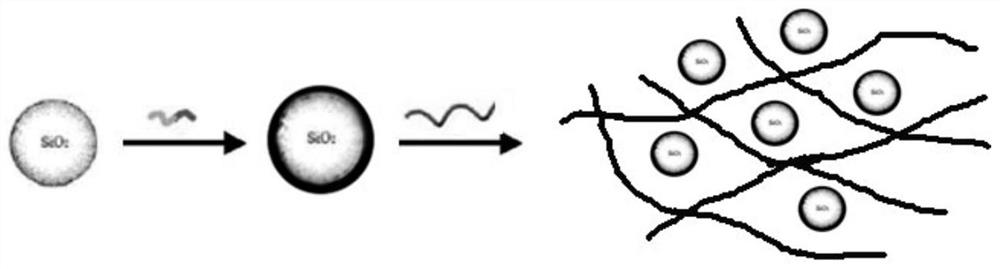

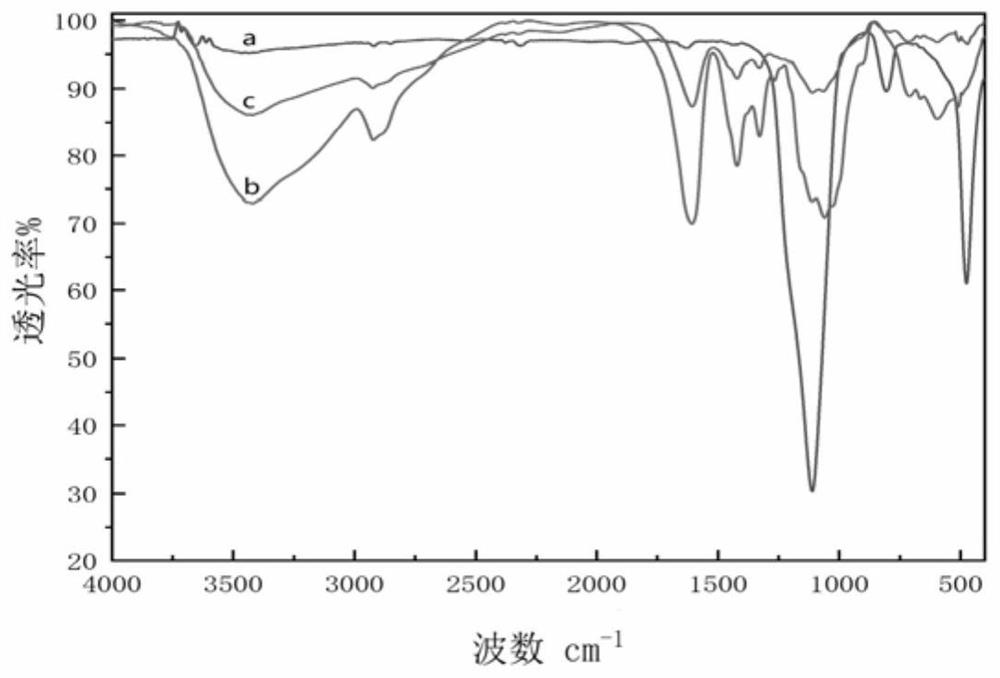

[0114] Nano colloid particle preparation example 1: Preparation of nano colloid particle

[0115] A, in parts by mass, take by weighing 10 parts of nano silicon dioxide (particle size is 20-60nm), 0.5 part of colloidal stabilizer hydroxyethyl cellulose, 2.25 parts of silicon dioxide adsorbent polyacrylic acid (molecular weight is 5000-12000 ) and 80 parts of ultrapure water, and the ultrapure water is divided into two equal parts (that is, each part is 40 parts by mass) for use;

[0116] B. Add the nano silicon dioxide to the first part of ultrapure water under stirring, then add the silicon dioxide adsorbent under stirring at 100rpm, continue stirring for 45 minutes to obtain agent 1, which is ready for use;

[0117] C. Add the colloidal stabilizer into the second part of ultrapure water under stirring, and keep stirring at 100 rpm until the colloidal stabilizer is fully swollen to obtain agent II for use;

[0118] D. At a temperature of 25°C, while stirring the I agent at 1...

preparation example 2

[0119] Nano colloid particle preparation example 2: Preparation of nano colloid particle

[0120] A, in parts by mass, weigh 5 parts of nano silicon dioxide (particle size is 20-60nm), 1 part of colloidal stabilizer cellulose, 0.5 part of silicon dioxide adsorbent polymaleic acid (molecular weight is 15000-20000) And 90 parts of ultrapure water, and described ultrapure water is divided into two equal parts (that is, every part is 45 mass parts) stand-by;

[0121] B. Add the nano silicon dioxide to the first part of ultrapure water under stirring, then add the silicon dioxide adsorbent under stirring at 100rpm, continue stirring for 30 minutes to obtain agent I, and set aside;

[0122] C. Add the colloidal stabilizer into the second part of ultrapure water under stirring, and keep stirring at 100 rpm until the colloidal stabilizer is fully swollen to obtain agent II for use;

[0123] D. At a temperature of 25°C, while stirring the I agent at 100 rpm, slowly add the II agent, a...

preparation example 3

[0124] Nano colloid particle preparation example 3: Preparation of nano colloid particle

[0125] A, in parts by mass, take by weighing 15 parts of nano silicon dioxide (particle size is 20-60nm), 0.1 part of colloid stabilizer hydroxypropyl cellulose, 4 parts of silicon dioxide adsorbent acrylic acid-maleic acid copolymer ( Molecular weight is 3000-8000) and 70 parts of ultrapure water, and described ultrapure water is divided into two equal parts (being every part is 35 mass parts) stand-by;

[0126] B. Add the nano silicon dioxide to the first part of ultrapure water under stirring, then add the silicon dioxide adsorbent under stirring at 100rpm, continue stirring for 60 minutes to obtain agent I, and set aside;

[0127] C. Add the colloidal stabilizer into the second part of ultrapure water under stirring, and keep stirring at 100 rpm until the colloidal stabilizer is fully swollen to obtain agent II for use;

[0128] D. At 25°C, while stirring the I agent at 100rpm, slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com