A kind of activated carbon with graded pores and preparation method thereof

A technology of activated carbon and channels, which is applied in the field of activated carbon and its preparation, can solve the problems of strong corrosion and high activation cost of potassium hydroxide, and achieve the effects of high specific capacity, good power characteristics and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to the production method of activated carbon for supercapacitors of the present embodiment, using Panjin Zhongyou Liaohe Petroleum Coke as the carbon source, the following steps are successively included:

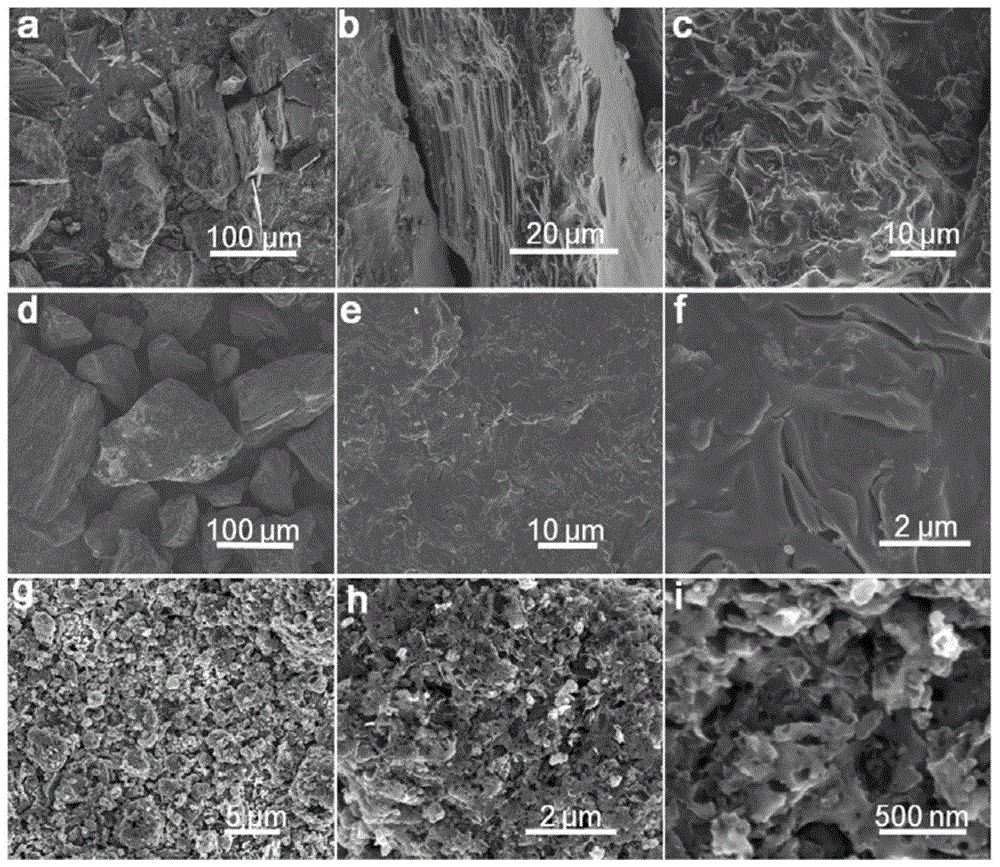

[0043] (1), petroleum coke is pulverized and sieved, and sieved to obtain 200 mesh petroleum coke powder (PC), and its electron microscope is as follows: figure 1 As shown in .a-c, it is a smooth block with a size of about 100um.

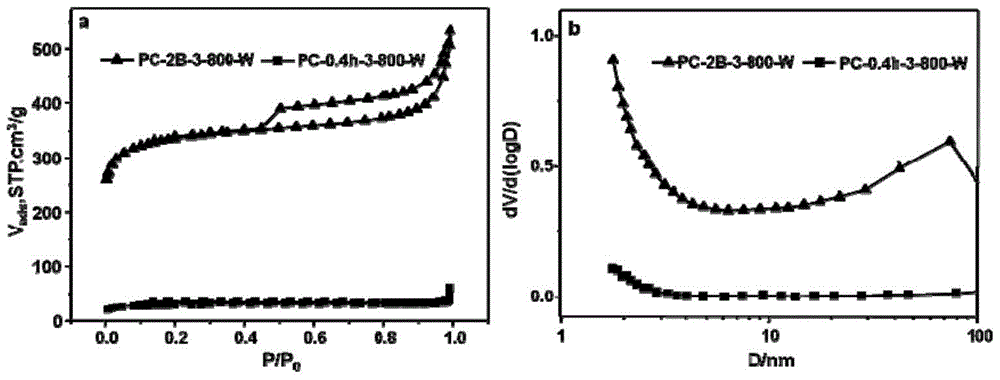

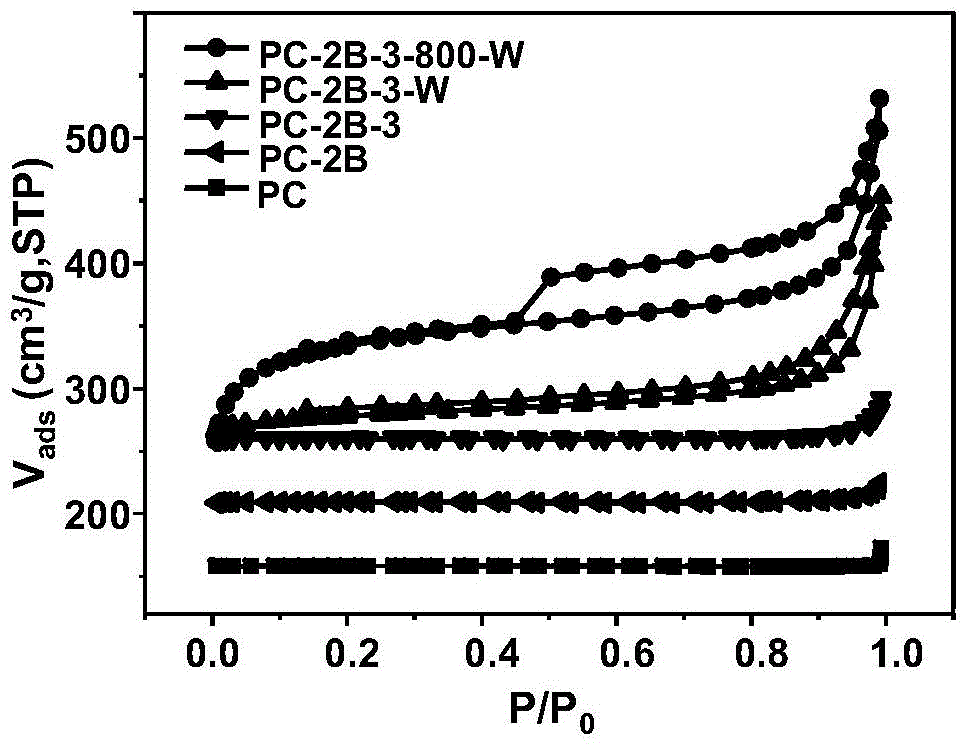

[0044] (2) Petroleum coke powder (PC) was ball milled for 2 hours to obtain PC-2B; in addition, PC and potassium carbonate were mixed at a mass ratio of 1:3, and ball milled for 2 hours to obtain a mixed powder (PC-2B-3), a part of the mixed powder (PC-2B-3) was acid-washed with HCl, washed with water, neutralized, and dried to obtain activated carbon powder (PC-2B-3-W) from which potassium carbonate was removed.

[0045] (3) Another part of the mixed powder (PC-2B-3) was placed in a carbonization furnace at 800°C, and activated f...

Embodiment 2

[0051] According to the production method of activated carbon for supercapacitors of the present embodiment, using Panjin Zhongyou Liaohe Petroleum Coke as the carbon source, the following steps are successively included:

[0052] (1), the petroleum coke is pulverized and sieved, and sieved to obtain a 200-mesh powder.

[0053] (2) Mix petroleum coke powder and potassium carbonate at a mass ratio of 1:0.5, and ball mill for 2 hours to obtain a mixed powder.

[0054] (3) Put the mixed powder in a carbonization furnace at 800°C, and activate it for 2 hours under the protection of an inert gas.

[0055] (4), cooling activator, pickling with 0.2mol / L HCl, washing with water puts neutrality, drying, obtains activated carbon (PC-2B-0.5-800-W) for supercapacitor, and its structural parameters are as shown in table 3:

[0056] Table 3: Structural parameters of activated carbon prepared from petroleum coke

[0057]

[0058] (5) The activated carbon PC-2B-0.5-800-W is made into an ...

Embodiment 3

[0060] According to the production method of activated carbon for supercapacitors of the present embodiment, using Panjin Zhongyou Liaohe Petroleum Coke as the carbon source, the following steps are successively included:

[0061] (1), the petroleum coke is pulverized and sieved, and sieved to obtain a 200-mesh powder.

[0062] (2) Mix petroleum coke powder and potassium carbonate at a mass ratio of 1:6, and ball mill for 2 hours to obtain mixed powder.

[0063] (3) Put the mixed powder in a carbonization furnace at 800°C, and activate it for 2 hours under the protection of an inert gas.

[0064] (4), cooling activator, 0.2mol / L HCl pickling, washing put neutral, dry, obtain supercapacitor active carbon (PC-2B-6-800-W), its structural parameters are as shown in table 4:

[0065] Table 4: Structural parameters of activated carbon prepared from petroleum coke

[0066]

[0067] (5) The activated carbon PC-2B-6-800-W is made into an electrode sheet, and a three-electrode test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com