A kind of high loading capacity aluminum chloride catalyst and its preparation method and application

A high-load, catalyst technology, used in the chemical industry, can solve problems such as high pressure and inappropriate filling of fine-particle fixed-bed reactors, and achieve the effects of solving material waste, improving catalyst efficiency, and overcoming corrosiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 15.24g γ-Al 2 o 3 (spherical, diameter 3-5mm, purity ≥99.5wt%, purchased from Sinopharm Chemical Reagent Co., Ltd.) into the first section of the tubular reactor (the material of the tubular reactor is 304 stainless steel, the outer diameter is 25mm, the inner diameter is 19mm, Length 52cm, heated by electric heating furnace). Access to N 2 Protection, flow control at 0.6L / min. After the temperature in the tube rises to 400°C, inject CCl with a constant flow pump 4 Liquid, the flow rate is 0.1ml / min.

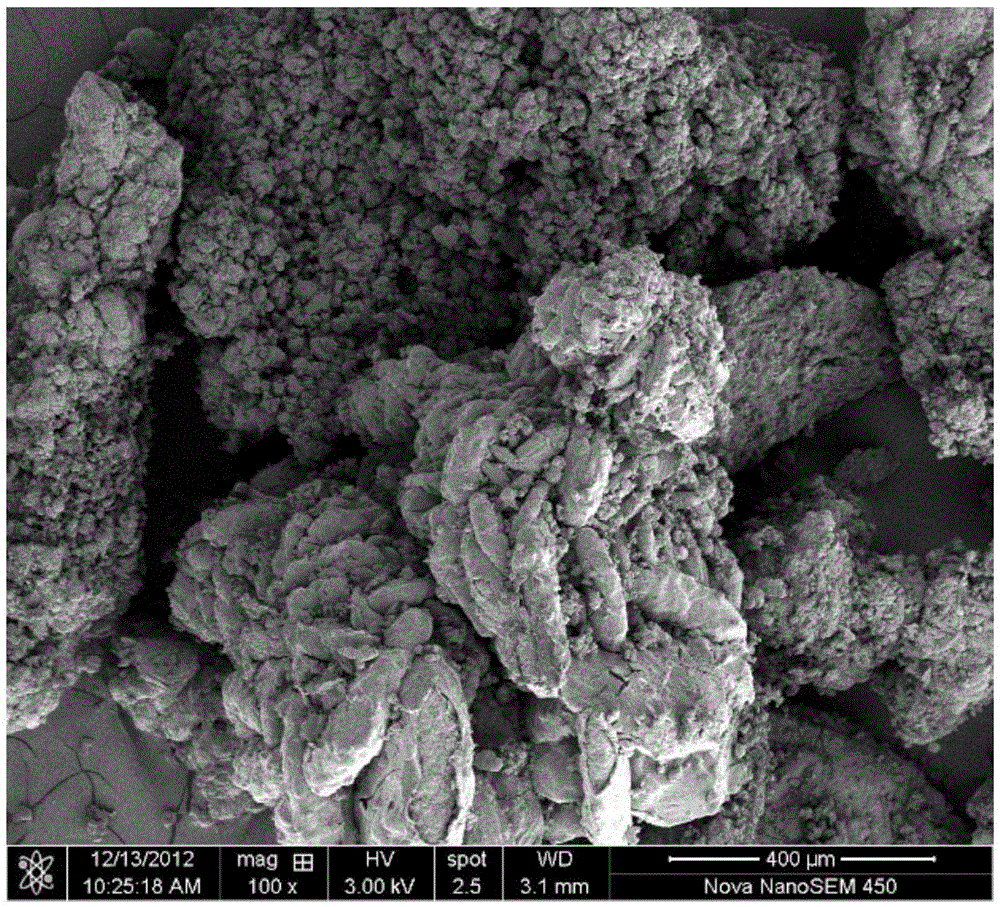

[0027] Measure 15.00 g of activated alumina (purchased from Sinopharm Chemical Reagent Co., Ltd.), grind it, and screen out Al with d=250 μm (60 mesh) 2 o 3 Fine particles as carrier (specific surface area: 150-250m 2 / g; Pore volume: 0.3~0.4cm 3 / g; average pore size: 500-800nm). put 12.00gAl 2 o 3 Load it into the second-stage tubular reactor (the material, size and heating method of the second-stage tubular reactor are exactly the same as those of the fi...

Embodiment 2

[0031] 14.89g γ-Al 2 o 3 (spherical, diameter 3-5mm, purity ≥99.5wt%, purchased from Sinopharm Chemical Reagent Co., Ltd.) into the first section of the tubular reactor (the material of the tubular reactor is 304 stainless steel, the outer diameter is 25mm, the inner diameter is 19mm, Length 52cm, heated by electric heating furnace). Access to N 2 Protection, flow control at 0.6L / min. After the temperature in the tube rises to 400°C, inject CCl with a constant flow pump 4 Liquid, the flow rate is 0.1ml / min.

[0032] Measure 15.00 g of activated alumina (purchased from Sinopharm Chemical Reagent Co., Ltd.), grind it, and screen out Al with d=150 μm (100 mesh) 2 o 3 Fine particles as carrier (specific surface area: 150-250m 2 / g; Pore volume: 0.3~0.4cm 3 / g; average pore size: 500-800nm). put 12.00gAl 2 o 3 Load it into the second-stage tubular reactor (the material, size and heating method of the second-stage tubular reactor are exactly the same as those of the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com