Train de-icing device and method

A technology for trains and main pipes, applied in the field of train deicing devices, which can solve the problems of deteriorating working conditions of workers, rising working environment temperature, and limited storage time, and achieve the effects of improving deicing efficiency, mild working conditions, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

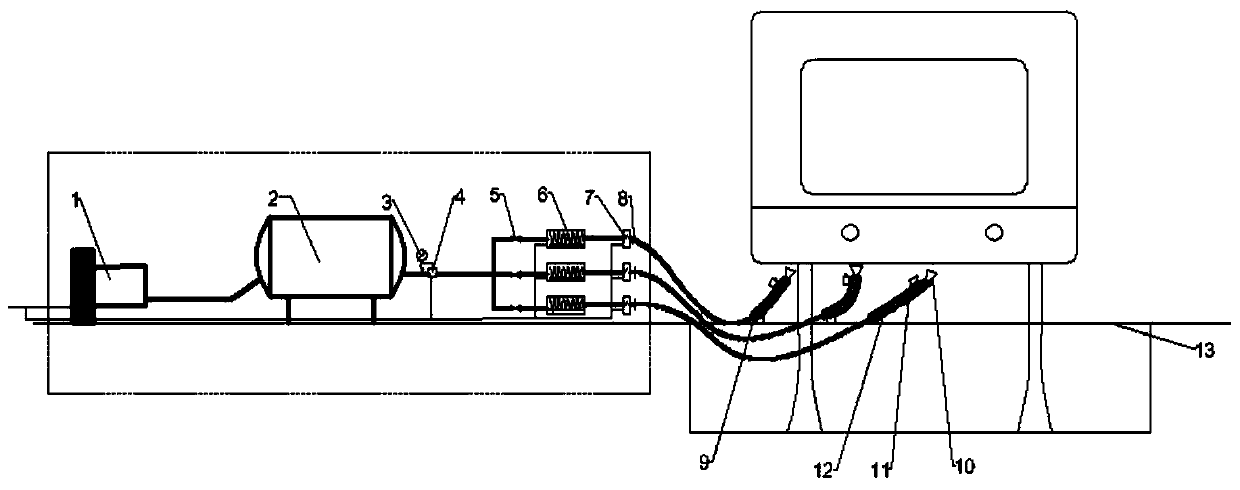

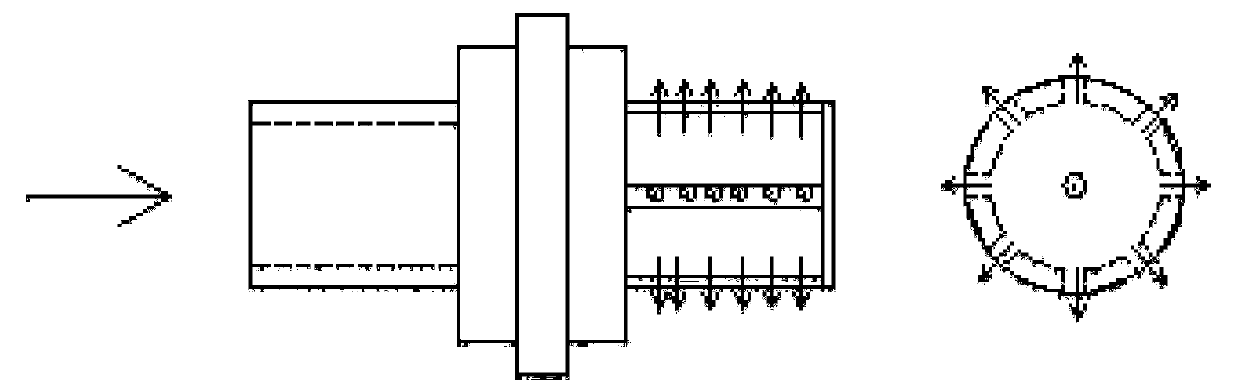

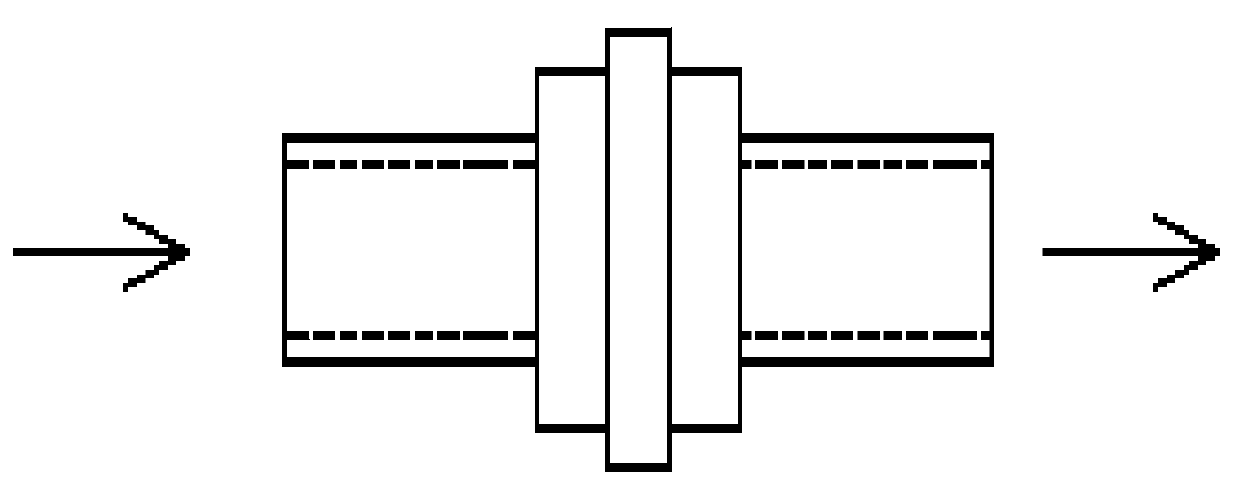

[0036] see figure 1 Describe this embodiment, a train deicing device, characterized in that it includes an air outlet mechanism, a heating mechanism, an air supply mechanism, an air supply main pipe and an air supply branch pipe, the air outlet mechanism is connected with the air supply main pipe, and the air outlet mechanism Provide stabilized pressure gas into the main air supply pipe. Several air supply branch pipes are connected to the air supply main pipe. A heating mechanism is provided on each of the air supply branch pipes. The heating mechanism includes a heater 6 and a temperature controller. 7. The heater 6 and the temperature controller 7 are respectively fixedly connected to the air supply branch pipe, the temperature controller 7 is located at the rear end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com