Patents

Literature

123 results about "Fenchol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fenchol or 1,3,3-trimethyl-2-norbornanol is a monoterpenoid and an isomer of borneol. It is a colorless or white solid. It occurs widely in nature. The naturally occurring enantiopure (1R)-endo-(+)-fenchol is used extensively in perfumery. Fenchol gives basil its characteristic scent, and comprises 15.9% of the volatile oils of some species of Aster.

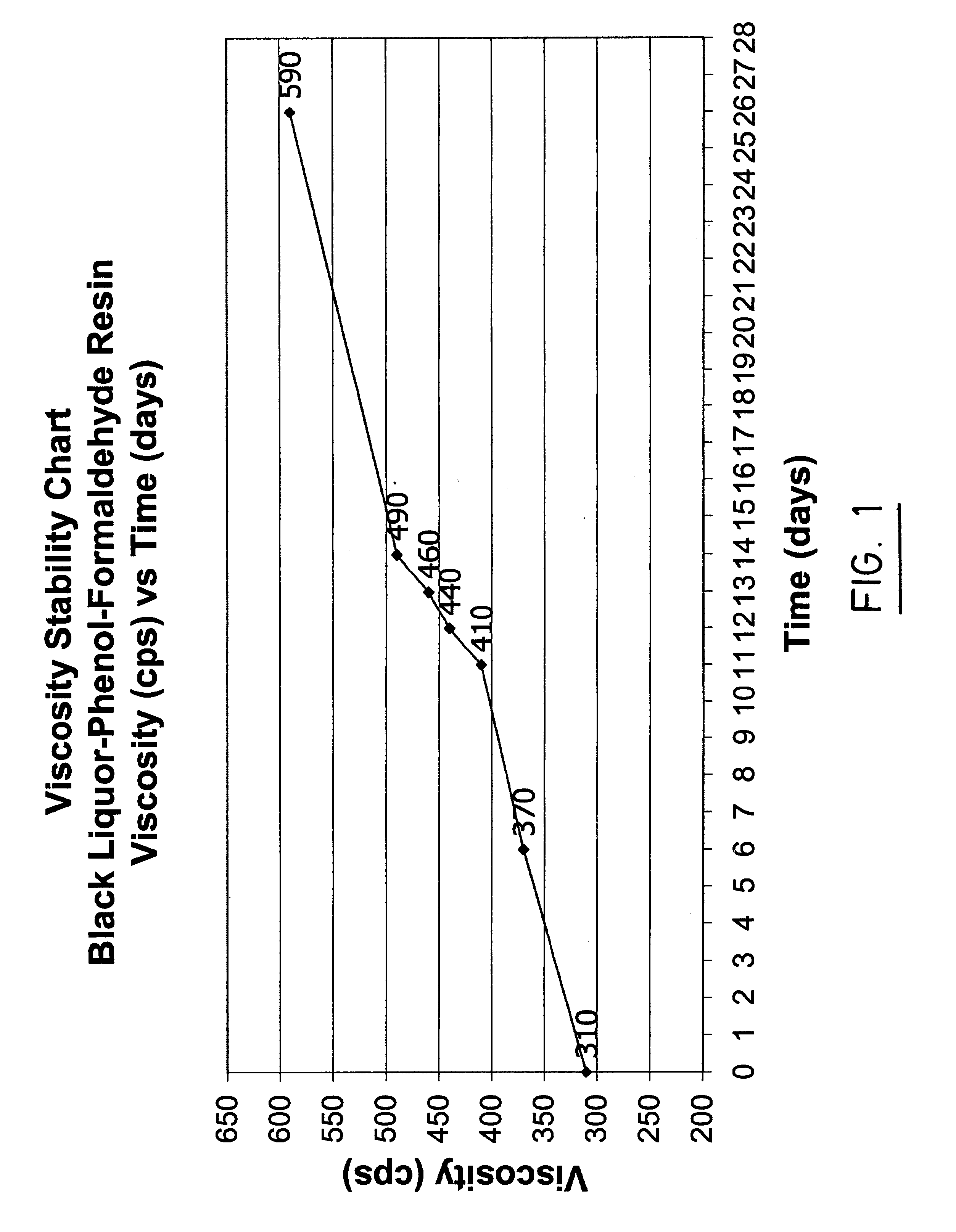

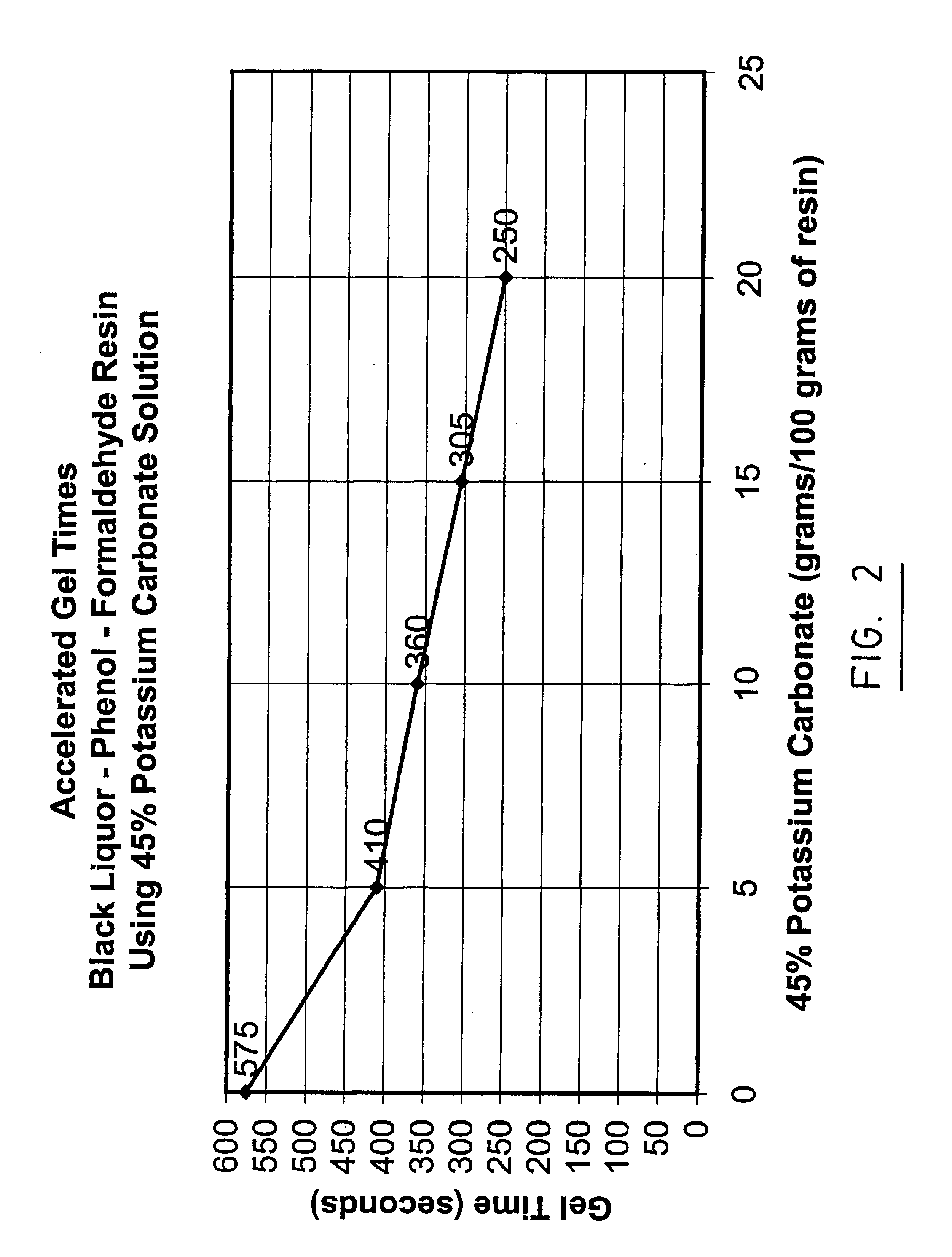

Process for preparing a black liquor-phenol formaldehyde thermoset resin

Owner:CASCADES CANADA INC

Preparation of biomass modified phenolic foam plastic

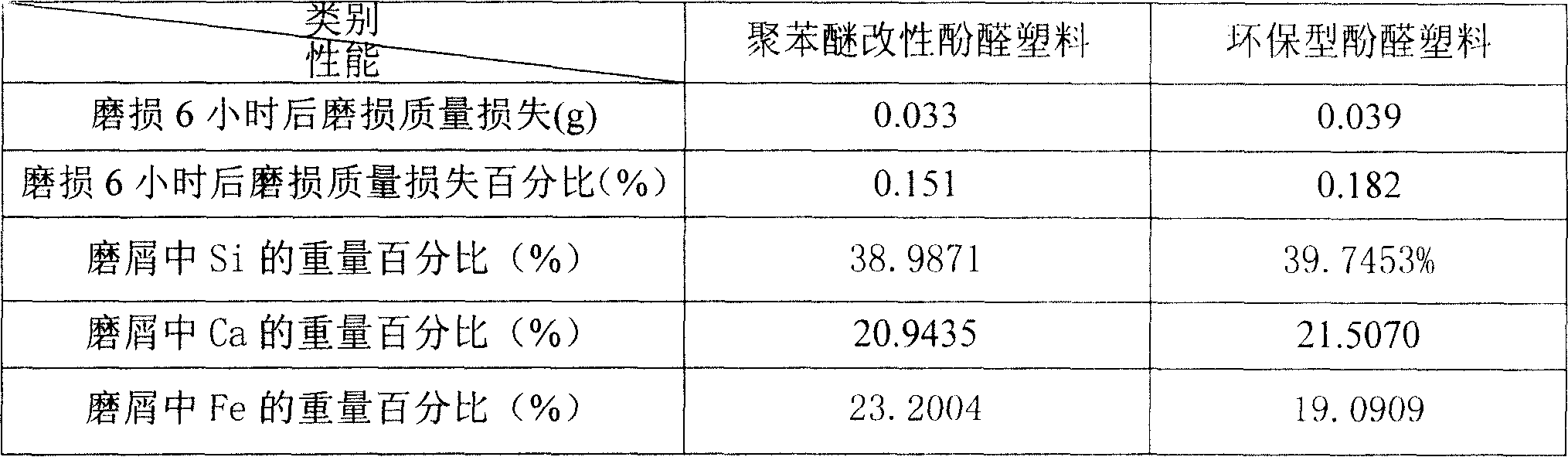

InactiveCN101440170AReduce manufacturing costIncreased post-processing costsPetrochemicalPerformance index

The invention relates to a method for preparing biomass modified phenol formaldehyde foamed plastics, which comprises: adding 5 to 10 mass portions of base catalyst aqueous solution and 30 to 60 mass portions of lignin into 100 mass portions of phenol, wherein the mass percent concentration of the base catalyst aqueous solution is between 2 and 10 percent; reacting for 1 to 2 hours at a reflux temperature of between 90 and 150 DEG C; dripping 72 to 39 mass portions of mixed solution again, wherein the mixed solution consists of formaldehyde and furfural, and the mass ratio of the formaldehyde to the furfural is 60-35:40-65; reacting for 2 to 3 hours at the reflux temperature of between 90 and 150 DEG C; using an acid for neutralization after the reaction is over, and obtaining resol of which the solid content of which is between 78 and 83 percent; and uniformly stirring 100 mass portions of the resol, 5 to 15 mass portions of foaming catalyst, 1 to 5 mass portions of surfactant and 6 to 15 mass portions of foaming agent for foaming at a temperature of between 5 and 160 DEG C, and obtaining a low-pollution heat-insulating building material the performance index of which reaches the petrochemical product level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

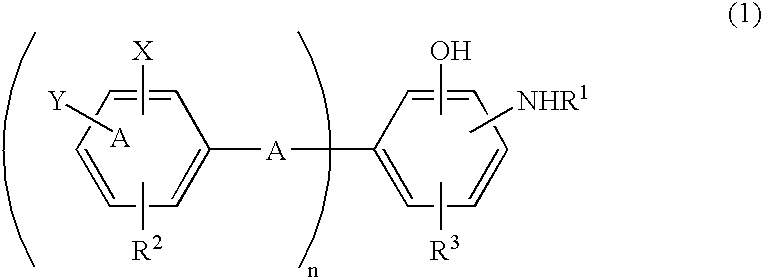

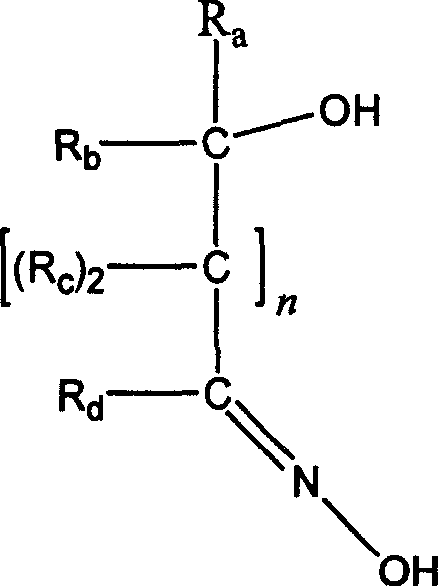

Antioxidant and bisaminophenol derivative

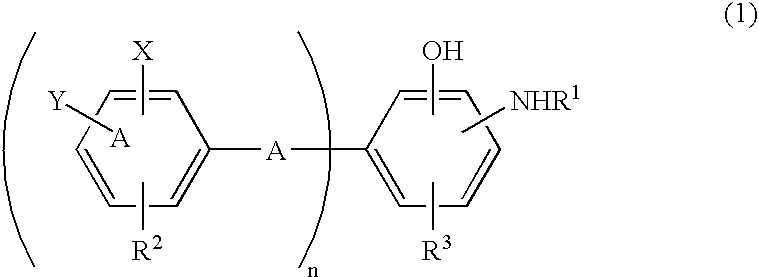

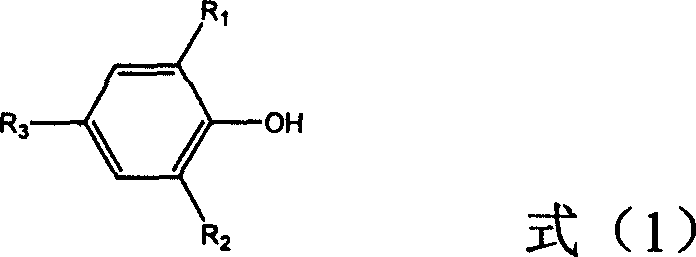

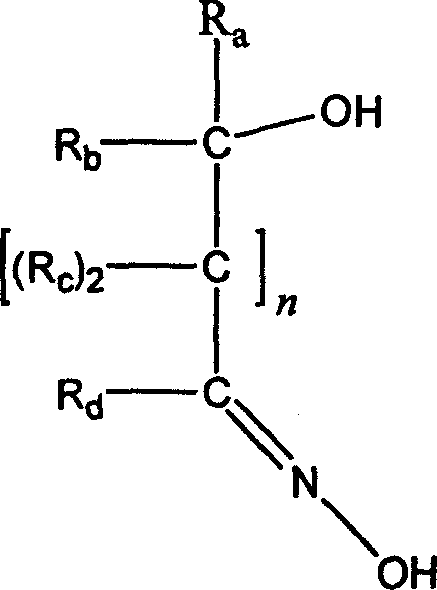

The present invention provides antioxidants made of an aromatic hydroxyamine derivative having a structure represented by the general formula (I):wherein R1, R2 and R3 are each independently a hydrogen atom or an alkyl group having 1 to 20 carbon atoms; X is a hydrogen atom or an OH group; Y is a hydrogen atom or an NHR1 group; A is a direct bond, —O—, —NH—, —SO2—, —CH2— or —C(CH3)2—, and when an OH group and an NHR1 group are introduced to a unilateral benzene ring, these groups are respectively bonded to adjacent positions of the benzene ring; and n is 0 or 1 with the proviso that when n is 0, R1 is not a hydrogen atom, as well as bisaminophenol derivatives represented by the above general formula (I) wherein n is 1; R2 and R3 are each a hydrogen atom; X is an OH group; Y is an NHR1 group; A is —C(CH3)2—; and R1 is isopropyl, isobutyl or isohexyl. The aromatic hydroxyamine derivatives having a structure represented by the general formula (I), in particular, the bisaminophenol derivatives as novel substances, exhibit an excellent oxidation-inhibiting property, and are usable as antioxidants or polymerization inhibitors.

Owner:IDEMITSU KOSAN CO LTD

Double component carried catalyst for synthesizing diphenyl carbonate and its preparing method

InactiveCN1391986AHigh catalytic activityGood repeatabilityMolecular sieve catalystsOrganic compound preparationPhenolOxidative carbonylation

The present invention relates to double-component carried catalyst PdCl2-Cu(OAc)2 / zeolite for synthesizing diphenyl carbonate and its preparation. The catalyst consists of zeolite in 50-100 weight portions, PdCl2 in 0.1-10 weight portions and Cu(OAc)2 in 0.1-30 weight protions. It is prepared through equi-volume soaking and roasting at 250-750 deg.c. The catalyst system has also metal acetate as inorganic oxidation-reduction assistant, hydroquinone as organic oxidation-reduction assistant, and tetrabutyl ammonium bride as surfactant. The catalyst has very high catalytic activity and excellent selectivity to liquid phenol in synthesizing diphenyl carbonate. The catalyst is easy to separate from product, easy to recover and regenerate and has simple preparation process.

Owner:HEBEI UNIV OF TECH

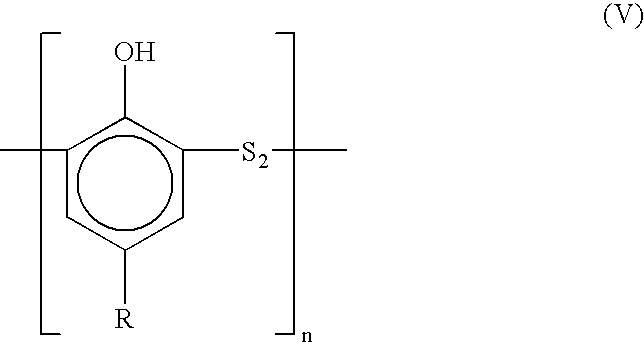

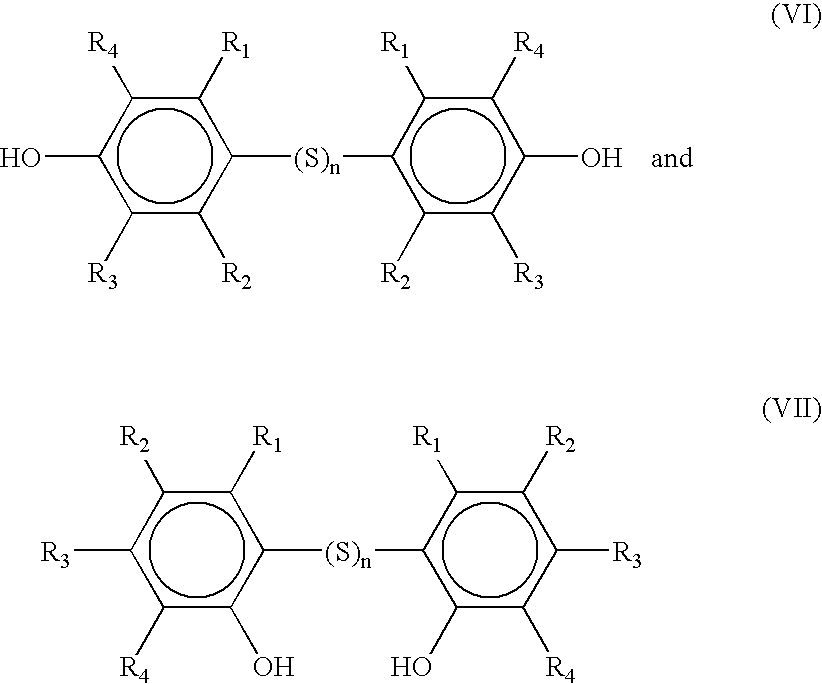

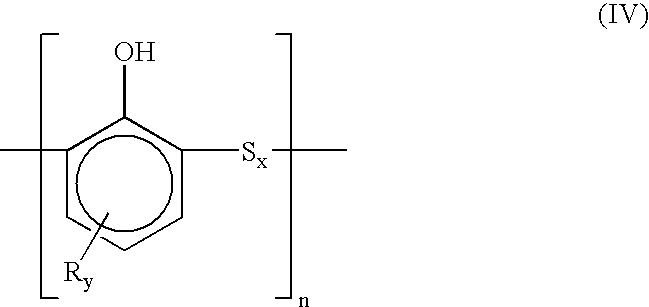

Dimeric and polymeric alkylphenol polysulfides

The invention relates to a process and composition-of-matter for the preparation of dimeric and polymeric alkylphenol polysulfides based on paracumyl phenol for use in vulcanizable rubbers in which the additive is a dimeric or polymeric alkylphenol polysulfide non-nitrosamine-releasing additive based on paracumyl phenol.

Owner:DOVER CHEM CORP

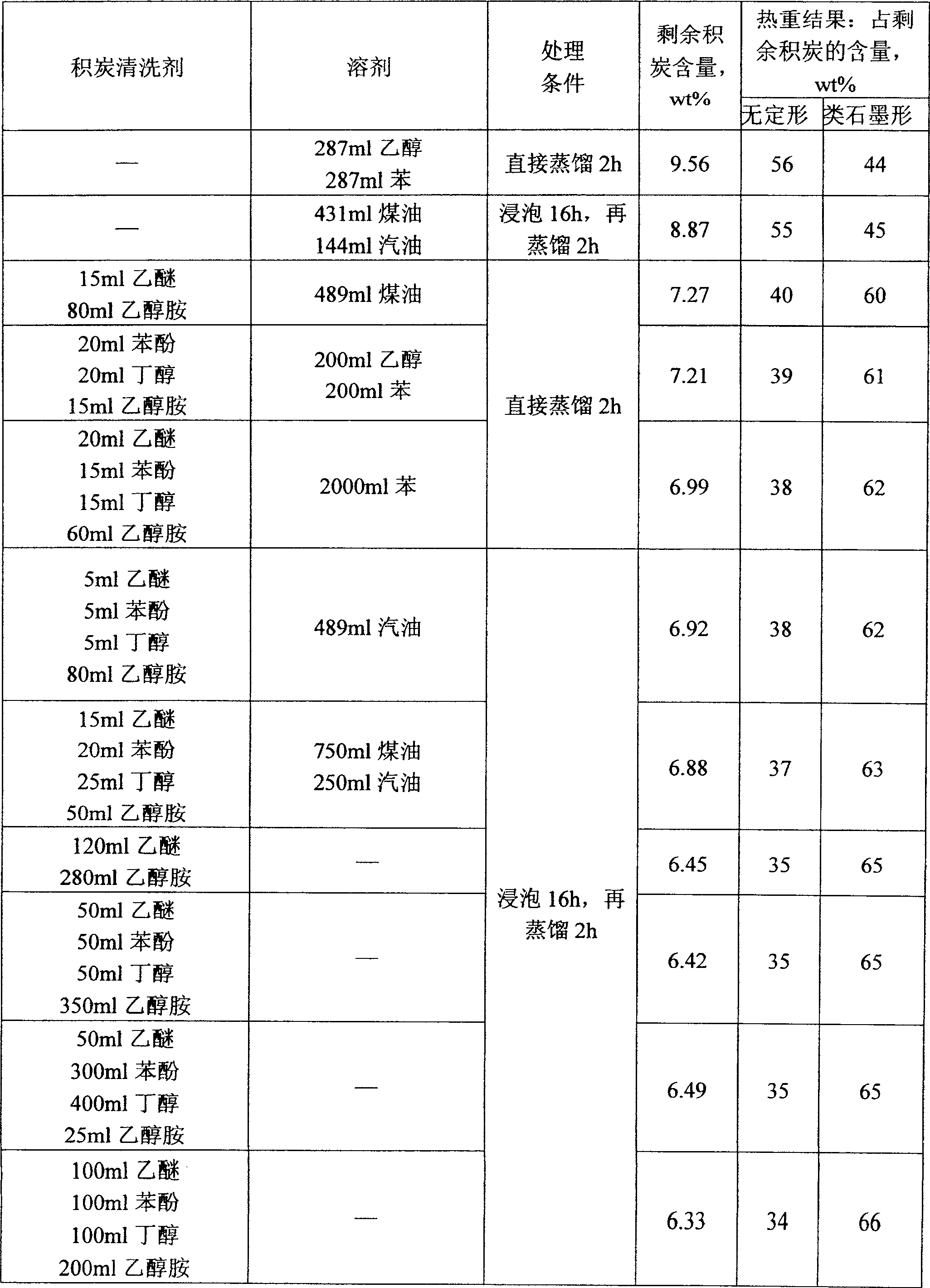

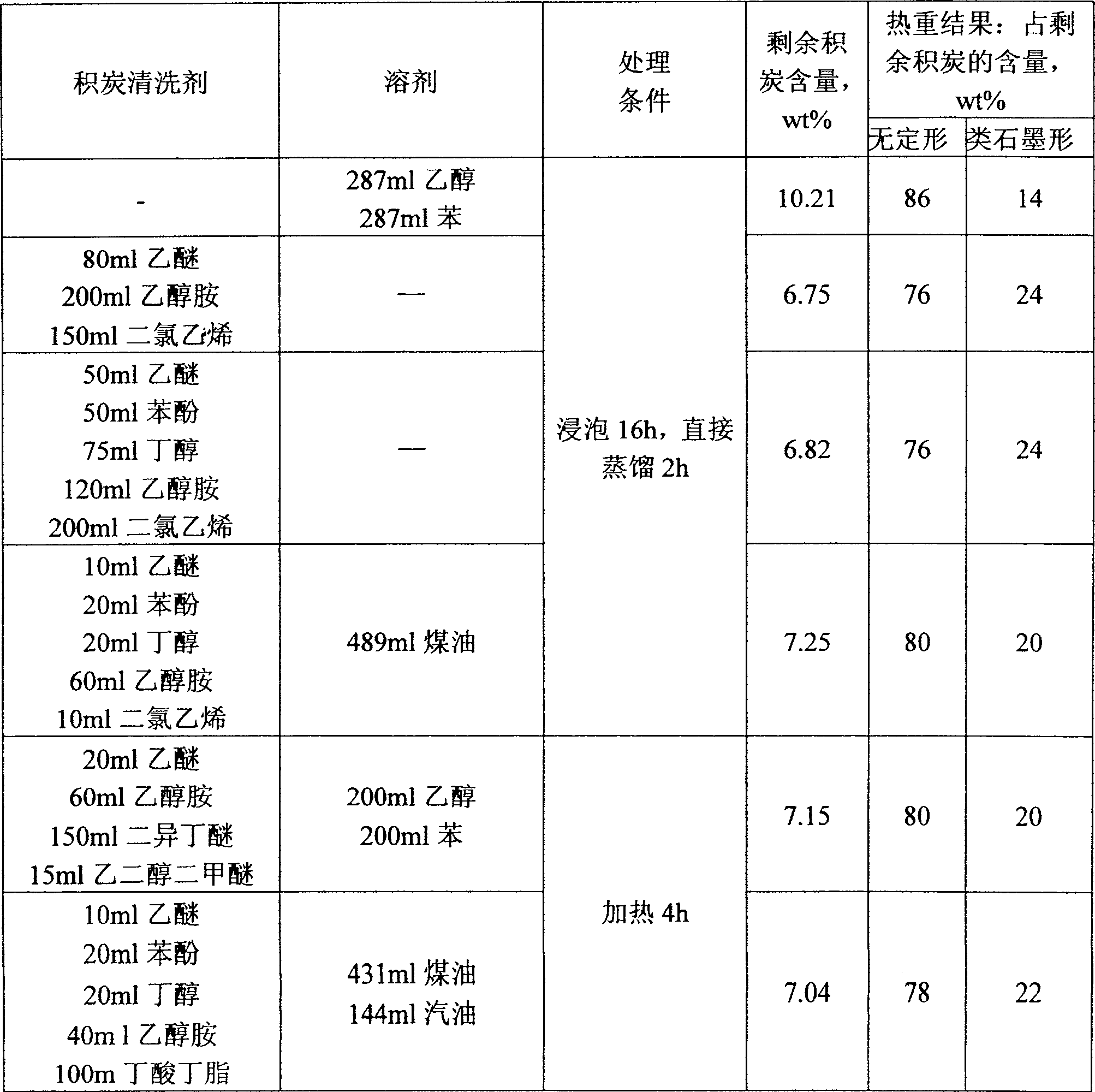

Carbon deposit cleaning agent and its application in reproduction process of carbon deposit deactivation catalyst

ActiveCN100496746CReduce carbon depositionNature has no effectCatalyst regeneration/reactivationCleansing AgentsCarbon deposit

The invention discloses a carbon build-up cleaning agent and its use in the regeneration process of devitalized catalyst, the carbon build-up cleaning agent comprises the following components: ethanolamine 5-95 v%, ethyl ether 5-95 v%, butanol 0-90 v%, phenol 0-90 v%. The carbon build-up cleaning agent can be used for catalysts with appreciable heat release during regeneration, especially for devitalized hydrogenation catalyst and methane aromatization catalyst requiring oxidation burning-out for carbon build-up cleaning.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst of preparing pyrocatechol and hydroquinone in phenol hydroxylation

The invention relates to a catalyst of preparing benzenediol in a phenol hydroxylation and a preparation technology thereof. The catalyst contains Fe2O3, ferro compound and zero valent ferri. The catalyst can transform phenol into the pyrocatechol and the hydroquinone in water containing oxyful in 0.5h (comprising about 25min of induction period) under the condition that the proportion of H2O2 to phenol is 1:1 and the temperature is 60 DEG C with the result that the transformation ratio of the phenol can reach 28 percent, the yield of the benzenediol reaches 25.5 percent, and the proportion of the pyrocatechol to the hydroquinone is about 1.3. When the proportion of H2O2 to phenol is 1.5:1, the transformation ratio of the phenol can reach 44 percent, and the yield of the benzenediol reaches 38.8 percent. The catalyst has low cost, simple preparation and stable performance. The catalyst is remarkably characterized by achieving the transformation ratio of the phenol from 0 to 28 percent within less than 2min of reaction, having higher activity and effectively reducing the side reaction.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method of tall oil modified alkyd resin

The invention relates to a preparation method for tall oil-modified phenolic resin. The resin comprises the following components according to parts by weight: 90 to 100 shares of phenol, 6 to 9 shares of tert butylphenol, 55 to 65 shares of formaldehyde with 37 percent content, 0.4 to 0.5 shares of oxalic acid, 30 to 40 shares of tall oil, 8 to 10 shares of colophony, and 0.1 to 0.2 shares of hexa (4-aldehyde phenoxy) cyclic triphosphonitrile The invention adopts the brand-new production method of the technology of tall oil-modified phenolic resin, with simple process. The production cost is not increased, compared with the prior product, the product performance is greatly improved (reaching about 20 percent), and the product performance achieves or exceeds the performance of similar foreign products.

Owner:WUHAN JINGHE CHEM

Broad spectrum attractant for tumblebug perfect insects

A broad-spectrum attractant for the adults of scarab contains proportionally cis-3-hexenol, the aromatic compound chosen from dibutyl phthalate, cinnamic aldehyde, phenylmethanol, phenylethanol, phenyl formaldehyde, phenol and vanillin, and assistant.

Owner:HENAN AGRICULTURAL UNIVERSITY

Fungicidal and bactericidal composition that comprises volatile organic compounds of natural origin

The present invention relates to a composition with fungicidal and bactericidal activity, which comprises volatile organic compounds (VOCs) obtained from plants and microorganisms, in which said VOCs are C4-C12 fatty alcohols or cyclic alcohols or phenol-derived compounds, or terpene-derived compounds, and also derivatives and mixtures thereof. Furthermore, the present invention likewise relates to the use of said compositions in the protection of agricultural crops, in post-harvest treatments, in food preservation and in the disinfection of facilities and equipment.

Owner:BIOFUNGITEK SOC

Oil-tea camellia husk polysaccharide and application thereof

InactiveCN101560266ADetermining AntioxidantReduce wasteCosmetic preparationsOrganic active ingredientsCamellia oleiferaPhenol

The invention discloses an oil-tea camellia husk polysaccharide which has the following characteristics: a. physicochemical properties: the polysaccharide is brown powder with small odor and is easily-soluble in water and not soluble in organic solvents such as chloroform and ether, the polysaccharide is orange if reacting with phenol-sulfuric acid, shows a negative reaction with Fehling reagent and shows a negative reaction with iodine-potassium iodide; b. composition of the polysaccharide: the content of the polysaccharide is 30 percent to 50 percent; the distribution range of molecular weight is 7,000 to 200,000,0Da; the polysaccharide is prepared by the following six kinds of monosaccharide: glucose, fucose, arabinose, galactose, seminose and rhamnose. The oil-tea camellia husk polysaccharide is used as free radical scavenger or used for preparing medicaments with anti-tumor function for curing tumors.

Owner:ZHEJIANG UNIV

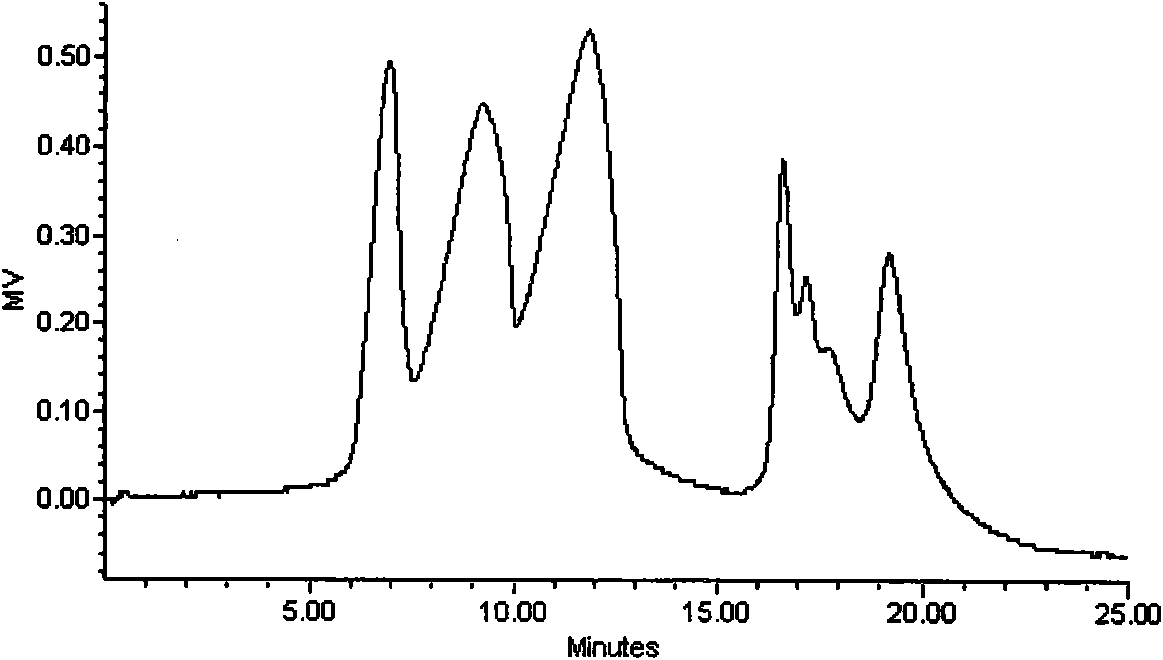

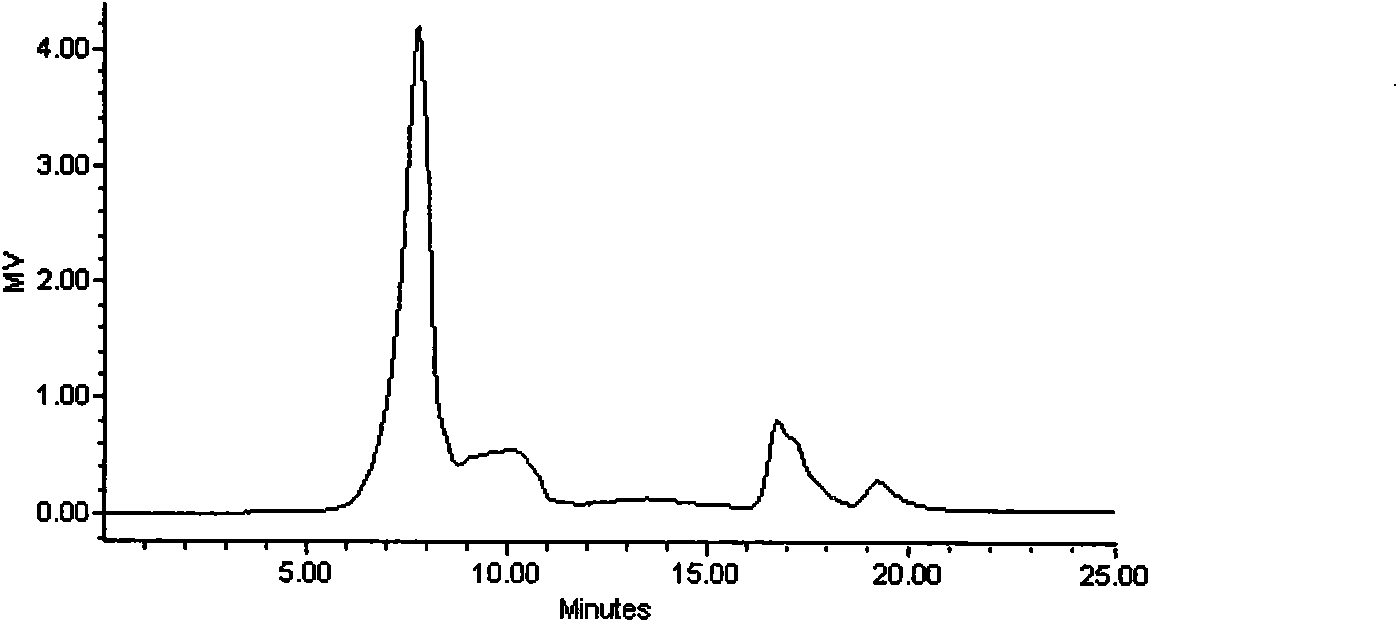

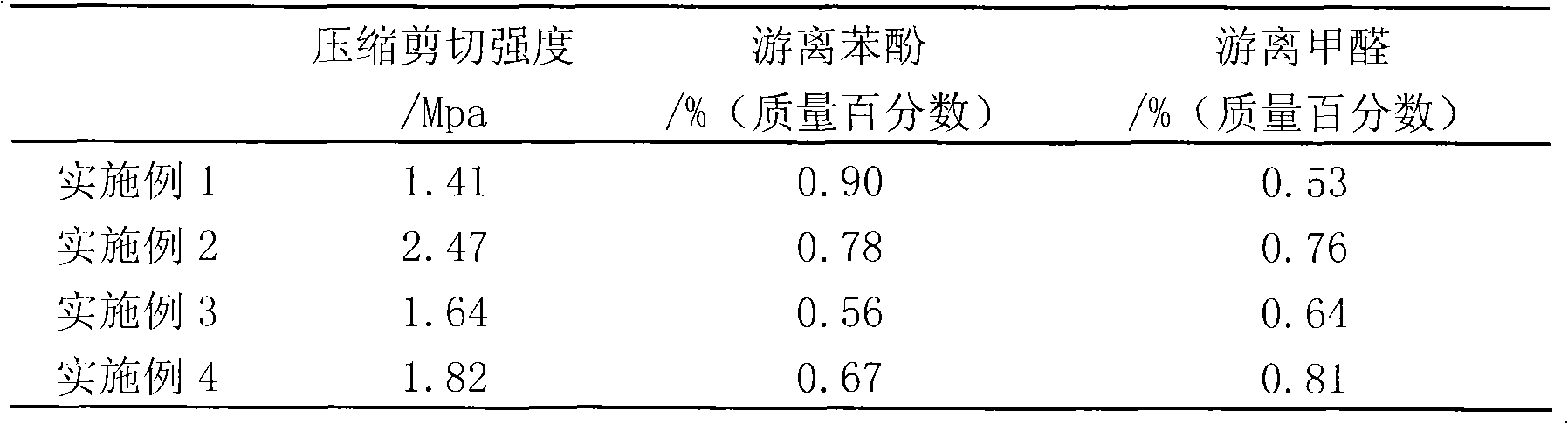

Preparation of low free monomer, degradable persimmon tannin modified phenolic resin

The invention relates to a method for preparing a modified phenol-formaldehyde resin. The method for preparing the degradable persimmon tannin modified phenol-formaldehyde resin with low free monomer content is characterized by comprising the following steps: firstly, raw materials are selected, namely phenol, a formaldehyde solution, a persimmon tannin solution and a catalyst are selected for standby according to the fact that the dosage of the persimmon tannin solution is 16.7 to 50 weight percent of the phenol, the mol ratio of formaldehyde to the phenol is between 0.6 and 1.5, and the dosage of the catalyst is 2 to 5 weight percent of the phenol; secondly, the phenol and the persimmon tannin solution are added into a reaction container in turn, uniformly stirred and then added with the catalyst, and the temperature is raised to between 80 and 100 DEG C; thirdly, the formaldehyde solution is dripped and the dripping process is finished within 30 and 60 minutes; and fourthly, after the dripping process is over, the mixture is heated to between 95 and 100 DEG C, undergoes reaction for 1 to 2 hours, and then undergoes decompression dehydration, and the degradable persimmon tannin modified phenol-formaldehyde resin with the low free monomer content is prepared through dehydration termination when the viscosity reaches between 100 and 600 cPa.s and temperature reduces to between 20 and 40 DEG C. The persimmon tannin modified phenol-formaldehyde resin has the characteristics of low free monomer content and degradability.

Owner:WUHAN UNIV OF TECH

Method for catalytically synthesizing paraethyl phenol

ActiveCN101792371AReduced orifice sizeReduce acidityOrganic chemistryMolecular sieve catalystsFencholReaction temperature

The invention relates to a method for catalytically synthesizing paraethyl phenol, which is characterized by taking diethyl carbonate and phenol as the raw materials and taking the modified microporous molecular sieve MCM-22, ZSM-5 or HY as a catalyst to carry out catalytic reaction under the following conditions: the reaction temperature is 200-350 DEG C, the mole ratio of diethyl carbonate to phenol is 1:2-2:1 and the mass space velocity is 1-12h<-1>. By the method, good raw material conversion rate and target product selectivity can be obtained. Under the best conditions, the conversion rate of phenol can reach 100% and the selectivity of paraethyl phenol can reach 82.2%. The method in which the modified microporous molecular sieve MCM-22, ZSM-5 or HY is taken as the catalyst and diethyl carbonate is taken as the alkylating agent to react with phenol to catalytically synthesize paraethyl phenol has the advantages of high raw material activity, mild reaction conditions, simple process, convenient product separation, good selectivity of the target product paraethyl phenol, etc.

Owner:溧阳常大技术转移中心有限公司

Catalyst for preparing phenol with catalysis distillation and method for preparing phenol

InactiveCN101342497AReduce adverse effectsAccelerate evaporationOrganic chemistryOrganic compound preparationDistillationFenchol

The invention discloses a catalyst for the preparation of phenol by catalytic rectification and a phenol preparation method thereof, relating to the preparation of a compound. The invention provides a non-porous solid catalyst used to catalyze phenol preparation by catalytic rectification, as well as a phenol preparation method integrated with catalytic reaction and rectification separation by reaction rectification. The catalyst is a resin polysiloxanes metal complex, and the compostion is SiMR, wherein, M indicates metal complex, R indicates organic carbon chain. The process of phenol preparation by catalytic rectification includes: firstly, double helix ring high-efficient filler is filled in the stripping section and the rectification section of the rectifying tower; proper catalyst is filled in the catalytic rectification section and diluted with the same filler at the ratio of 4:1; the main feed CHP inlet is arranged between the rectification section and the reaction section, and the feed CHP is diluted with acetone at the ratio of 1:1; the auxiliary feed acetone inlet is arranged between the stripping section and the reaction section, the feed quantity covers 50-100 percent of the main feed quantity, and the product is collected at the tower top and the tower bottom. The heat of reaction can be applied to rectifying separation.

Owner:XIAMEN UNIV

Process for the purification of aromatic hydrocarbons and process for the preparation of high-purity aromatic hydrocarbons

InactiveUS6664433B1Efficient separationReduce conversionBiocideDistillation purification/separationDistillationPhenol

This invention provides a process for purifying to a high degree of purity aromatic hydrocarbons containing impurities which are difficult to separate by distillation such as sulfur compounds and nitrogen compounds. The process of this invention for purifying aromatic hydrocarbons comprises treating crude aromatic hydrocarbons with a formaldehyde or with a formaldehyde and a phenol in the presence of an acid catalyst to form oligomers, distilling or evaporating the reaction mixture thereby separating the unreacted aromatic hydrocarbons from the oligomers, and crystallizing or washing with an organic solvent the separated aromatic hydrocarbons. In case the target hydrocarbon is naphthalene, it is possible to prepare naphthalene which has a purity of 99.9999 wt % or more, emits little odor, and can be readily flavored by perfumes. Naphthalene of this quality is used to prepare an insecticide of excellent fragrance.

Owner:DAI NIPPON TORYO CO LTD

Method for synthesizing high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone through Cu-BTC catalysis

ActiveCN107540529AProcess environmental protectionLow costQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsEmulsionFenchol

The invention discloses a method for synthesizing high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone through Cu-BTC catalysis. According to the method, trimesic acid and copper nitrate hydrateare hydrothermally synthesized into a Cu-BTC catalyst; under the alkaline emulsion reaction condition, hydrogen peroxide is utilized as an oxidizing agent, and 2,6-xylenol is oxidized and coupled intothe high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone; product quality yield of the high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone is 90 to 95%, and a product purity mass percent of the high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone is 98%; reaction temperature is 70 to 85 DEG C, and reaction time is 4 to 8h; the catalyst is easy to separate and recycle; after beingrepeatedly used for four times, quality yield of the 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone still reaches 87.5%, and purity of the 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone is 97.8%; alkaliemulsified filtrate and washing liquor can be recycled and deployed to be used repeatedly; a reaction condition is moderate, and a synthesizing technology has the advantages of greenness and environmental friendliness.

Owner:XIANGTAN UNIV

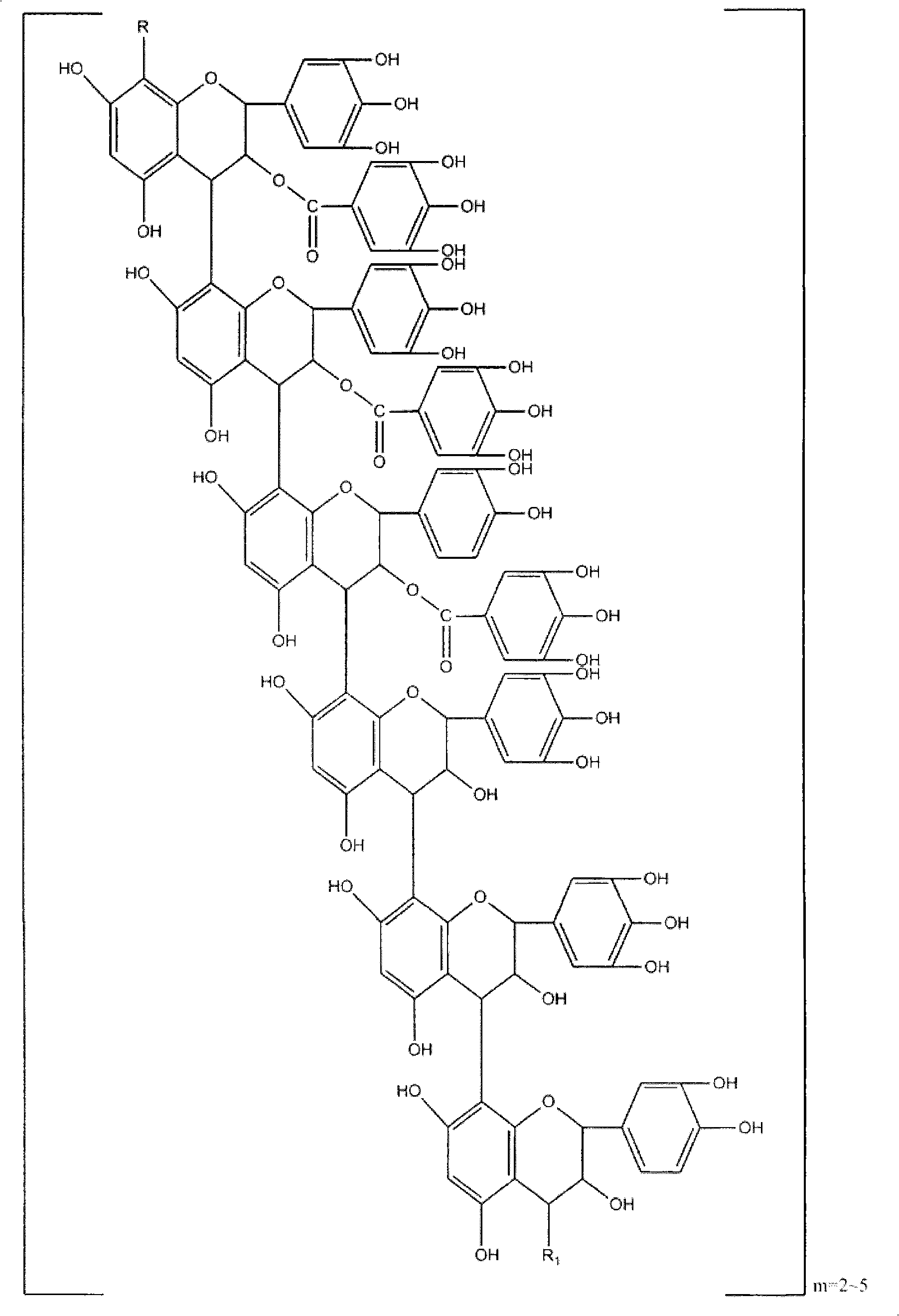

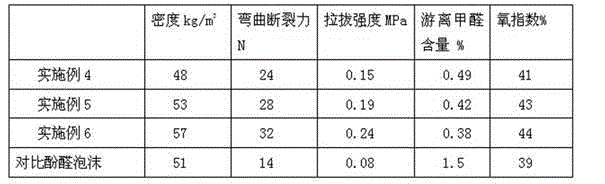

Vegetable tannin extract modified phenol formaldehyde foam and preparation method thereof

The invention relates to a vegetable tannin extract modified phenol formaldehyde foam and a preparation method thereof. The vegetable tannin extract modified phenol formaldehyde foam is prepared from the following raw materials in parts by weight: 100 parts of vegetable tannin extract modified phenol formaldehyde resin, 5-8 parts of surfactant, 3-9 parts of foaming agent and 15-20 parts of curing agent, wherein the vegetable tannin extract modified phenol formaldehyde resin is prepared from the following raw materials in parts by weight: 100 parts of phenol, 30-50 parts of vegetable tannin extract degradation liquid, 61-73 parts of polyformaldehyde, 5-7 parts of urea, 1-3 parts of melamine and 8-12 parts of ethylene glycol; and the vegetable tannin extract degradation liquid is degraded vegetable tannin extract obtained by performing degradation pretreatment on vegetable tannin extract with oxydol under alkaline conditions. According to the invention, on the premise of not influencing the own flame retardancy and heat-insulating property of the phenol formaldehyde foam, the pull strength and bending failure force of the phenol formaldehyde foam are obviously improved, and the free formaldehyde content in the phenol formaldehyde foam is obviously reduced. The phenol formaldehyde foam can be used as a heat isolation, heat insulation and fireproofing material for buildings, and is a product having favorable market prospects.

Owner:北京傲德新材料科技有限公司

Method for liquefying bamboo wood

The invention relates to a method for liquefying bamboo wood, which comprises the following steps: a mixed liquefying agent, polymerization inhibitor and acidic catalyst are mixed uniformly, heated to 100 DEG C by heating a reactor, added with bamboo powders, and heated while being stirred to 120-170 DEG C to perform liquefying reaction of bamboo wood. The mixed liquefying agent comprises phenol and a mixture of polyethylene glycol and glycerol. In the liquefying system, the mass ratio of phenol to the mixture of polyethylene glycol and glycerol to the polymerization inhibitor to the acidic catalyst to the bamboo powders is 5-95:95-5:1-4:1-6:20-50. The method for liquefying the bamboo wood has the beneficial effects that the method can be used for liquefying the bamboo wood; the liquefying ratio of the bamboo wood is relatively high; the liquefied product can be widely used, for example for substituting phenol to prepare biobased phenolic resin, for substituting partial polyether or polyester polyol to prepare polyurethane foam, and for preparing a plurality of novel polymer materials such as fiber and carbon fiber, so that the utilization ratio of the bamboo wood is up to 100%.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

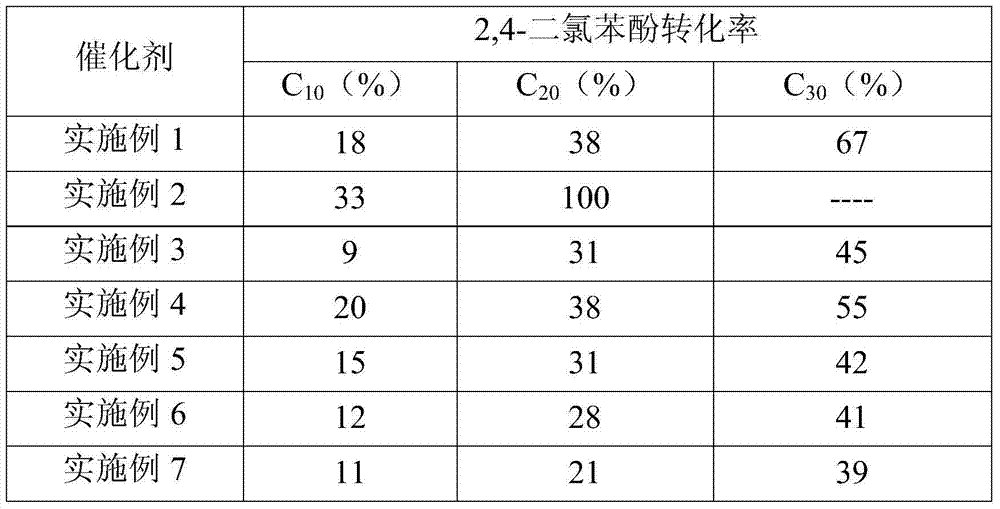

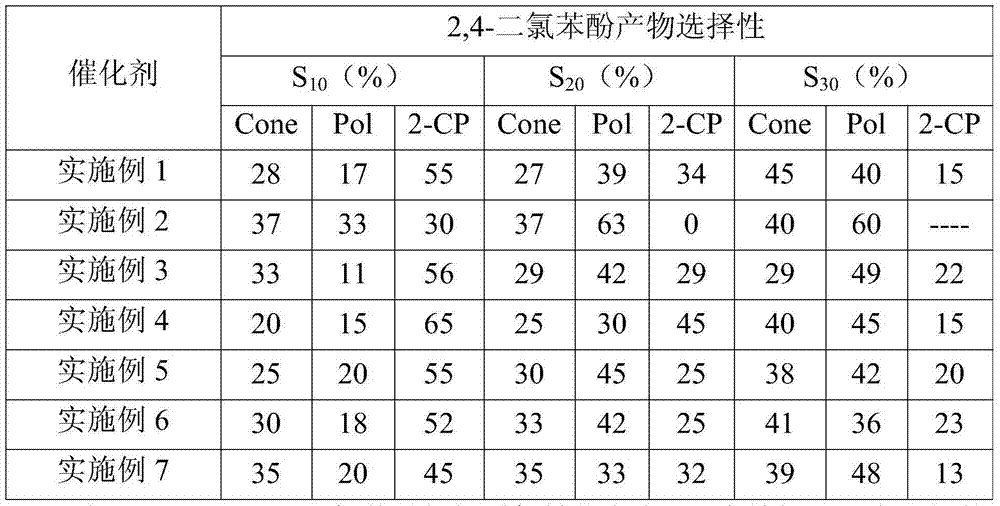

Catalyst for removing chlorophenol compounds in water through low-temperature catalytic hydrogenation and preparation and application of catalyst

InactiveCN103691464AActivity does not decreaseSimple preparation processPhysical/chemical process catalystsOrganic compound preparationCyclohexanonePhosphoric acid

The invention discloses a catalyst for removing chlorophenol compounds through catalytic hydrogenation. The catalyst is mainly composed of a phosphoric acid modified aluminum oxide carrier and a metal palladium loaded by the phosphoric acid modified aluminum oxide carrier. Nitrogen used as a reducing agent is introduced into a reactor, and the chlorophenol compounds are finally transformed into cyclohexanone and phenol without secondary pollution under the conditions of low temperature or room temperature and normal pressure or low pressure. The catalyst disclosed by the invention is high in catalytic activity, mild in reaction conditions, and convenient to operate, and is especially suitable for removing chlorophenol compounds in water thruogh catalytic hydrogenation.

Owner:EAST CHINA UNIV OF SCI & TECH

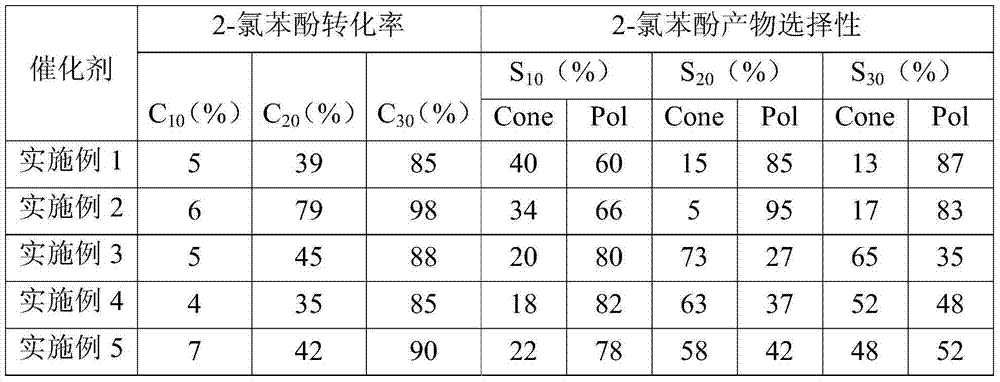

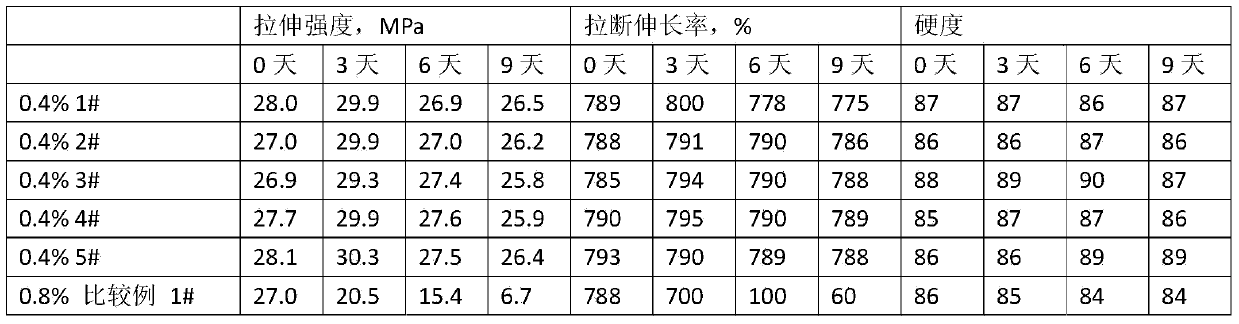

Antioxidant for thermoplastic butylbenzene segmented copolymer

The invention relates to an antioxidant for a thermoplastic butylbenzene segmented copolymer. The antioxidant comprises the following components in parts by weight: 1.0 part of 4-hydroxy-3,5-di-tert-butyl propanoic acid C7-C9 mixed alcohol ester, 1.8-2.2 parts of 2-methyl-4,6-di(methyl octyl sulfide) phenol and 0.8-1.2 parts of reaction products of N-aminobiphenyl and 2,4,4-trimethylpentene. The compound antioxidant system disclosed by the invention is added in a production process of SBS (Styrene Butadiene Styrene), and the addition amount of the compound antioxidant system accounts for 0.2%-0.6% of the weight of SBS crude rubber. The antioxidant disclosed by the invention is a liquid product, has 100% oxidation resisting function, can be dissolved into a cyclohexane solvent at high concentration, can not be precipitated at usage temperature, can not block a conveying pipeline, and achieves the convenience for use.

Owner:RIANLON

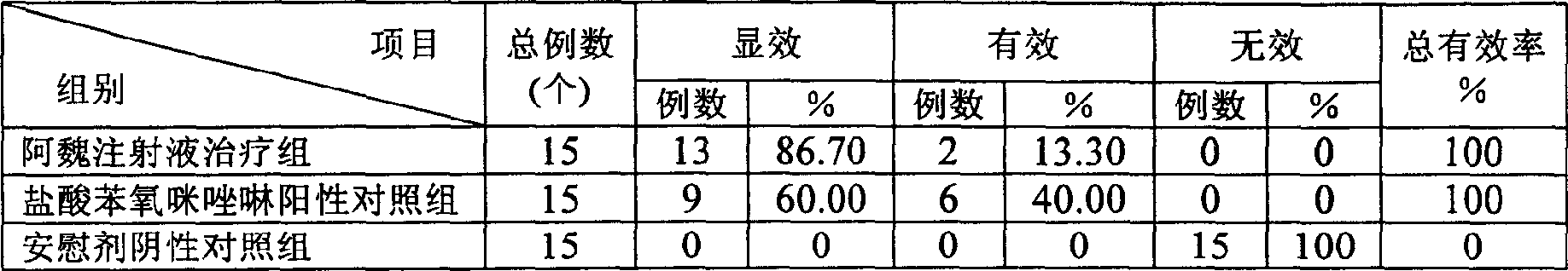

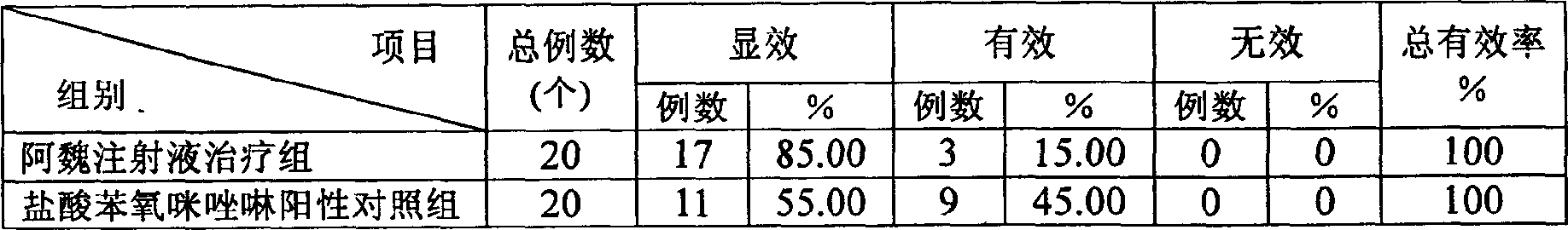

Asafetida extract and its pharmaceutical use

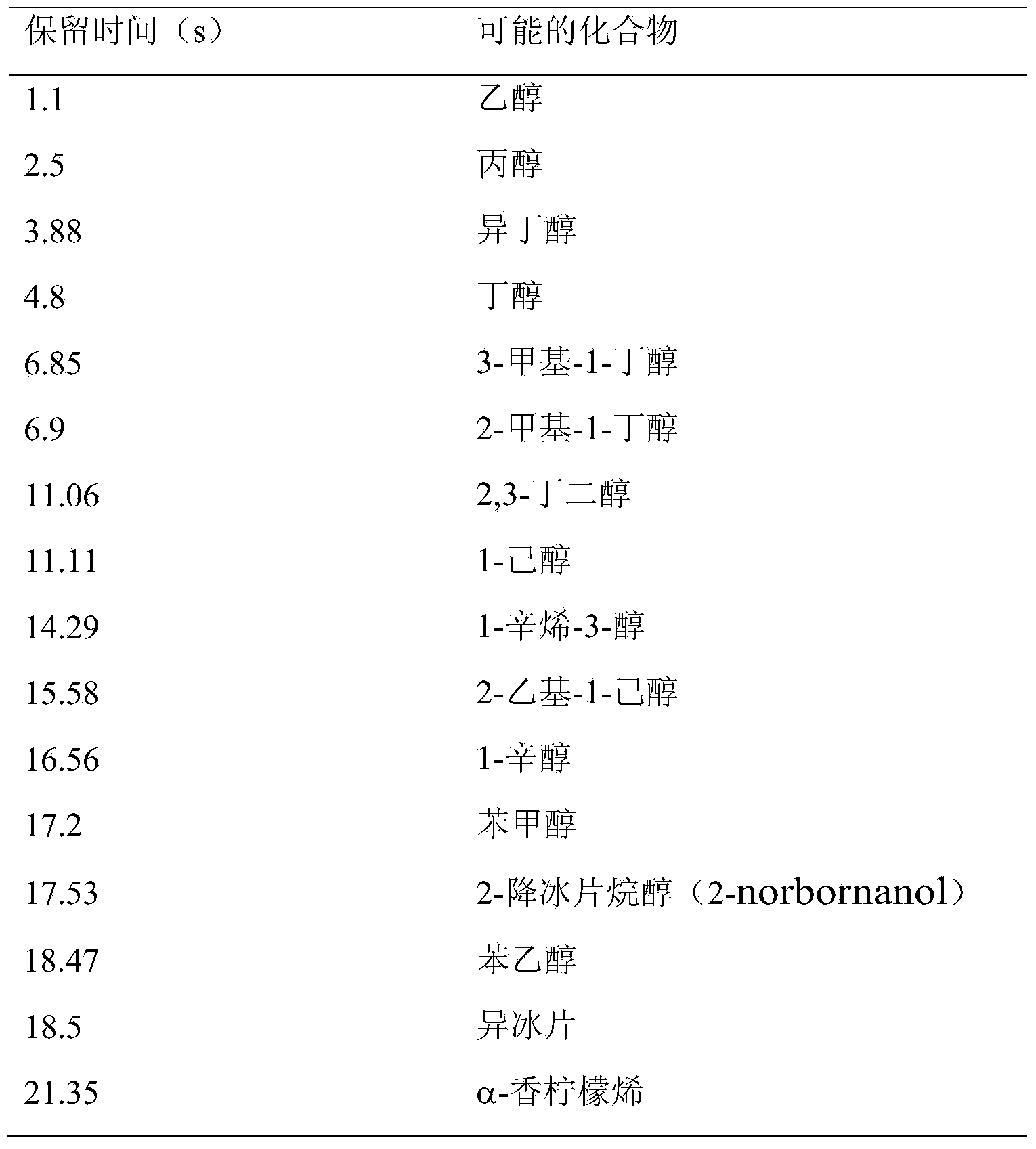

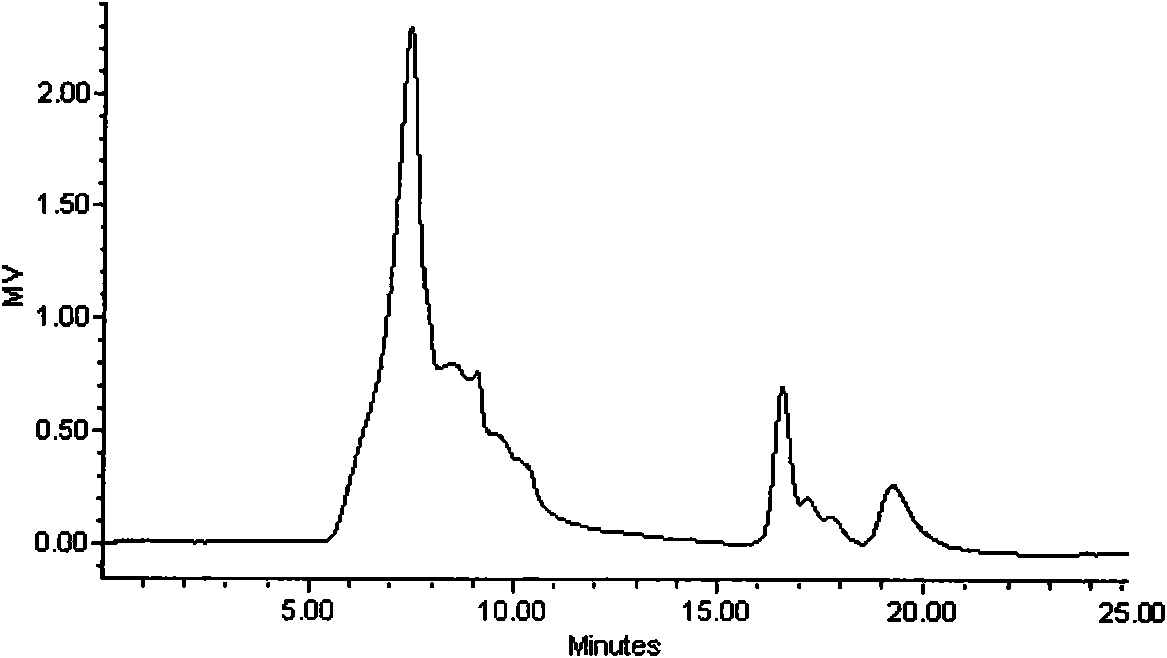

InactiveCN1548037AGood application effectOdor maskingOrganic compounds purification/separation/stabilisationNervous disorderFencholHeroin

The present invention is asafetida extract and its pharmaceutical use, and aims at eliminating offensive odor of asafetida and providing one new use. The asafetida extract contains alpha-terpinene, 2-borneol, terpine tetraol, D-fenchol, pinocarveol, etc. and is extracted via conventional process. The asafetida extract is used in preparing drug addiction stopping medicine, and the medicine may be injection, capsule, tablet or granule.

Owner:王彦丁 +1

Herba epimedii antibacterial essential oil

InactiveCN108478761AHas inhibitory effectAntibacterial agentsAntimycoticsEscherichia coliPelargonium graveolens oil

The invention discloses herba epimedii antibacterial essential oil which is prepared from the following components in percentage by weight: 0.1-0.2% of compounded essential oil, 0.1-0.5% of eucalyptusglobulus oil, 0.5-2% of ginger root oil, 0.3-1.0% of rosemary leaf oil, 0.1-0.5% of cinnamon oil, 0.5-1.5% of basil oil, 0.5-1% of crocus sativus, 1.4-2.5% of pelargonium roseum ait oil, 1-3% of camellia-seed oil, 0.5-1.0% of clove oil, 0.1-0.3% of borneol, 50% of sweet almond oil, 0.1-0.3% of p-chloro-dimethylphenol, 0.01-0.2% of butylated hydroxytoluene and the balance of olive oil, wherein thecompounded essential oil is prepared by the following steps: respectively weighing truffle, centella asiatica, herba epimedii and honeysuckle according to a weight ratio of 1:3:3:3, crushing into granules of which the diameter is 3-8mm, adding 10 times of water, and soaking for 30-60 minutes at a normal temperature. The invention relates to the technical field of medicine preparations. The herbaepimedii antibacterial essential oil has inhibition functions on various fungi, mold, tritirachium album, staphylococcus aureus, escherichia coli, various viruses and common pathogenic bacteria.

Owner:江苏善唯斯生物科技有限公司

Method for producing anisole from phenol and methanol

ActiveCN109879730ASimple preparation processLow costMolecular sieve catalystsEther preparation by compound dehydrationCerium nitrateFixed bed

The invention discloses a method for producing anisole from phenol and methanol. According to the method, a fixed bed reactor is adopted, a molecular sieve modified by sodium nitrate, potassium nitrate, cesium nitrate or magnesium nitrate is loaded with silver nitrate, palladium chloride, lanthanum nitrate, cerium nitrate and and other active components to serve as a catalyst, the efficient synthesis of the anisole is realized, the phenol conversion rate is high, and the selectivity of the anisole is high, the preparation process of the catalyst is simple, the cost is low, the stability is high, the service life is long, and the application requirements of the industrial catalyst are met.

Owner:BAOJI UNIV OF ARTS & SCI +1

Method for recovering 1,8-eucalyptol from eucalyptus oil by product

The invention discloses a method for recovering 1,8-eucalyptol from eucalyptus oil by products; the eucalyptus oil by products are subject to two-step rectification, wherein in the first step, phenol is added into the eucalyptus oil by products, and then reduced-pressure rectification is performed to obtain kettle bottom liquid; in the second step, water is added into the kettle bottom liquid, then normal pressure rectification is performed to obtain an azeotrope of 1,8-eucalyptol and water; a water layer of the azeotrope is removed by layering; the azeotrope is dried to obtain the 1,8-eucalyptol product. The method of the invention provides a 1,8-eucalyptol recovery rate of more than 70% and a purity of more than 98%, and has the advantages of simple operation, short rectification time, high recovery rate, green and environmental protection, and suitability for industrial application.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

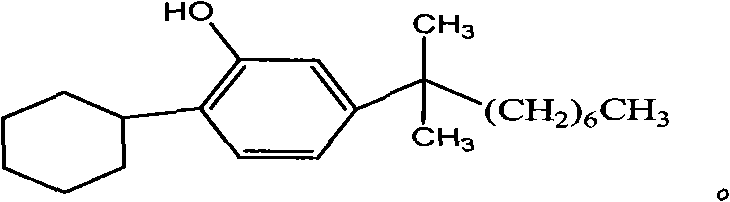

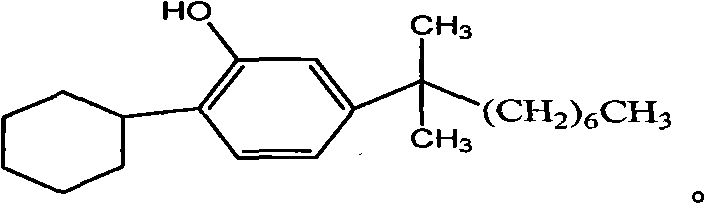

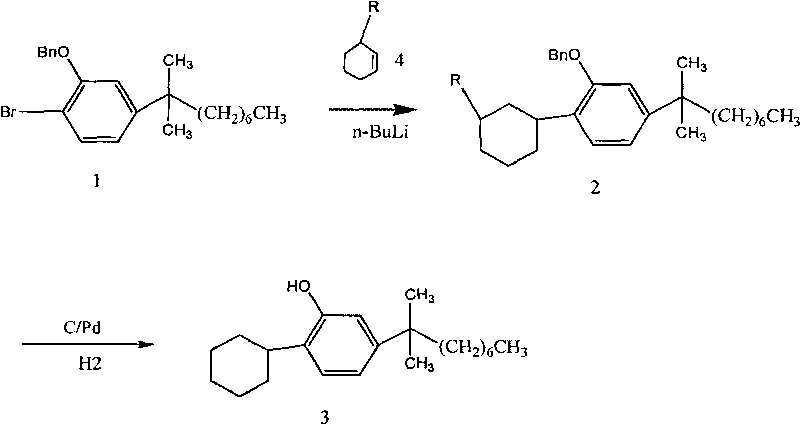

2-cyclohexyl-5-(1,1- dimethyl octyl) phenol and synthesizing method thereof

InactiveCN101712594ASimple methodHigh yieldAntibacterial agentsLiquid crystal compositionsCleansing AgentsPhenol

The invention relates to a 2-cyclohexyl-5-(1,1-dimethyl octyl) phenol and a synthesizing method thereof. 2-benzyloxy-1-bromine-4-(1,1-dimethyl octyl) benzene carries out addition reaction to obtain 2-benzyloxy-1-(cyclohexyl or 3'-alkoxy cyclohexyl)-4-(1,1-dimethyl octyl) benzene, and the 2-benzyloxy-1-(cyclohexyl or 3'-alkoxy cyclohexyl)-4-(1,1-dimethyl octyl) benzene is hydrogenated to carry outbenzyl removing reaction to obtain the 2-cyclohexyl-5-(1,1-dimethyl octyl) phenol. The invention has short synthesizing route, simple method and higher yield and is easy for industrialized production. The 2-cyclohexyl-5-(1,1-dimethyl octyl) phenol has liquid crystal performance and excellent antibiosis inflammation eliminating effect, can be used as one of liquid crystal composition components ofa liquid crystal display, has the inhibiting effect on porphyromonas gingialis, streptococcus, spider-shaped selenomonas, and the like and can be used for preparing a mouth cleaning agent and a medicament for preparing oral cavity diseases.

Owner:WUHAN SYNCHALLENGE UNIPHARM INC

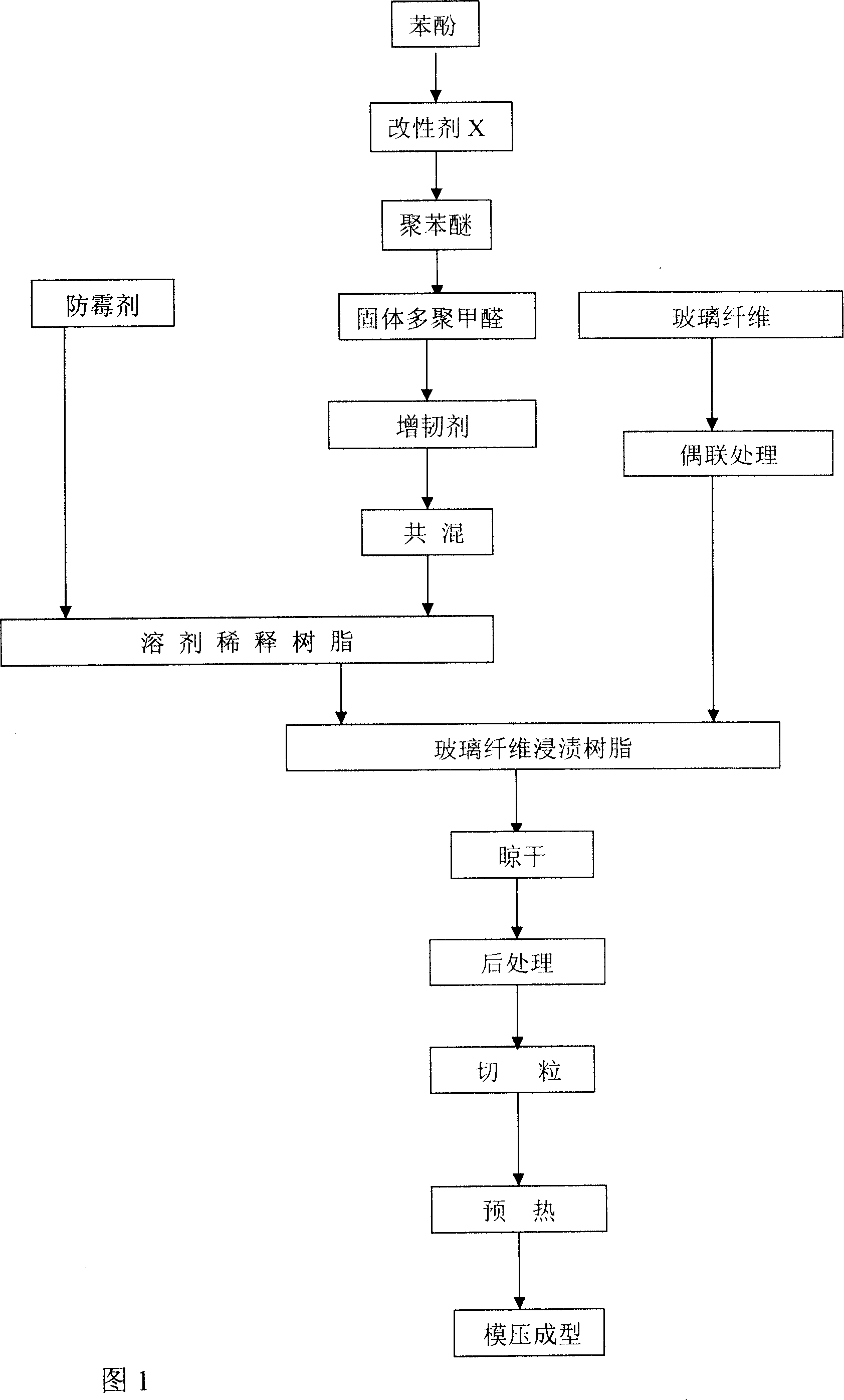

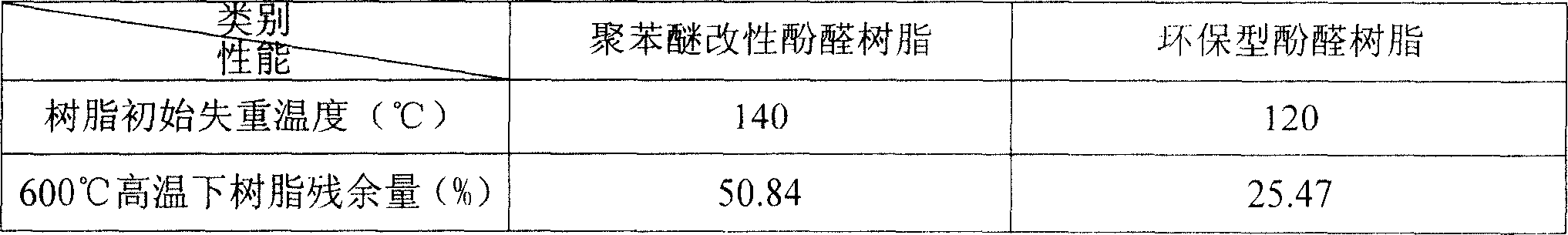

Polyphenylether modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The ratio of the components : Phenol 100, solid paraform 40 - 45, polyphenylene oxide ether10- 15, modifier X 10-15, fiberglass 55 - 60, polysulfone 10 - 20, while sodium pentachlorophenate 2 -5, solvents 94 -100. Through the stir conditions adding modifier X into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Separation method of m-ethylphenol and paraethyl phenol

The invention provides a separation method of m-ethylphenol and paraethyl phenol, and particularly relates to a method using the steps that composite ion liquid is used as a catalyst and a solvent; under a certain condition, m-ethylphenol and paraethyl phenol are subjected to tert-butylation and rectification so that the two isomers are separated; then, tertiary butyl removal is performed to obtain m-ethylphenol products and paraethyl phenol products.

Owner:陕西巴斯腾科技有限公司

BPA and Polycarbonate Made from Renewable Materials

ActiveUS20100152406A1Less carbon contentOrganic chemistryOrganic compound preparationDiacetone alcoholPolymer science

Bio-derived bisphenol A is made by combining bio-derived phenol and / or bio-derived acetone in the presence of a catalyst, The phenol or the acetone or both contain at least 0.5%, for example at least 1 weight % of bio-derived impurities. In the case of bio-derived phenol, these impurities may include one or more of 2-methylbenzofuran, 2-methoxyphenol, 2-methylphenol, 4-methylphenol (para-cresol) or 2-methoxy-4-methylphenol. In the case of acetone, the impurity may be ethanol, mesityl acetone and / or diacetone alcohol. This bio-derived BPA can be used in the production of polycarbonates with less fossil fuel-based carbon content.

Owner:SHPP GLOBAL TECH BV

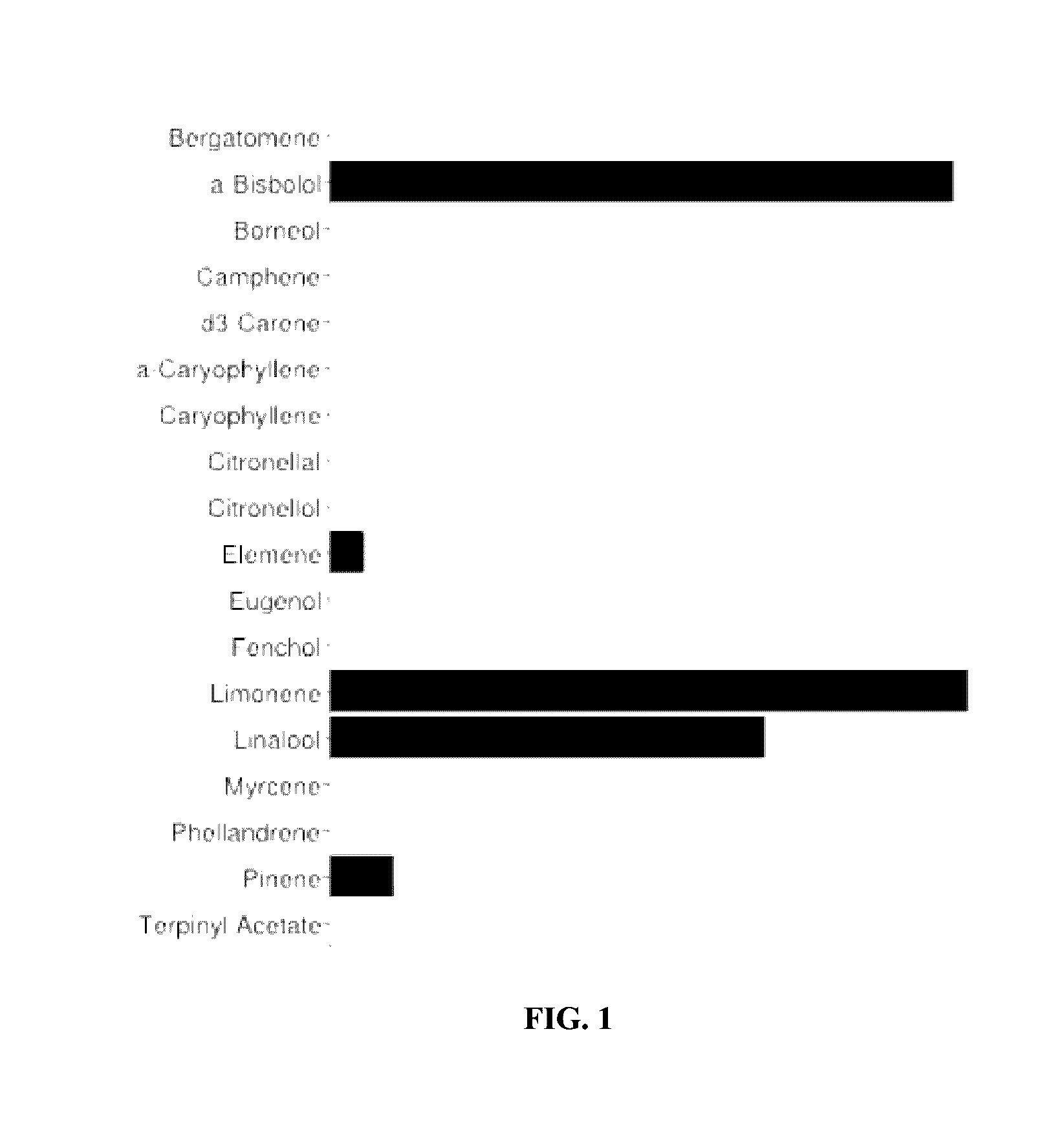

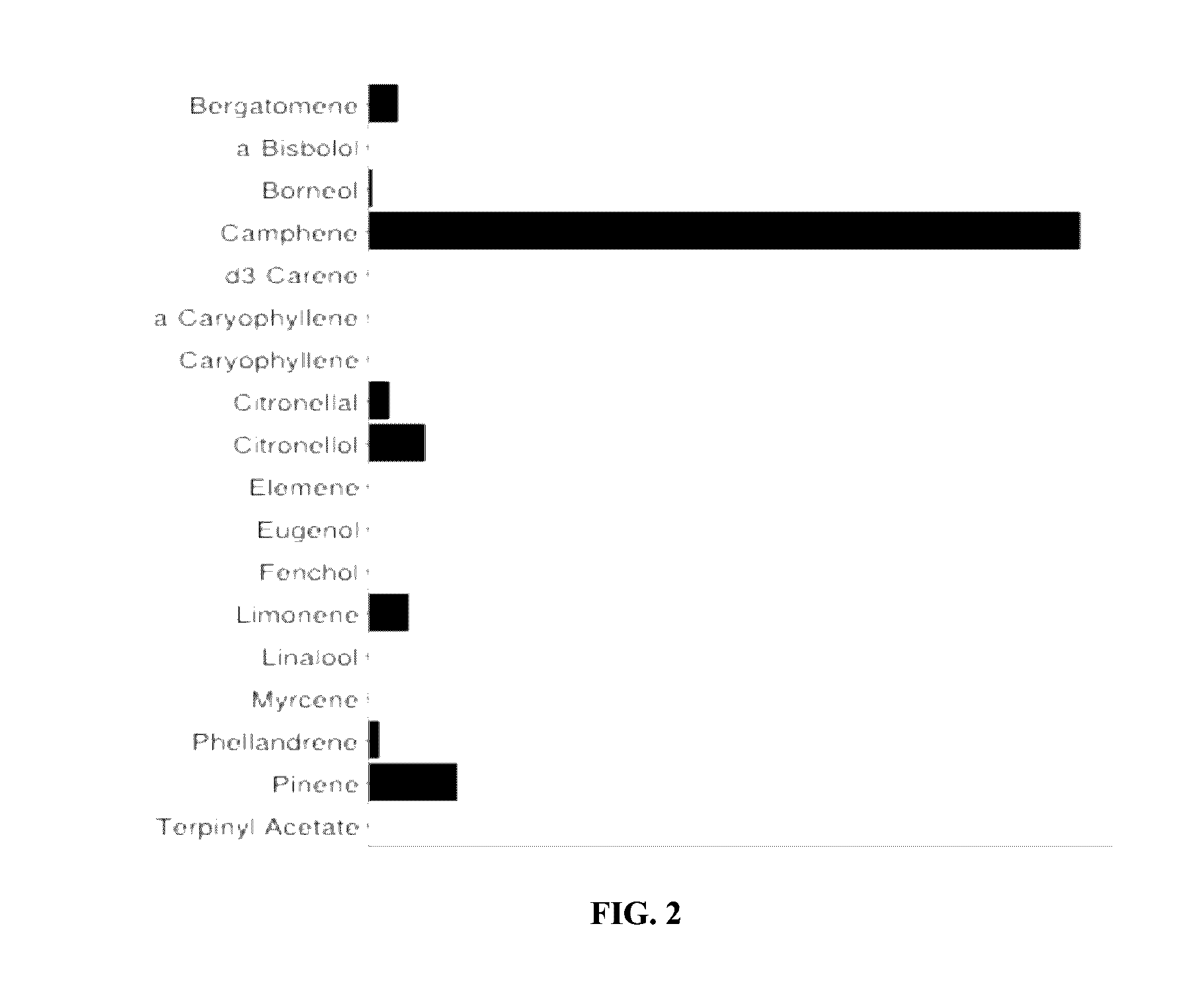

Terpene profile replication blends and their applications

InactiveUS20160374388A1Add flavorReduce harmTobacco preparationOrganic active ingredientsPhellandreneEugenol

The embodiments herein relate to a method of preparing a terpene profile replication blend. The method comprises determining a combination of terpene for a predetermined application and blending a predetermined quantity of the terpene in a blender for a predetermined time. The combination of terpenes is selected from the group consisting of limonene, linalool, alpha humulene, alpha perpineole, pinene, bergatomene, a-bisbolol, borneol, camphene, d3-carene, a-caryophyllene, caryophyllene, citronellal, citronellol, elemene, eugenol, fenchol, myrcene, phellandrene, or terpinyl acetate.

Owner:THOMSON ANDREW JON

Polymrization method of preparing polyphonyl ether/phenylethylene kind polymer alloy in reactor

A process for preparing polyphenylether / styrene polymer alloy by polymerizing in reactor includes such steps as oxidizing-polymerizing reaction between phenol compound and oxidant in water under existence of styrene, catalyst, surfactant and alkaline compound, adding trigger or thermal triggering, free radical polymerizing reaction of styrene, centrifugal filter or shearing coagulation, centrifugal filter and drying. It features no environmental pollution.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com