Antioxidant for thermoplastic butylbenzene segmented copolymer

A styrene-butadiene block and antioxidant technology, which is applied in the field of antioxidants for thermoplastic styrene-butadiene block copolymers, achieves ideal cost performance, low additive cost, and good protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

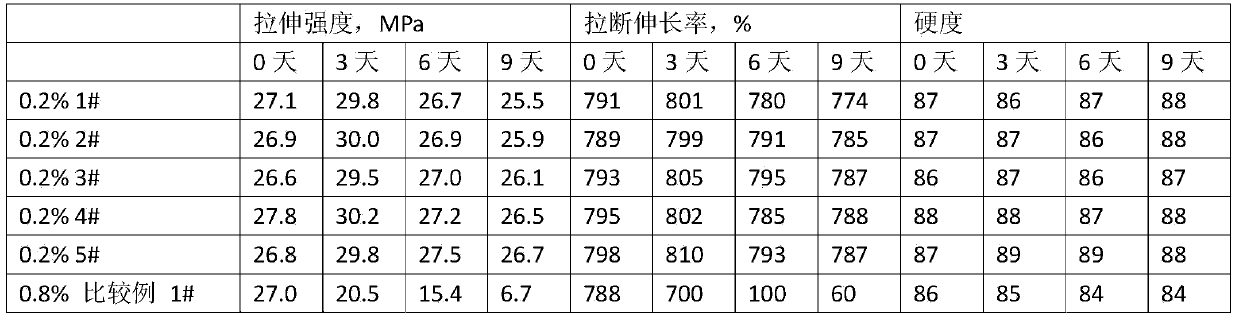

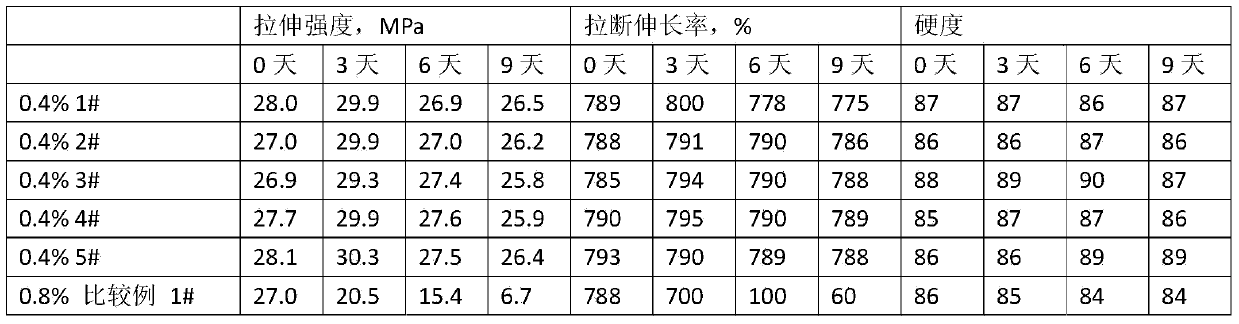

Examples

example 1

[0022] Weigh the sample 4-hydroxy-3,5-di-tert-butylphenylpropionic acid C7-C9 mixed alcohol ester (antioxidant 1135) 18g (1.8 parts), 2-methyl-4,6-di(octylthiomethyl ) 10g (1.0 parts) of phenol, 8g (0.8 parts) of the reaction product of N‐phenylaniline and 2,4,4‐trimethylpentene (antioxidant 5057) to make compound antioxidant 1#.

example 2

[0024] Weigh the sample 4‐hydroxy‐3,5‐di-tert-butylphenylpropionic acid C7‐C9 mixed alcohol ester 18g (1.8 parts), 2‐methyl‐4,6‐di(octylthiomethyl)phenol 10g (1.0 Parts), N-phenylaniline and 2,4,4-trimethylpentene reaction product 12g (1.2 parts), made of compound antioxidant 2#.

example 3

[0026] Weigh the sample 4-hydroxy-3,5-di-tert-butylphenylpropionic acid C7-9 mixed alcohol ester 22g (2.2 parts), 2-methyl-4,6-bis(octylthiomethyl)phenol 10g (1.0 Parts), N-phenylaniline and 2,4,4-trimethylpentene reaction product 12g (1.2 parts), made of compound antioxidant 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com