Vegetable tannin extract modified phenol formaldehyde foam and preparation method thereof

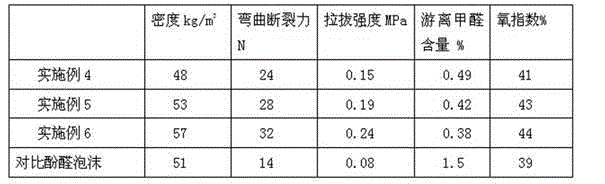

A technology of phenolic foam and tannin extract, applied in the field of phenolic foam, can solve the problems of increased viscosity of phenolic resin, insufficient strength of phenolic foam and high content of free formaldehyde, and achieves the effects of reducing viscosity, reducing dependence on petrochemical resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, this tannin extract modified phenolic foam is made from the following raw materials in proportion by weight:

[0053] 100 parts of tannin extract modified phenolic resin;

[0054] 5 parts of surfactant;

[0055] 3 parts foaming agent;

[0056] 15 parts of curing agent;

[0057] The tannin extract modified phenolic resin is made from the following raw materials in proportions by weight:

[0058] 100 parts of phenol;

[0059] 35 parts of tannin extract degradation solution;

[0060] 65 parts of paraformaldehyde;

[0061] 5 parts of urea;

[0062] 1 part of melamine;

[0063] 8 parts of ethylene glycol.

[0064] The tannin extract degradation solution is the degraded tannin extract obtained by degrading and pretreating tannin extract with hydrogen peroxide under alkaline conditions.

[0065]

Embodiment 2

[0066] Embodiment 2, this tannin extract modified phenolic foam is made from the following raw materials in proportion by weight:

[0067] 100 parts of tannin extract modified phenolic resin;

[0068] 8 parts of surfactant;

[0069] 7 parts foaming agent;

[0070] 20 parts of curing agent;

[0071] The tannin extract modified phenolic resin is made from the following raw materials in proportions by weight:

[0072] 100 parts of phenol;

[0073] 45 parts of tannin extract degradation solution;

[0074] 71 parts of paraformaldehyde;

[0075] 7 parts of urea;

[0076] 2 parts of melamine;

[0077] 12 parts of ethylene glycol.

[0078] The tannin extract degradation solution is the degraded tannin extract obtained by degrading and pretreating tannin extract with hydrogen peroxide under alkaline conditions.

[0079]

Embodiment 3

[0080] Embodiment 3, this tannin extract modified phenolic foam is made by the following raw materials in proportion by weight:

[0081] 100 parts of tannin extract modified phenolic resin;

[0082] 5 parts of surfactant;

[0083] Foaming agent 9 parts;

[0084] 18 parts of curing agent;

[0085] The tannin extract modified phenolic resin is made from the following raw materials in proportions by weight:

[0086] 100 parts of phenol;

[0087] 40 parts of tannin extract degradation solution;

[0088] 66 parts of paraformaldehyde;

[0089] 6 parts of urea;

[0090] 2 parts of melamine;

[0091] 11 parts of ethylene glycol.

[0092] The tannin extract degradation solution is the degraded tannin extract obtained by degrading and pretreating tannin extract with hydrogen peroxide under alkaline conditions.

[0093]

[0094] In the above embodiments 1 to 3, the surfactant can be Tween-80, Tween-60, EL-40 or PEG-25.

[0095] The blowing agent can be any one of n-pentane, cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com