Preparation method of titanium dioxide nanotube array photoelectrochemical oxygen evolution electrode co-modified with polyacid and nine cobalt octasulfide

A nanotube array and titanium dioxide technology, applied in the field of photoelectrochemistry, can solve problems such as affecting electron transport and weakening photoelectrochemical water splitting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

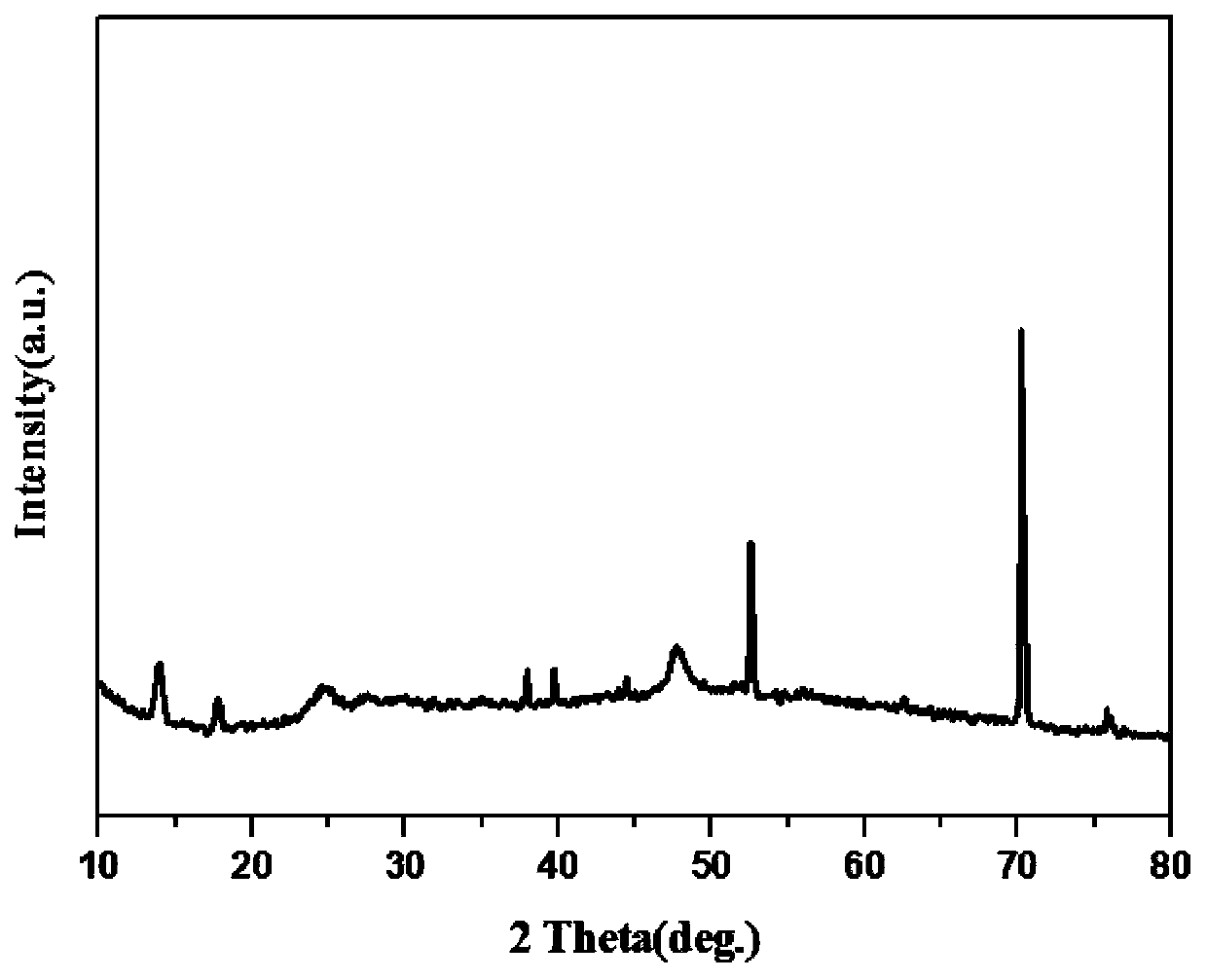

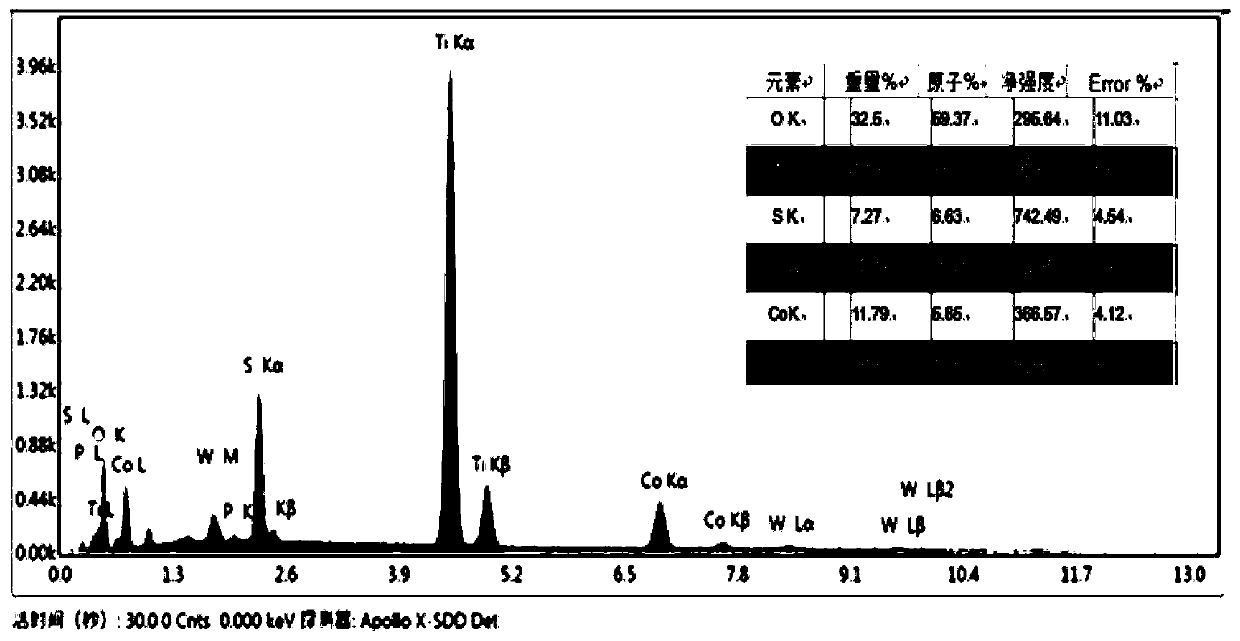

[0028] The experiment was carried out in a quartz beaker using a three-electrode system. The titanium dioxide photoanode and the titanium dioxide-cobalt octasulfide-polyacid composite film photoanode were used as working electrodes respectively, and the effective area was 1×1cm 2 , the platinum wire was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode. The supporting electrolyte is 0.5M sodium sulfate solution. A 300W xenon lamp is used as the light source, and the radiation intensity is 100mW·cm -2 . The voltage range is 0.2-1.6V (compared to the standard hydrogen electrode). As can be clearly seen from the figure, after introducing nine cobalt eight sulfides and polyacids, the composite film photoanode photocurrent has a significant promotion (see attached Figure 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com