Process for separating superfine particles

A technology of ultra-fine particles and processes, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of poor specificity of pharmaceuticals, low grade and recovery rate, large dosage, etc., and achieve mild working conditions, easy to scale up, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

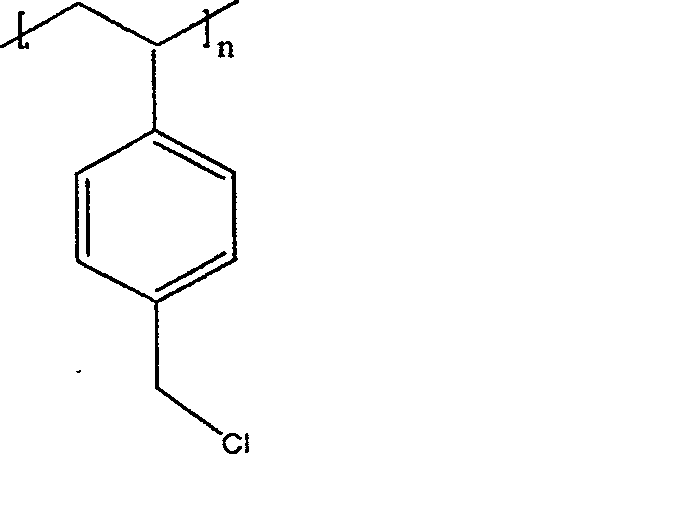

Embodiment 1

[0034] Add 10mL of PEG4000 with a mass fraction of 7.81% and Dextran20000 with a mass fraction of 14.06 to a 10mL test tube, then add 0.01g of Ps, place in an ultrasonic cleaner and vibrate for 0.5h to make it evenly dispersed in the system. After the separation of the two phases is clear, it is obvious that Ps is uniformly dispersed in the PEG-rich upper phase, forming a relatively stable system, showing a certain turbidity. The two phases were separated and centrifuged to obtain Ps.

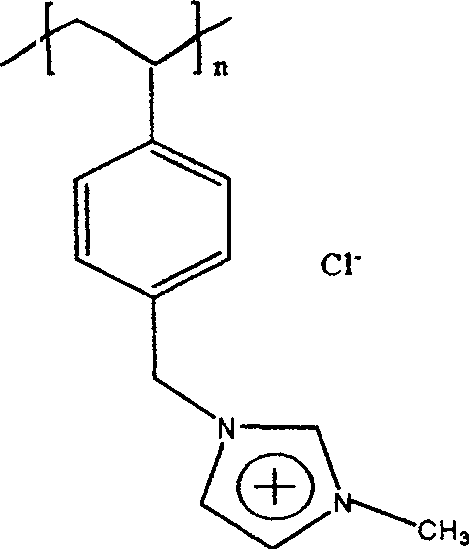

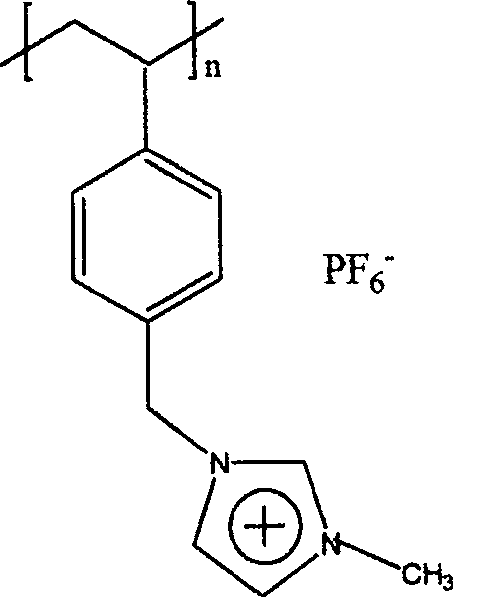

Embodiment 2

[0036] According to the method of Example 1, but adding 0.01g of PsMimCl, after the two phases were separated, it was clearly observed that: PsMimCl was uniformly dispersed into the Dextran-rich lower phase, forming a relatively stable system, showing a certain turbidity. The two phases were separated and centrifuged to obtain PsMimCl.

Embodiment 3

[0038] According to the method of Example 1, but adding a mixture of 0.01g Ps and PsMimCl, after the two phases are clearly separated, it is clearly observed that: Ps is uniformly dispersed into the PEG-rich upper phase, and PsMimCl is uniformly dispersed into the Dextran-rich lower phase, A relatively stable system is formed, showing a certain turbidity. The two phases were separated and centrifuged to obtain pure PsMimCl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com