Method for extracting tea seed oil by using water

A technology of tea seed oil and water immersion, which is applied in the production of fat oil/fat and fat production, can solve the problems of large loss of nutrients, long process flow, low oil yield, etc., and achieves low production cost, short process flow, The effect of mild working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh 100 kg of dehulled tea seed kernels with 47.10% oil content and crush them to 80-100 mesh. Add 250L of water to the crushed material to adjust the slurry at a rate of 2.5:1. Stir and extract at a constant temperature of 75°C and 40r / min for 35 minutes. Centrifugal separation obtains 44.02kg of finished tea seed oil, and the calculated oil rate is:

[0016] 44.02kg / 47.10kg*100%=93.46%

Embodiment 2

[0018] Weigh 100 kg of dehulled tea seed kernels with 50.60% oil content and crush them to 80-100 mesh. Add 850L of water to the crushed material to adjust the slurry according to 8.5:1. Stir at a constant temperature at 85°C and 180r / min for 150 minutes. Centrifugal separation obtains 47.60kg of finished tea seed oil. The calculated oil rate is:

[0019] 47.60kg / 50.6kg*100%=94.07%

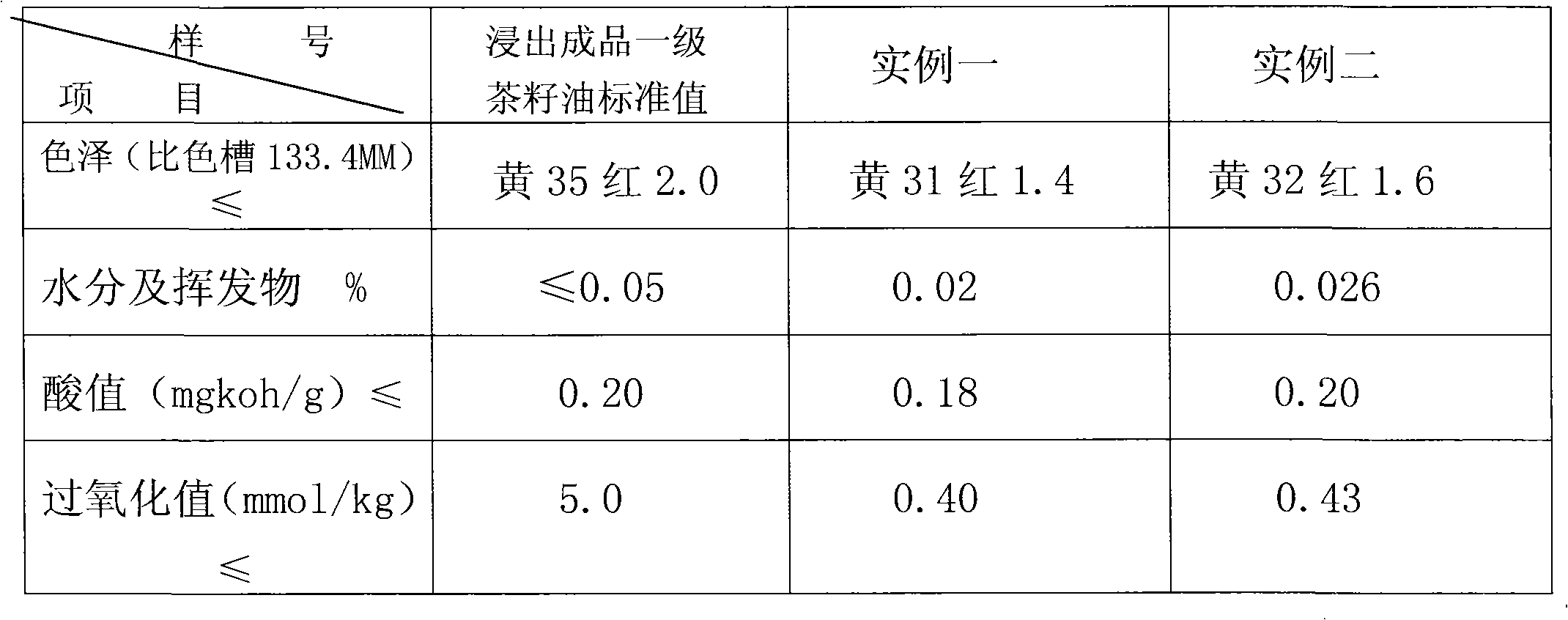

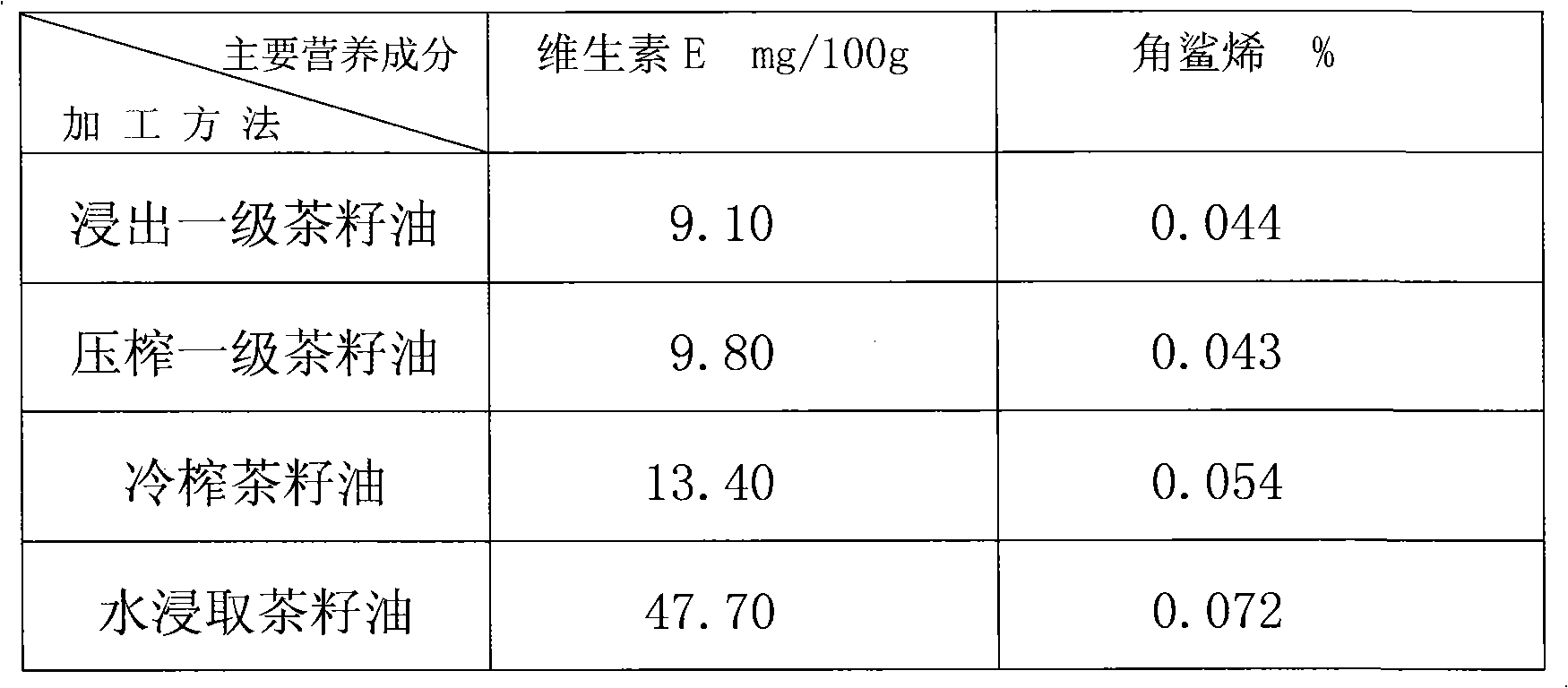

[0020] After testing, the main indicators of the tea seed oil obtained in Examples 1 and 2 have reached the national standard for extracting first-class finished tea seed oil; and the main nutrients in the oil are significantly higher than those of the tea seed oil prepared by conventional traditional methods. The specific data As shown in Table 1 and Table 2.

[0021] Table 1 The comparison table of the main indicators of the national first-level tea seed oil and the main indicators of Examples 1 and 2

[0022]

[0023] Table 2 Comparison table of main nutrients in finished tea seed oil obtained by diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com