Preparation, performance test method and application of zirconium-containing supported nano-ruthenium catalyst

A supported, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of increased production cost, high reaction risk factor, difficult recovery, etc., to prevent precious metal sintering , The effect of low reaction conditions and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Ru / Zr x The preparation method of AlO (zirconium-containing supported nanometer ruthenium catalyst) comprises the steps:

[0049] S1. On the magnetic stirrer that rotating speed is 550rpm, make 15.01g mass molar concentration be 2.66mmol / gAl(NO 3 ) 3 9H 2 O and 1.29g molar concentration is 3.10mmol / g ZrOCl 2 ·8H 2 O was dissolved in 150ml water and stirred to form a homogeneous solution;

[0050] S2. Add triethylamine dropwise to the homogeneous solution in S1 until the solution pH=9, then control the solution temperature at 65° C., and age for 18 hours;

[0051] S3. Pour the aged solution into a sand core funnel, suction filter, wash with deionized water until the pH of the solution is 7, after washing, dry the obtained filter cake at 110° C. for 12 hours;

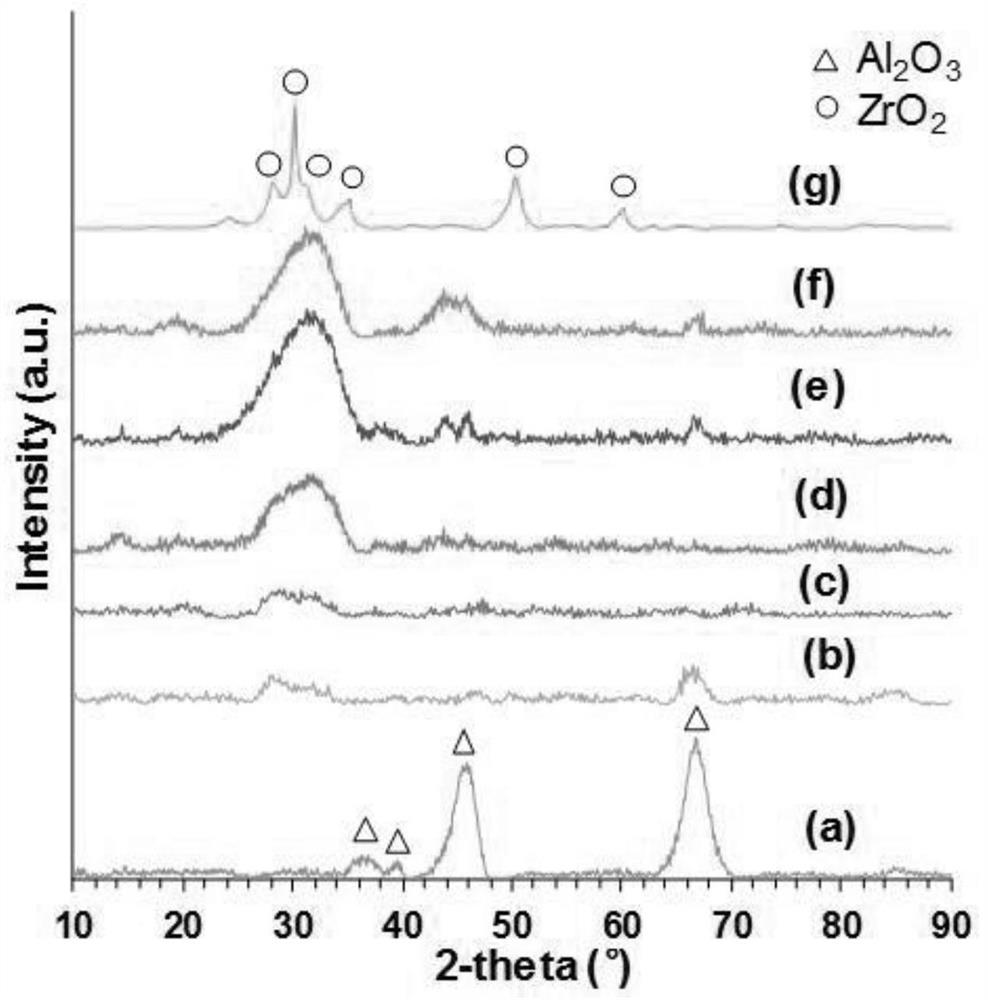

[0052] S4. Grind the filter cake in S3 into powder, bake it in a muffle furnace at 400°C for 4h, the heating rate in the muffle furnace is 2°C / min, and take it out after cooling down to room temperature to ob...

Embodiment 2

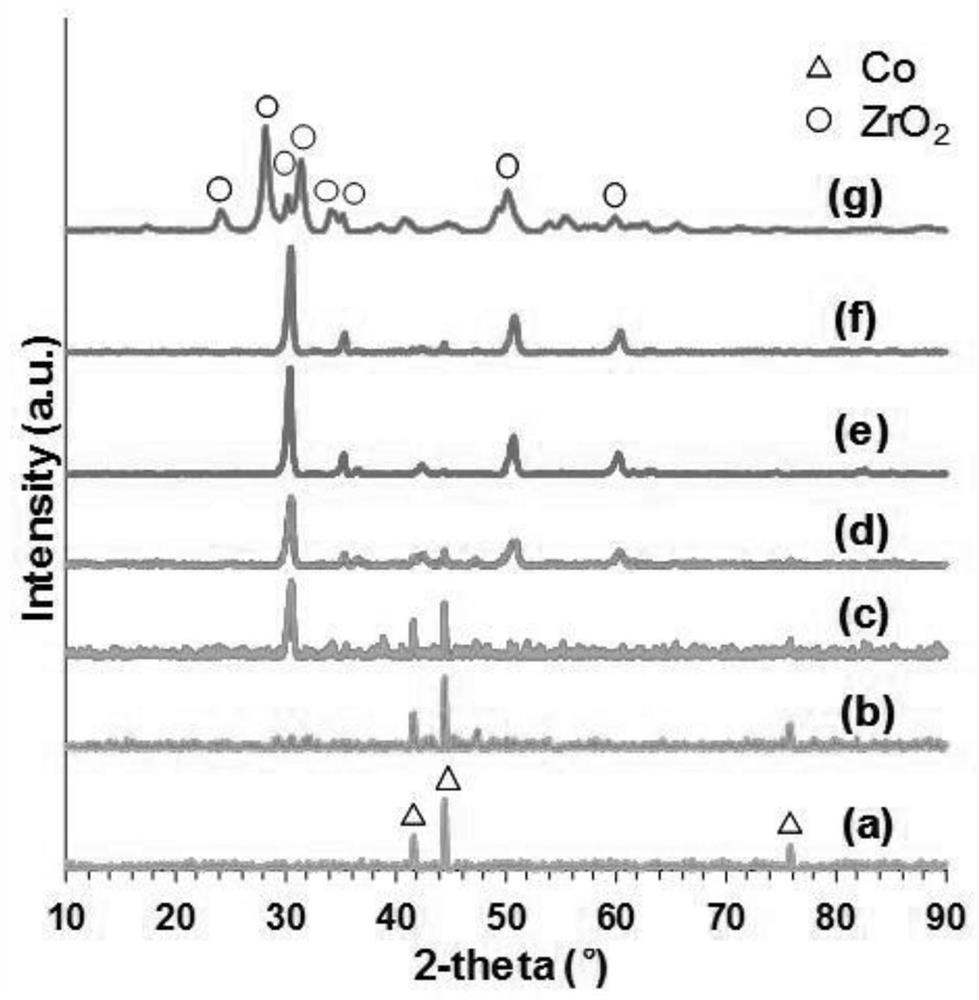

[0068] Ru / CoZr x The preparation method of O (containing zirconium supported nanometer ruthenium catalyst), comprises the steps:

[0069] S1. On the magnetic stirrer that rotating speed is 550rpm, make 11.64g mass molar concentration be 3.44mmol / g Co(NO 3 ) 2 ·6H 2 O and 1.29g molar concentration is 3.10mmol / g ZrOCl 2 ·8H 2 O was dissolved in 150ml water and stirred to form a homogeneous solution;

[0070] S2. Add triethylamine dropwise to the homogeneous solution in S1 until the solution pH=9, then control the solution temperature at 65° C., and age for 18 hours;

[0071] S3. Pour the aged solution into a sand core funnel, suction filter, wash with deionized water until the pH of the solution is 7, after washing, dry the obtained filter cake at 110° C. for 12 hours;

[0072] S4. Grind the filter cake in S3 into powder, bake it in a muffle furnace at 500°C for 4h, the heating rate in the muffle furnace is 2°C / min, and take it out after cooling down to room temperature to...

Embodiment 3

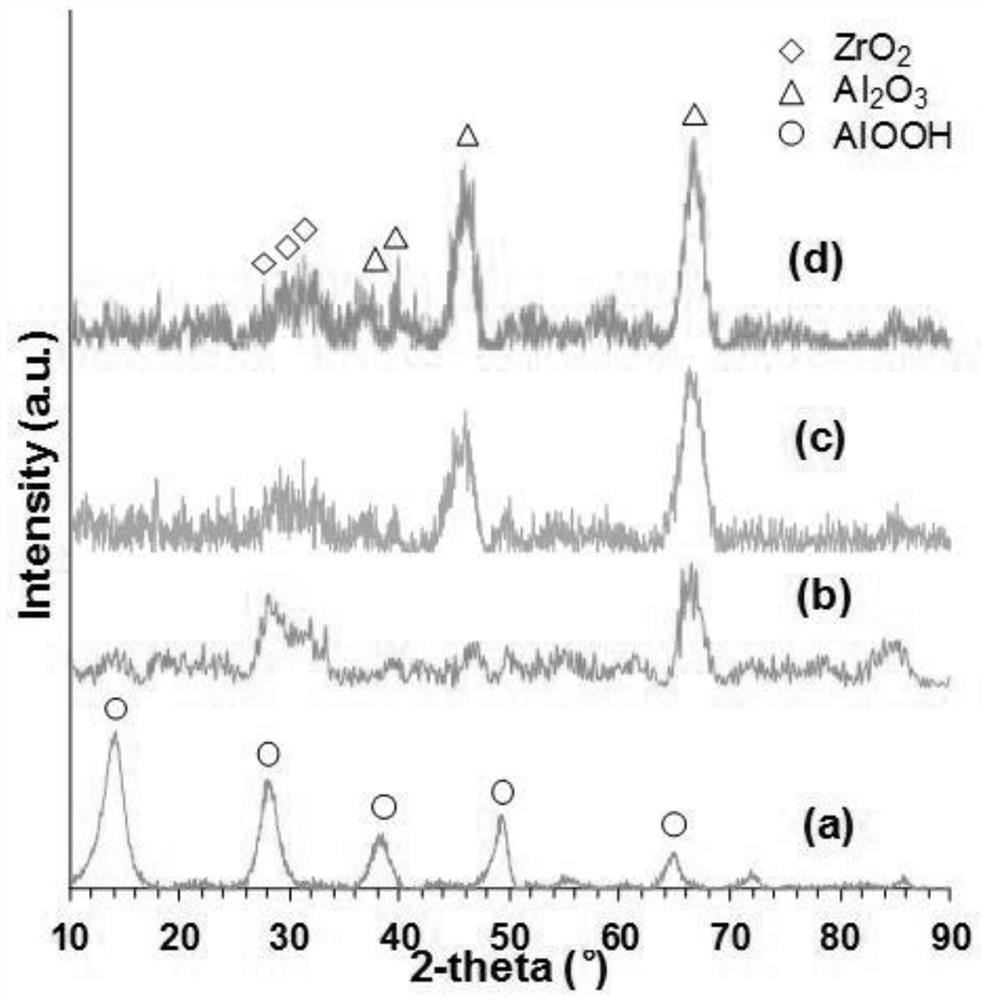

[0088] Ru / Zr at different calcination temperatures 0.1 The preparation method of AlO (zirconium-containing supported nanometer ruthenium catalyst) comprises the steps:

[0089] S1. On the magnetic stirrer that rotating speed is 550rpm, make 15.01g mass molar concentration be 2.66mmol / g Al(NO 3 ) 3 9H 2 O and 1.29g molar concentration is 3.10mmol / g ZrOCl 2 ·8H 2 O was dissolved in 150ml water and stirred to form a homogeneous solution;

[0090] S2. Add triethylamine dropwise to the homogeneous solution in S1 until the solution pH=9, then control the solution temperature at 65° C., and age for 18 hours;

[0091] S3. Pour the aged solution into a sand core funnel, suction filter, wash with deionized water until the pH of the solution is 7, after washing, dry the obtained filter cake at 110° C. for 12 hours;

[0092] S4. Grind the filter cake in S3 into powder, and roast it in a muffle furnace at 300°C, 400°C, 500°C, and 600°C for 4 hours respectively. The heating rate in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com