Surface modified aramid, surface modifying method and application

A surface modification, aramid fiber technology, used in textiles and papermaking, fiber types, ultrasonic/sonic fiber treatment, etc., can solve the problems of low shear strength, easy deactivation of active points on the fiber surface, and high interfacial shear strength. Achieve the effects of high interfacial shear strength, easy industrial processing, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

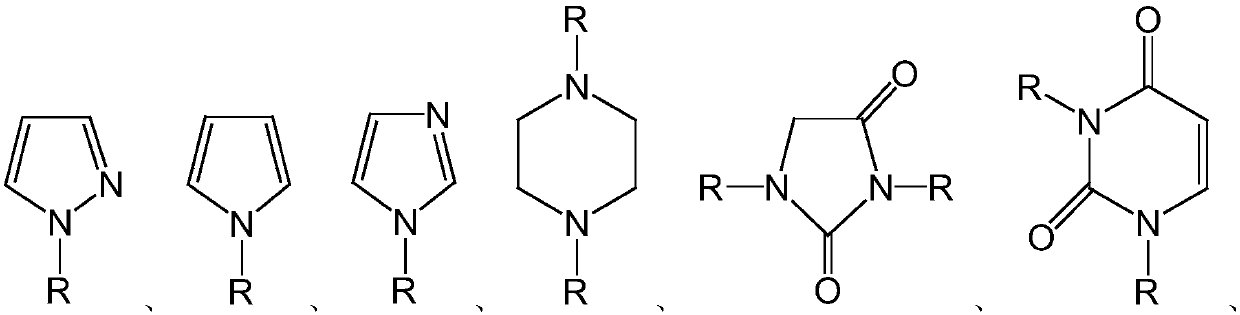

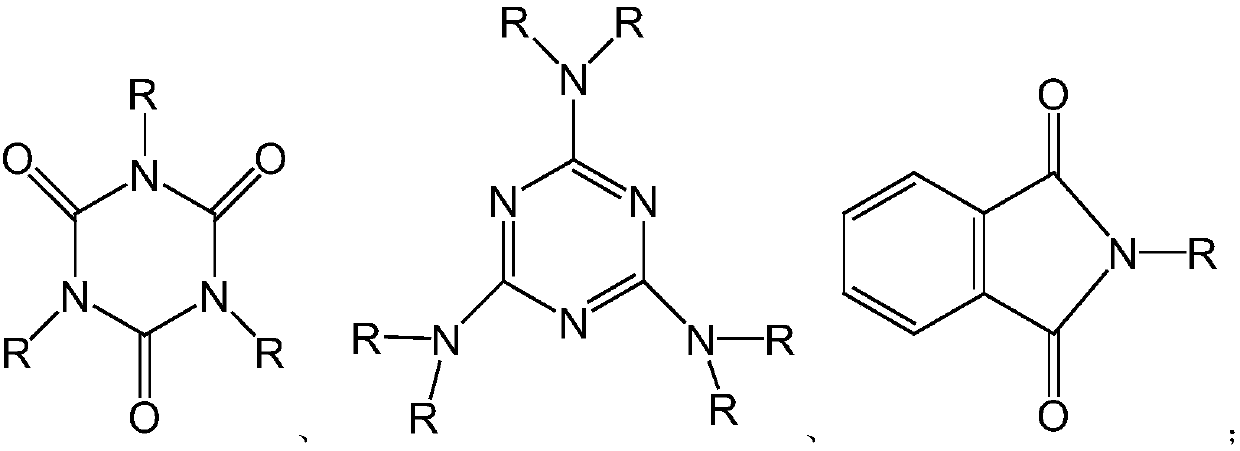

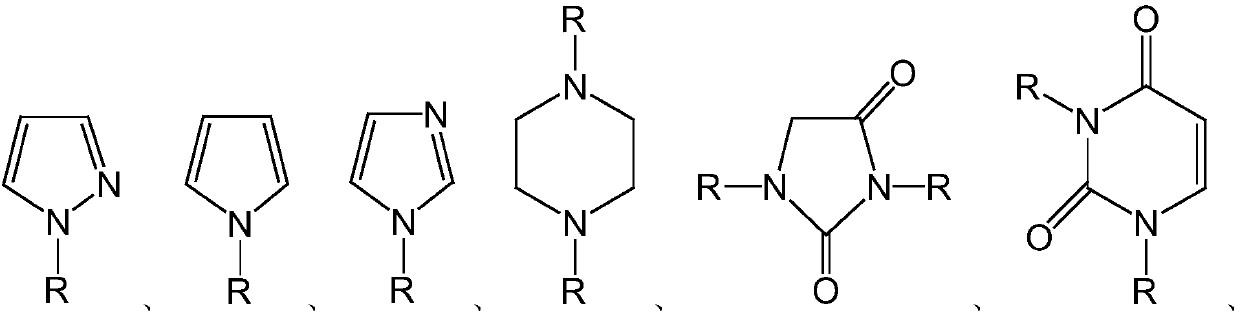

Image

Examples

Embodiment 1

[0053] Surface modification of aramid fibers:

[0054] (1) Put the continuous aramid fiber in a blast oven and dry it at 80°C for 12 hours.

[0055] (2) Place the dried continuous aramid fiber evenly between the positive and negative electrodes of the vacuum plasma processor, the processing medium is air, and the gas flow rate is 50cm 3 / min, the plasma generation power is 400w, and the treatment time is 60s, and the aramid fiber after plasma treatment is obtained.

[0056] (3) Pour 1,3-dried hydantoin epoxy resin (epoxy value: 0.75mol / 100g) into the oiling tank, heat to 70°C, and the viscosity is 58mPa.s (Brookfield DV-Ⅲ rotary Viscometer, rotor type SC4-18, the rotating speed is 10 rev / min). The plasma-treated aramid fiber is continuously passed through the oiling tank to obtain the surface-modified aramid fiber. In this embodiment, the surface treatment agent content is 1.6%.

[0057] The interfacial shear strength (IFSS) of surface-modified aramid fiber and epoxy resin...

Embodiment 2

[0063] Surface modification of aramid fibers:

[0064] (1) Put the continuous aramid fiber in a blast oven and dry it at 80°C for 12 hours.

[0065] (2) Place the dried continuous aramid fiber evenly between the positive and negative electrodes of the vacuum plasma processor, the processing medium is air, and the gas flow rate is 50cm 3 / min, the plasma generation power is 400w, and the treatment time is 60s, and the aramid fiber after plasma treatment is obtained.

[0066] (3) Pour 5,5-methylphenyl-1,3-dihydrated hydantoin epoxy resin (epoxy value 0.77mol / 100g) into the oil tank, heat to 70°C, and the viscosity is 65mPa .s (Brookfield DV-Ⅲ rotational viscometer, rotor type SC4-18, rotating speed is 10 rpm). The plasma-treated aramid fiber is continuously passed through the oiling tank to obtain the surface-modified aramid fiber. In this embodiment, the surface treatment agent content is 1.5%.

[0067] Surface treatment agent content, IFSS and ILSS determination method are...

Embodiment 3

[0069] Surface modification of aramid fibers:

[0070] (1) Put the continuous aramid fiber in a blast oven and dry it at 80°C for 12 hours.

[0071] (2) Place the dried continuous aramid fiber evenly between the positive and negative electrodes of the vacuum plasma processor, the processing medium is air, and the gas flow rate is 50cm 3 / min, the plasma generation power is 400w, and the treatment time is 60s, and the aramid fiber after plasma treatment is obtained.

[0072] (3) Pour 5,5-methylphenyl-1,3-dihydrated hydantoin epoxy resin (epoxy value 0.70mol / 100g) into the oiling tank, heat to 70°C, and the viscosity is 72mPa .s (Brookfield DV-Ⅲ rotational viscometer, rotor type SC4-18, rotating speed is 10 rpm). The plasma-treated aramid fiber is continuously passed through the oiling tank to obtain the surface-modified aramid fiber. In this embodiment, the surface treatment agent content is 1.8%.

[0073] Surface treatment agent content, IFSS and ILSS determination method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com