Route detection device of waste material extruding cylinder

A stroke detection and extrusion cylinder technology, which is applied to fluid pressure actuators, presses, manufacturing tools, etc., can solve problems affecting normal production, detection signal fluctuations, encoder damage, etc., to reduce maintenance workload, reduce Maintenance cost, the effect of overcoming fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but this embodiment should not be construed as limiting the present invention:

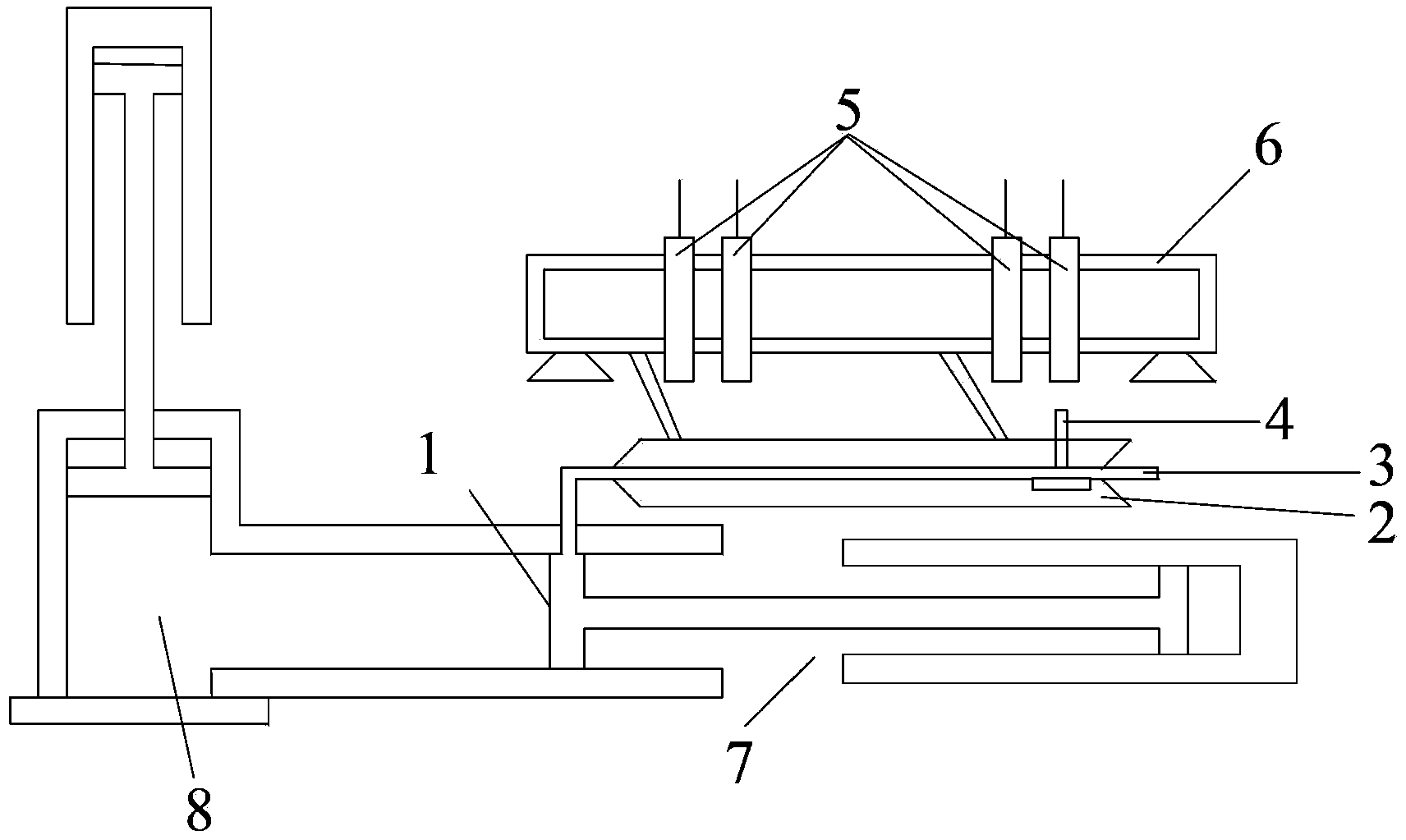

[0011] The waste extrusion cylinder stroke detection device shown in the figure includes extrusion cylinder shear blade 1, and is also provided with positioning guide groove 2, slide bar 3, metal rod 4, electromagnetic sensor 5 and bracket 6, slide bar 3 and extrusion The edge of the cylinder cutting edge 1 is fixedly connected, the positioning guide groove 2 is fixed on the bracket 6, the axis of the positioning guide groove 2 is parallel to the axis of the extrusion cylinder cutting edge 1, and the slide bar 3 is located in the positioning guide groove 2 and aligned with the positioning guide groove 2 sliding fit, the metal rod 4 is vertically fixed on the slide bar 3, the bracket 6 is fixed on the foundation, 3-6 electromagnetic sensors 5 are arranged on the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com