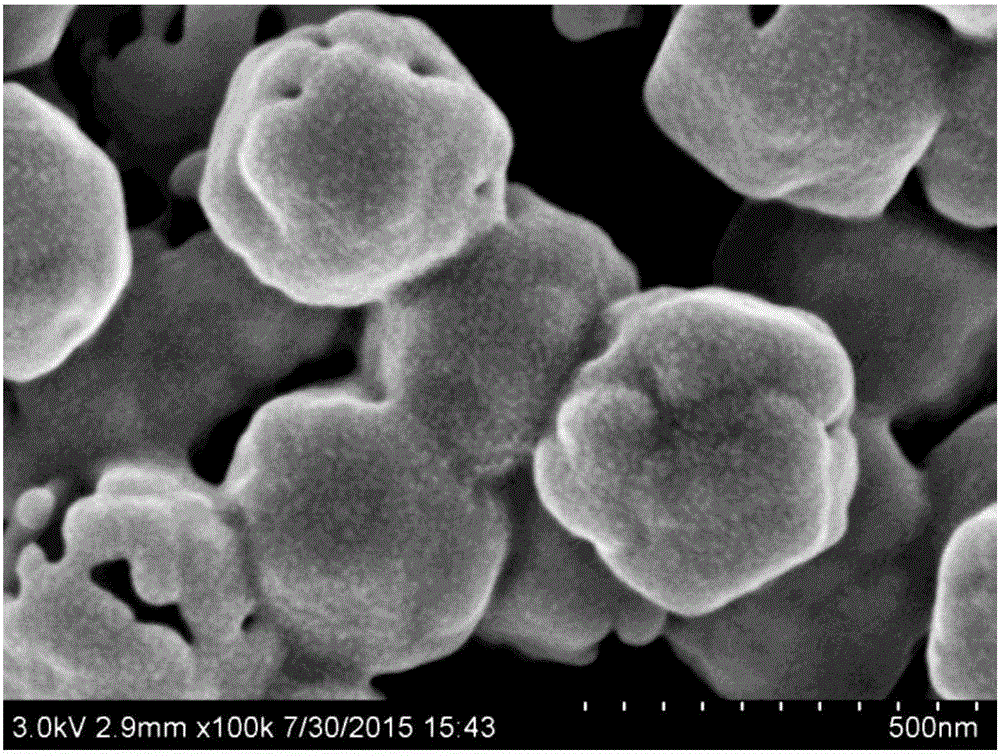

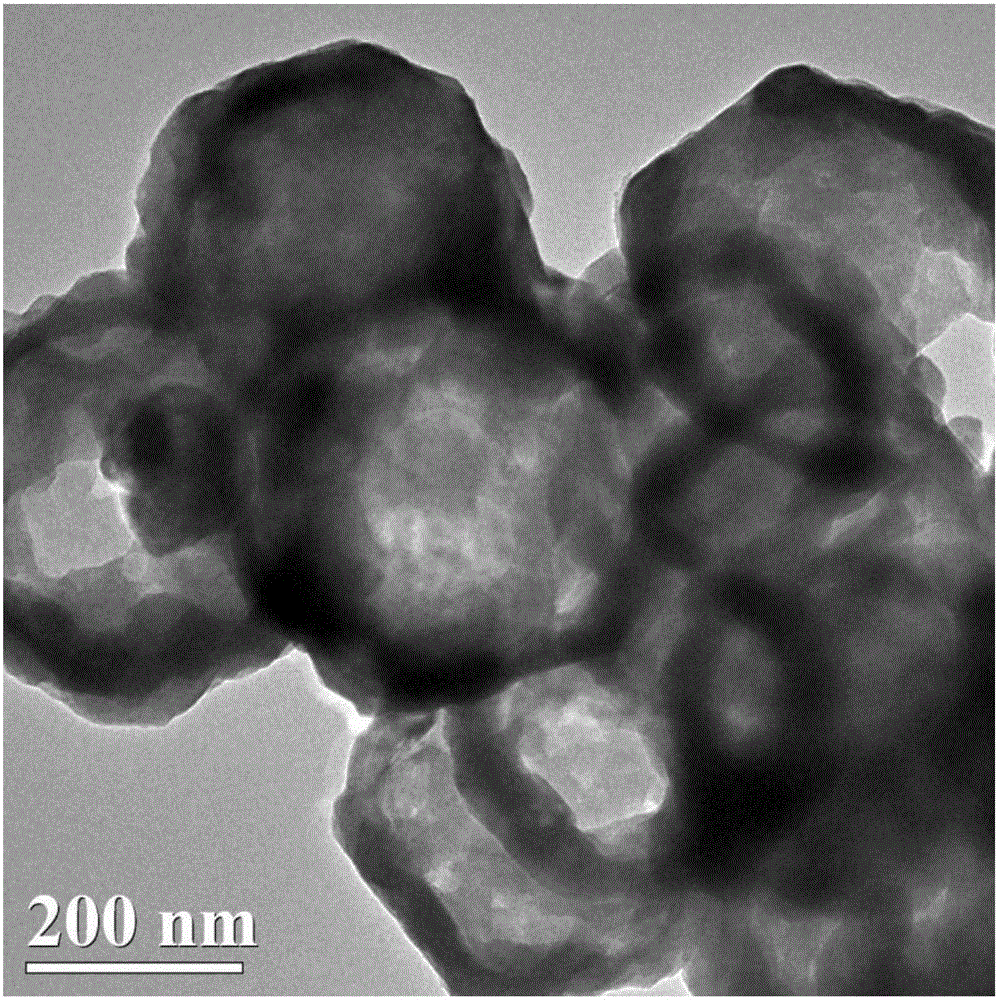

Technology for preparing micro-nano cuprous oxide hollow polyhedrons through reduction method

A cuprous oxide, micro-nano technology, applied in the field of nano-materials, can solve the problems of long time-consuming oxidation and etching, damage to material structure, poor effect, etc., and achieve the effect of clear outline, good dispersion, and no need for etchant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step (1): Add 1 mL of CuCl to 16.24 mL of deionized water successively 2 solution (0.1mol / L), 174mgSDS, 0.36mLNaOH solution (1mol / L) and 2.4mLNH 2 OH·HCl solution (0.1mol / L);

[0023] Step (2): Stir the above mixed solution magnetically at room temperature for 1 h;

[0024] Step (3): The above reaction liquid is centrifuged and vacuum-dried at low temperature to obtain hollow polyhedrons of micronano cuprous oxide.

Embodiment 2

[0026] Step (1): Add 1 mL of CuCl to 16.24 mL of deionized water successively 2 Solution (0.1mol / L), 174mgSDS, 2.4mLNH 2 OH·HCl solution (0.1mol / L) and 0.36mL NaOH solution (1mol / L);

[0027] Step (2): Stir the above mixed solution magnetically at room temperature for 1 h;

[0028] Step (3): The above reaction liquid is centrifuged and vacuum-dried at low temperature to obtain hollow polyhedrons of micronano cuprous oxide.

Embodiment 3

[0030] Step (1): Add 1 mL of CuCl to 16.24 mL of deionized water successively 2 solution (0.1mol / L), 174mgSDS, 0.36mLNaOH solution (1mol / L) and 2.4mLNH 2 OH·HCl solution (0.1mol / L);

[0031] Step (2): Stir the above mixed solution magnetically at room temperature for 1 h;

[0032] Step (3): The above reaction liquid is centrifuged and vacuum-dried at low temperature to obtain hollow polyhedrons of micronano cuprous oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com