Method for preparing metal-organic framework material from metallurgical mine solid wastes

An organic skeleton and mining technology, applied in the field of comprehensive utilization of resources, can solve problems such as high energy consumption and high pollution, and achieve the effect of reducing energy consumption and great guiding significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

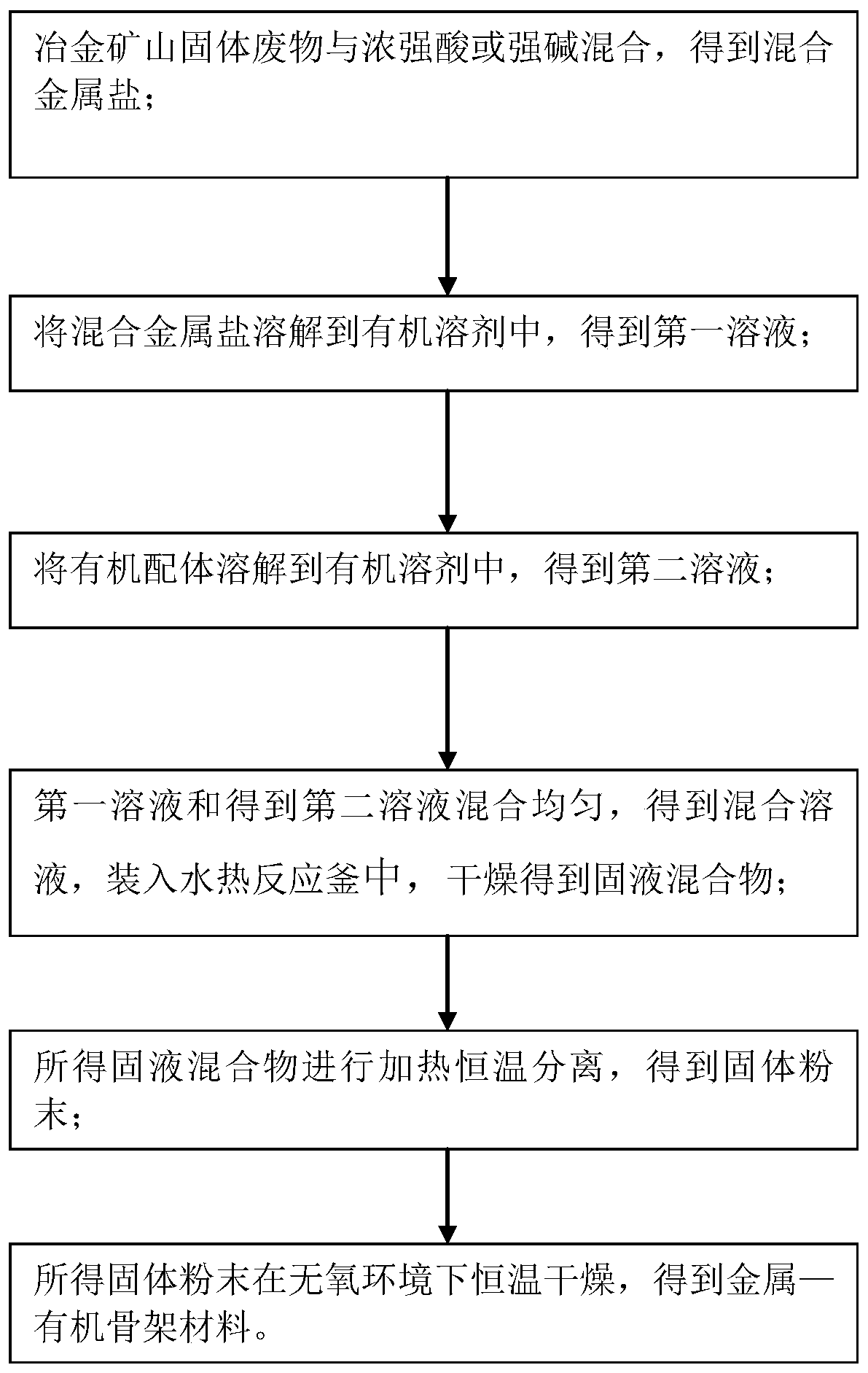

Method used

Image

Examples

Embodiment 1

[0044] S1) Mix 80 grams of dust (particle size 200 microns) from a domestic iron and steel plant with 100 ml of concentrated strong acid, dissolve and separate by centrifugal filtration (the centrifugal separation factor Fr is controlled at 7000), and keep the obtained liquid in an oven at a constant temperature of 120°C for 24 hours. Get mixed salt.

[0045] S2) Add 1.2 g of mixed salts into 15 ml of dimethylacetamide, and ultrasonicate for 5 minutes to obtain the first solution.

[0046] S3) Add 0.2g C 8 h 6 o 4 Added to 15ml of dimethylacetamide, ultrasonic treatment for 5 minutes to obtain the second solution.

[0047] S4) mixing the first solution and the second solution, ultrasonic treatment for 3 minutes to obtain a mixed solution,

[0048] S5) Transfer the mixed solution into a 40 mL stainless steel hydrothermal reaction kettle, and keep the temperature at 110° C. for 20 h. After the reaction, the solid-liquid mixture obtained by the reaction was separated by suct...

Embodiment 2

[0051]S1) Mix 80 grams of dust (particle size 200 microns) from a domestic iron and steel plant with 100ml of concentrated strong acid, dissolve and separate by centrifugal filtration, (the centrifugal separation factor Fr is controlled at 8500) and keep the obtained liquid in an oven at a constant temperature of 120°C for 24h. Get mixed salt.

[0052] S2) Add 0.6 g of mixed salts into 15 ml of dimethylformamide, and ultrasonicate for 3 minutes to obtain a first solution.

[0053] S3) add 0.1g C 4 h 6 N 24 Added to 15ml of dimethylformamide, ultrasonic treatment for 3 minutes, to obtain the second solution.

[0054] S4) mixing the first solution and the second solution, ultrasonic treatment for 3 minutes to obtain a mixed solution,

[0055] S5) Transfer the mixed solution into a 40 mL stainless steel hydrothermal reaction kettle, and keep the temperature at 110° C. for 20 h. After the reaction, the solid-liquid mixture obtained in the reaction was separated by suction fil...

Embodiment 3

[0058] S1) Mix 80 grams of dust (particle size 200 microns) from a domestic iron and steel plant with 100 ml of concentrated strong acid, dissolve and separate by centrifugal filtration (the centrifugal separation factor Fr is controlled at 10,000), and keep the obtained liquid in an oven at a constant temperature of 120°C for 24 hours. Get mixed salt.

[0059] S2) Add 0.2 g of mixed salts into 15 ml of diethylformamide, and ultrasonicate for 3 minutes to obtain the first solution.

[0060] S3) 0.4g C 8 h 6 o 4 Added into 45ml of diethylformamide, ultrasonic treatment for 3 minutes to obtain the second solution.

[0061] S4) mixing the first solution and the second solution, ultrasonic treatment for 3 minutes to obtain a mixed solution,

[0062] S5) Transfer the mixed solution into a 70 mL stainless steel hydrothermal reaction kettle, and keep the temperature at 110° C. for 20 h. After the reaction, the solid-liquid mixture obtained in the reaction was separated by suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com