Braking device of high-speed train

A braking device and high-speed train technology, applied in the direction of brake types, brake components, mechanical equipment, etc., can solve problems such as difficult heat dissipation, brittle fracture of brake discs, and impact on driving safety, so as to reduce braking accidents The probability of reducing harsh requirements and reducing the effect of mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described in detail below in conjunction with the examples.

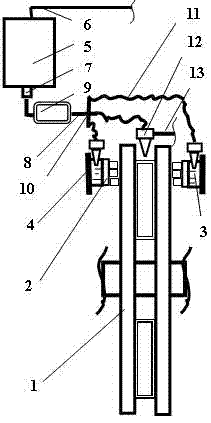

[0030] Such as figure 1 As shown, the device of the present invention at least includes: brake disc 1, brake pad 2, brake pad cooling chamber 3, caliper 4, water tank 5, water inlet pipe 6, tank bottom valve 7, water outlet pipe 8, high-pressure water pump 9, four Through pipe 10 , water delivery hoses 11A, 11B, 11C, nozzles 12A, 12B, 12C, positioning rods 13A, 13B, 13C and drive mechanism 14 .

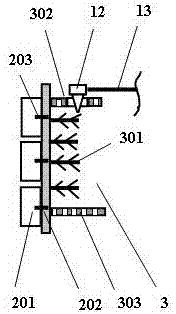

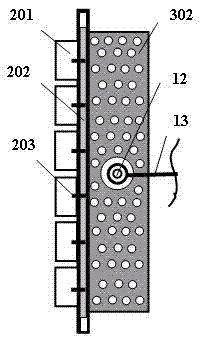

[0031] Such as Figure 2-3 As shown, the brake pad 2 includes a friction block 201 , a steel back 202 , and an anti-off post 203 .

[0032] Such as Figure 2-3 As shown, the heat dissipation cavity 3 is composed of a steel back 2 and heat dissipation fins 301 welded thereon, a top plate 302 and a bottom plate 303. The heat dissipation fins 301, the top plate 302 and the bottom plate 303 are all made of stainless steel, and the top plate and the bottom plate have mesh holes. , Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com