Patents

Literature

115results about How to "Improve oil output efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for pre-treating oil crop seeds by using microwave

InactiveCN101911983AEasy extractionLarge Diffusion PoresEdible oils/fats production/working-upAgricultural scienceMicrowave power

The invention belongs to the food processing field, and particularly relates to a microwave treatment method before oil crop seeds are cold-pressed to produce oil. A method for pre-treating oil crop seeds by using microwave is characterized by comprising the following steps of: (1) adjusting the mass water content of the oil crop seeds to between 7 and 30 percent, and stirring the oil crop seeds uniformly; (2) uniformly spreading the oil crop seeds after the water content adjustment in a container, adjusting microwave power and microwave time, and performing microwave treatment on the oil crop seeds to obtain a final temperature of between 80 and 150 DEG C; and (3) spreading and cooling the oil crop seeds after the microwave treatment, and then performing cold pressing or peeling and cold pressing to produce oil. The method for treating the oil crop seeds is favorable for increasing the yield of cold-pressed oil and improving the quality of the cold-pressed oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Synchronous aqueous enzymatic ultrasonic extraction for walnut oil and walnut protein peptide

InactiveCN101280327AQuality improvementMild treatment conditionsCheese manufactureVegetable proteins working-upOil phaseDietary fibre

The invention relates to an enzyme method ultrasonic extraction method of walnut oil and walnut protein, which belongs to the food and the functional food field. Water is added into walnut kernel or walnut powder to be grinded into paste, protease or compound protease are added into to be performed hydrolization, and simultaneously ultrasonic processing is performed, then the walnut kernel or walnut powder is agitated to perform enzymatic extraction, and then centrifugal separation oil phase, protein peptide oil water phase and residual solid phase are performed; walnut oil is acquired by refining the obtained oil phase, which meets the requirements of green foods; the protein peptide aqueous solution can be directly used to produce degreased walnut protein nutrient milk, or to prepare walnut antioxidation peptide after performed nanofiltration, which is used in health products, food additives, cosmetics or daily chemical articles, or to produce nutrient condensed milk after being performed low temperature concentrating, or to produce walnut protein nutrition powder after performed spray drying; the solid phase residue is prepared into diet fiber food after being dried and grinded into powder; walnut nutrient protein peptide products can be obtained through performing vacuum concentration and spray drying to walnut protein peptide extracting solution containing nutrient content.

Owner:KUNMING UNIV OF SCI & TECH

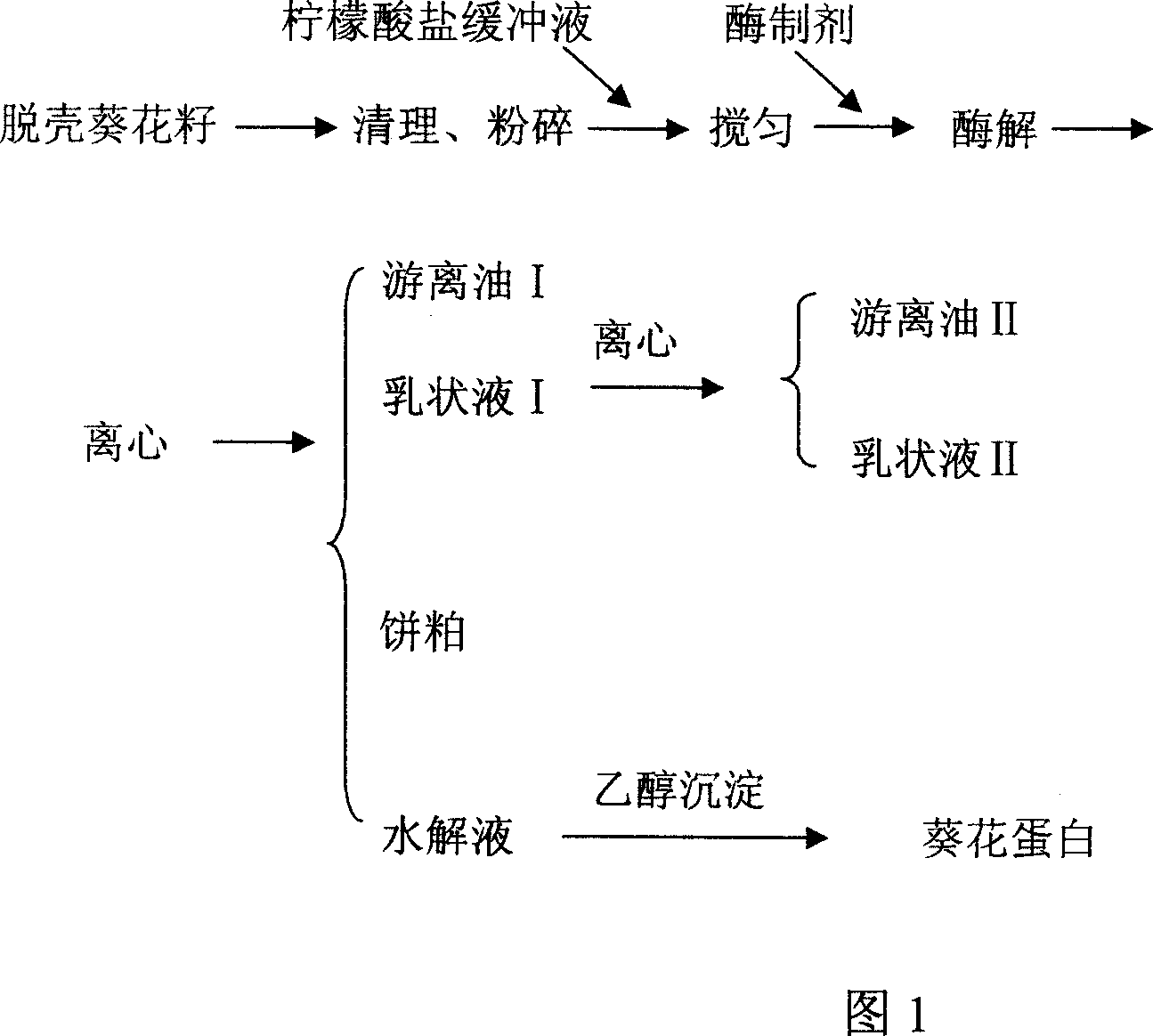

Process for extracting sunflower seed oil and recovering protein by aqueous enzymatic method

InactiveCN1952094AQuality improvementMild treatment conditionsEnzymesFatty-oils/fats productionCelluloseNutritive values

The method relates to the method to extract the sunflower oil and recover the protein by water-enzyme method. The producing procedure comprises the following steps: dry-pulverizing the uncoated sunflower seed, adding citrate buffer to the powder and decomposing the powder by compound cellulose; centrifugalizing to get free oil, emulsion, digest and tablet; high speed centrifugalizing to get some free oil; filtering, vacuum concentrating, alcohol precipitating, centrifugalizing and freeze-drying to recycle the protein. The special treatment in the invention has substantially increased the free oil yield and the quality of the free oil is better than the refined oil. The water-extracting and alcohol-precipitating method to get the protein is simple and efficient; besides, the method has maintained the sunflower protein's nutritive value and functional value very well. Compared with the traditional squeezing and water-extracting technologies, the invention has many advantages such as simple producing equipments, safe operation, less energy expenditure and less pollution.

Owner:JIANGNAN UNIV

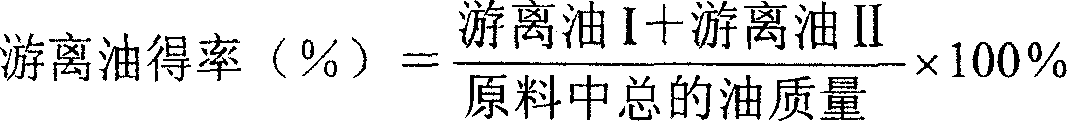

Method for preparing aromatic rapeseed oil

ActiveCN104694243AStrong fragranceStrong tasteFatty-oils/fats refiningFatty-oils/fats productionFlavorDecomposition

The invention discloses a method for preparing aromatic rapeseed oil. The method comprises the following steps: (1) wetting and tempering, namely feeding rapeseeds into a wetting device, spraying water for wetting, and conveying the rapeseeds into a tempering device for tempering; (2) frying and smoking, and removing the glucosinolate decomposition products; (3) pressing to prepare crude rapeseed oil; and (4) crystallizing and filtering the crude rapeseed oil, thereby obtaining the aromatic rapeseed oil. The preparation method disclosed by the invention is simple and easy to operate, any chemical additive does not need to be added in the preparation process, the wastewater and waste gas pollution is avoided, the prepared aromatic rapeseed oil is strong in flavor, the content of total glucosinolate is extremely low, the residual oil content of the rape seed cake is low, and the oil extraction efficiency of the rapeseeds is high.

Owner:安徽嘉旗粮油工程技术有限公司

Method for synchronously preparing walnut oil and walnut protein peptide by microwave-assisted protease hydrolysis

The invention provides a method for synchronously preparing walnut oil and walnut protein peptide by microwave-assisted protease hydrolysis, comprising the following steps of: grinding walnut raw materials into walnut powder, adding 100,000 to 1000,000 units of protease or composite protease to 1kg of walnut powder, adding water in the mass ratio of the walnut powder to the water is 1: (0.5-20), and then performing microwave processing for 1-10 minutes under the stirring condition of 60 to 300rpm when the microwave power is 10 to 1000 W / L and the temperature is 35 to 65 DEG C, and performing centrifugal separation of oil phase, aqueous phase and solid phase after the reaction ends, wherein the oil phase is walnut oil, the aqueous phase is walnut protein peptide, and the solid phase is residues. The method provided by the invention has mild extraction condition and excellent product performance, and can improve the efficiency of ingress of oil. Furthermore, the obtained walnut oil is higher in quality and is easy to refine; the processing time is greatly shortened by microwave-assisted extraction; the oil phase, the aqueous phase and the solid phase residues can be separated at the same time, therefore, the production efficiency is efficiently improved; and no waste water, waste air or waste residues exists in the producing process, therefore, the invention is environmentally-friendly.

Owner:KUNMING UNIV OF SCI & TECH

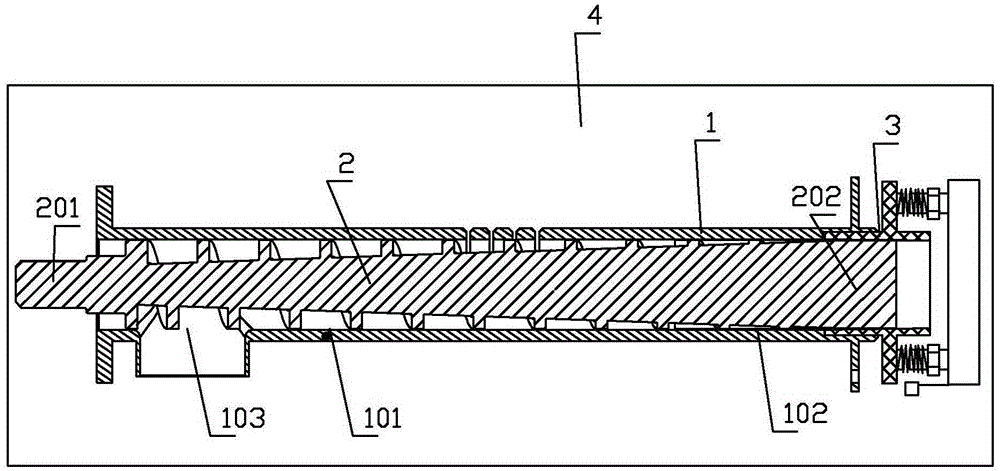

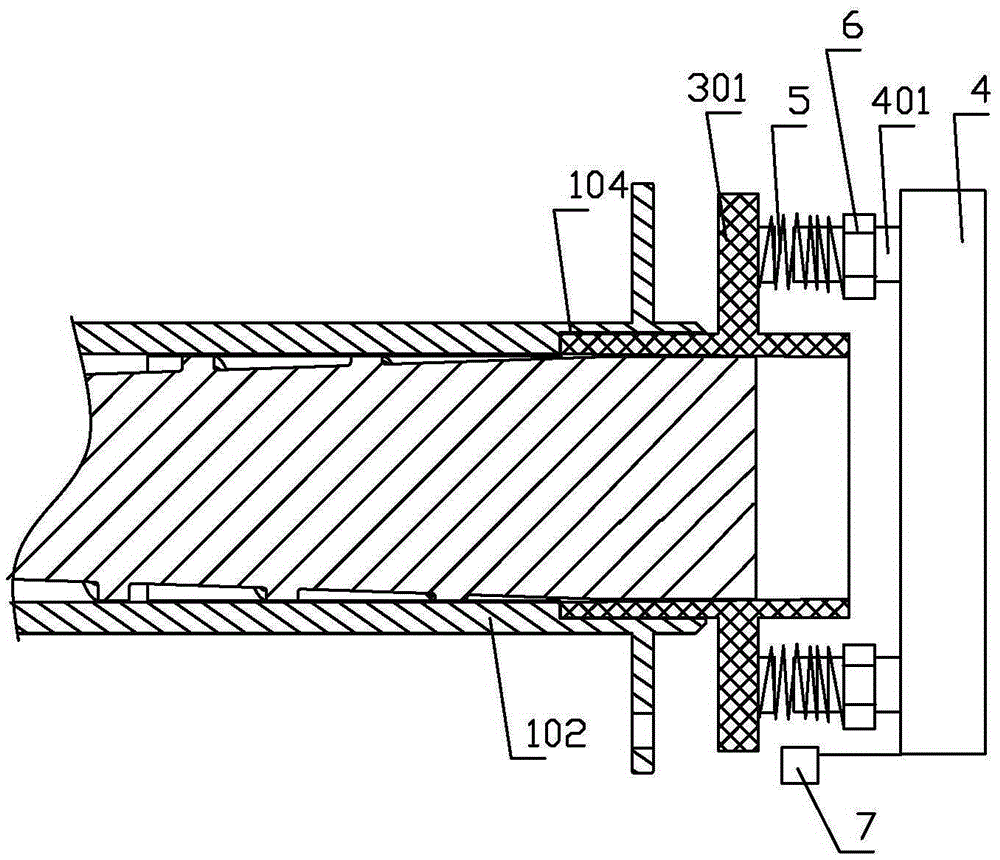

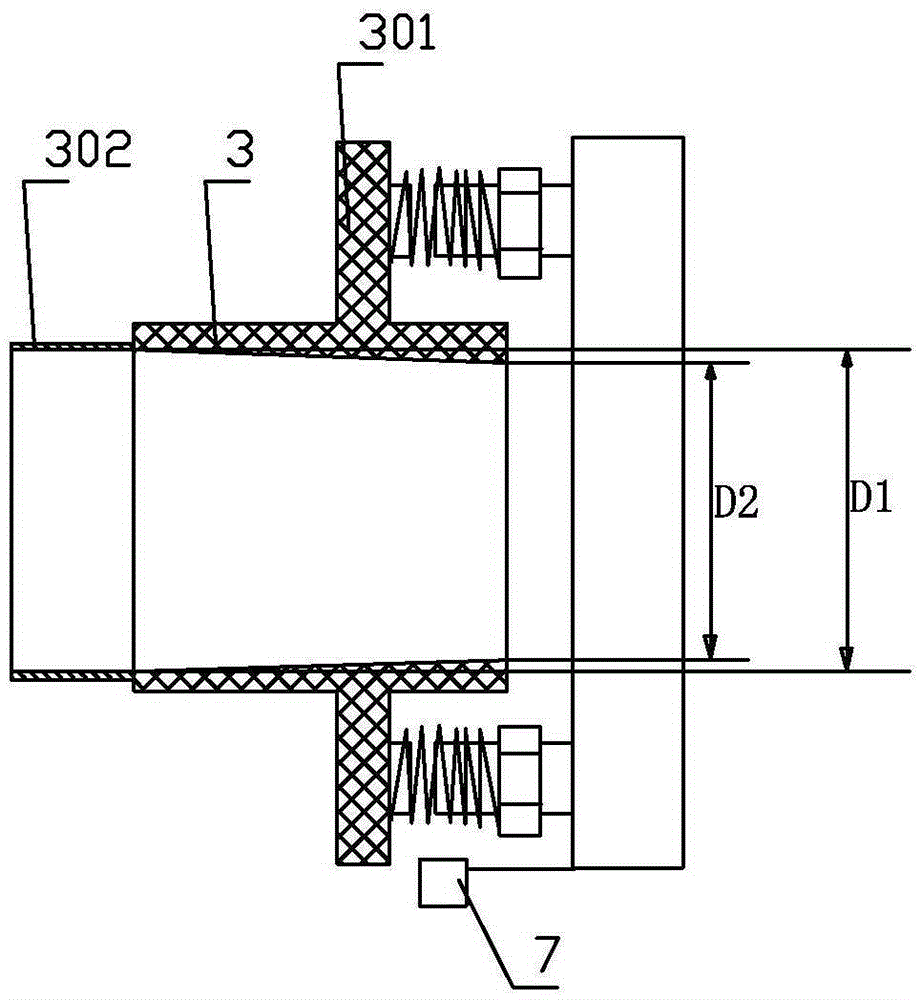

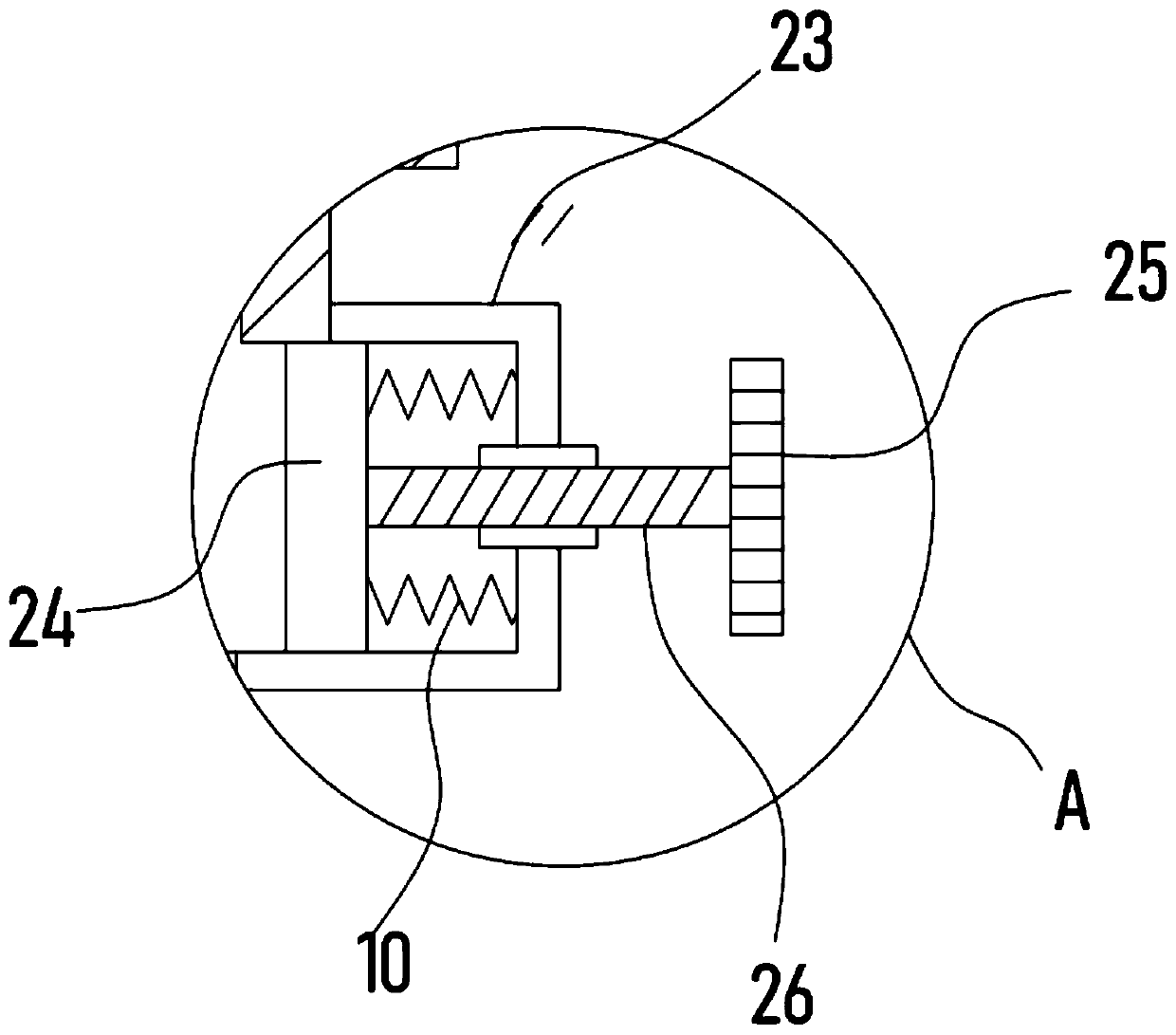

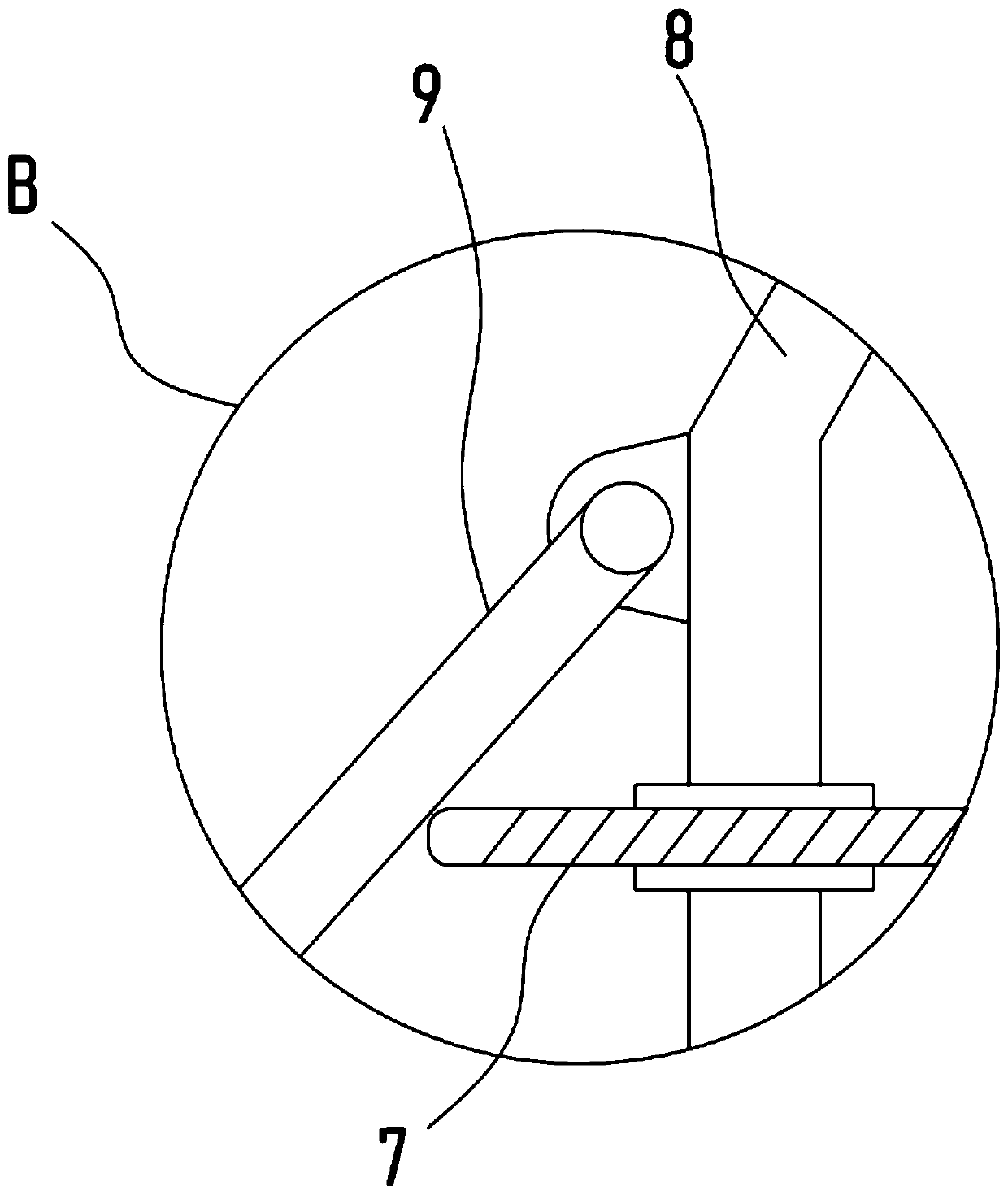

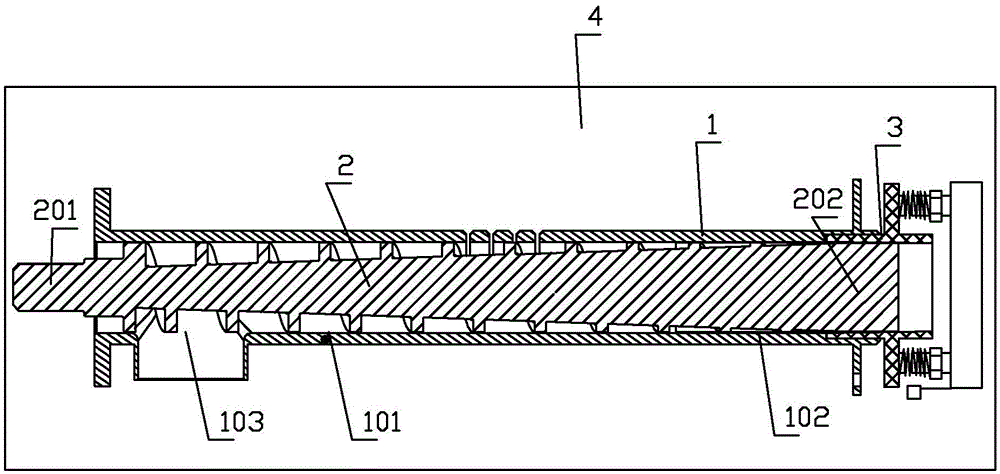

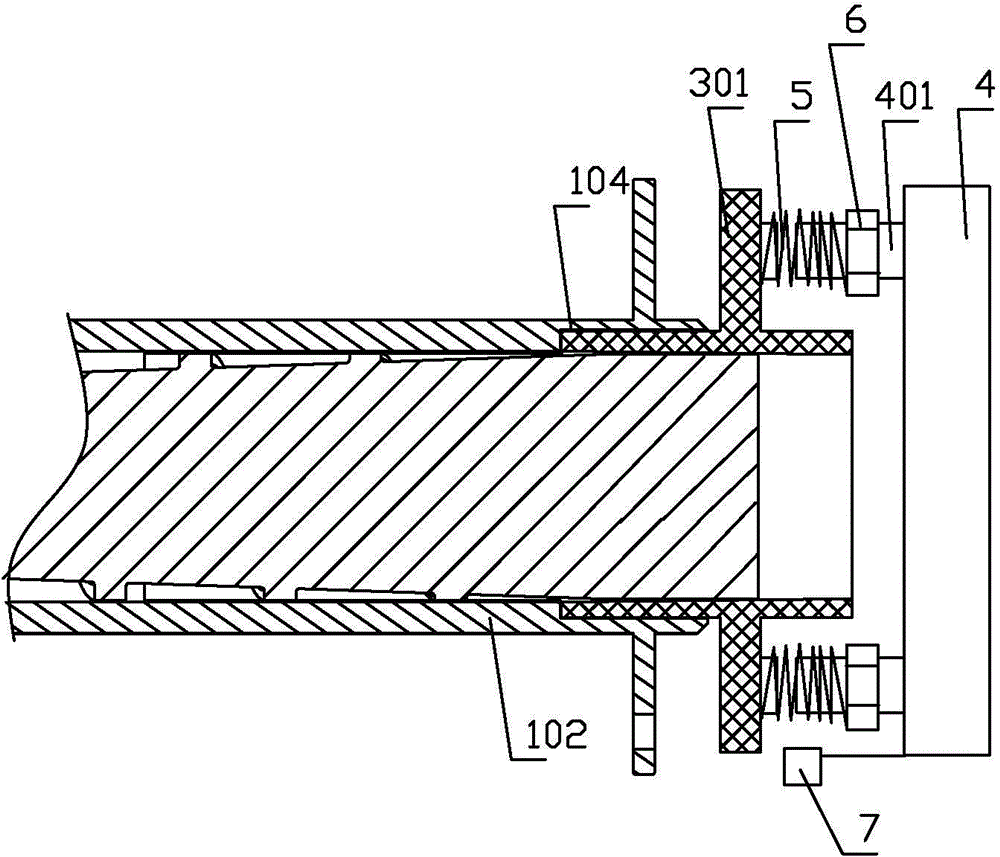

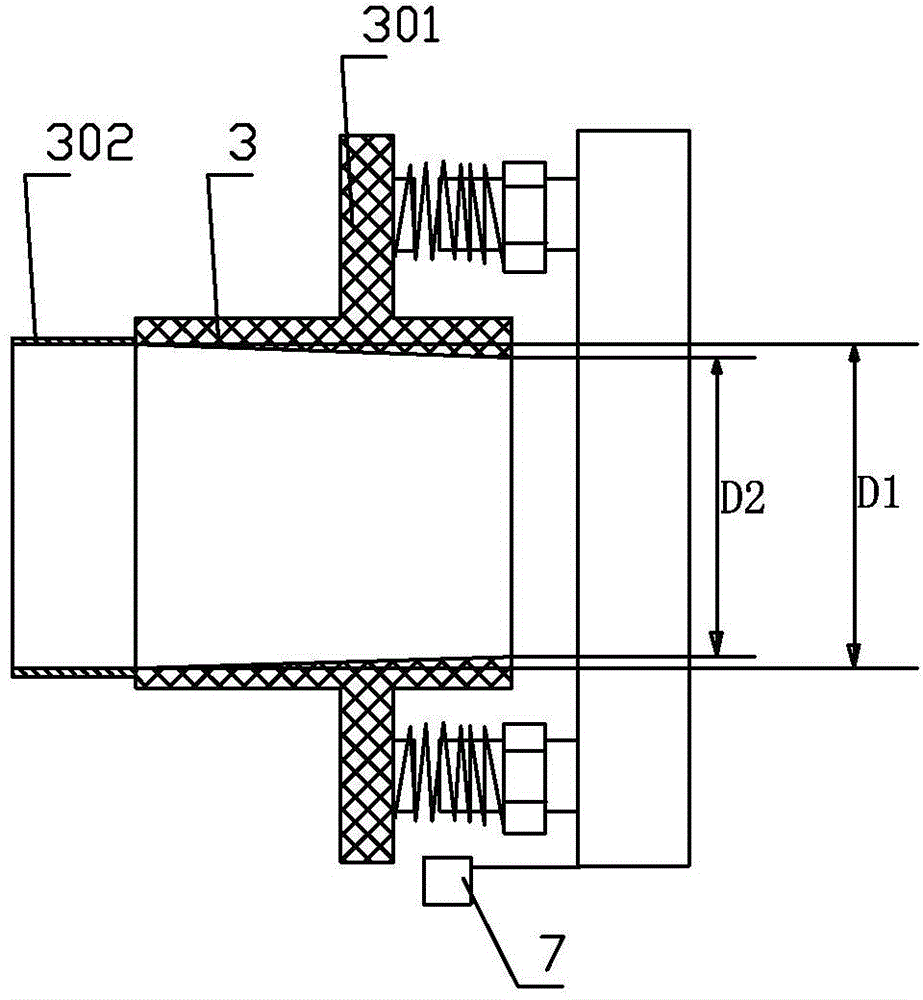

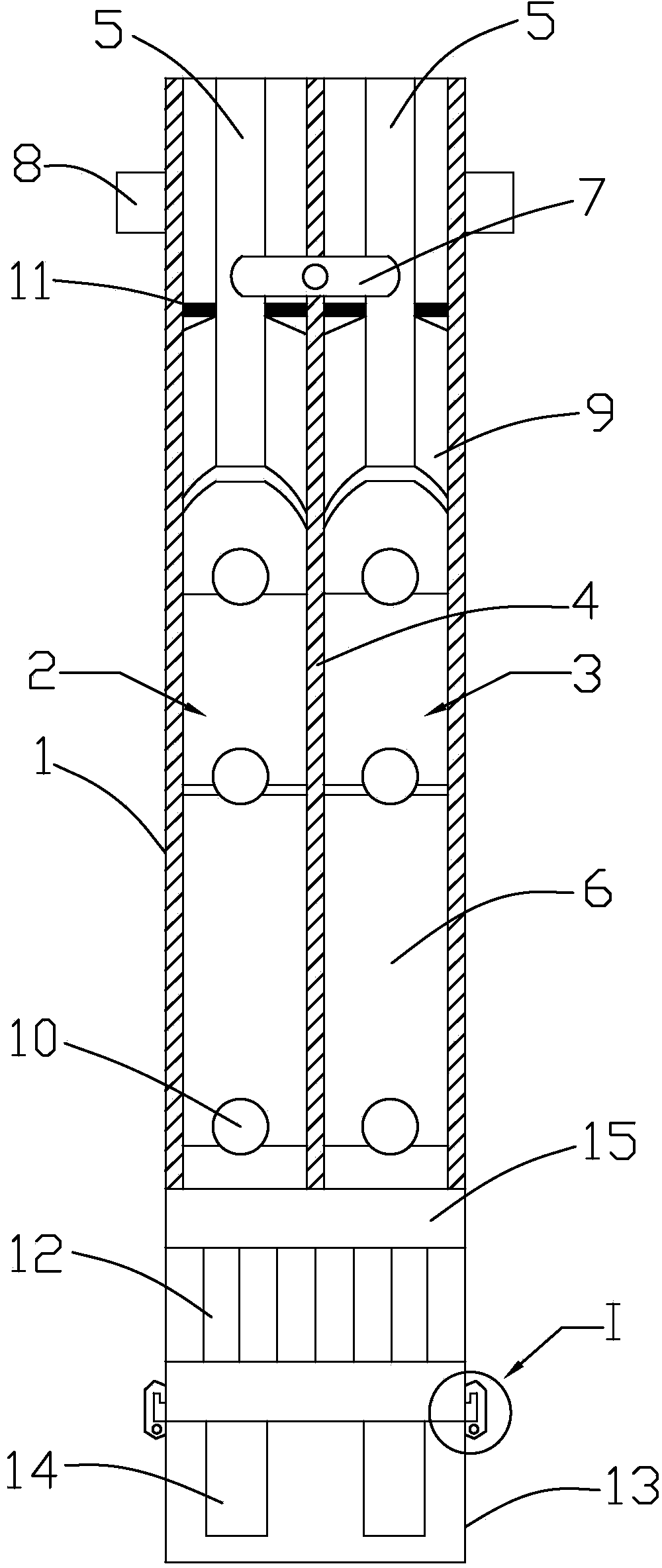

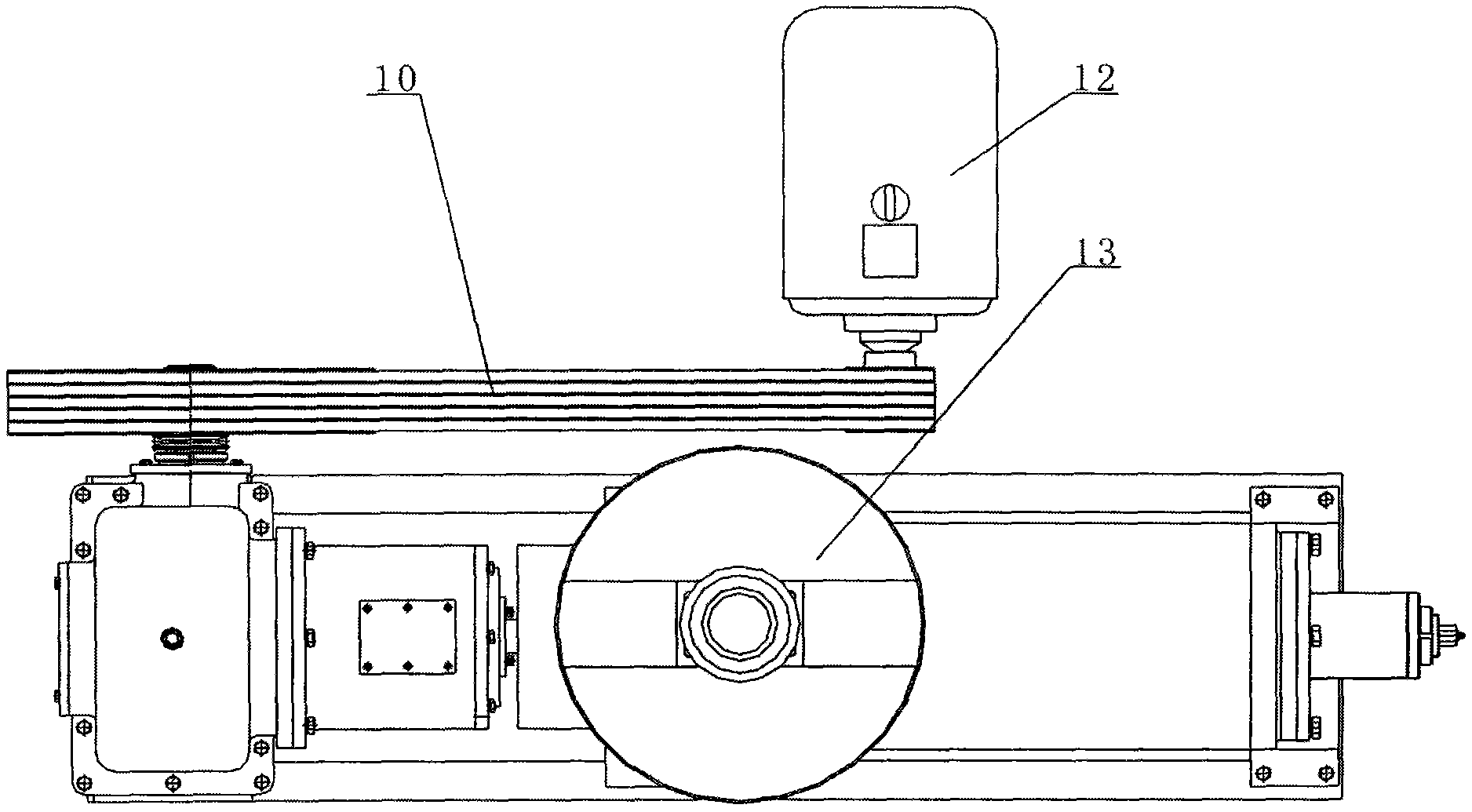

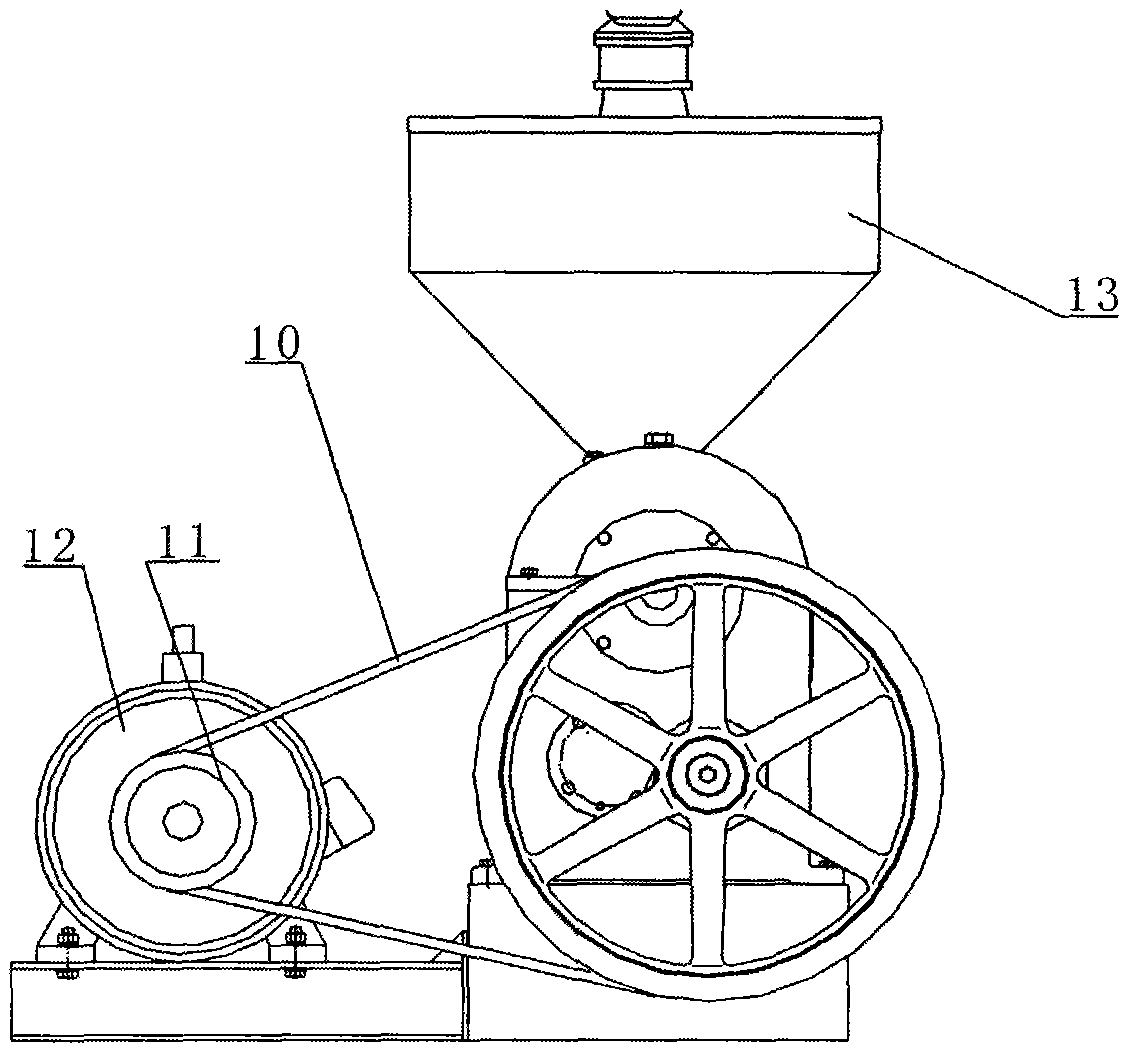

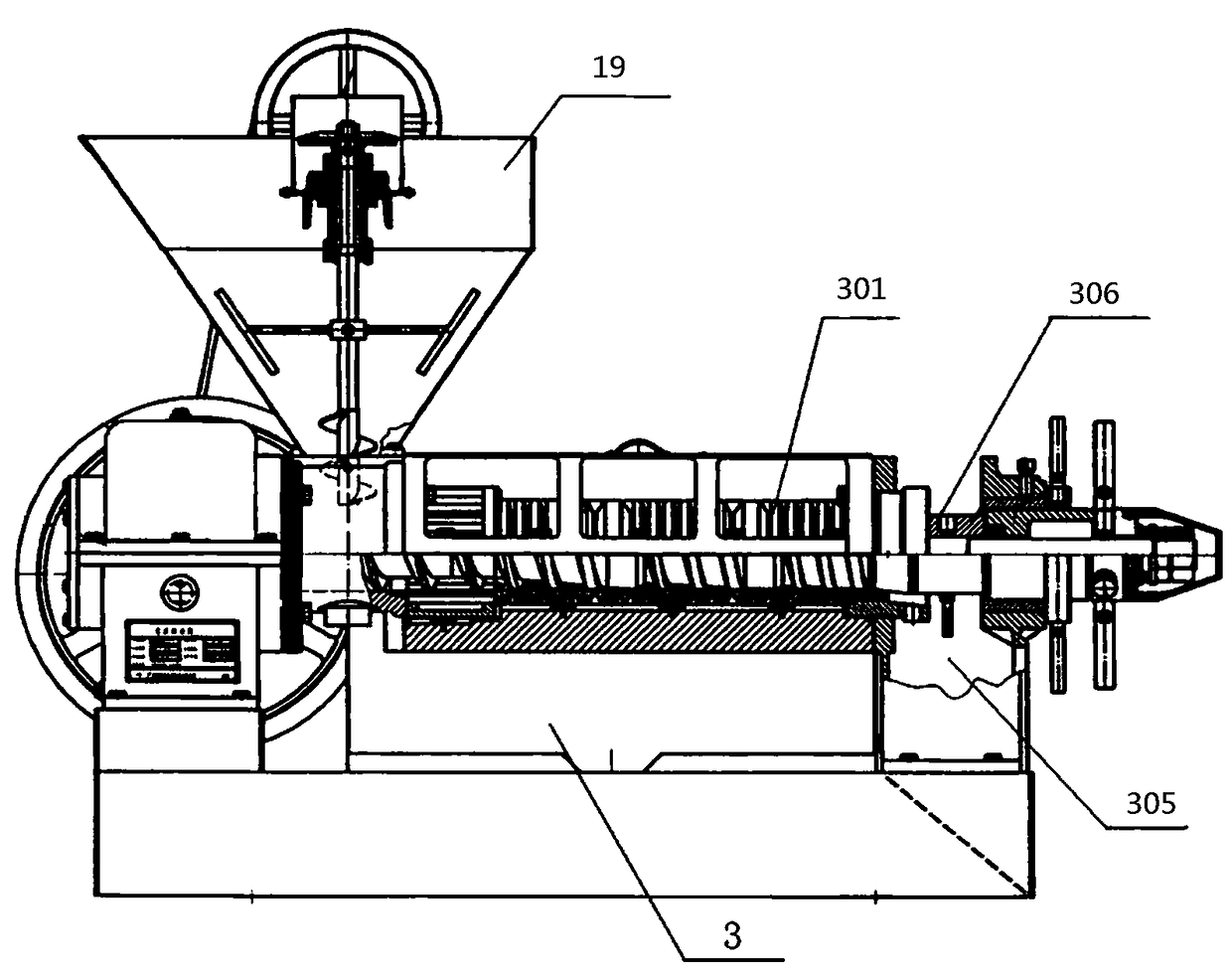

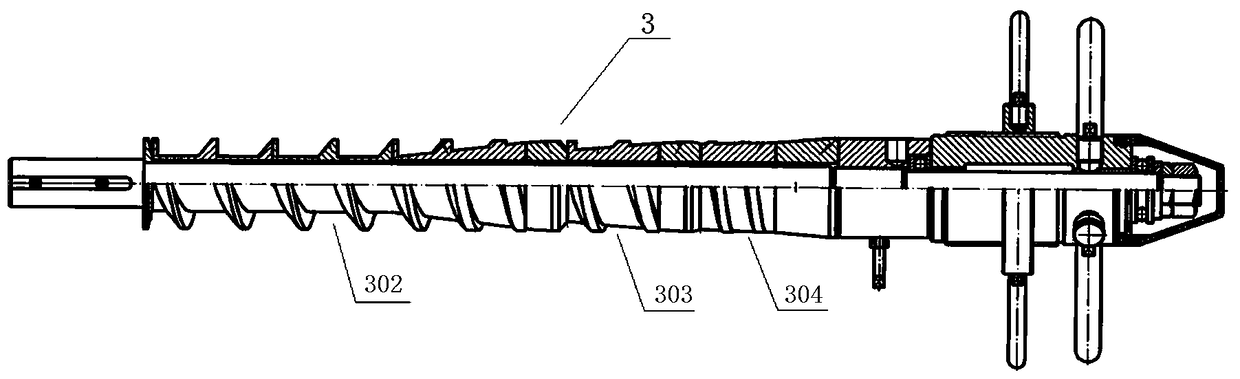

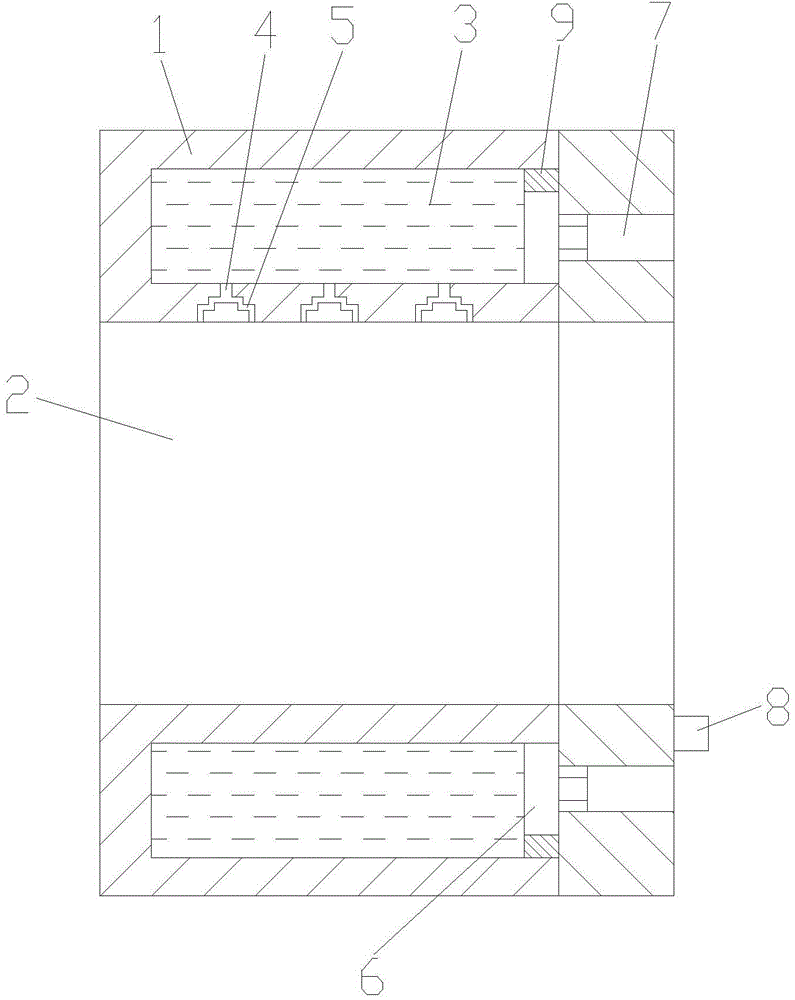

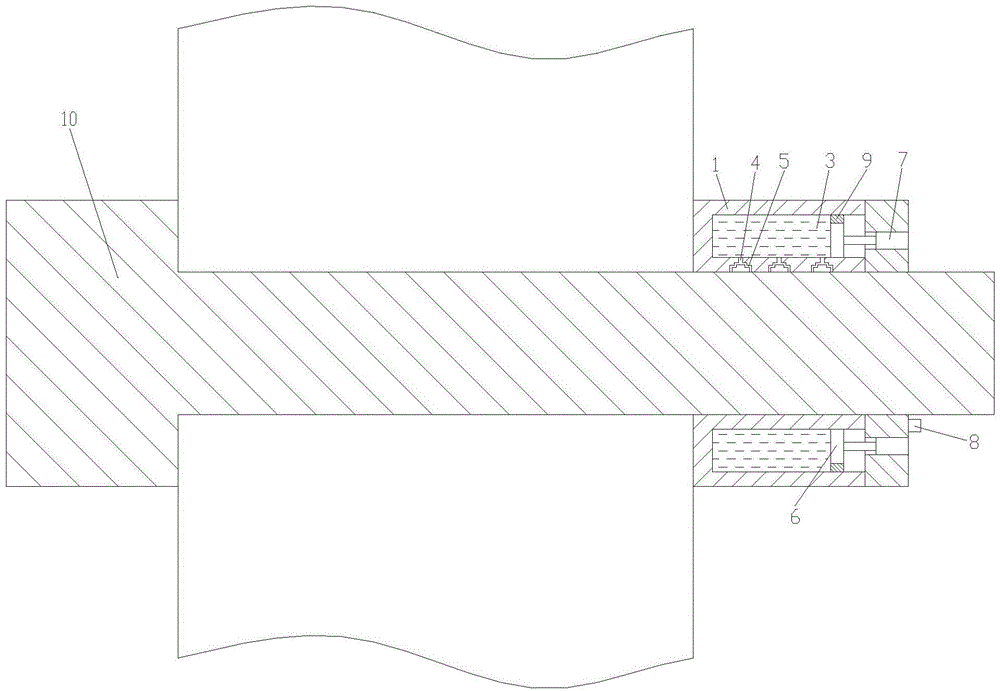

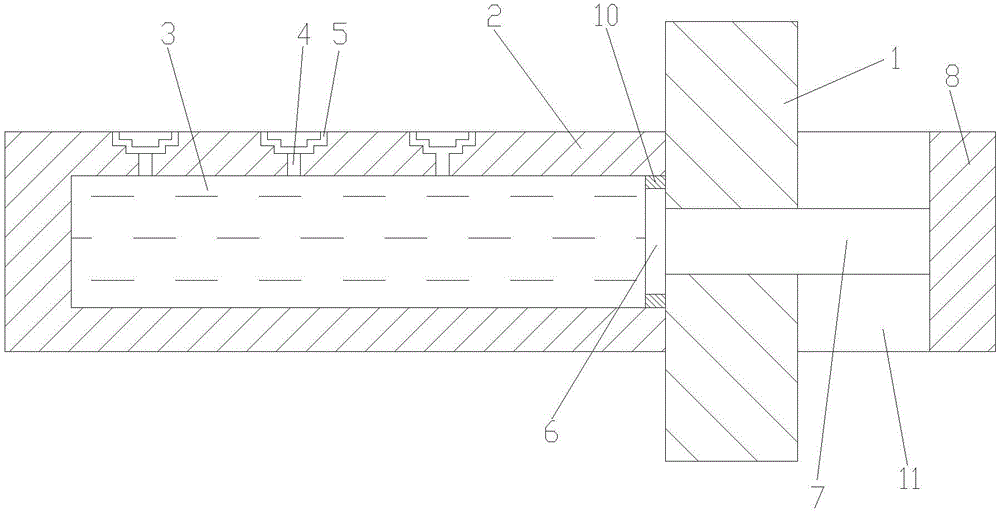

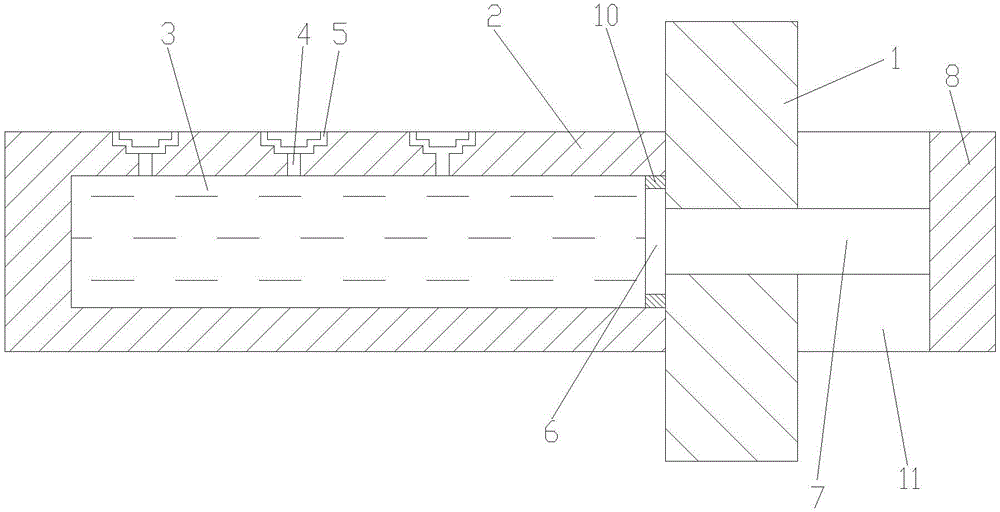

Pressing mechanism automatically applicable to multiple materials

ActiveCN105252799AOvercome inability to workImprove oil output efficiencyPressesDynamic balanceEngineering

The invention discloses a pressing mechanism automatically applicable to multiple materials. The portion, located outside a pressing cavity, of a cylinder part is provided with a stress part; the portion, corresponding to the stress part, of a machine frame is provided with a horizontal adjusting column; a spring is arranged on the adjusting column; one end of the spring ejects the stress part; the other end of the spring ejects an adjusting nut rotationally screwed on the adjusting column through threads. The caliber of the inner wall of the inner end of the cylinder part is larger than that of the inner wall of the outer end of the cylinder part, and the caliber of the inner wall, from the inner end of the cylinder part to the outer end of the cylinder part, of the cylinder part is gradually decreased; and the inner end of the cylinder part is provided with an outward extending part, and the extending part stretches into a pressing segment, and the outer wall of the extending part is matched with the inner wall of the pressing segment. According to the pressing mechanism, the cylinder part moves to achieve dynamic balance, and the problems that the oil outflow efficiency is low in the oil pressing process, the pressing mechanism possibly cannot work if the oil outflow efficiency is forcibly improved, or even a motor breaks down are solved. The pressing mechanism is high in oil outflow efficiency, the pressing efficiency is high, and the machine can not be damaged.

Owner:浙江国丰油脂有限公司

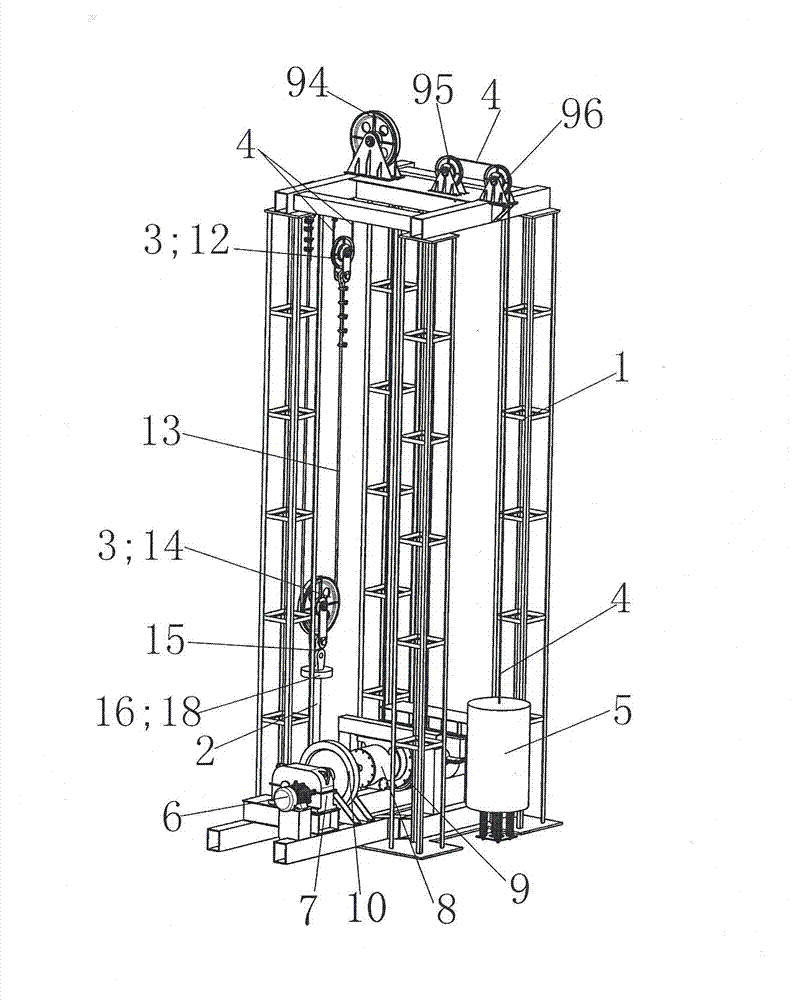

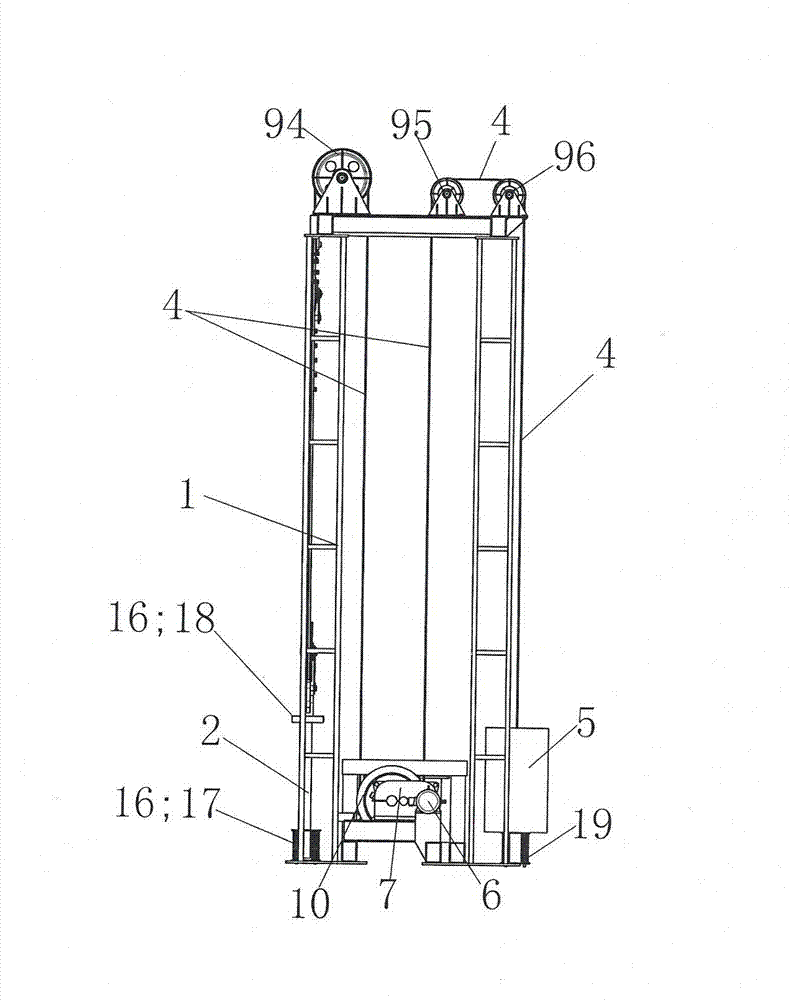

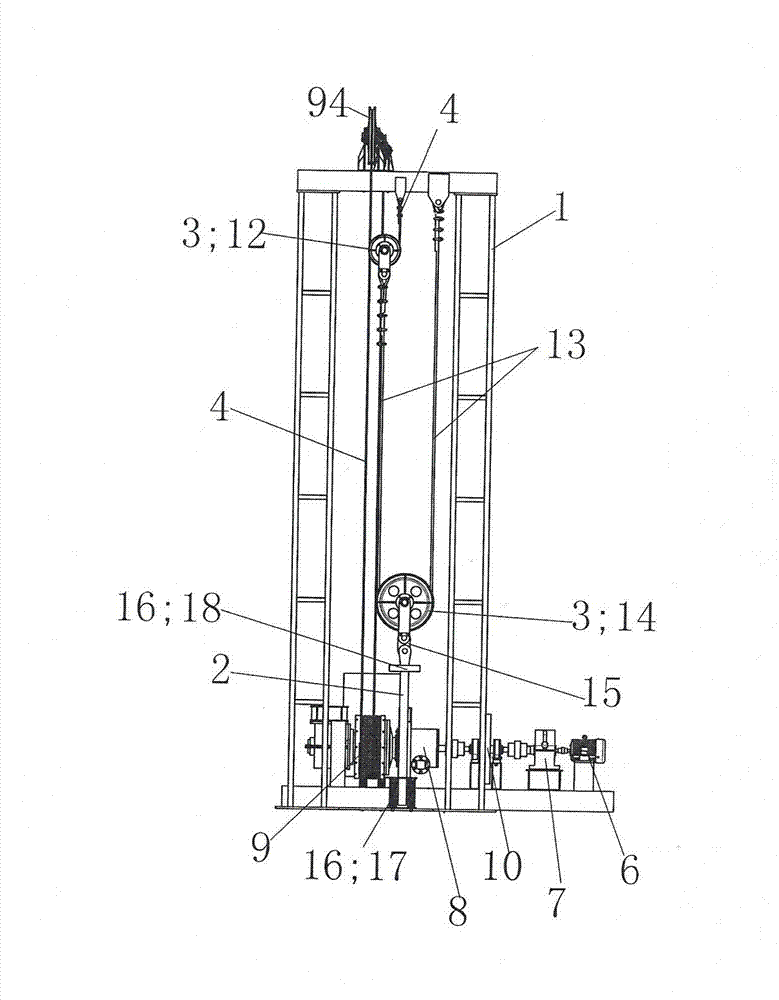

Efficient energy-saving oil pumping machine

The invention discloses an efficient energy-saving oil pumping machine, which comprises a derrick, an oil pumping rod, a movable pulley set, a hanging rope, a drive motor, a reversing lifting device and a winding drum, wherein the derrick is erected on an oil well; the drive motor, the reversing lifting device and the winding drum are arranged at the bottom of the derrick; the hanging rope is wound on the winding drum; one end head of the hanging rope is fixed at the top of the derrick through bypassing a first fixed pulley and the movable pulley set arranged at the top of the derrick; the other end head of the hanging rope bypasses a second fixed pulley and a third fixed pulley arranged at the top of the derrick to hang a counterweight; a hanging chain is hung on the movable pulley set; the oil pumping rod is hung to the lower end of the hanging chain; an output shaft of the drive motor is connected with an input shaft of the reversing lifting device; and the winding drum is connected with an output shaft of the reversing lifting device. According to the efficient energy-saving oil pumping machine, the drive motor rotates in one direction all the time, and the rotation direction of the winding drum is automatically changed by the reversing lifting device according to the ascending and descending programs of the oil pumping rod, so that the energy loss of the drive motor, a speed reducer and a flywheel in the reversing process is avoided.

Owner:宋嗣新

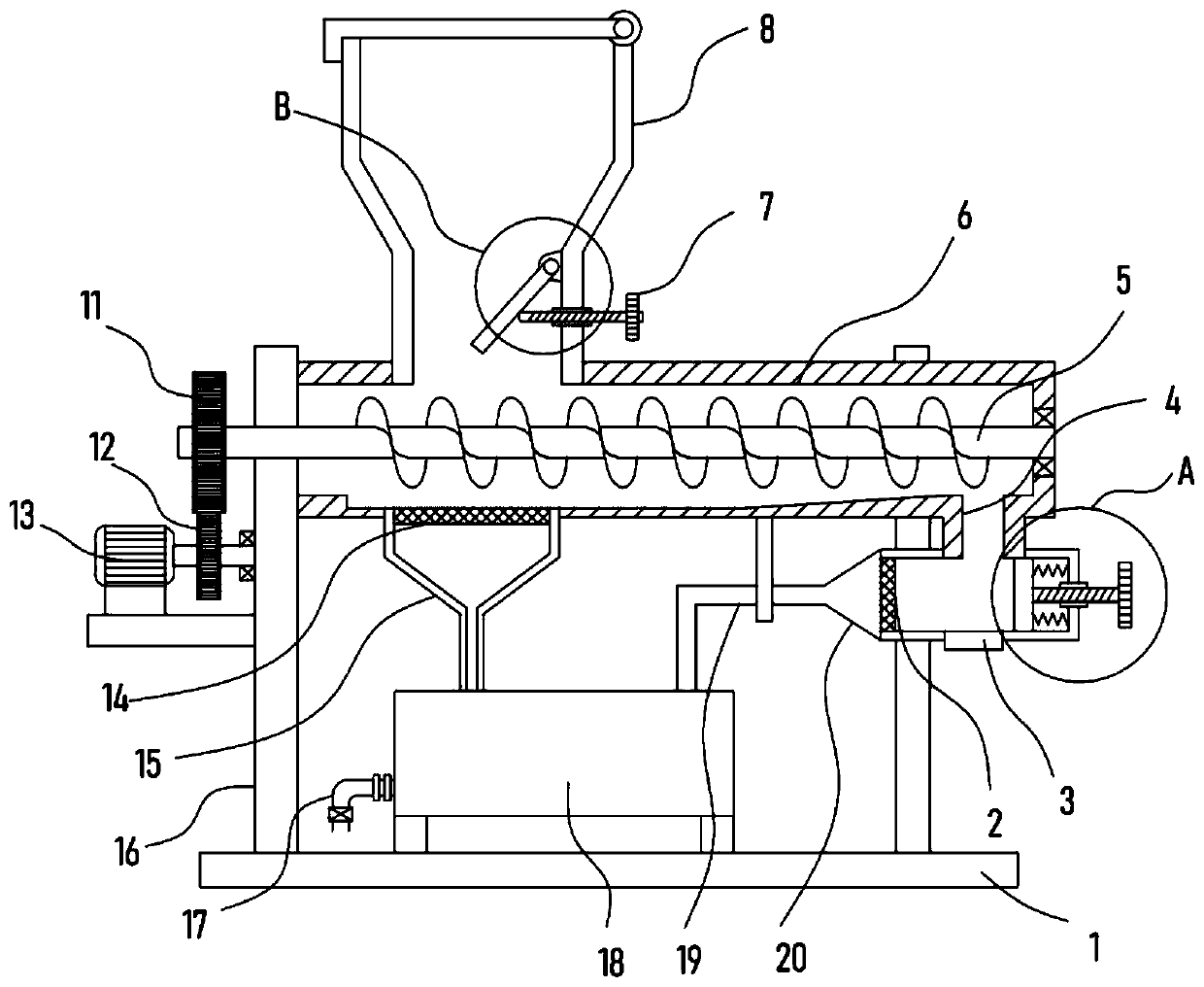

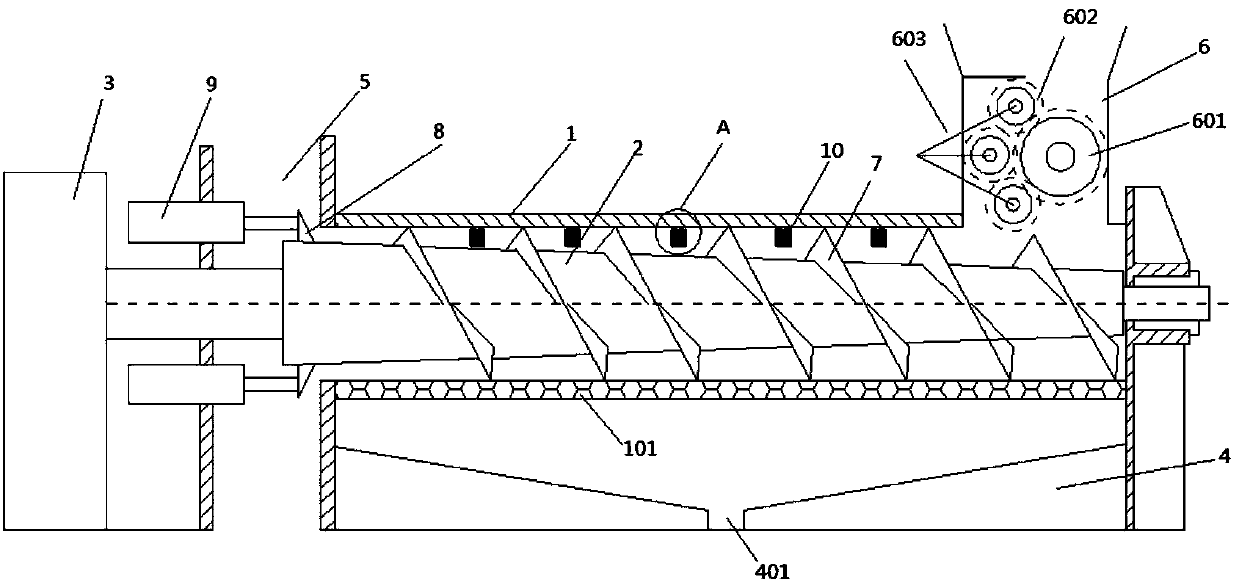

Peanut oil extracting device for processing peanut oil

InactiveCN109878132AIncrease profitImprove the extrusion effectFatty-oils/fats productionPressesFuel tankPulp and paper industry

The invention discloses a peanut oil extracting device for processing peanut oil, and relates to the technical field of peanut oil processing. The peanut oil extracting device comprises a bottom plate, wherein a supporting frame is fixedly arranged on the bottom plate, and an oil extracting cylinder is horizontally and fixedly arranged on the supporting frame; and the peanut oil extracting deviceis characterized in that an extracting screw rod I driven to rotate by a driving motor is rotatably arranged in the oil extracting cylinder, an oil collecting tank in communication with an oil collecting hopper is fixed on the bottom plate, an oil discharging pipe is arranged on the lower side wall of the oil collecting tank, and a discharging box in communication with the oil extracting cylinderis arranged on the oil extracting cylinder. According to the peanut oil extracting device, through the synchronous rotation of the arranged extracting screw rod I and an extracting screw rod II, shelled peanuts in the oil extracting cylinder are subjected to novel extrusion oil extraction, the extrusion effect of the peanuts is better, and the oil extraction efficiency is greatly improved; and peanut crumbs obtained after the oil extraction can be conveyed into a piston cylinder through the conveying of the extracting screw rod I and the extracting screw rod II and subjected to the extrusion effect of a piston pressing plate, so that the secondary oil extraction effect is realized, and the oil in the shelled peanuts can be fully extracted.

Owner:安庆市汇智科技咨询服务有限公司

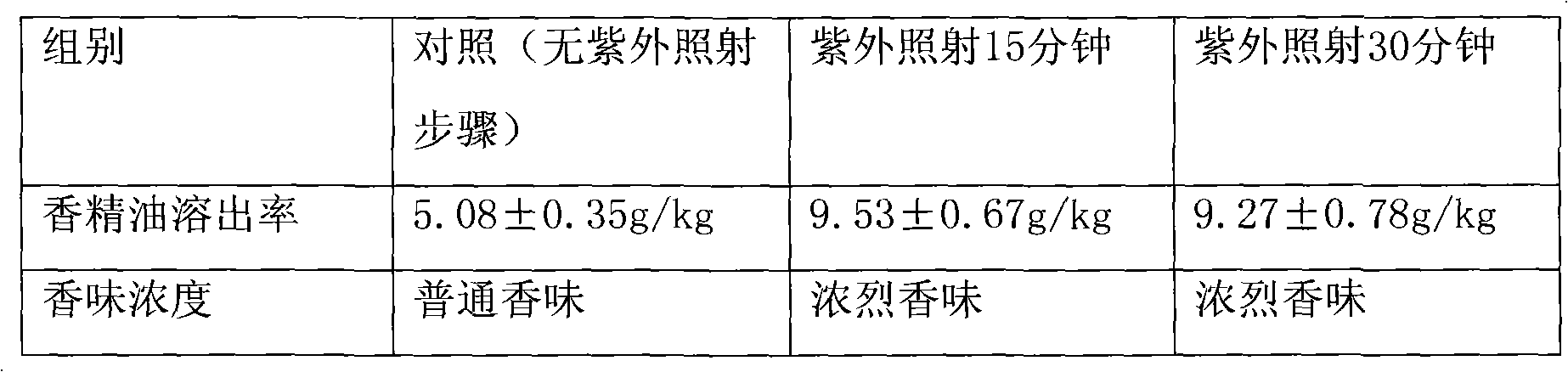

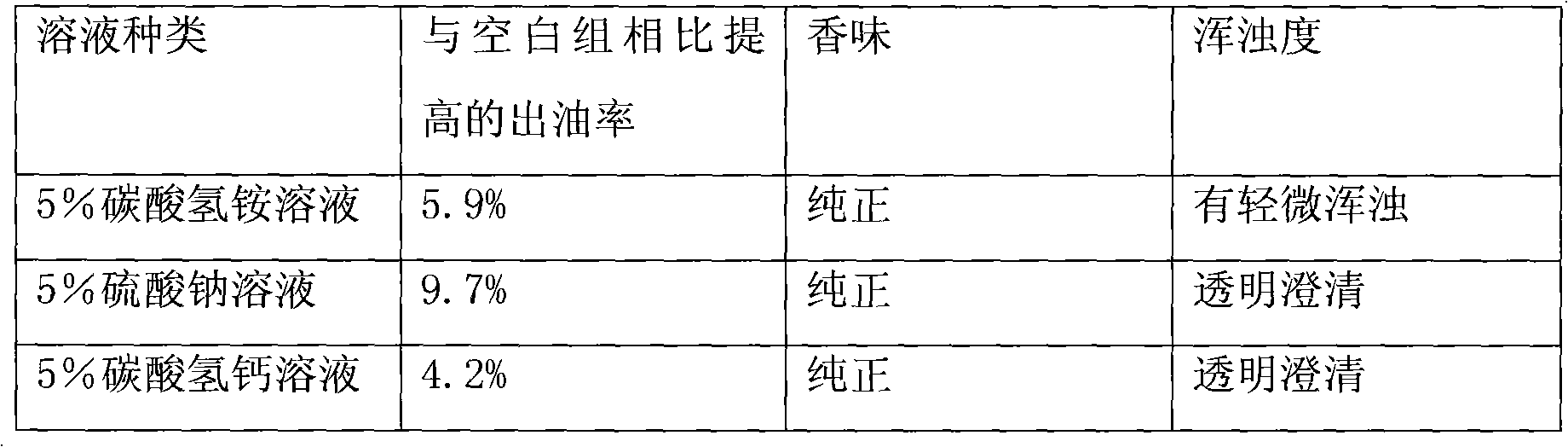

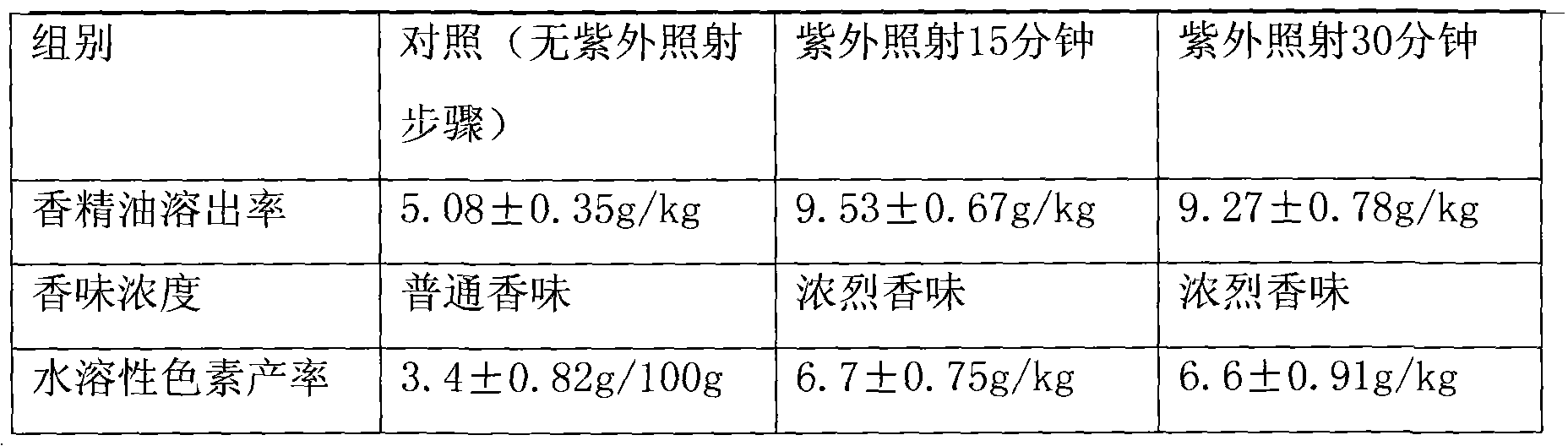

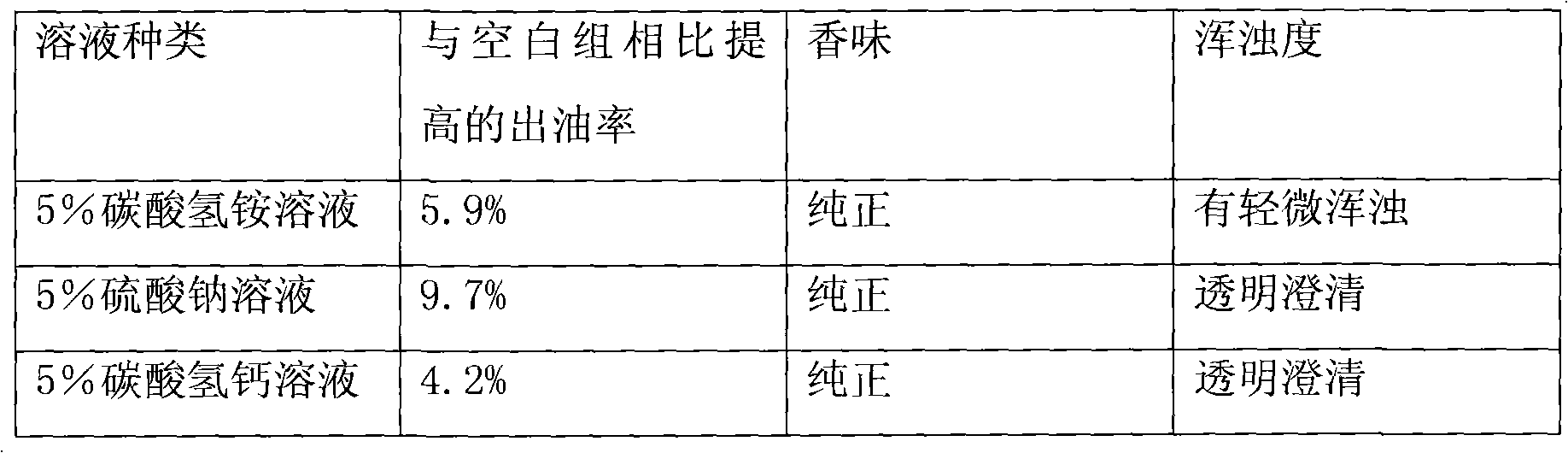

Method for extracting essential oil from orange peel

ActiveCN102796618AImprove oil output efficiencyEssential-oils/perfumesUltraviolet irradiationExtraction methods

The invention relates to a technology for extracting essential oil from a plant, and particularly relates to a preparation technology for extracting essential oil from an orange peel. The technology improves and optimizes the conventional extraction method in the prior art, boldly adopts the steps such as ethanol treatment, ultraviolet irradiation, salt ion aging and the like, and effectively combines and optimizes reaction parameters, thereby greatly improving the production efficiency of essential oil and having wide application prospects.

Owner:北京碧优雅韵科技有限公司

Squeezing mechanism for oil press

The invention discloses a squeezing mechanism for an oil press. A part of a cylinder part positioned outside a barrel is provided with a stress part; a horizontal adjusting column is arranged on a frame corresponding to the stress part; a spring is arranged on the adjusting column; one end of the spring is pressed against the stress part; the other end of the spring is pressed against an adjusting nut which is in threaded connection with the adjusting column; the aperture of the inner wall of the inner end of the cylinder part is greater than the aperture of the inner wall of the outer end of the cylinder part; the aperture of the part of inner wall between the inner end of the cylinder part and the outer end of the cylinder part is reduced gradually; an outward extending part is arranged at the inner end of the cylinder part; the extending part extends into a squeezing segment; the outer wall of the extending part is matched with the inner wall of the squeezing segment. Dynamic balance to the working situation is realized through the movement of the cylinder part, and the problem of failure in working of the squeezing mechanism or even damage to a motor due to poor oil discharge efficiency occurring in an oil squeezing process and forced increase of the oil discharge efficiency is solved. The squeezing mechanism has high oil discharge efficiency and high squeezing efficiency, and does not damage any machine.

Owner:河北宏润油脂工业有限公司

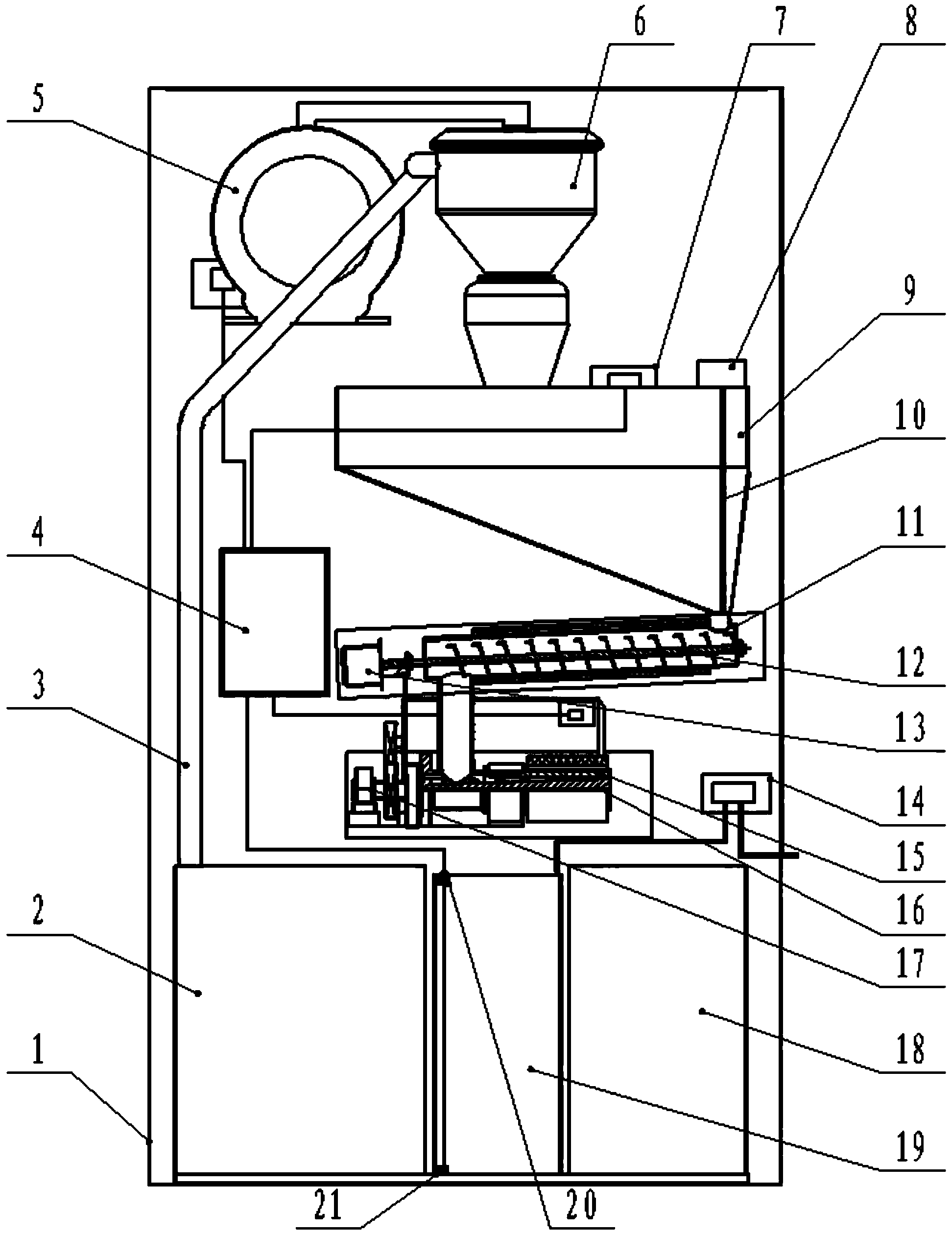

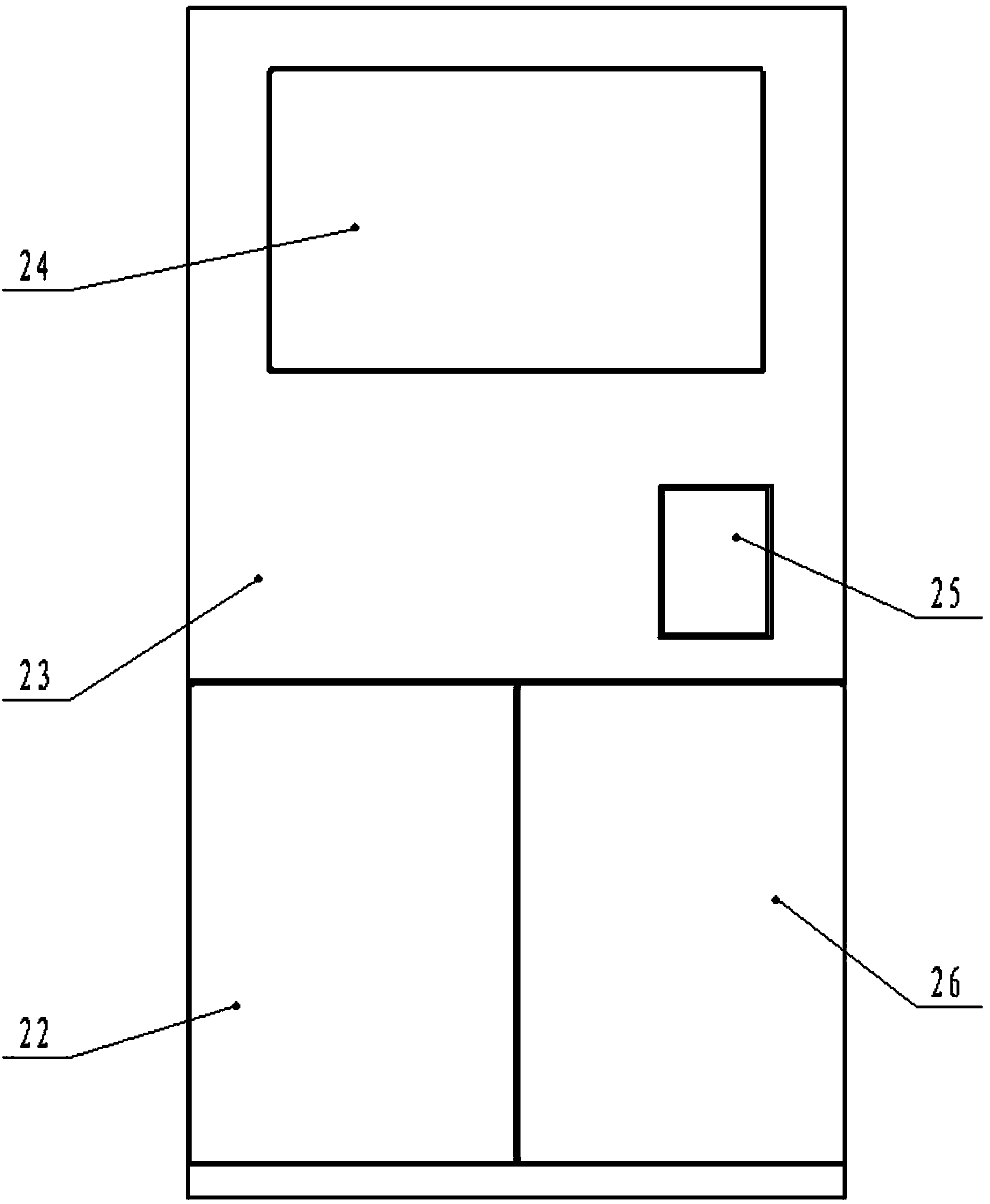

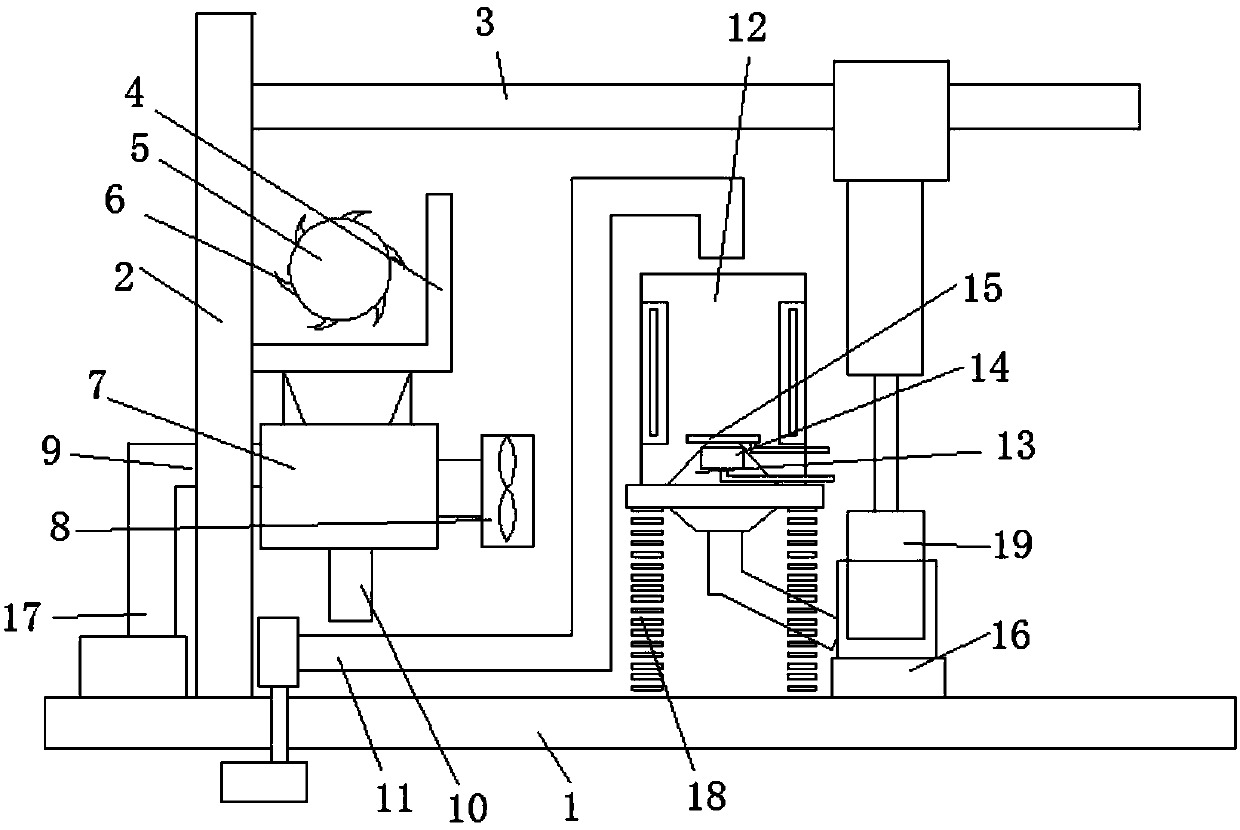

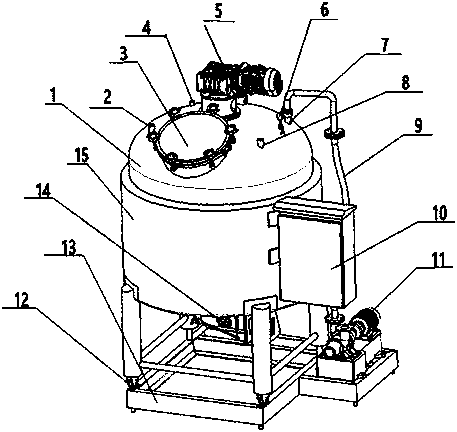

Commercial squeezing device

The invention discloses a commercial squeezing device. The commercial squeezing device comprises a box body, a feeding system, a control system, a drying and squeezing system, an oil collecting barrel and an oil residual barrel, wherein the feeding system comprises a storage barrel, a suction barrel and a suction fan, the drying and squeezing system comprises a feeding hopper and a squeezer, a feed inlet of the feeding hopper is connected with an outlet of the suction barrel in the feeding system, a discharge outlet of the feeding hopper is connected with an inlet of the squeezer, the control system comprises a control center, an automatic feeding control device, a drying and squeezing control device and an oil storage control device, and the automatic feeding control device, the drying and squeezing control device and the oil storage control device are connected with the control center through wires respectively. According to the commercial squeezing device, a mechanical appliance and an electronic appliance are integrated according to the ergonomic principle, the device is more user friendly, oil squeezing can be achieved through one key, the oil squeezing efficiency is high, the device can work continuously for a long time, and the requirement of people for edible oil is met.

Owner:润桐(苏州)技术服务有限公司

Improved regeneration technique for decolorizing and deodorizing waste tyre oil and method for preparing diesel fuel thereof

InactiveCN101659878AIncrease contact reaction areaDouble catalysisCatalytic crackingTreatment with plural serial stages onlyEngineeringPower performance

The invention discloses an improved regeneration technique for decolorizing and deodorizing waste tyre oil and a method for preparing diesel fuel thereof, which comprise the following steps: a, mixing 100 parts of waste tire oil, 1-8 parts of hydrogen peroxide and 1-5 parts of core catalyst, and reacting for 2-5 hours after mixing, wherein the core catalyst is the mixture of at least two components selected from Fe2O3, Al2O3, SiO2 and MnO2; b, adding anhydrous materials at the upper layer after reaction in the step a to a reaction kettle, adding the core catalyst, heating, and extracting distillate at 365 DEG C under the normal pressure or at 280-300 DEG C under 0.09 MPA negative pressure; c, adding concentrated sulphuric acid to the distillate obtained in the step b, stirring, adding argil for precipitating, and filtering by a filter press or filter sands to obtain pale yellow primary diesel oil; and d, preparing the primary diesel oil obtained in the step c to a desired type of diesel oil. Compared with the prior art, the invention adopts a more improved reaction principle, and the product oil prepared by the method has the advantages of pale yellow color, stable quality, favorable evaporability and power performance, low temperature flow property, non-corrosiveness, and the like; furthermore, the product oil has the advantage of preparing the diesel oil by mixing with the traditional fossil diesel oil or other fuel diesel oils according to any proportion.

Owner:刘新宇

Blowout prevention oil well pump for oil field

InactiveCN104358677AImprove continuityImprove oil recovery efficiencyPositive displacement pump componentsFlexible member pumpsEconomic benefitsOil field

The invention discloses a blowout prevention oil well pump for an oil field, which comprises a pump body, wherein the pump body is internally provided with an oil pumping mechanism and a blowout prevention device; the oil pumping mechanism comprises a first oil pumping part and a second oil pumping part; the second oil pumping part comprises a second oil pumping device, an oil pipe and a pump cylinder; the first oil pumping device and the second oil pumping device comprise plungers and valve rods; oil-collecting hoods are arranged at the tops of the plungers; a connection bracket is arranged between every two adjacent valve rods and comprises a rotation support block, a telescopic connecting rod and a locating block; and the blowout prevention device comprises a housing; the housing is internally provided with a one-way guide plate; a buffer plate is arranged on the one-way guide plate; and an oil nipple and a filter screen are arranged at the bottom of the pump body. The oil recovery efficiency of the oil well pump is improved, continuous oil recovery is realized, simultaneous oil production of the double valve rods is realized, the oil production efficiency is improved, the oil recovery cost is lowered, and the economic benefit is significant.

Owner:HANGZHOU HELLER SCI & TECH

Method for preparing oil by low aqueous enzymatic method and organic solvent extraction

InactiveCN102181321ALow residual oil rateRaise the denaturation rateFatty-oils/fats productionPectinaseOrganic solvent

The invention discloses a method for preparing oil by a low aqueous enzymatic method and organic solvent extraction. The method comprises the following steps of: based on 100 Kg of oil plants, dissolving 0.5 to 3.0 Kg of complex enzyme which comprises cellulolytic enzyme, pectinase, protease, and flavourzyme in a ratio of 2 to 3 to 4 to 3 in 40 to 70L of buffer solution with the pH value of 5.0 to 7.0 to obtain enzyme solution; cleaning the oil plants and removing impurities, crushing and sieving, wherein the particle diameter is 40 to 80 meshes; spraying the enzyme solution onto the crushed oil plants, stirring uniformly, and reacting at the constant temperature of between 40 and 55 DEG C for 2 to 4 hours; placing the reacted materials in a drying oven at the temperature of between 40 and 65 DEG C and drying for 2 days; hardening and tempering the materials to ensure that the moisture content is kept to be 3+ / -5 percent; and extracting the dried, hardened and tempered materials by anorganic solvent at the temperature of between 50 and 70 DEG C for 1 to 2 hours to obtain the extraction oil and egg oil material cakes. The method is high in oil yield, and the obtained oil and cake have high quality.

Owner:GUIZHOU UNIV

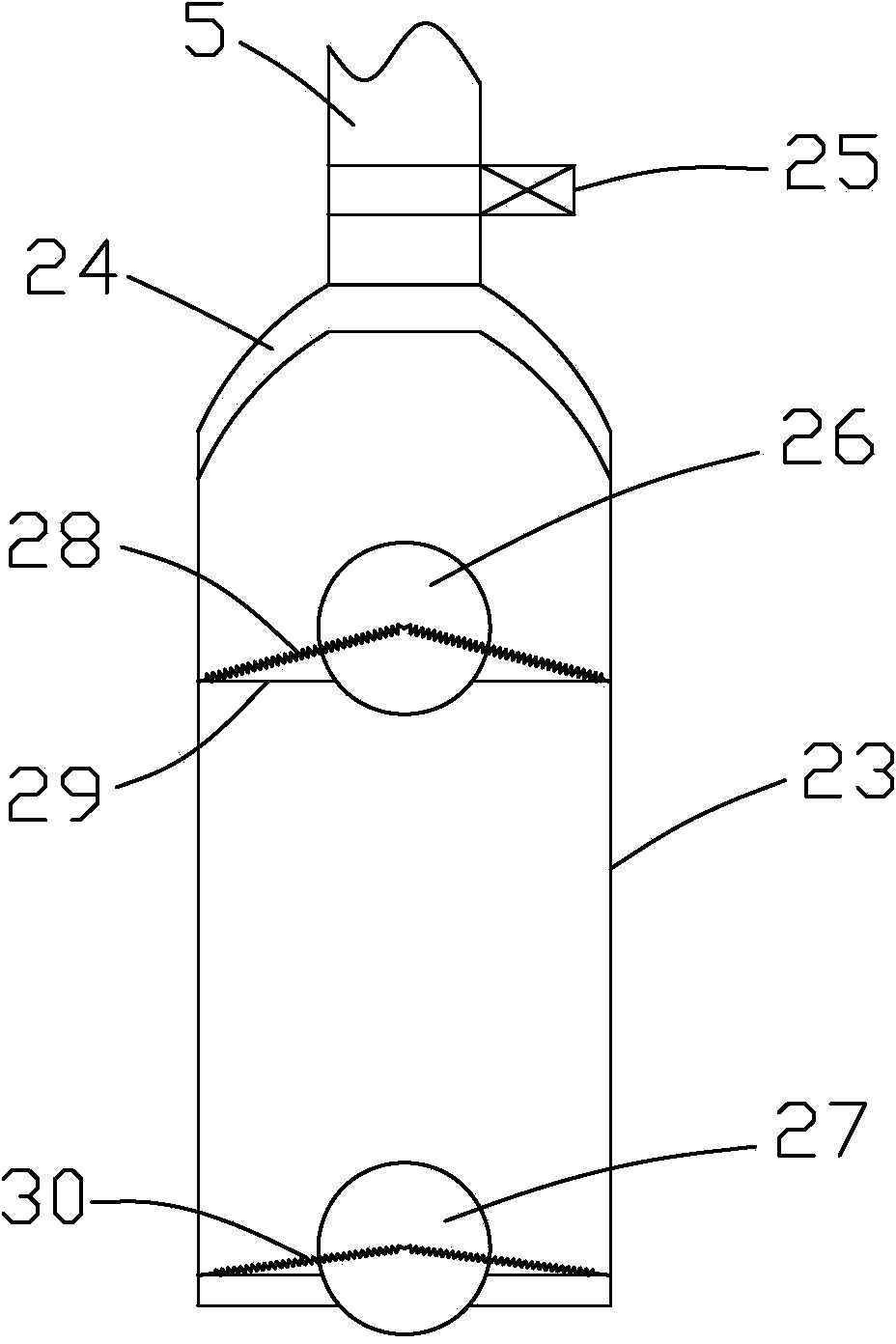

Emen trichosanthis oil extracting device with pretreatment device

PendingCN107553957AEasy to removeIncrease temperatureFatty-oils/fats productionGrain treatmentsFiltrationAgitator

The invention provides an emen trichosanthis oil extracting device with a pretreatment device. The emen trichosanthis oil extracting device with the pretreatment device comprises a shell, a rotating shaft and a driving device, wherein the two ends of the rotating shaft are rotatably arranged on the shell by a bearing assembly; a plurality of uniformly distributed filtration holes are formed in thelower end of the shell; the upper end of the shell is formed by curved plates; an oil collecting tank is arranged at the lower end of the shell; a discharging groove is formed in the rear end of theshell, and a feeding groove is formed in the front end of the shell; the pretreatment smashing device is arranged in the feeding groove; the diameter of the rotating shaft gradually increases from thefront end to the rear end; and a plurality of spiral stirrers are arranged around the rotating shaft. The emen trichosanthis oil extracting device with the pretreatment device has the beneficial effects that oil materials enter a barrel from a hopper and are spirally pushed by the spiral stirrers arranged at the rotating shaft so as to be pressed; meanwhile, an annular baffle plate is arranged ata discharging opening, so that blanks friction with one another to cause the relative movement and increase the temperature of the interior of the barrel and improve the oil extracting efficiency; and the preliminary smashing effect of the materials is improved by arranging the pretreatment device in the feeding groove so as to facilitate follow-up feeding squeezing.

Owner:潜山县绿锦源农业发展有限公司

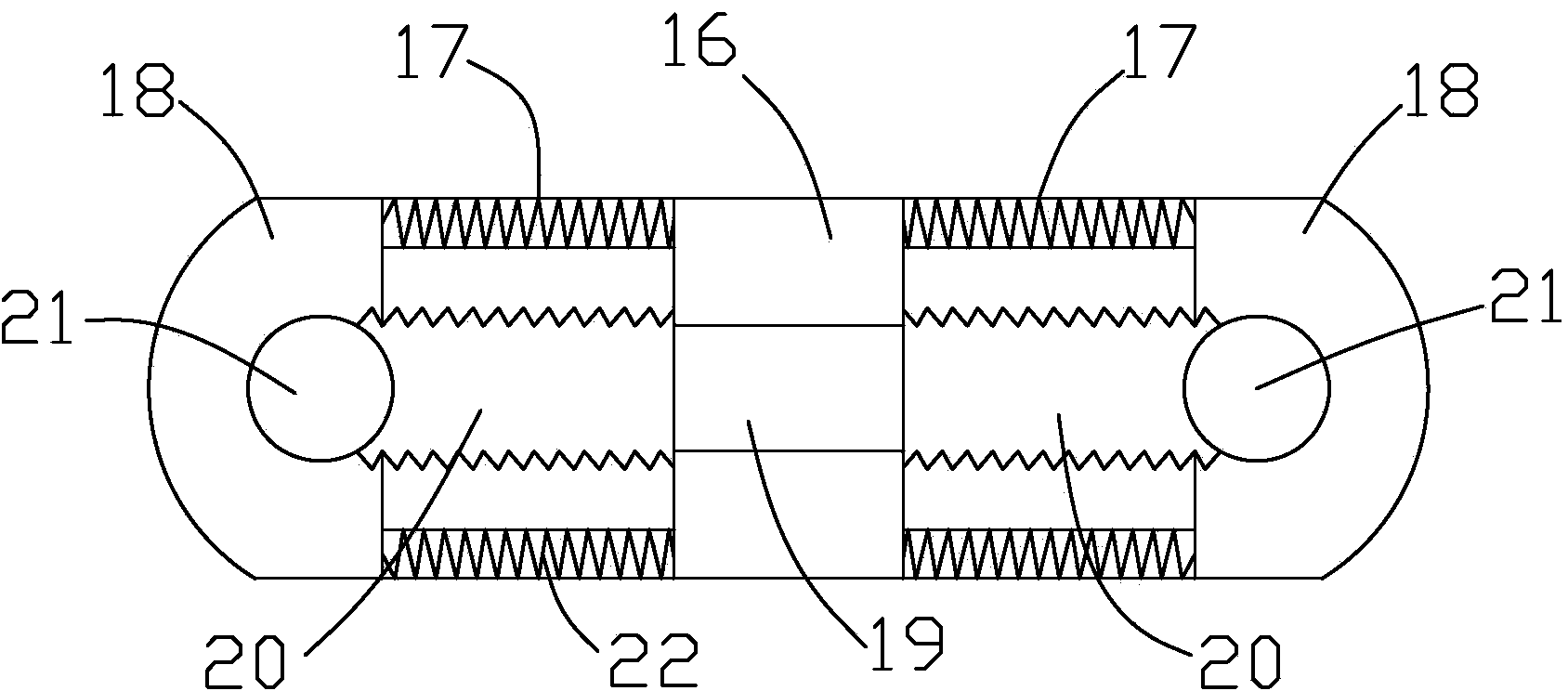

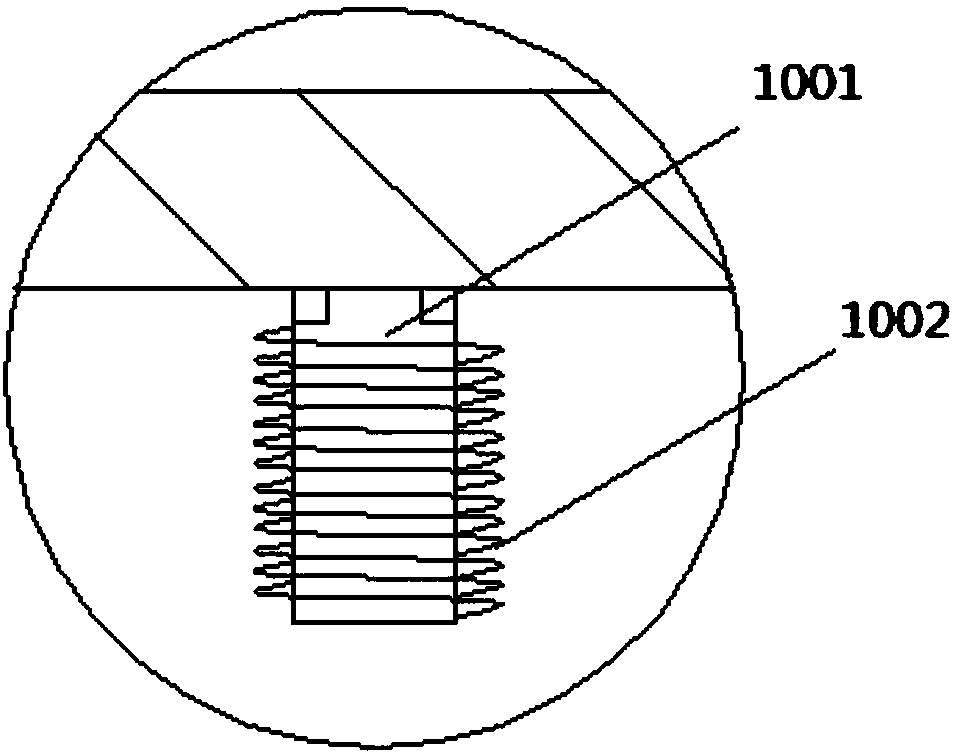

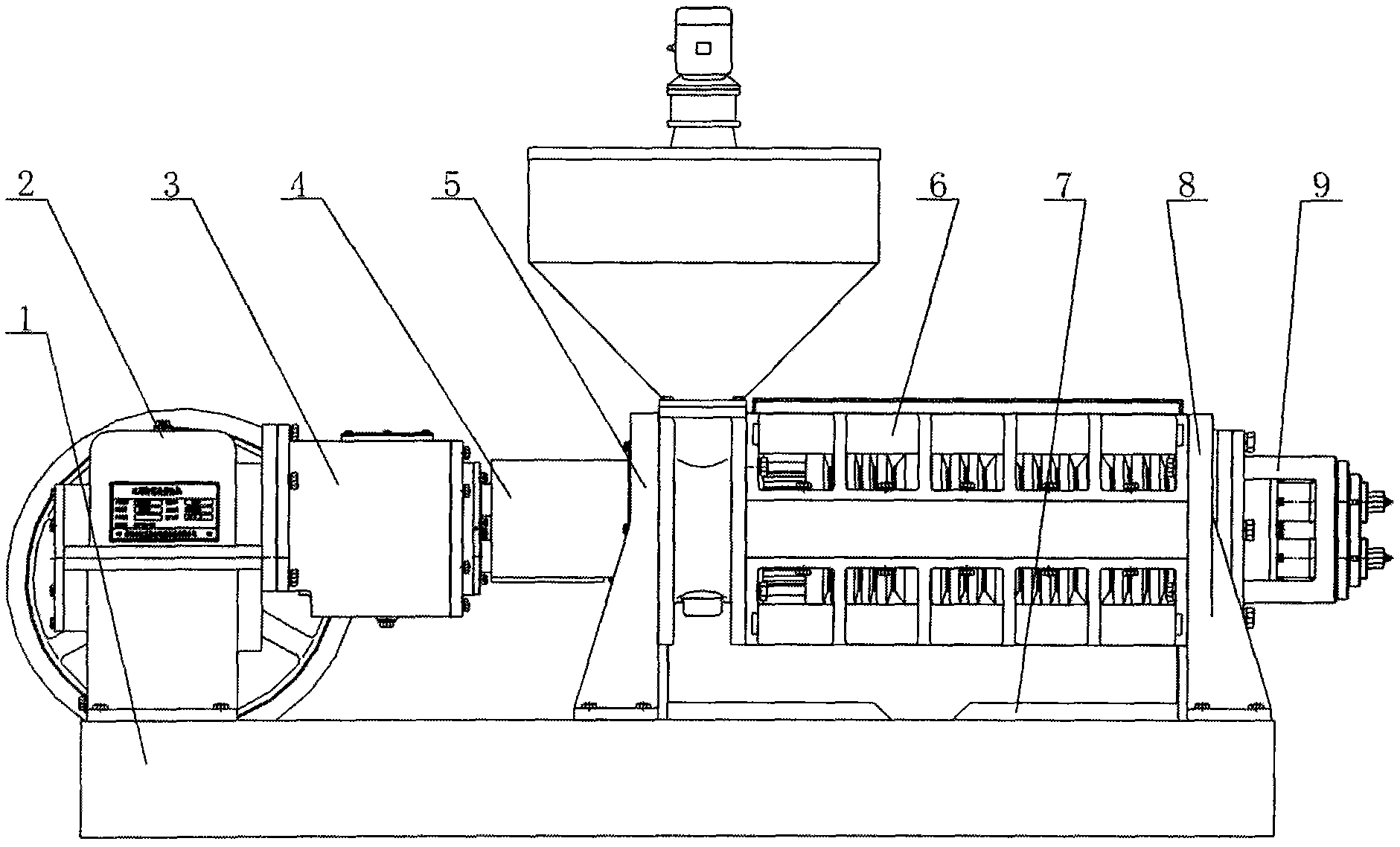

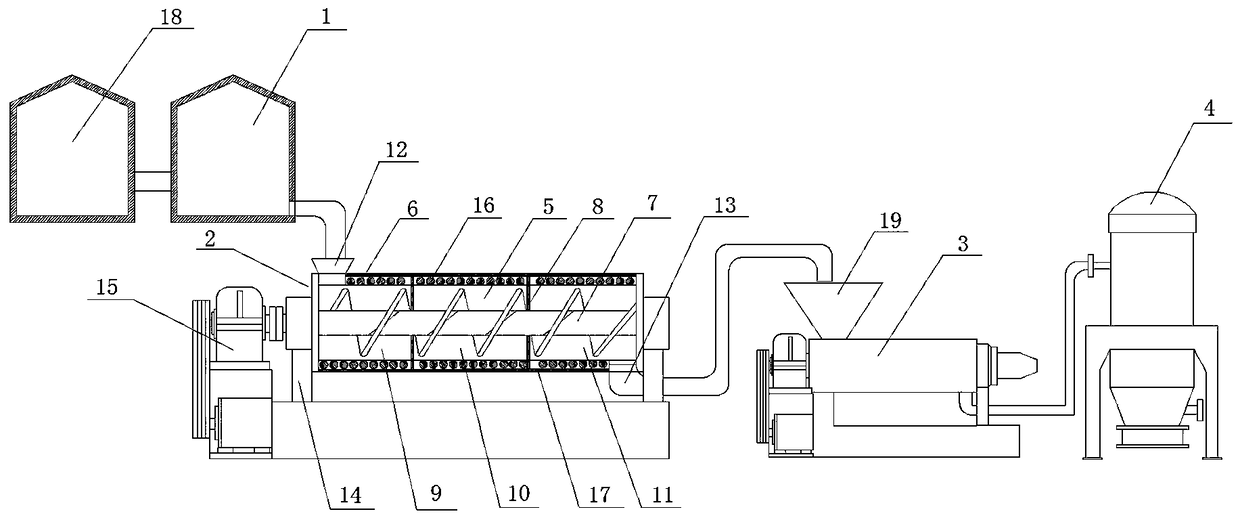

Pressing ring type double-screw spiral oil press

InactiveCN103895249AIncrease pressureImprove oil output efficiencyToothed gearingsPressesEngineeringRing type

The invention discloses a pressing ring type double-screw spiral oil press comprising a base, a motor mounted on the base, a transmission mechanism, a left support and a right support. The motor is connected to the transmission mechanism through a conveying belt. A pressing cage mechanism is mounted between the left support and the right support, an oil collecting plate is mounted below the pressing cage mechanism, and the tail of the pressing cage mechanism is provided with an oil cake regulating mechanism. A three-way feeding hole communicated with the pressing cage mechanism is formed in the left support, and the left support is provided with a feeding mechanism communicated with the three-way feeding hole. The pressing ring type double-screw spiral oil press is characterized in that the transmission mechanism is connected to a power distribution mechanism which is connected to the pressing cage mechanism; the pressing chamber of the pressing cage mechanism comprises a plurality of pressing rings mounted in a pressing cage; the end face of one side of the pressing ring is provided with a plurality of oil discharging grooves. The pressing ring type double-screw spiral oil press has the advantages that structure is simple, parts are few, equipment manufacturing cost is low, operation and maintenance can be performed simple and conveniently, and cold pressing and hot pressing can be performed both.

Owner:苟安富 +1

Method for extracting pigment from tangerine peel

ActiveCN102911514AIncrease productivityImprove oil output efficiencyEssential-oils/perfumesNatural dyesTangerine PeelUltraviolet irradiation

The invention relates to a technique for extracting pigment and essential oil from plants, particularly a preparation technique for extracting pigment and essential oil from tangerine peel. The technique improves and optimizes the conventional extraction method in the prior art, adopts the steps of ethanol treatment, ultraviolet irradiation, acetone extraction and the like, optimizes the reaction parameters, and greatly enhances the output efficiency of pigment and essential oil, thereby having wide application prospects.

Owner:遂川万力电子科技有限公司

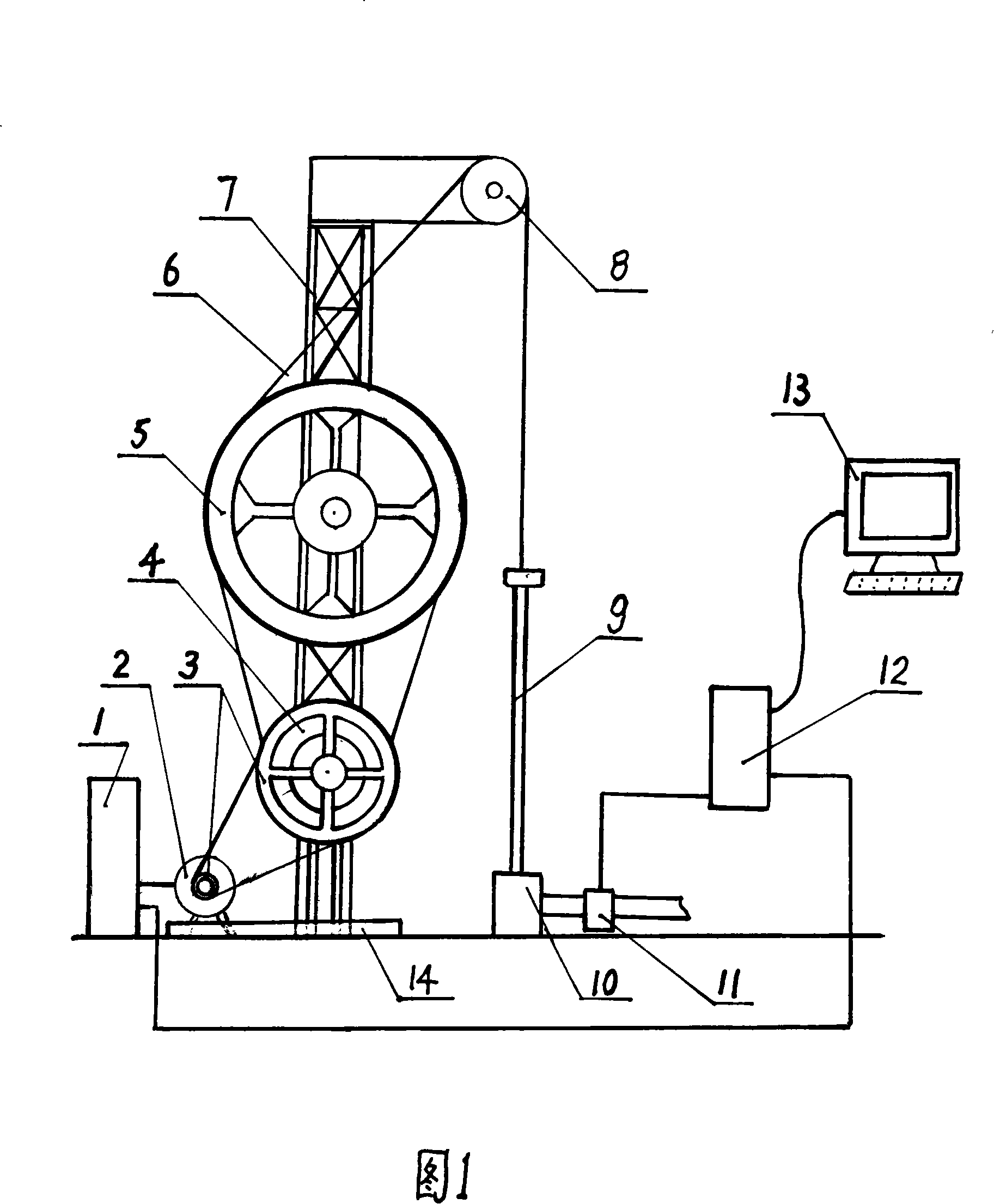

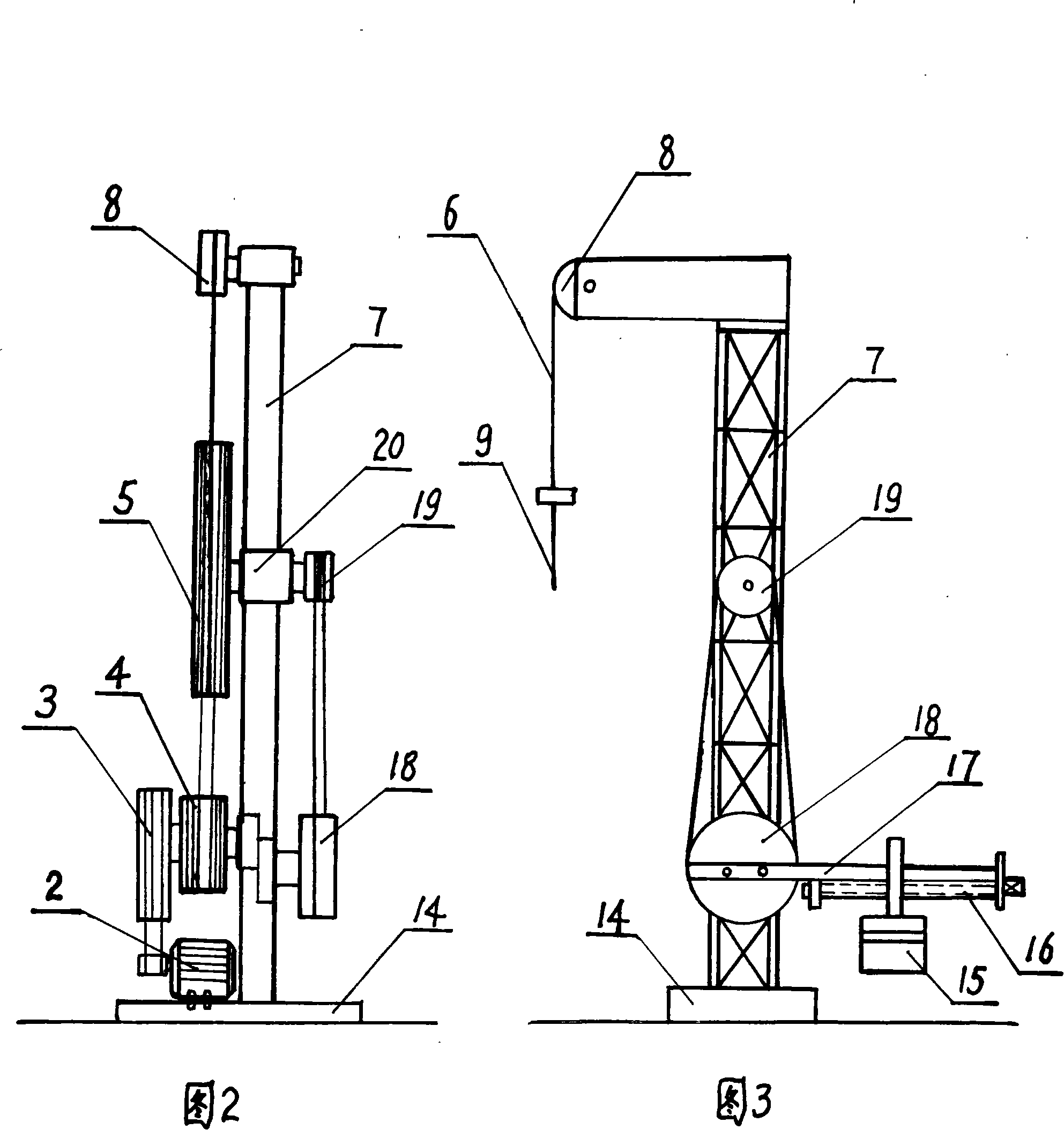

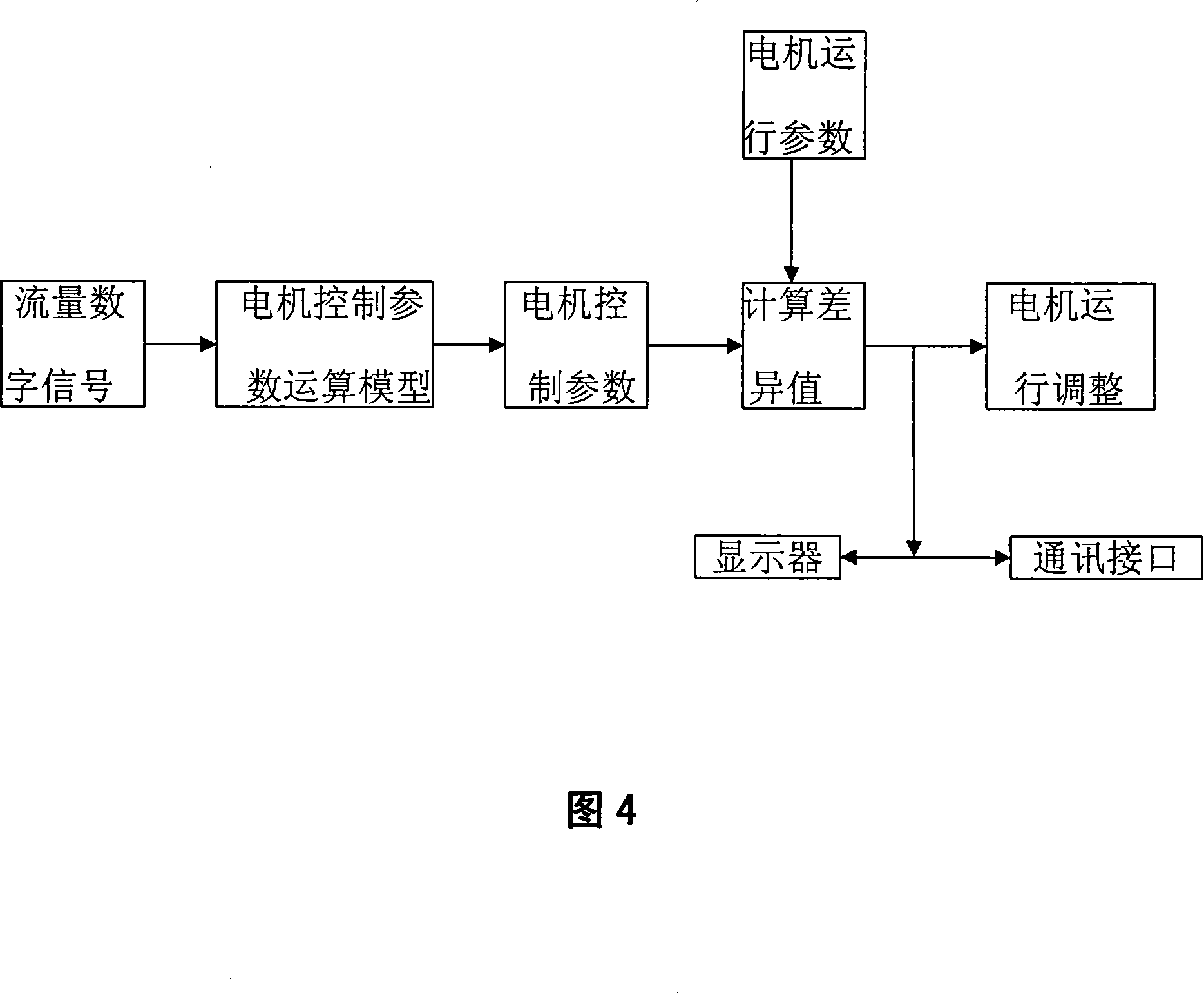

Pendulum type balance intelligent control pumping unit

InactiveCN101169263AReduced power configurationIncreased balance factorDomestic stoves or rangesLighting and heating apparatusControl vectorAutomatic control

The invention relates to a swing-type balance intelligent control oil extractor which is mainly characterized in that the machine frame is in cantilever structure with extending top. The extending end of the machine frame is provided with a suspension rope wheel. A reversing mechanism is formed by a driving reversing wheel and a driven reversing wheel with a positive rope groove and a negative rope groove; the driving and the driven reversing wheels are connected through a reversing pull rope, the driven reversing wheel is fixedly connected with a suspension rope. A balancing mechanism adopting the swing-type balance is connected with the reversing mechanism through a bridge shaft in linkage; a motor is connected with a motor vector control cabinet which is connected with an intelligent control device through a data bus; wherein, the intelligent control device is connected with a flow sensor for monitoring the swabbing flow through a signal transmitting line. The oil extractor which can automatically control the stroke frequency and the stroke of the oil extractor according to the underground conditions, improve the motor efficiency and reduce the labor intensity, the invention has the advantages of simple structure, high balance degree and reliable performance as well as saving the electric energy and decreasing the producing and using cost, etc.

Owner:陈宗武

Preparation method of camellia oil

InactiveCN105670772AKeep active ingredientsIncrease added valueFatty-oils/fats refiningFatty-oils/fats productionCooking & bakingBiology

The invention discloses a preparation method of camellia oil. The preparation method comprises the following steps of firstly, treating camellia seeds, and taking out the camellia seeds after camellia seed fruits are cracked; secondly, treating the camellia seeds, cleaning the camellia seeds in the first step, then drying in the air or baking on a Kang, drying in the air until the water content is 3 percent, and taking out rotten camellia seeds; thirdly, selecting straws and treating the straws: selecting the straws with better color, cleaning and drying in the air; fourthly, performing breaking treatment; fifthly, drying and preheating: placing the broken camellia seed residues in the fourth step into a preheating furnace with the temperature of 75 to 90DEG C for drying and preheating; sixthly, mixing the camellia seeds with the straws; seventhly, squeezing: starting an oil press; after the temperature of the oil press is increased to be 75 to 85DEG C, adding a mixture of the camellia seed residues treated in the sixth step and the straws for squeezing, and controlling the temperature to be 75 to 85DEG C in the squeezing process; eighthly, filtering the camellia oil; ninthly, precipitating. The preparation method disclosed by the invention has the advantages of simplicity, simplicity and convenience in operation, high efficiency and energy conservation.

Owner:HUNAN SHENGLE ECOO MANOR CO LTD

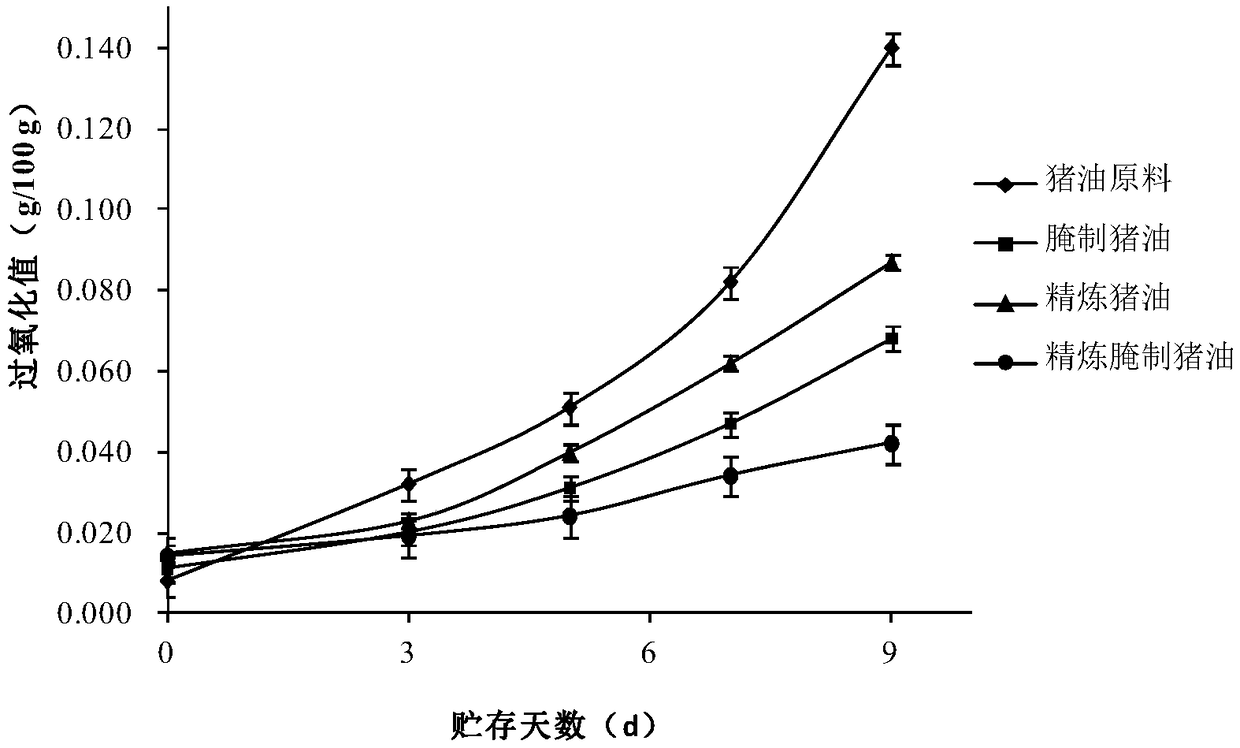

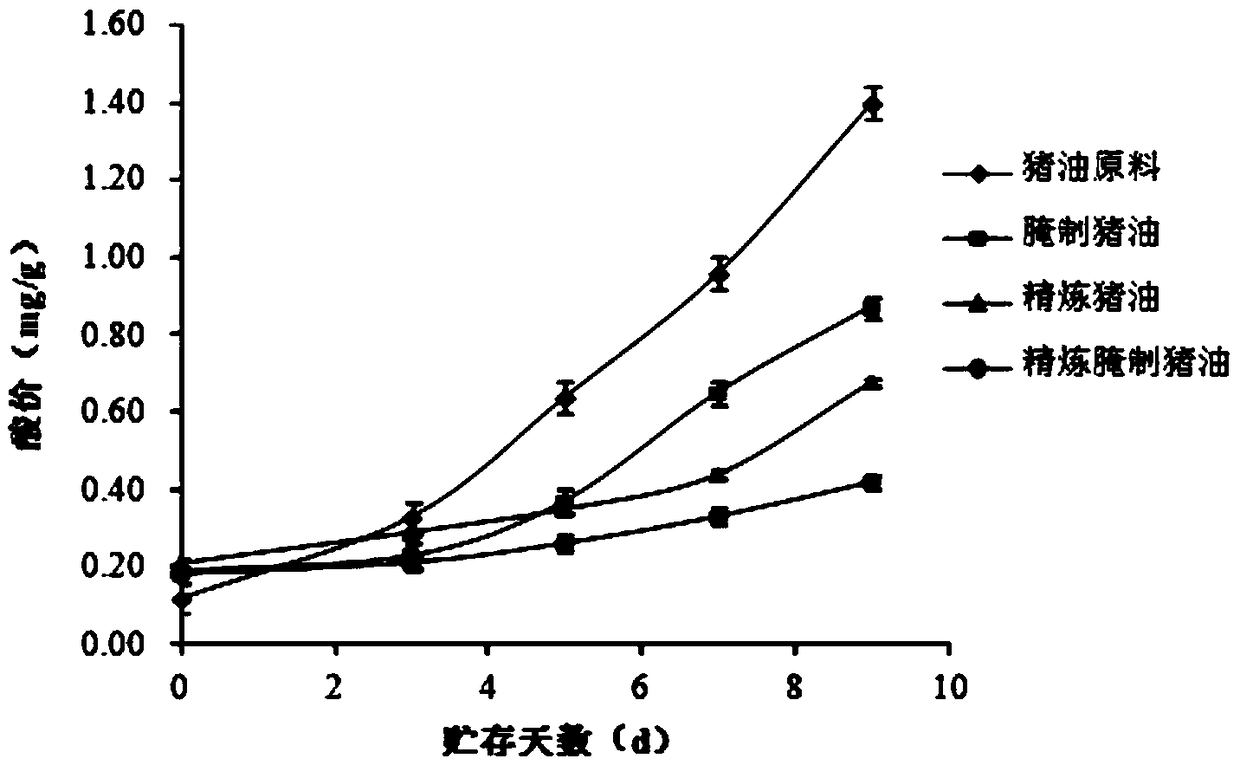

Method for making low-temperature refined pickled lard oil

PendingCN109055002AImprove qualitySure seepFatty oils/acids recovery from wasteFatty substance recoveryAcid valuePeroxide value

The invention belongs to the technical field of lard oil processes and in particular relates to a method for making low-temperature refined pickled lard oil. The method comprises the following steps:selecting raw materials, trimming and cleaning, cutting into pieces, pickling, carrying out vacuum refining, separating oil from residues, filtering, filling, preserving, and the like, thereby obtaining a product. By adopting the method, the problems that in the prior art, lard oil is liable to deterioration in the production process and a product cannot be quantitatively added can be solved; withthe combination of pickling and vacuum refining, the acid value and the peroxide value of a pickled lard oil product can be remarkably reduced, the preservation time of the lard oil can be effectively prolonged, and meanwhile, quantitative packaging and addition of the pickled lard oil product can be achieved.

Owner:INST AGRO PROD PROCESSING ANHUI ACADEMY AGRI SCI

Method for enzymolysis treatment of oil crop seeds

InactiveCN105820867AImprove oil output efficiencyImprove stabilityFatty-oils/fats productionProteaseAgricultural science

The invention discloses a method for enzymolysis treatment of oil crop seeds. The method comprises the following steps that 1, oil crop seeds are contained in a closed container and subjected to the humidification and pressurization conditions for 10-15 min, then, pressure is decreased to 1500-2000 Pa, the pressure is maintained for 10-20 min, then, the pressure is increased to 1.6-2.5*10<5>pa, and the pressure is maintained for 20-30 min; 2, the oil crop seeds are smashed, and water is added into the smashed oil crop seeds; 3, firstly, oil crop seed granules are baked, and then subjected to microwave processing; 4, the temperature of the oil crop seed granules is decreased to be 20 DEG C to below, then, cellulase and compound protease are added into the oil crop seed granules, enzymolysis is performed under the temperature of 40-45 DEG C for 5-8 h, and finally the enzymolyzed oil crop seed granules are subjected to low-temperature vacuum drying to obtain oil crop seeds for cold pressing method extraction.

Owner:林智生

Extracting method of castor oil

InactiveCN104560356AImprove oil output efficiencySimple processFatty-oils/fats refiningFatty-oils/fats productionSolventPre treatment

The invention discloses an extracting method of castor oil. The extracting method is characterized by comprising the following steps: firstly, castor oil processing, secondly, enzymolysis, thirdly, microwave processing, fourthly, pressing, fifthly, alkali refining, sixthly, hydrating, and seventhly, essential oil preparing. The method preprocesses oil plant seeds through a microwave technology, realizes high-strength uniform heating, improves the oil yield efficiency of cold pressing oil extraction, removes phospholipid through alkali refining and hydration, keeps the appearance of oil, does not contain any chemical solvent residual, ensures that the nutritional ingredients of castor oil do not run off to the greatest extent, and can obtain purely natural full fat castor oil. The method is simple in technology, low in equipment investment, low in energy consumption, safe and efficient, and can be massively popularized.

Owner:刘夏

Raw material pre-treatment device for processing of sesame oil

InactiveCN107858200AHigh purityIncrease the fragranceFatty-oils/fats productionPre treatmentImpurity

The invention discloses a raw material pre-treatment device for processing of sesame oil. The raw material pre-treatment device comprises an engine base and is characterized in that a support column is arranged on the engine base, a crossbeam rod is fixedly installed on the top of the support column, a material bin is fixedly installed on the side wall of the support column, a peel removing rolleris installed in the material bin in a rolling manner, peel removing teeth are arranged on the side wall of the peel removing roller, the bottom of the material bin is communicated with a wind cavitythrough a pipeline, the side wall of the wind cavity is provided with a blower, the other side of the blower is provided with an impurity blowing port, the bottom of the wind cavity is provided with amaterial discharge pipeline, the material discharge pipeline is connected with a convey device, the convey device sends the raw material into an oven, and the bottom of the oven is provided with a conical drum. The raw material pre-treatment device has a simple structure, can treat the material clearly and thoroughly, can pre-treat the raw material rapidly, and can press the raw material into oilcakes rapidly.

Owner:ANHUI PROVINCE YINGSHANG COUNTY SANJIN GRAINS ANDOILS CO LTD

Method for extracting oat oil through microwave pretreatment

InactiveCN103122273AChanges in seed coat structureIncrease leaching rateFatty-oils/fats productionAgricultural engineeringAgronomy

The invention discloses a method for extracting oat oil through microwave pretreatment. The method comprises the following steps: cleaning oat raw materials, draining the cleaned oat, and drying the oat in a drying oven; hulling the oat in a huller, and separating oat bran; crushing the oat bran in a crusher; and extracting the oat oil from the crushed oat bran, and performing microwave treatment after the oat is dried and before the dried oat is hulled in the huller, wherein the microwave treatment method comprises the following step of: putting the dried oat particles into a microwave dryer, wherein the power is regulated to be 180-900W, the treatment time is 60-150 seconds, the drying temperature in the drying step is 60 DEG C, and the moisture content of the dried oat is 15wt%. The method provided by the invention is simple and reliable, convenient to operate, low in cost, high in speed and high in leaching efficiency and has a high economic value.

Owner:HENAN UNIV OF SCI & TECH

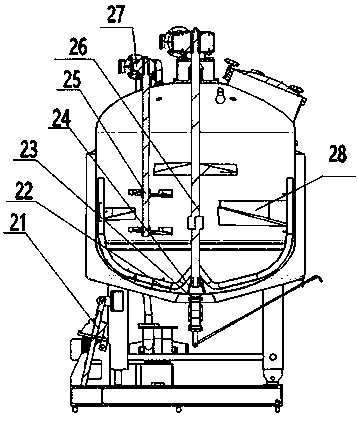

Mixing, stirring and oil discharging equipment and oil discharging process method of ground sesame oil

PendingCN111040864AHigh degree of mechanizationReduce the amount of solutionFatty-oils/fats productionInlet valveElectric machinery

The invention discloses mixing, stirring and oil discharging equipment and an oil discharging process method of ground sesame oil. The equipment comprises a bracket, which is connected with a weighingsensor and is connected with a tank body jacket, wherein the bottom of the tank body jacket is connected with a material outlet, the tank body jacket is connected with a tank body, the tank body is connected with a gas sucking port, the gas sucking port is connected with a metal hose, the metal hose is connected with a vacuum pump, the vacuum pump is connected with a control box, the tank body isconnected with a material inlet, a manhole, a pressure gauge and a water inlet, the tank body is connected with a gas inlet valve, and the tank body is fixedly provided with a variable frequency motor. The equipment and the method are used for mixing, stirring and oil discharging equipment of ground sesame oil.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI

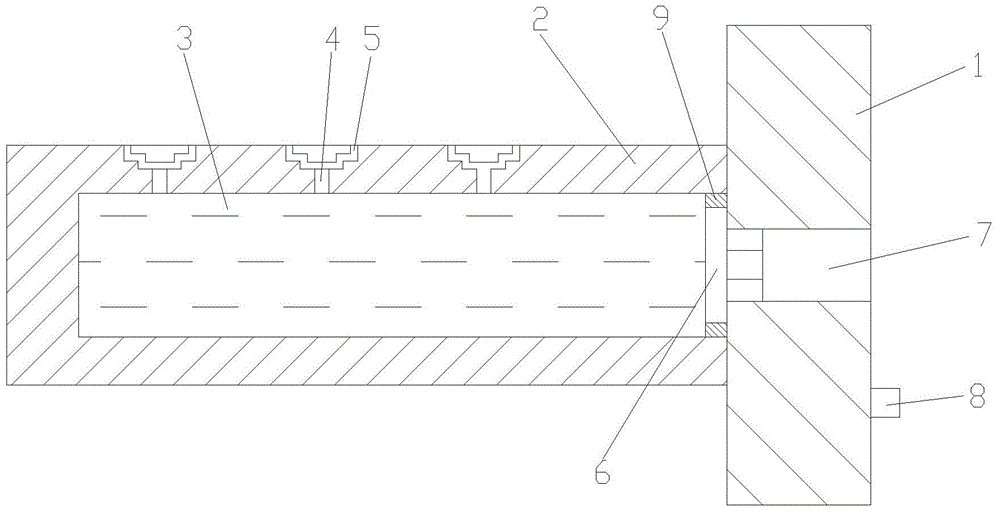

Automatic oil outlet bolt

The invention discloses an automatic oil outlet bolt which comprises a bolt body. A bolt head and a screw are connected with each other to form the bolt body, and an oil storage groove is formed inside the screw; the oil storage groove is filled with lubricating oil; oil outlet holes which are communicated with the oil storage groove are axially formed in the screw; the oil outlet holes comprise oil inlet flow channels and oil outlet flow channels; the oil inlet flow channels are communicated with the oil outlet flow channels; each oil outlet hole comprises the two corresponding labyrinth oil outlet flow channels; a piston is arranged at an opening of the oil storage groove; a cylinder is arranged in the bolt head; an end of a telescopic rod of the cylinder is connected with the piston; a switch for controlling the cylinder is arranged on the outer surface of the bolt head. The automatic oil outlet bolt has the advantages that the automatic oil outlet bolt is simple in operation, convenient to use and high in oil outlet and lubrication efficiency; each oil outlet hole comprises the two corresponding labyrinth oil outlet flow channels, accordingly, the lubricating oil can be prevented from leaking when stored in the oil storage groove, and lubrication effects of the lubricating oil can be guaranteed when the automatic oil outlet bolt is used.

Owner:SUZHOU SHUNYI HARDWARE

Stage-by-stage temperature control pressing process for edible oil

InactiveCN108441314APrevent spoilageAvoid churnFatty-oils/fats refiningFatty-oils/fats productionTemperature controlOil and grease

The invention discloses a stage-by-stage temperature control pressing process for edible oil. The process comprises the following steps: an oil material is put in a constant-temperature wait-for-pressing storage house at a constant temperature of 50 plus or minus 5 DEG C after being selected; then, the oil material is fed into a preheating bin to be preheated from the constant-temperature wait-for-pressing storage house; the preheated oil material enters a stage-by-stage heating and frying process, and the frying process is divided into three-stage heating and frying zones where the temperature rises stage by stage; the frying temperature in the first-stage frying zone is 150 plus or minus 2 DEG C, and frying time is 100-120 s; the frying temperature in the second-stage frying zone is 180plus or minus 2 DEG C, and frying time is 100-120 s; the frying temperature in the third-stage frying zone is 210 plus or minus 2 DEG C, and frying time is 90-100 s; the fried oil material is put in apressing system for pressing; oil and fat output from a presser is conveyed to a sedimentation and filtration device through a pipe, and residues are removed by filtering. The problems of sudden temperature rise, uneven heating, local strong heating and low oil yield during oil frying are effectively solved by reasonable process design.

Owner:山丹县祝福油脂有限责任公司

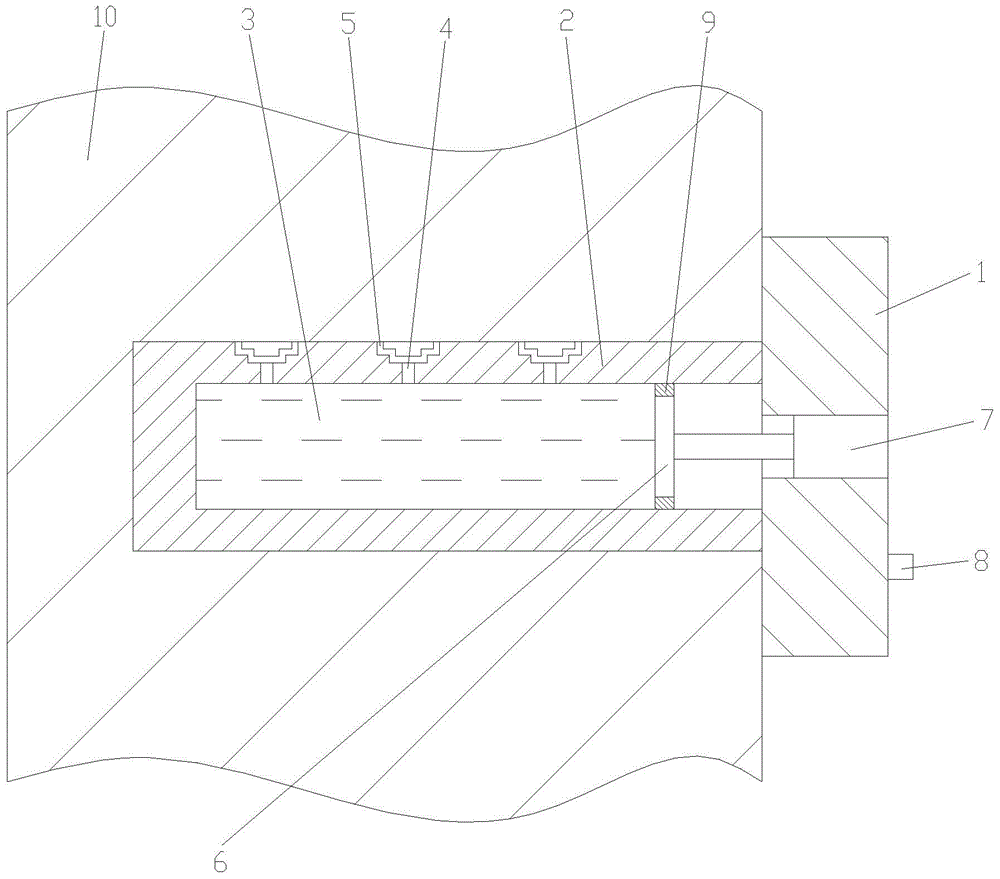

Automatic oil outlet nut

InactiveCN104482015AGuaranteed lubrication effectEasy to operateNutsEngine lubricationOil canScrew thread

The invention discloses an automatic oil outlet nut. The automatic oil outlet nut comprises a nut body, wherein a threaded hole is formed inside the nut body; an annular oil storage tank is arranged inside the nut body and is filled with lubricating oil; at least two oil outlet holes are axially formed in the nut body; each oil outlet hole comprises an oil inlet flow channel and two labyrinth-shaped oil outlet flow channels; each oil inlet flow channel is communicated with the oil storage tank; each oil outlet flow channel is communicated with the threaded hole; a piston is arranged at an opening of the oil storage tank; at least two cylinders are annularly arrayed in the nut body; the end part of a telescopic rod of each cylinder is connected with the piston; a switch which controls the cylinders is arranged on the outer surface of the nut body. The automatic oil outlet nut is easy to operate, convenient to use and high in oil outlet efficiency and lubricating efficiency; the lubricating oil cannot be leaked when being stored in the oil storage tank, so that the lubricating effect of the lubricating oil during use is guaranteed.

Owner:SUZHOU SHUNYI HARDWARE

Pickling method of five-spice-scented salted duck eggs

The invention discloses a pickling method of five-spice-scented salted salted duck eggs. The pickling method of the five-spice-scented salted salted duck eggs comprises the following steps: step one,weighing raw materials according to the following parts by weight: 50-60 parts of fresh gingers, 20-30 parts of star anises, 20-30 parts of fennels, 100-150 parts of Chinese prickly ash, 70-90 parts of white sugar, 150-200 parts of baijiu, and 3000 parts of water; step two, cooking fresh gingers, star anises, fennels and Chinese prickly ash in water, turning off the fire when aroma is produced, adding coarse salt until the solution reaches saturation state, and adding the white sugar and the baijiu after the temperature of the solution is cooled to room temperature so as to obtain a saturatedfive-spice-flavor saline water ready for using; and step three, thoroughly washing duck eggs, air-drying the washed duck eggs, evenly placing the air-dried duck eggs in a sealed container, pouring thesaturated five-spice-flavor saline water into the container, sealing the container, and carrying out storing for 20-25 days. The pickling method of the five-spice-scented salted duck eggs overcomes disadvantages of the prior art. The fresh gingers, the star anises, the fennels, the Chinese prickly ash and the white sugar are utilized so as to improve taste of the duck eggs, and thus, the salted duck eggs have better taste; moreover, an appropriate amount of baijiu is added so that good sterilization effect and oil production effect are ensured.

Owner:肥西县双凤禽蛋制品厂

Bolt with oil discharge function

InactiveCN104454886AGuaranteed lubrication effectEasy to operatePinsNutsMechanical componentsInlet flow

The invention discloses a bolt with an oil discharge function. The bolt comprises a bolt body formed by connection of a bolt head and a screw. An oil storage slot is formed in the screw and is filled with lubricating oil. Oil outlet holes communicated with the oil storage slot are formed in the screw. Each oil outlet hole comprises an oil inlet flow pass and two oil outlet flow passes in the shape of a labyrinth. The oil inlet flow passes are communicated with the oil outlet flow passes. A piston is arranged at an opening of the oil storage slot. A push rod is connected to the outer end of the piston and penetrates the bolt head to be connected with the piston. A push plate is arranged at the outer end of the push rod. The bolt with the oil discharge function has the advantages that the oil storage slot is filled with the lubricating oil, the piston squeezes internal space of the oil storage slot in case of rusting, and the lubricating oil leaks out from the oil outlet holes to lubricate a joint part of the screw and a mechanical component, so that the bolt is simple in structure, convenient to use and high in oil discharge and lubrication efficiency; since each oil outlet hole comprises the two oil outlet flow passes in the shape of the labyrinth, and the lubricating oil is stored in the oil storage slot and is not leaked, so that lubrication effect during use of the lubricating oil is guaranteed, and use cost is low.

Owner:SUZHOU SHUNYI HARDWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com