Method for preparing aromatic rapeseed oil

A rapeseed oil and rapeseed technology, applied in the field of preparation of fragrant rapeseed oil, can solve the problems of waste of resources, low oil production efficiency, high residual oil, and achieve no waste water and waste gas pollution, rich aroma and taste, and resource utilization. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

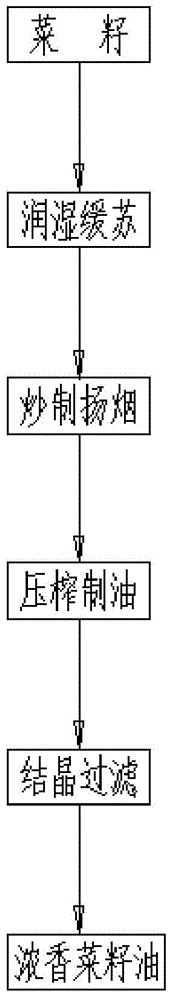

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation method of the fragrant rapeseed oil of the present embodiment comprises the following steps:

[0026] (1) Wetting and dampening: Use a screw conveyor to send the cleaned rapeseed into the humidifier, spray 5% of the mass of the rapeseed for wetting, and transport the wetted rapeseed to the damper. Soak in the soaking vessel for 20 minutes, and the soaking temperature is 30°C, so that the protein and phospholipids in the rapeseed can fully absorb water, and the water content of the soaked rapeseed is controlled at 15-20%;

[0027] (2) Frying and raising smoke: transport the moistened and slow-supplemented rapeseed to the horizontal heat-conducting oil frying machine, raise the temperature to 130°C, heat and fry for 60 minutes under humid and hot conditions, and the rapeseed will produce a strong fragrance. Use a smoke blower to remove the glucosinolate decomposition products with a pungent smell from the fried rapeseed, and the water content...

Embodiment 2

[0031] Embodiment 2: the preparation method of the fragrant rapeseed oil of the present embodiment comprises the following steps:

[0032] (1) Wetting and dampening: send the cleaned rapeseed into the humidifier through a screw conveyor, spray 10% of the mass of the rapeseed for wetting, and transport the wetted rapeseed to the slowing Soak in the soaker for 40 minutes, and the soaking temperature is 50°C, so that the protein and phospholipids in the rapeseed can fully absorb water, and the water content of the rapeseed is controlled at 18-20%;

[0033] (2) Frying and raising smoke: transport the moistened and slow-supplemented rapeseed to a horizontal heat-conducting oil frying machine, raise the temperature to 150°C, heat and fry for 55 minutes, the rapeseed will produce a strong fragrance, and the fried The rapeseed uses a smoke machine to remove the glucosinolate decomposition products with a pungent smell, and the water content of the rapeseed after the smoke is 2.5%;

...

Embodiment 3

[0037]Embodiment 3: the preparation method of the fragrant rapeseed oil of the present embodiment comprises the following steps:

[0038] (1) Wetting and dampening: send the cleaned rapeseed into the humidifier through the screw conveyor, spray the water accounting for 18% of the mass of the rapeseed for wetting, and transport the wetted rapeseed to the slowing Soak in the soaking vessel for 60 minutes, and the soaking temperature is 60°C, so that the protein and phospholipids in the rapeseed can fully absorb water, and the water content of the rapeseed is controlled at 18-20%;

[0039] (2) Frying and raising smoke: transport the moistened and slow-supplemented rapeseed to a horizontal heat-conducting oil frying machine, raise the temperature to 180°C, heat and fry for 50 minutes, the rapeseed will produce a strong fragrance, and the fried The rapeseed uses a smoke machine to remove the glucosinolate decomposition products with a pungent smell, and the moisture content of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com