Commercial squeezing device

A commercial and press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of single product function, high price, and failure to satisfy customers, and achieve the effects of high oil output efficiency, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

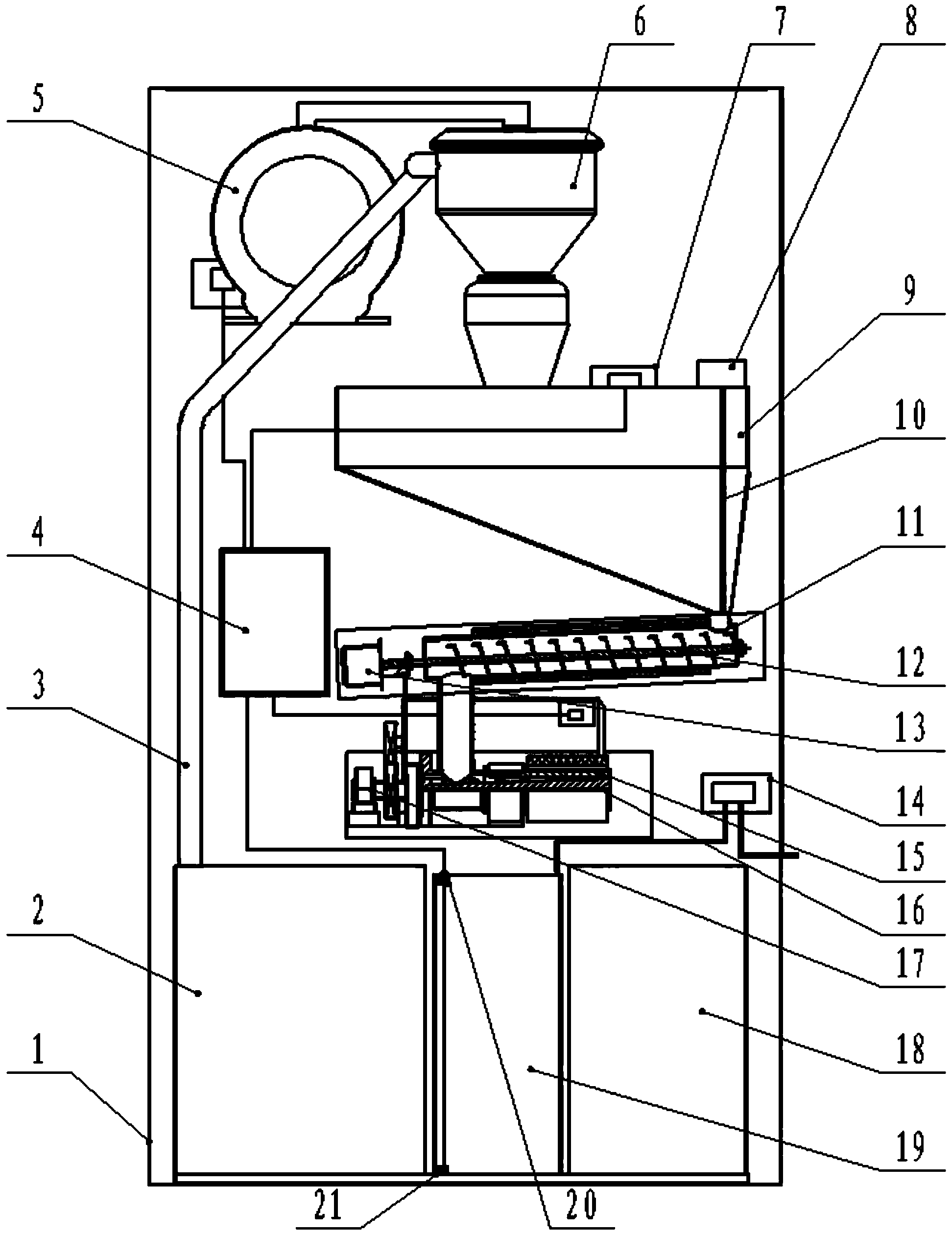

Embodiment 1

[0031] A commercial pressing device includes a box body 1, a feeding system, a control system, a drying pressing system, an oil receiving barrel 19 and an oil residue barrel 18. The feeding system includes a material storage tank 2, a material suction cylinder 6 and a material suction fan 5; the material storage tank 2, the material suction cylinder 6 and the material suction fan 5 are connected in sequence through the delivery pipeline 3; the material suction cylinder 6 and the material suction Fans 5 are all arranged above the box body 1, and storage barrel 2 is arranged on the bottom plate of box body 1; the suction fan 5 is connected with the suction tube 6, and drives the suction tube 6 to suck material. The dry pressing system comprises a hopper 9 and a squeezer; the inlet of the hopper 9 is connected to the outlet of the suction cylinder 6 in the feeding system, and the outlet of the hopper 9 is connected to the inlet of the squeezer .

[0032] Press machine comprises ...

Embodiment 2

[0041] A commercial pressing device includes a box body 1, a feeding system, a control system, a drying pressing system, an oil receiving barrel 19 and an oil residue barrel 18. The feeding system includes a storage tank 2, a material suction cylinder 6 and a material suction motor 5; the material storage tank 2, the material suction cylinder 6 and the material suction fan 5 are connected in sequence through the delivery pipeline 3; the material suction cylinder 6 and the material suction The fan 5 is arranged above the box body 1, and the material storage barrel 2 is arranged on the bottom plate of the box body 1; the suction fan is connected with the suction tube 6, and drives the suction tube 6 to absorb material. The dry pressing system comprises a hopper 9 and a squeezer; the inlet of the hopper 9 is connected to the outlet of the suction cylinder 6 in the feeding system, and the outlet of the hopper 9 is connected to the inlet of the squeezer . An anti-blocking motor 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com