Automatic oil outlet nut

An oil screw, automatic technology, applied in the direction of nuts, threaded fasteners, engine components, etc., can solve the problems of slow oil discharge and lubrication efficiency, and no lubricating oil out of the oil outlet hole, so as to achieve high oil discharge and lubrication efficiency, Guaranteed lubricating effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

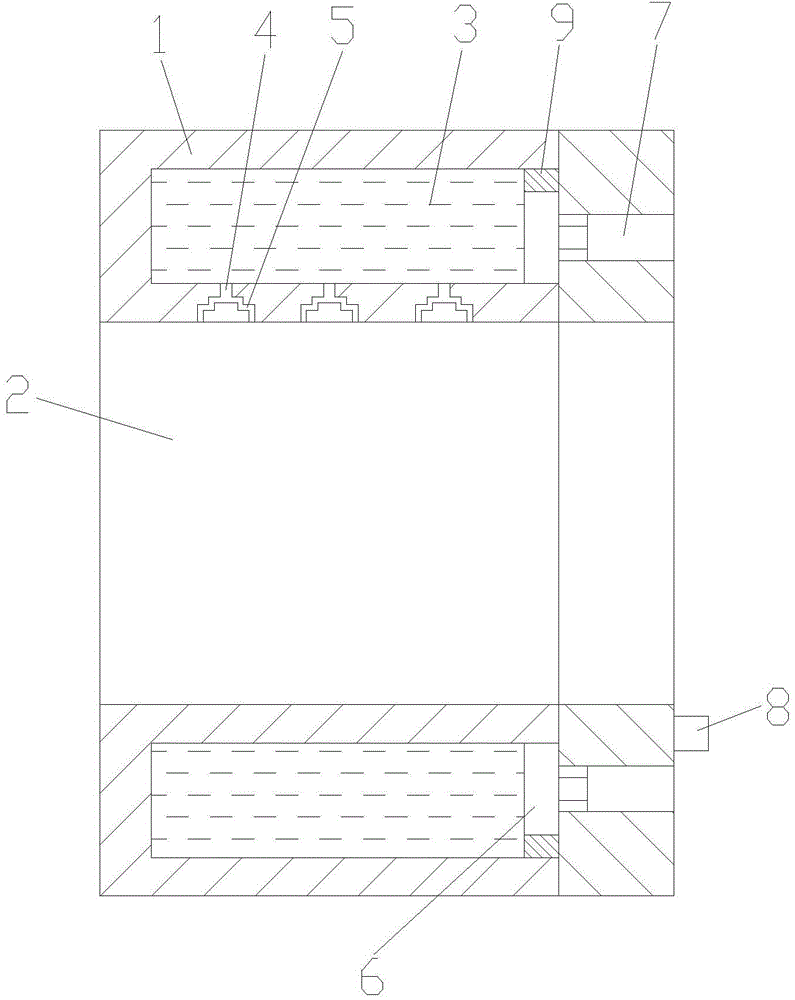

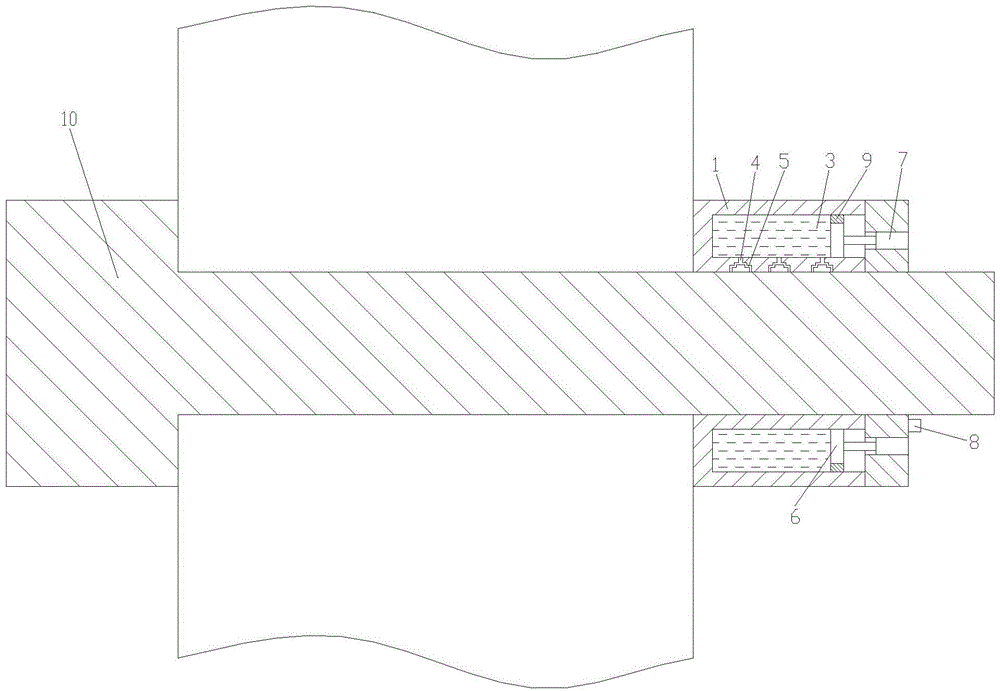

[0015] as attached figure 1 The shown automatic oil outlet nut according to the present invention comprises a nut body 1, a threaded hole 2 is opened in the nut body 1, and an annular oil storage tank 3 is arranged inside the nut body 1; the oil storage tank 3 The inside is filled with lubricating oil; the nut body 1 has at least two oil outlet holes in the axial direction; the oil outlet hole includes an oil inlet flow channel 4 and an oil outlet flow channel 5; The oil tank 3 communicates; the oil outlet channel 5 communicates with the threaded hole 2; the oil outlet channel 5 is provided with two, and is labyrinth; the opening of the oil storage tank 3 is provided with a piston 6; the nut There are at least two cylinders 7 in the annular array in the body 1; the end of the telescopic rod of the cylinder 7 is connected with the piston 6; the outer surface of the nut body 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com