Stage-by-stage temperature control pressing process for edible oil

An edible oil and process technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve problems such as uneven heating, local strong oil yield, sudden temperature rise, etc., to avoid oil deterioration and avoid Loss, avoid over-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention and its effects will be further described below in conjunction with the accompanying drawings and embodiments.

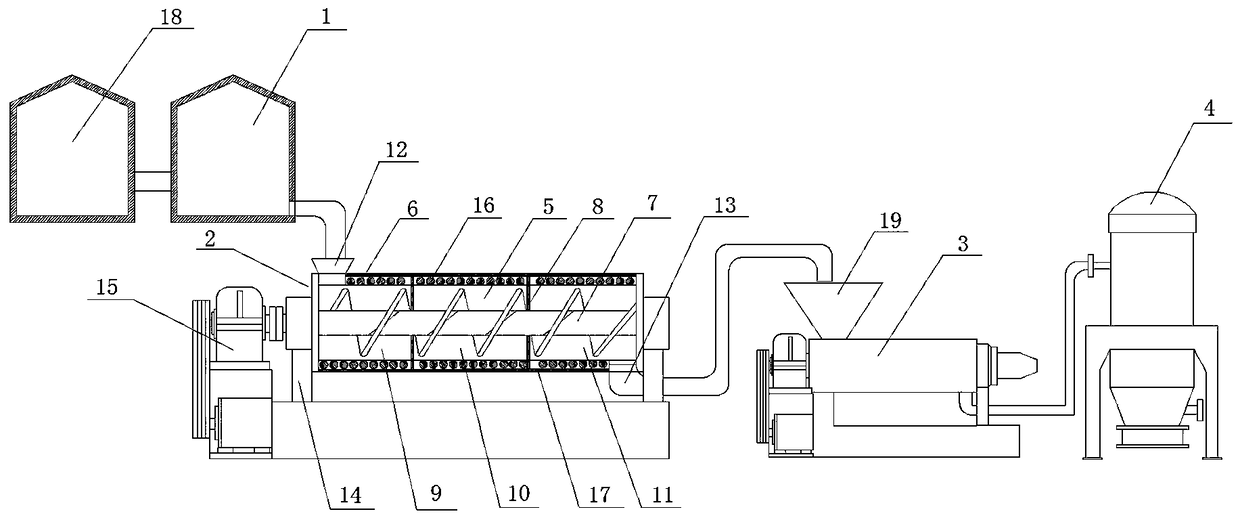

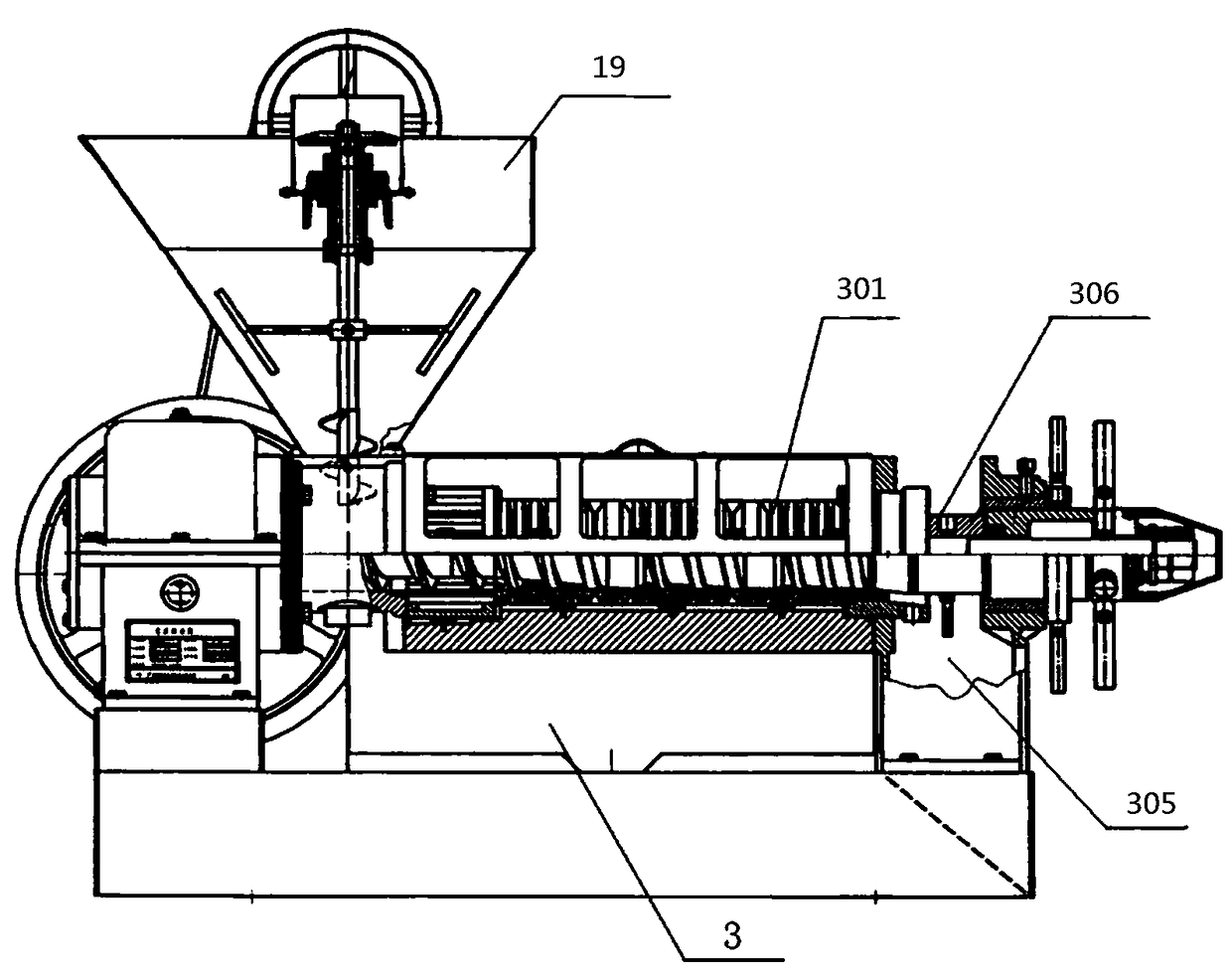

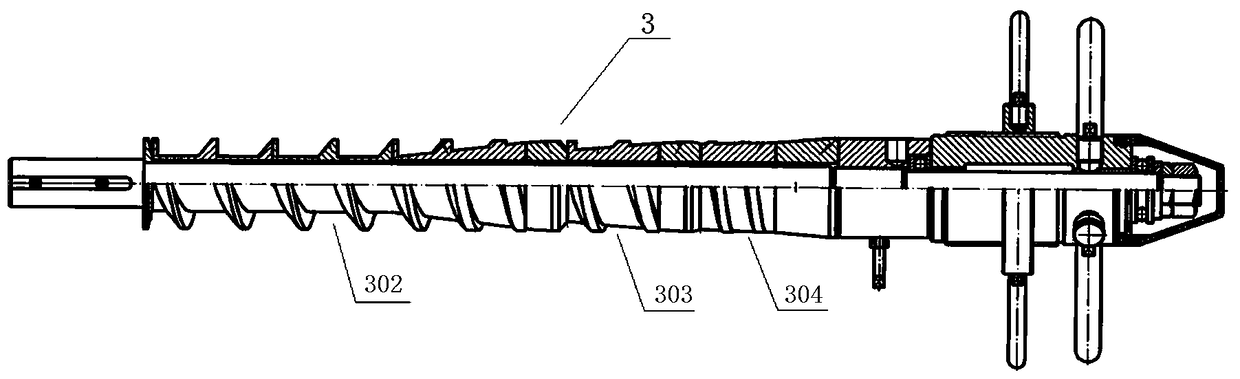

[0031] Such as figure 1 As shown, the edible oil step-by-step temperature-controlled physical pressing process specifically includes the following steps:

[0032] Step 1. Raw material preparation: The oil (linseed / rapeseed) is removed by a negative pressure dedusting and impurity removal device. The sediment and other impurities mixed in the raw material not only affect the quality of edible oil, but also absorb oil during processing, reducing output. Therefore, fully removing impurities before processing can effectively improve the quality and oil yield of edible oil; the selected flax seeds / rapeseeds are put into the constant temperature storage 18, and the temperature in the constant temperature storage 18 is constant at 50 ± 5 ℃.

[0033]Step 2. Oil preheating and frying: The oil is put into the preheating bin 1 from the constant-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com