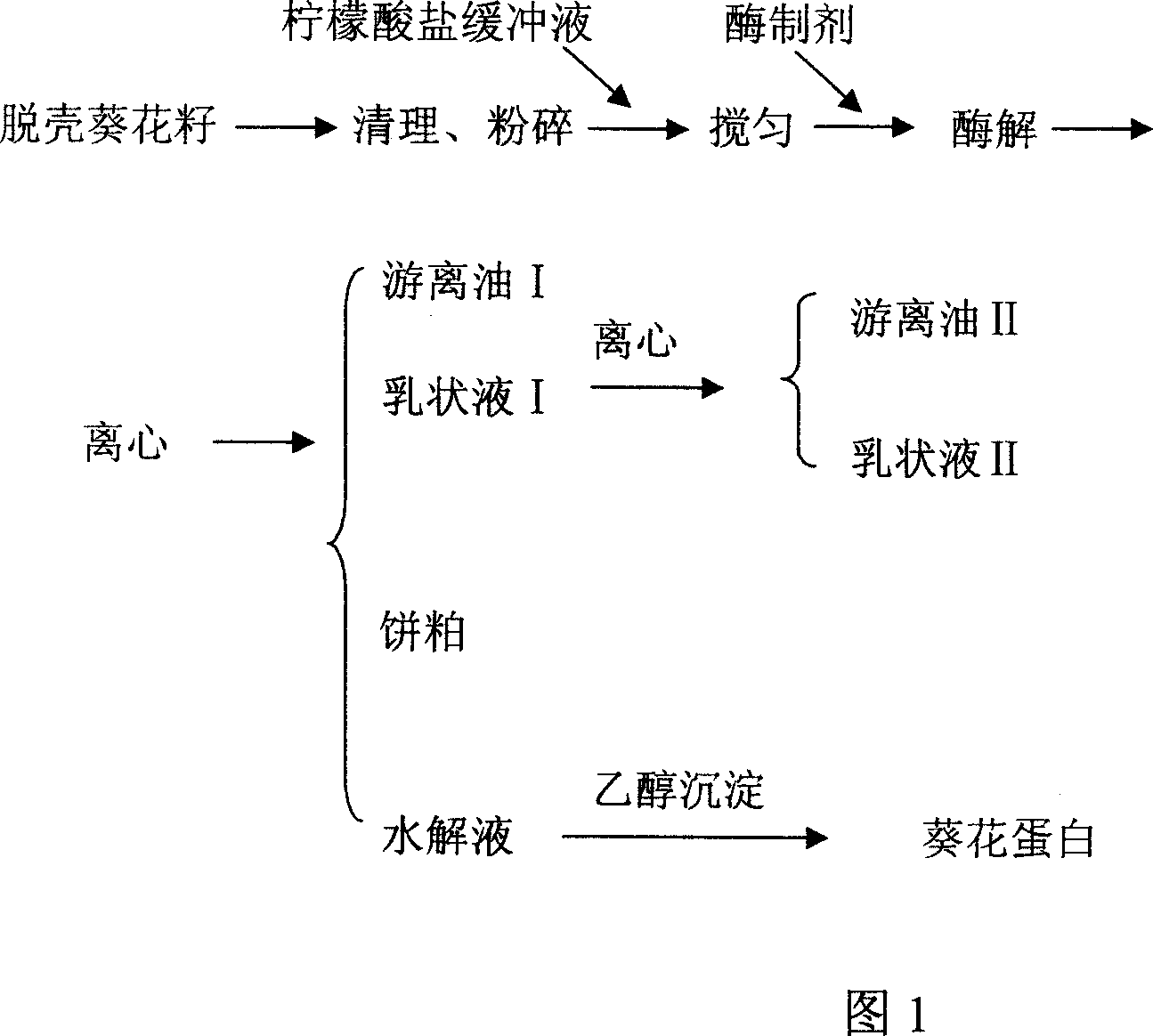

Process for extracting sunflower seed oil and recovering protein by aqueous enzymatic method

A technology for sunflower oil and protein, applied in the fields of biochemical equipment and methods, enzymes, fat oil/fat production, etc., to achieve the effects of simple equipment, high quality and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

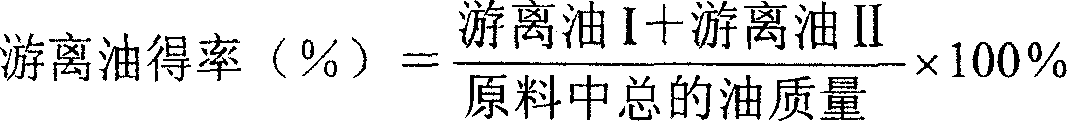

[0032] Shelled sunflower seeds are dry crushed with a traditional Chinese medicine grinder. Add the 0.05mol / L citric acid buffer solution of 750mlpH4.8 to the sunflower seed 150g after pulverizing, stir the complex cellulase that adds 2.5% (w / w shelled sunflower seed dry basis) after being made into slurry, at 50 Enzyme hydrolysis at ℃ for 7h. Centrifuge at 3000rpm to obtain free oil, emulsion layer, hydrolyzate and precipitate after centrifugation. Carefully take out the emulsion layer and carry out secondary centrifugation with a centrifugal force of 8000g to separate the oil in the emulsion layer. Calculate the free oil yield, which can reach 87%.

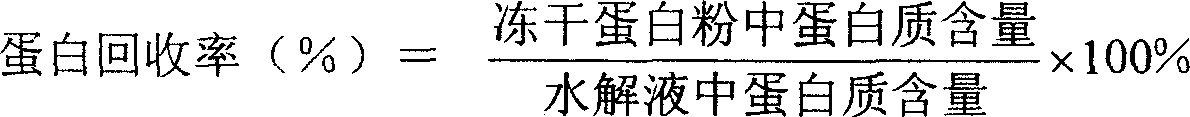

[0033] Take 200ml of the filtered hydrolyzate, concentrate it in vacuum until the solid content is about 13%, add 600ml of absolute ethanol at about -20°C to precipitate the protein, let it stand for a certain period of time and then centrifuge at 3000rpm, redissolve the precipitate with deionized water, and spin in vacuum Th...

Embodiment 2

[0035] Shelled sunflower seeds are dry crushed with a traditional Chinese medicine grinder. The sunflower seed 150g after pulverizing is added the 0.05mol / L citrate buffer solution of 750mlph4.8, stirs the compound cellulase that adds 2% (w / w shelled sunflower seed dry basis) after being stirred into slurry, in Enzymatic hydrolysis at 50°C for 5h. Centrifuge at 3000rpm to obtain free oil, emulsion layer, hydrolyzate and precipitate after centrifugation. Carefully take out the emulsion layer and carry out secondary centrifugation with a centrifugal force of 8000g to separate the oil in the emulsion layer. Calculate the yield of free oil, which can reach 80%.

[0036] Take 200ml of the filtered hydrolyzate, concentrate in vacuum until the solid content is about 9%, add 200ml of absolute ethanol at about -20°C to precipitate the protein, let it stand for a certain period of time and then centrifuge at 3000rpm, redissolve the precipitate with deionized water, and spin in vacuum ...

Embodiment 3

[0038] Shelled sunflower seeds are dry crushed with a traditional Chinese medicine grinder. The sunflower seed 150g after pulverizing is added the 0.05mol / L citrate buffer solution of 900mlpH4.8, after being stirred into slurry, add the complex cellulase of 1% (w / w shelling sunflower seed dry basis), in Enzymatic hydrolysis at 50°C for 5h. Centrifuge at 3000rpm to obtain free oil, emulsion layer, hydrolyzate and precipitate after centrifugation. Carefully take out the emulsion layer and carry out secondary centrifugation with a centrifugal force of 8000g to separate the oil in the emulsion layer. Calculate the free oil yield, which can reach 78%.

[0039] Take 200ml of the filtered hydrolyzate, concentrate in vacuum until the solid content is about 15%, add 370ml of absolute ethanol at about -20°C to precipitate the protein, let it stand for a certain period of time and then centrifuge at 3000rpm, redissolve the precipitate with deionized water, and spin in vacuum The prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com