Blowout prevention oil well pump for oil field

An oil pumping and blowout prevention technology, which is applied to variable displacement pump components, pumps, and components of pumping devices for elastic fluids, etc., can solve the problems of high oil production cost, low oil production efficiency, intermittent oil production, etc. Achieve the effect of improving safety and stability, prolonging service life, and protecting blowout preventers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

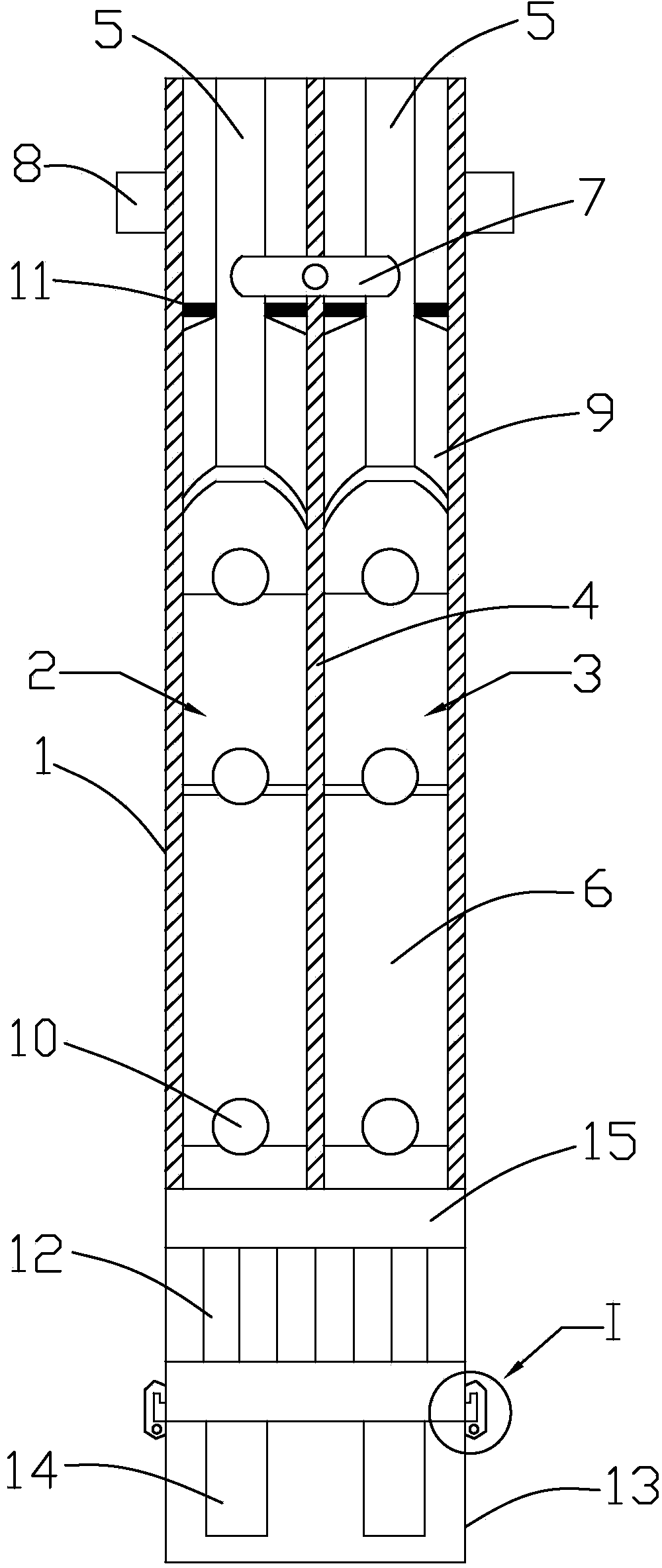

[0030] Such as Figure 1 to Figure 7As shown, it is a blowout prevention type oil well pump for oil field according to the present invention. The blowout prevention type oil well pump includes a pump body 1, and the upper end of the pump body 1 is provided with a mounting ring 8, which can make the installation of the pump body 1 firmer and more stable. , to prevent the pump body 1 from shaking during the oil pumping process, which improves safety. The pump body 1 is provided with an oil pumping mechanism and a blowout prevention device 12. The blowout prevention device 12 is located below the oil pumping mechanism. The oil pumping mechanism includes the first An oil pumping part and a second oil pumping part, a partition plate 4 is arranged between the first oil pumping part and the second oil pumping part, and the first oil pumping part includes a first oil pumping device 2, an oil pipe 6 and a pump barrel 9 , the second oil pumping part includes a second oil pumping device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com