Efficient energy-saving oil pumping machine

A high-efficiency, energy-saving, pumping unit technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high energy consumption, low system efficiency, high power consumption, etc. The effect of reducing consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

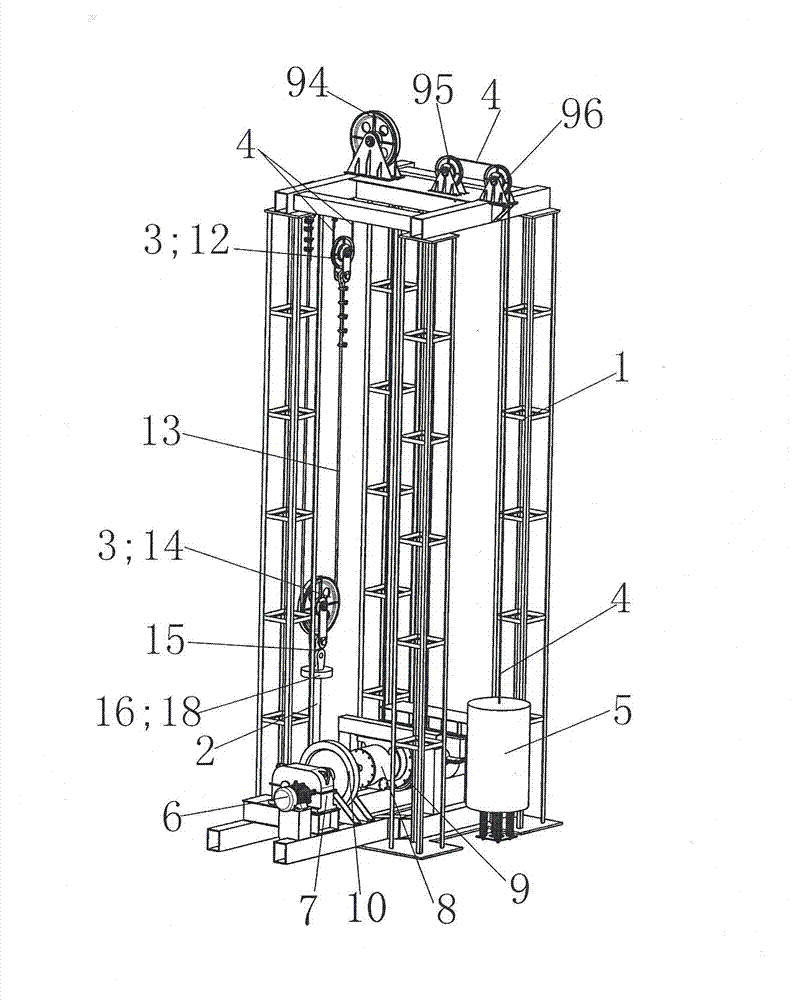

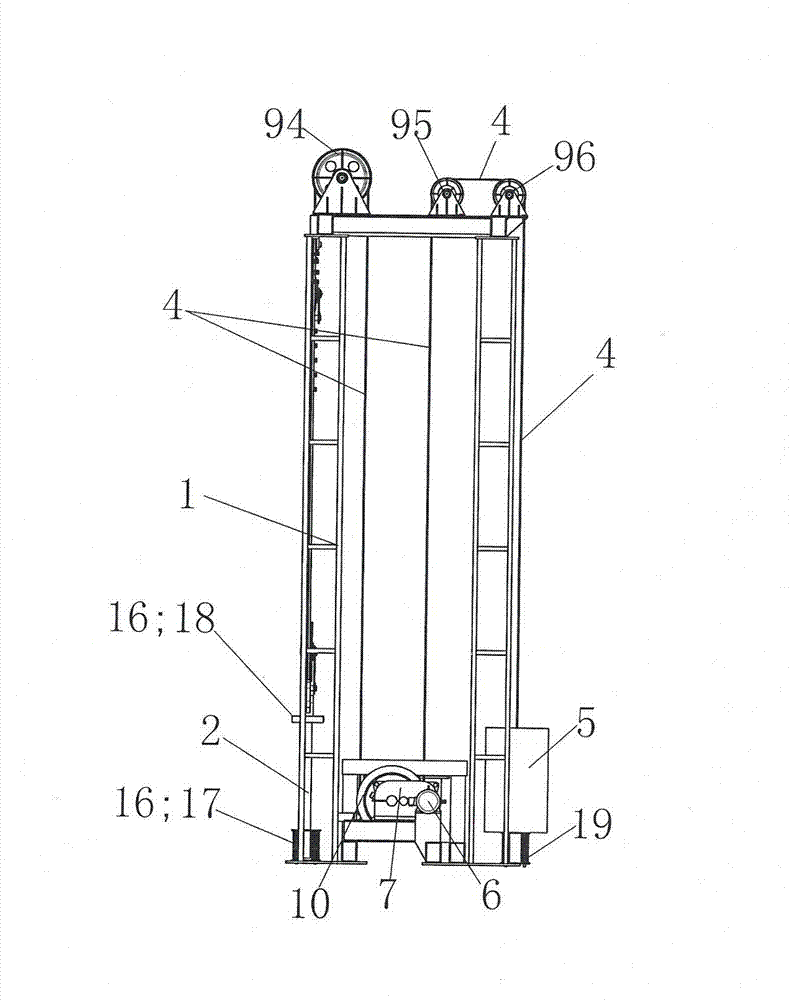

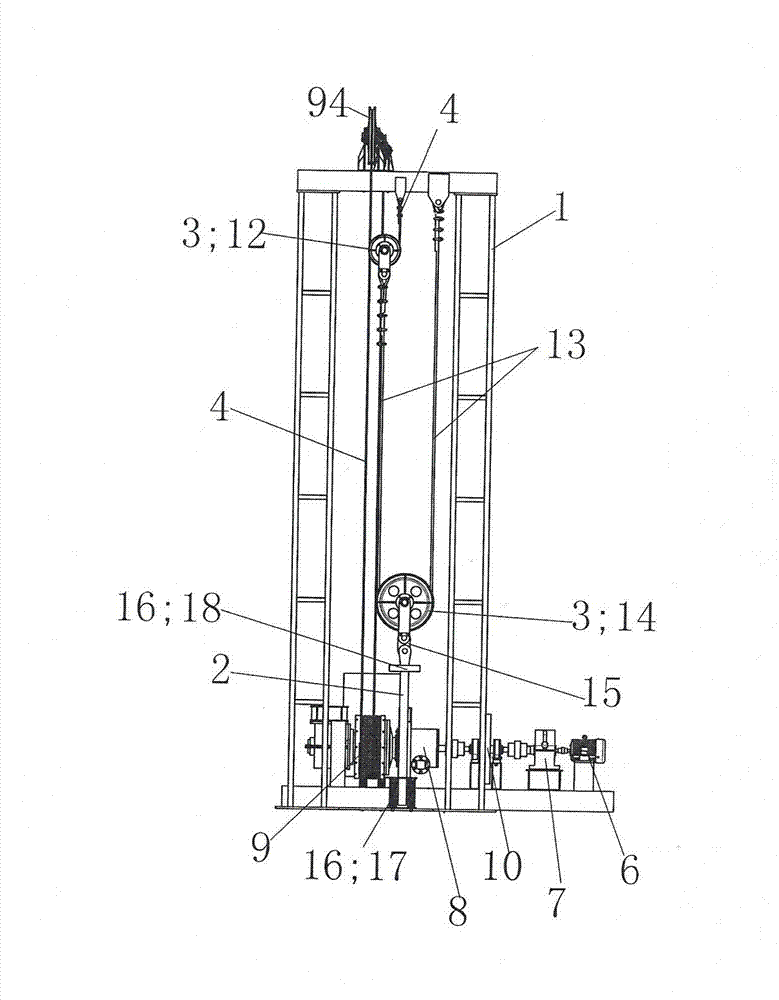

[0042] see figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment is composed of a derrick 1, a sucker rod 2, a moving pulley block 3, a suspension rope 4, a counterweight 5, a drive motor 6, a reducer 7, a reversing lifting device 8 and a reel 9, and the derrick 1 is erected Above the oil well, the driving motor 6, the reducer 7, the reversing lifting device 8 and the reel 9 are arranged at the bottom of the derrick 1, the suspension rope 4 is wound on the reel 9, and one end of the suspension rope 4 goes around the bottom of the derrick 1 The first fixed pulley 94 at the top and the first movable pulley 12 of the movable pulley block 3 are fixed on the top of the derrick 1, and the other end of the suspension rope 4 is passed around the second fixed pulley 95 and the third fixed pulley 96 on the top of the derrick 1. The counterweight 5 is suspended, the first movable pulley 12 is suspended with a suspension cable 13, and the other end of the suspension c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com