Raw material pre-treatment device for processing of sesame oil

A pretreatment device, sesame oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of development constraints, high labor intensity, oil production rate and oil quality impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

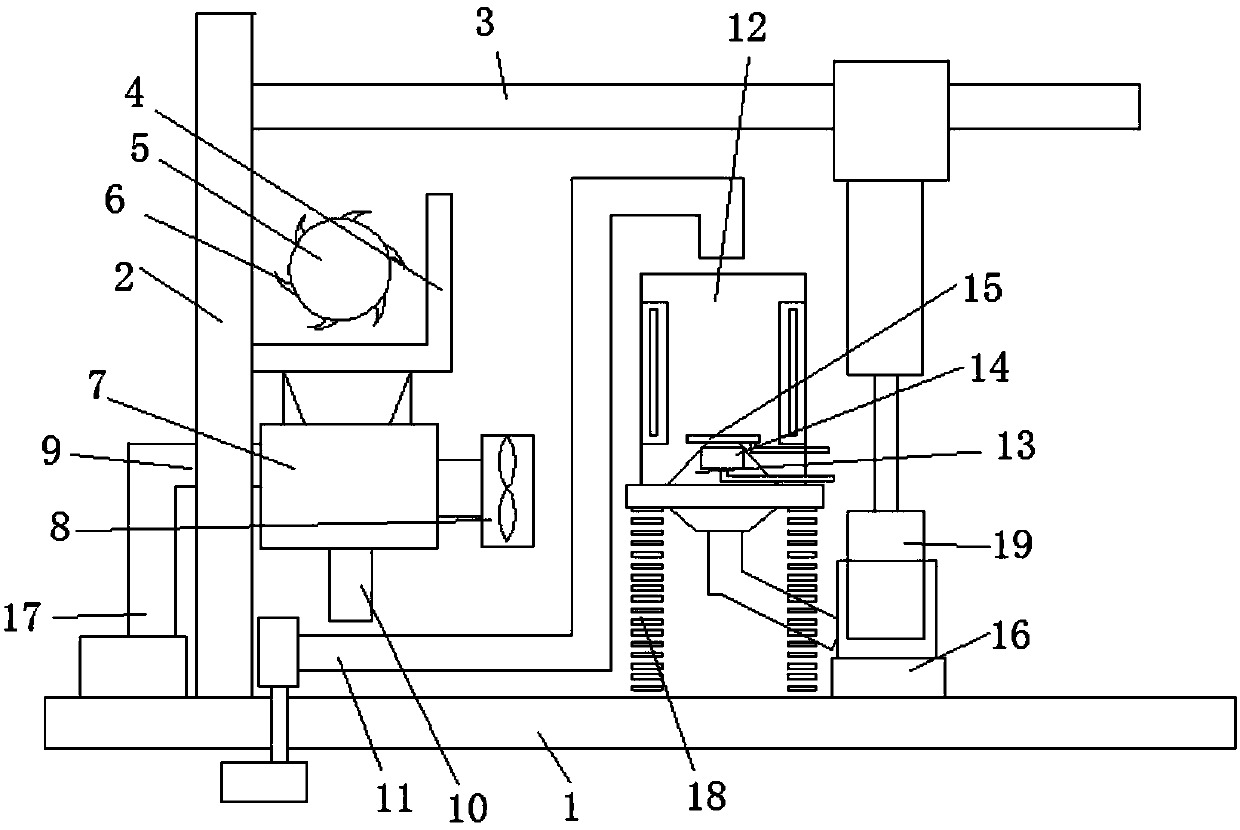

[0011] Referring to accompanying drawing, a kind of raw material pretreatment device for sesame oil processing comprises machine base 1, and described machine base 1 is provided with support column 2, and the top of described support column 2 is fixedly equipped with crossbeam bar 3, and described support column 2 A silo 4 is fixedly installed on the side wall of the silo 4, and a peeling roller 5 is installed rolling in the silo 4. The side wall of the peeling roller 5 is provided with a peeling tooth 6, and the bottom of the silo 4 passes through a pipeline. Connect with the air selection chamber 7, the side wall of the air selection chamber 7 is provided with a blower 8, the other side of the air blower 8 is provided with an impurity blowing port 9, and the bottom of the air selection chamber 7 is provided with a discharge pipe 10. The discharge pipeline 10 is connected to the conveying device 11, and the conveying device 11 sends the raw materials into the oven 12. The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com