Pendulum type balance intelligent control pumping unit

An intelligent control and pumping unit technology, applied in heating methods, oil fume removal, household heating, etc., can solve problems such as difficult balance, difficult control of pumping unit wells, time-consuming and labor-intensive problems, and reduce mechanical failures and pumps. leakage, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

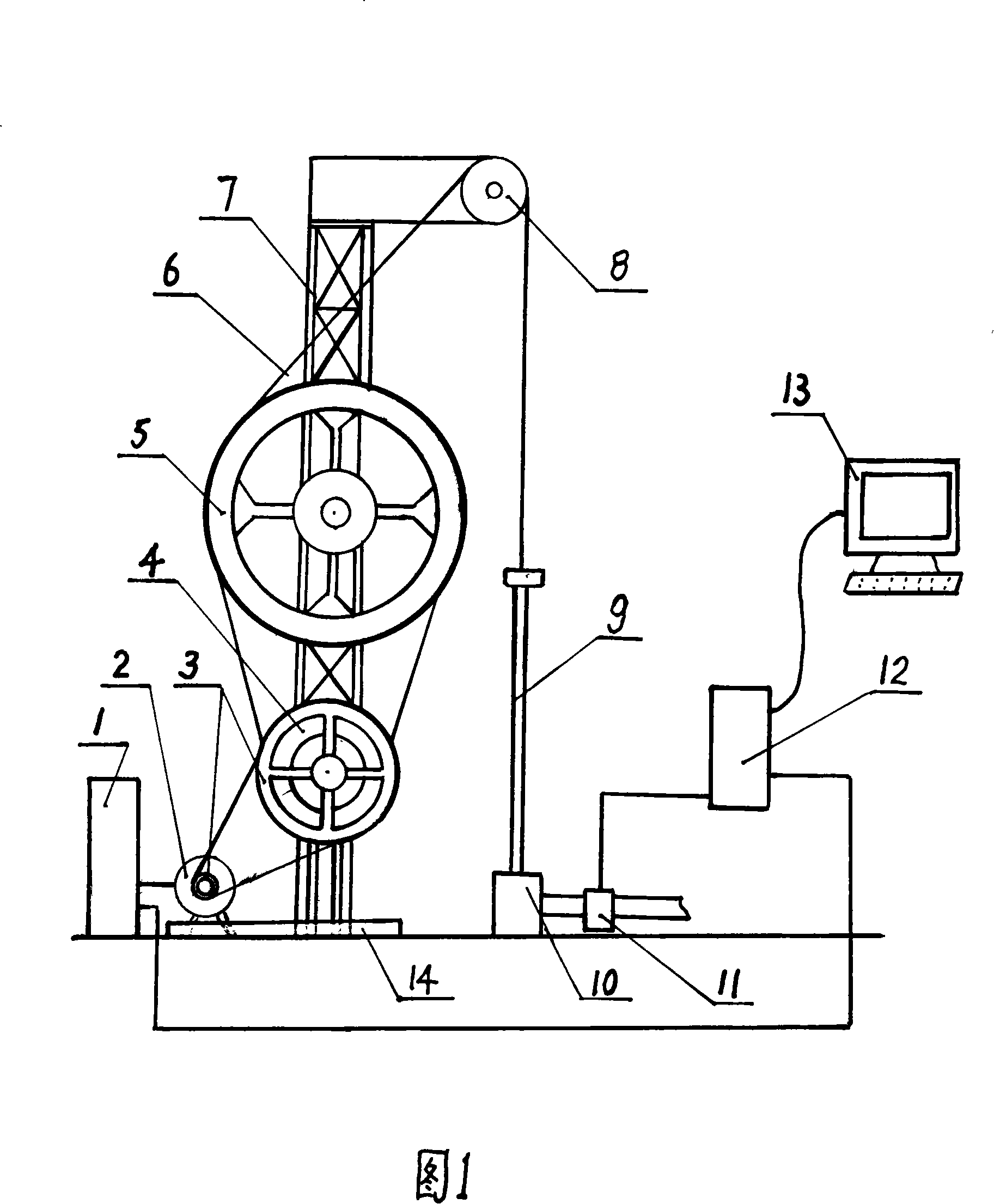

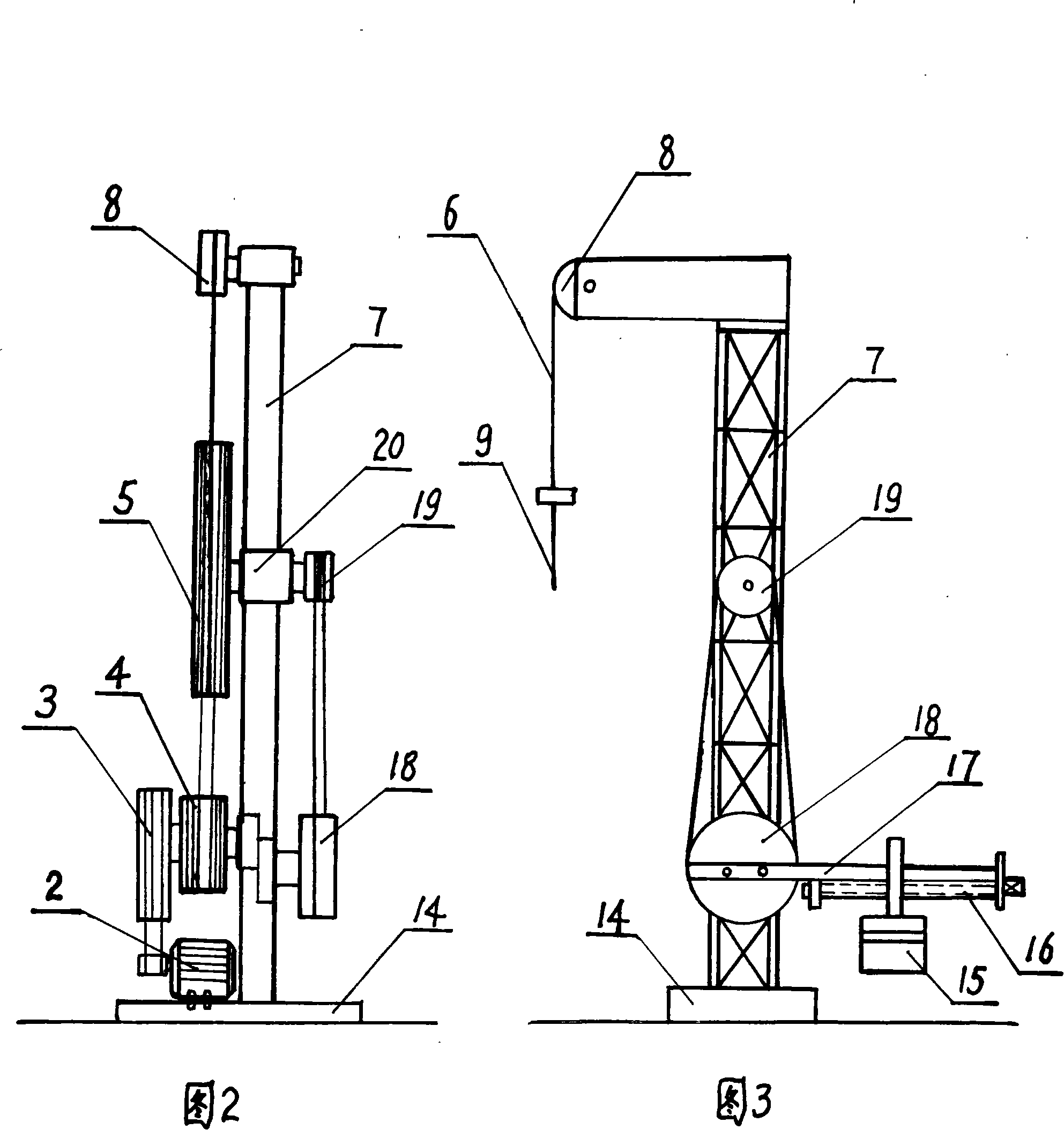

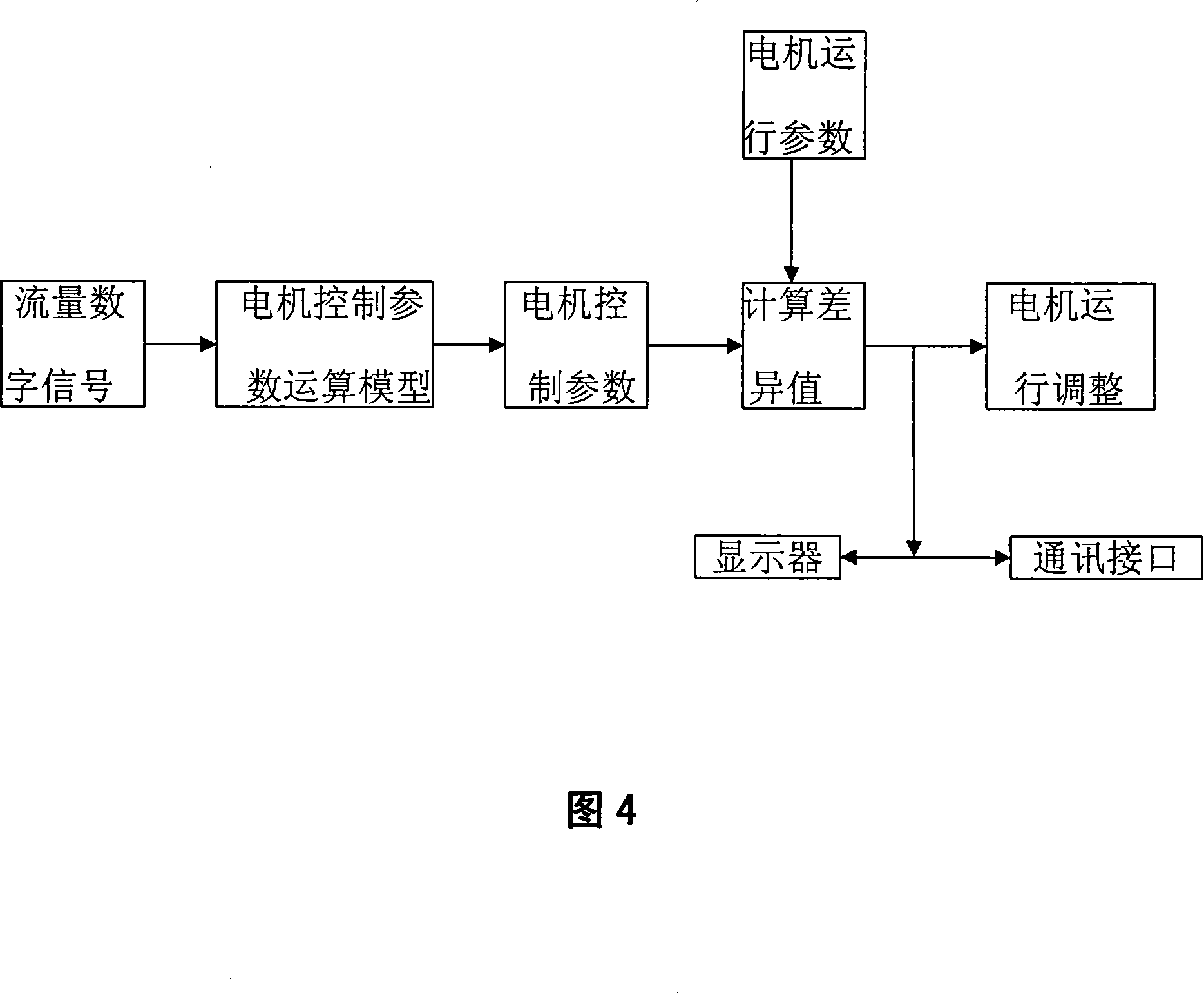

[0024] Referring to Fig. 1, Fig. 2, Fig. 3, the pendulum balance intelligent control pumping unit of the present invention has a base 14, a frame 7, a motor 2, a reversing mechanism and a balancing mechanism. Wherein: the frame 7 is a cantilever structure protruding from the top, and the extension end is equipped with a rope pulley 8 to maintain the distance between the main body of the frame 7 and the wellhead 10, which is convenient for workover operations and downhole fault handling. The reversing mechanism is arranged on one side of the frame 7 and is composed of active and passive reversing wheels 4 and 5. Both the active and passive reversing wheels 4 and 5 are provided with forward and reverse spiral rope grooves to prevent the pulling of the rope. Damaged by extrusion friction during winding. Active reversing wheel 4 is contained in the bottom of frame 7, and is connected with motor 2 by belt transmission part 3, and passive reversing wheel 5 is contained in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com