Preparation method for disinfection algicide for swimming pool

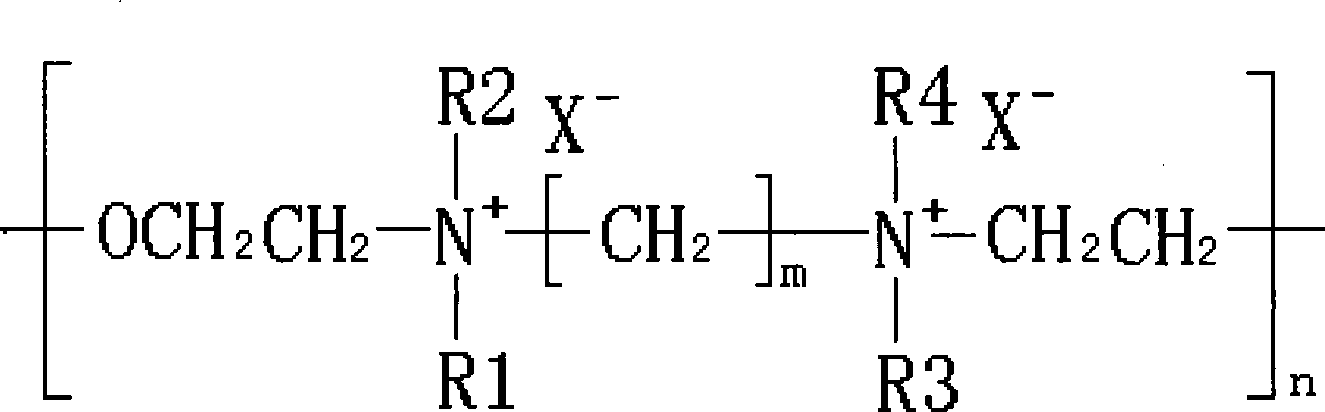

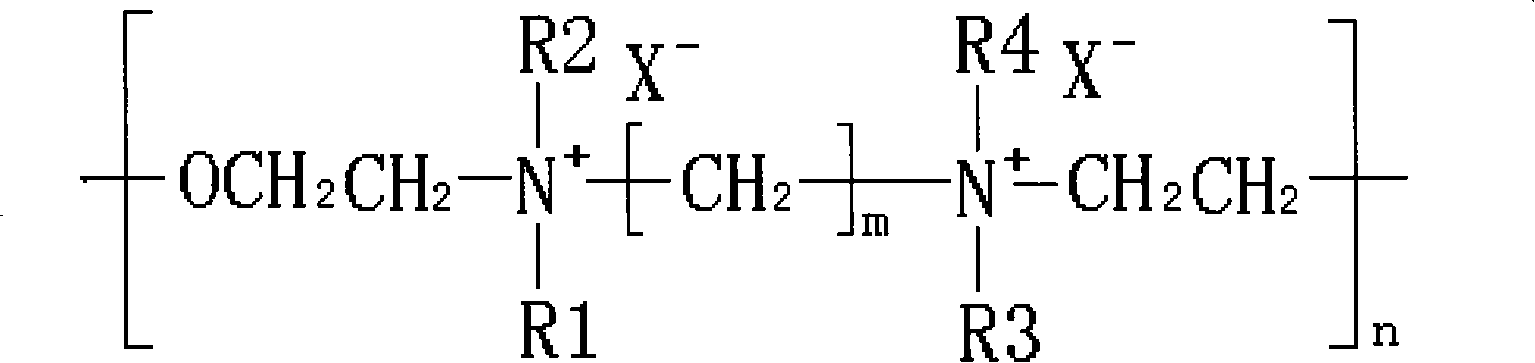

A technology of swimming pool bactericidal algaecide and post-treatment agent, applied in the direction of sterilization / microdynamic water / sewage treatment, etc. Excellent environmental compatibility and skin compatibility, excellent biodegradability, low ecotoxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 600g of deionized water and 3.5mol of dichloroethyl ether into the reactor, replace it with nitrogen until the oxygen content is less than 100ppm, turn on the stirring, raise the temperature to 60°C, and start to drop tetraethylethylenediamine (3.51mol in total), After the diamine is dripped, slowly raise the temperature to 80-95°C, keep the temperature constant for 20 hours, take a sample and control it, if the pH is less than 6.0, lower the temperature to below 50°C. Add a 30% aqueous solution containing 3.0 g of sodium bisulfite, stir for 2 hours, and adjust the pH to 7.0 with sodium hydroxide to obtain the finished product.

Embodiment 2

[0018] Add 600g of deionized water and 3.44mol of dibromoethyl ether into the reactor, replace it with nitrogen until the oxygen content is less than 100ppm, turn on the stirring, raise the temperature to 50°C, and start to drop tetramethylpropylenediamine (3.50mol in total), After the diamine is dripped, slowly raise the temperature to 100-105°C, keep the temperature constant for 10-15 hours, take a sample and control it, if the pH is less than 6.0, lower the temperature to below 50°C. Add 30% aqueous solution containing 1.0 g of sodium sulfite and 1.5 g (30%) of sodium borohydride solution, stir for more than half an hour, and adjust the pH to 7.0 with sodium hydroxide to obtain the finished product.

Embodiment 3

[0020] Add 600g of deionized water and 3.60mol of dibromoethyl ether into the reactor, replace it with nitrogen until the oxygen content is less than 60ppm, turn on the stirring, raise the temperature to 75°C, and start to drop tetramethylpropylenediamine (3.40mol in total), After the diamine is dropped, the temperature is slowly raised to 110-120°C, kept at a constant temperature for 8 hours, and controlled during sampling. If the pH is less than 6.0, the temperature is lowered to below 50°C. Add a 30% solution containing 2.0 g of sodium thiosulfate, stir for more than 1 hour, and adjust the pH to 7.0 with sodium hydroxide to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com