Sand mold rotary gravity mould and casting method thereof

A technology of gravity molds and sand molds, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of clay sand mold casting occupying a large space, increasing the grinding and polishing allowance, and increasing the cost of manpower and material resources, so as to save Cost and resources, ease of processing and polishing, effects of overcoming high cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

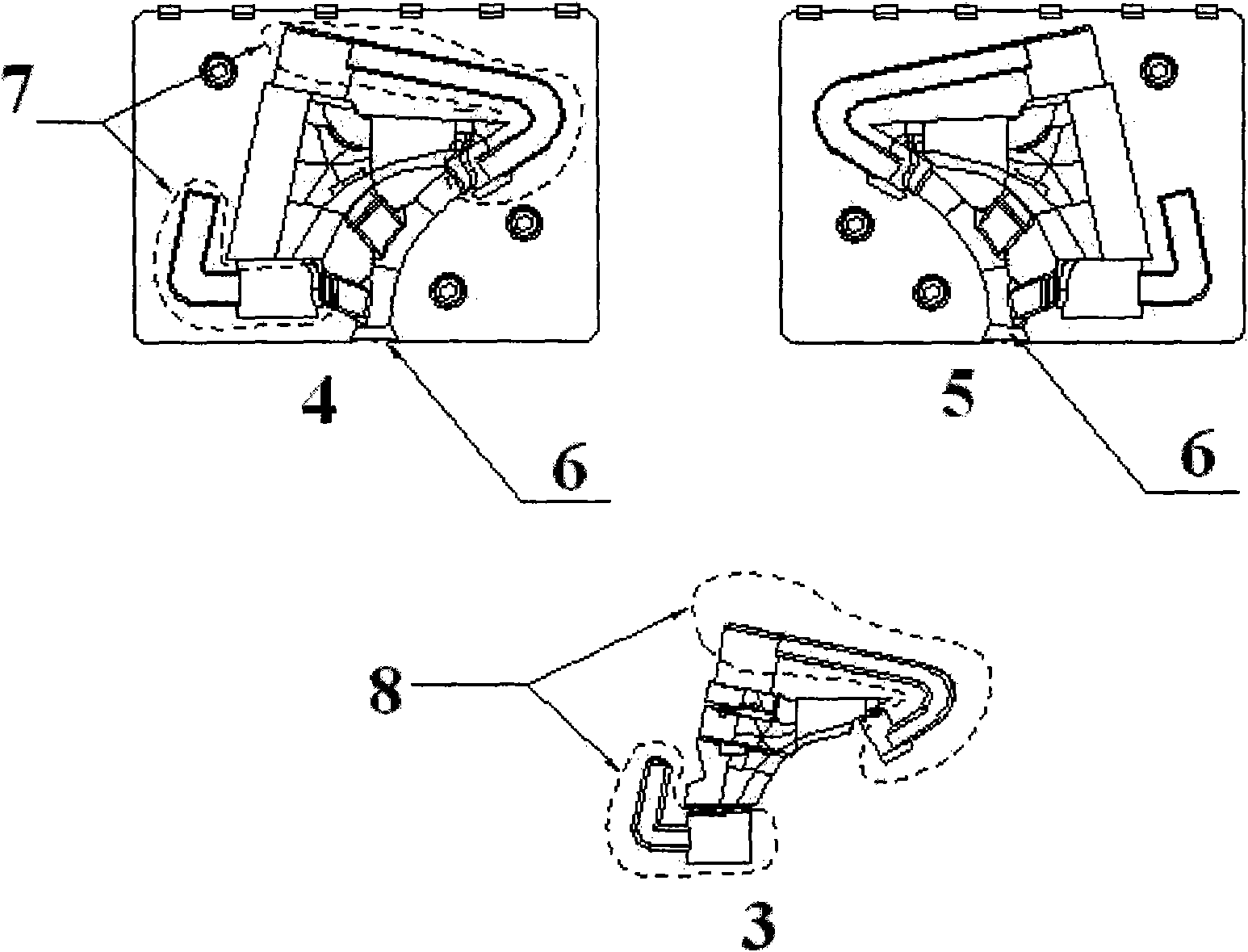

[0043] Example 1: (2) In the sand mixing process, the raw sand is 70 mesh-100 mesh raw sand and 150 mesh-200 mesh raw sand according to a 1:1 ratio; take 100 kg of raw sand with a good ratio as an example, and the resin is 3 kg , The curing agent is 0.4kg. (3) During mold heating: according to the structure size of the sand core and sand mold, heat to a suitable curing temperature, and the temperature is controlled at 220 degrees; (4) The casting temperature of alloy copper is 1020 degrees; (5) The casting after casting is completed for 15 seconds Take out from sand mold gravity mold 4,5 afterward.

Embodiment 2

[0044] Example 2: (2) In the sand mixing process, the raw sand is 70 mesh-100 mesh raw sand and 150 mesh-200 mesh raw sand in a 2:1 ratio; take 100 kg of raw sand with a good ratio as an example, and the resin is 2 kg , The curing agent is 0.3kg. (3) Mold heating: According to the structure size of the sand core and sand mold, heat to a suitable curing temperature, and the temperature is controlled at 300 degrees; (4) The alloy copper casting temperature is 1040 degrees; (5) The casting after casting is completed for 35 seconds Take out from sand mold gravity mold 4,5 afterward.

Embodiment 3

[0045] Example 3: (2) In the sand mixing process, the raw sand is 70 mesh-100 mesh raw sand and 150 mesh-200 mesh raw sand in a 3:1 ratio; take 100 kg of raw sand with a good ratio as an example, and the resin is 6 kg , The curing agent is 0.9kg. (3) Mold heating: According to the structure size of the sand core and sand mold, heat to a suitable curing temperature, and the temperature is controlled at 320 degrees; (4) The alloy copper casting temperature is 1030 degrees; (5) The casting after casting is completed for 25 seconds Take out from sand mold gravity mold 4,5 afterward.

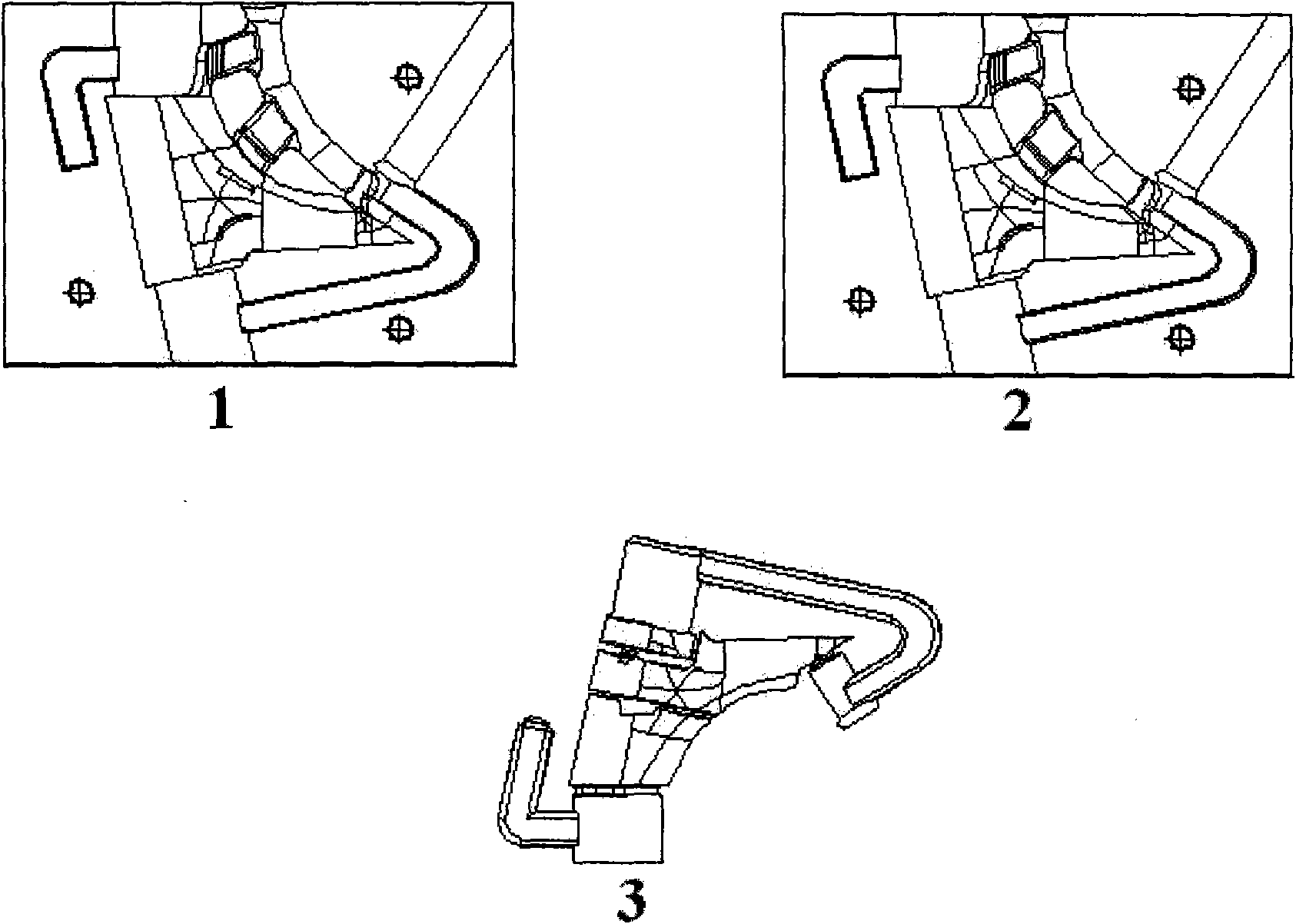

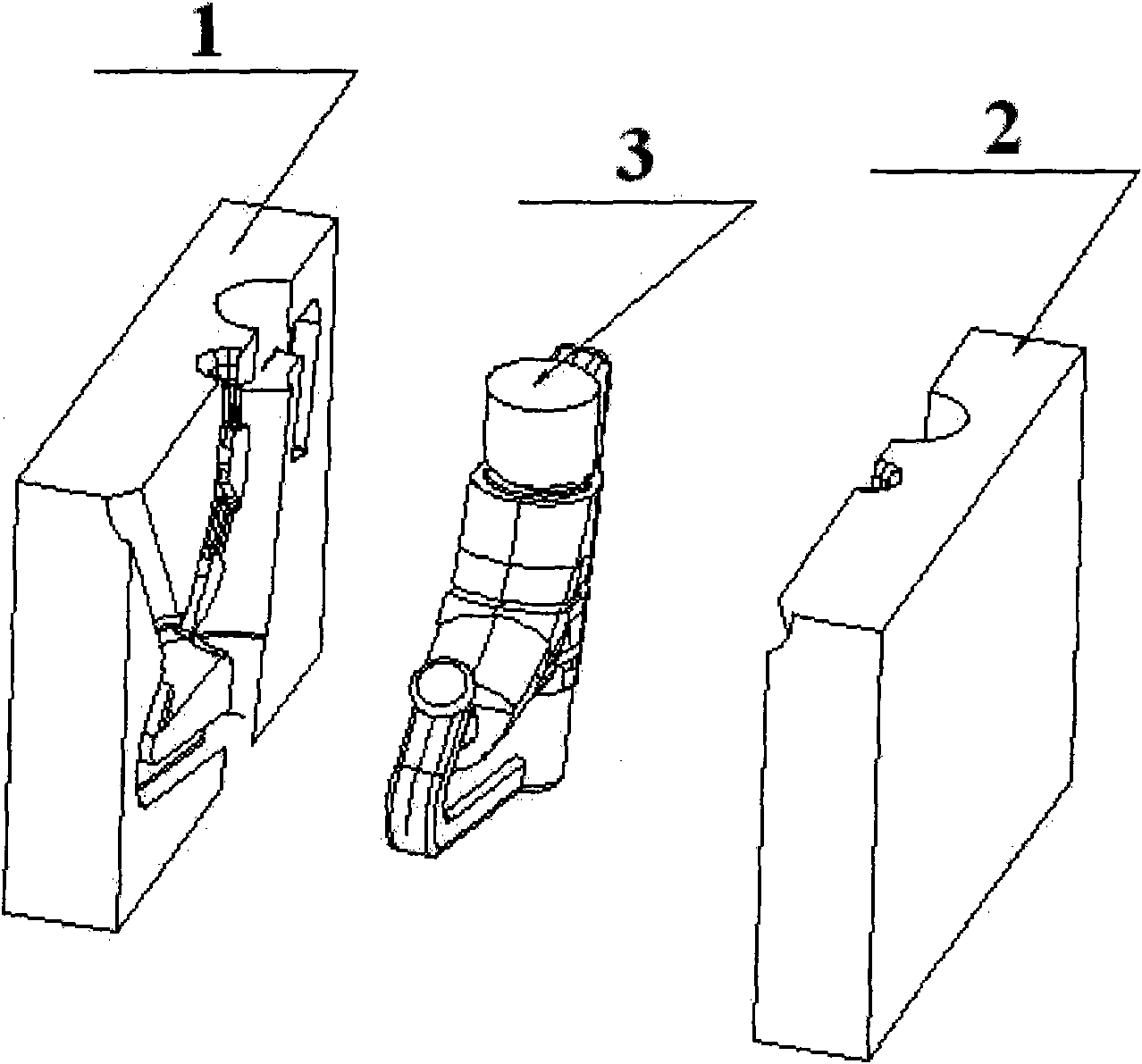

[0046] The traditional metal mold gravity casting process is as follows: figure 1 with figure 2 as shown,

[0047] (1) Install the internal structure sand core 3 on the sand core machine, and adjust the parameters at the same time (the sand blowing time, sand blowing pressure and curing time are adjusted according to the structure size of the sand core and sand mold).

[0048] (2) Sand mixing: r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com