Automatic bag sticking machine

A bag patching machine, fully automatic technology, applied in the direction of cloth pressing mechanism, cloth feeding mechanism, sewing machine components, etc., can solve the problems of unable to achieve the same color, unable to achieve double-sided multi-color automatic sewing, etc., to solve the contradiction between supply and demand, Reduce the frequency of shuttle change, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

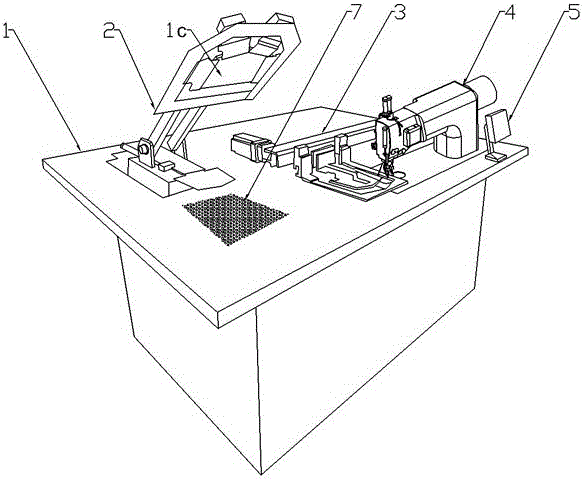

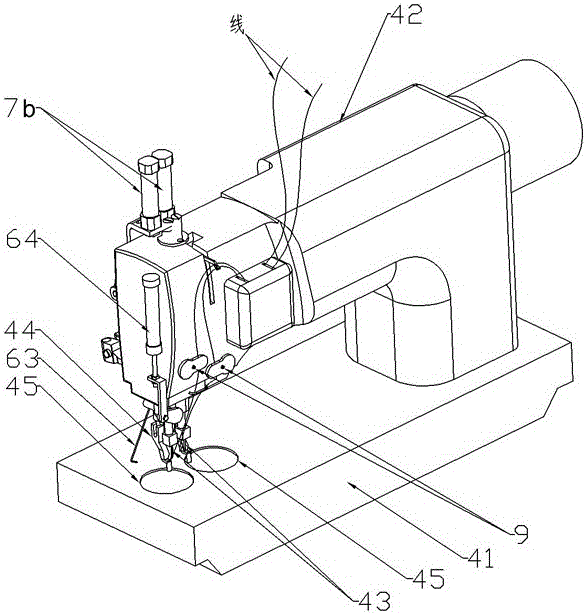

[0028] Such as Figure 1 to Figure 3 As shown, in this embodiment, the present invention includes a base 1, a folding mechanism 2, a feeding mechanism 3, a sewing mechanism 4, and a controller 5 provided on the base 1. The sewing mechanism 4 includes a sewing table 41. The machine head 42, two working needles 43 arranged on the machine head 42, two presser feet 44 that are adapted to the work needle 43 and an automatic needle change module, which are compatible with the presser foot 44 Equipped with a presser foot lifting mechanism, the sewing table 41 is provided with two shuttles 45 that are adapted to the working needle 43. In this embodiment, the shuttle 45 is a rotary shuttle. Of course, the shuttle 45 is also Can be a shuttle.

[0029] Such as Figure 4 As shown, in this embodiment, the sewing mechanism 4 further includes a thread pulling mechanism 6. The thread pulling mechanism 6 includes a thread pulling seat 61, a thread pulling shaft 62 rotatably connected with the th...

Embodiment 2

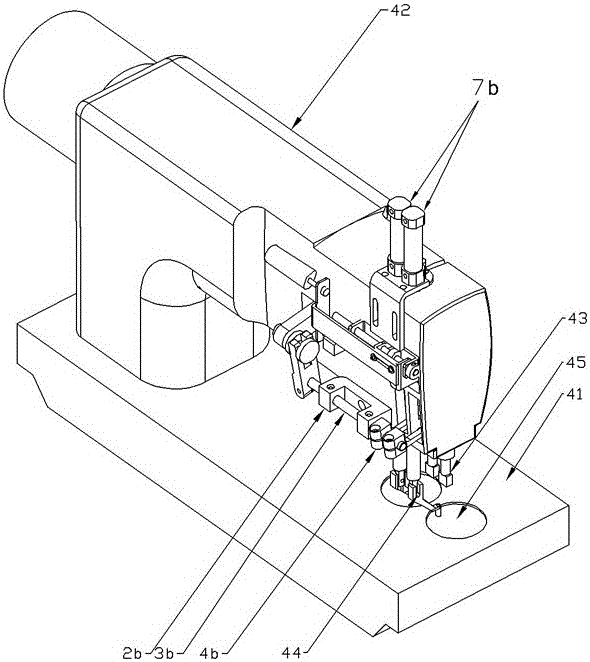

[0039] Such as Figure 5 with Image 6 As shown, in this embodiment, the difference between this embodiment and the first embodiment is that the sewing mechanism 4 further includes a thread pulling mechanism 6, and the thread pulling mechanism 6 includes a thread pulling seat 61 and The spooling support shaft 65 fixedly connected to the spooling seat 61, the spooling rotating member 66 sleeved on the spooling support shaft 65, the hook 63 fixedly arranged on the spooling rotating member 66, and the The thread-switching cylinder 64 is connected to the thread-switching member 66 in transmission. One side of the thread-switching component 66 is provided with an adjusting ring 67, and the other side of the thread-switching component 66 is provided with a thread-switching spring 68. The rotating member 66 abuts against the adjusting ring 67 under the action of the wire pulling spring 68, and the adjusting ring 67 is provided with a protrusion 69 that is adapted to the adjusting ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com