Buffer-braking anti-falling device for disposing rope breakage of vertical conveyor

A technology of buffer braking and elevators, applied in elevators, transportation and packaging, etc., can solve the problems of brake and guide rail wear, long friction braking distance, squatting accidents, etc., and achieve short braking distance, high safety, work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

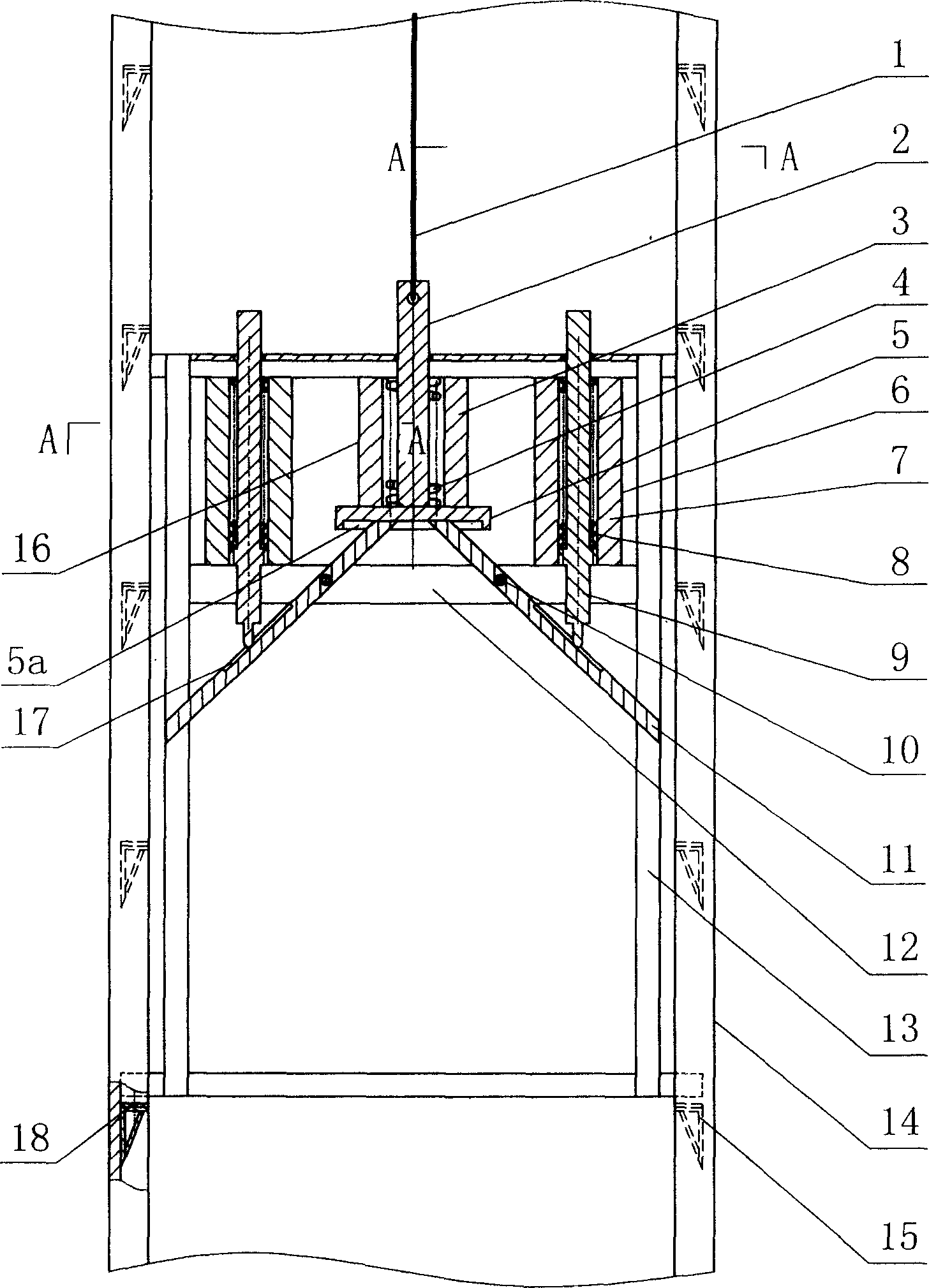

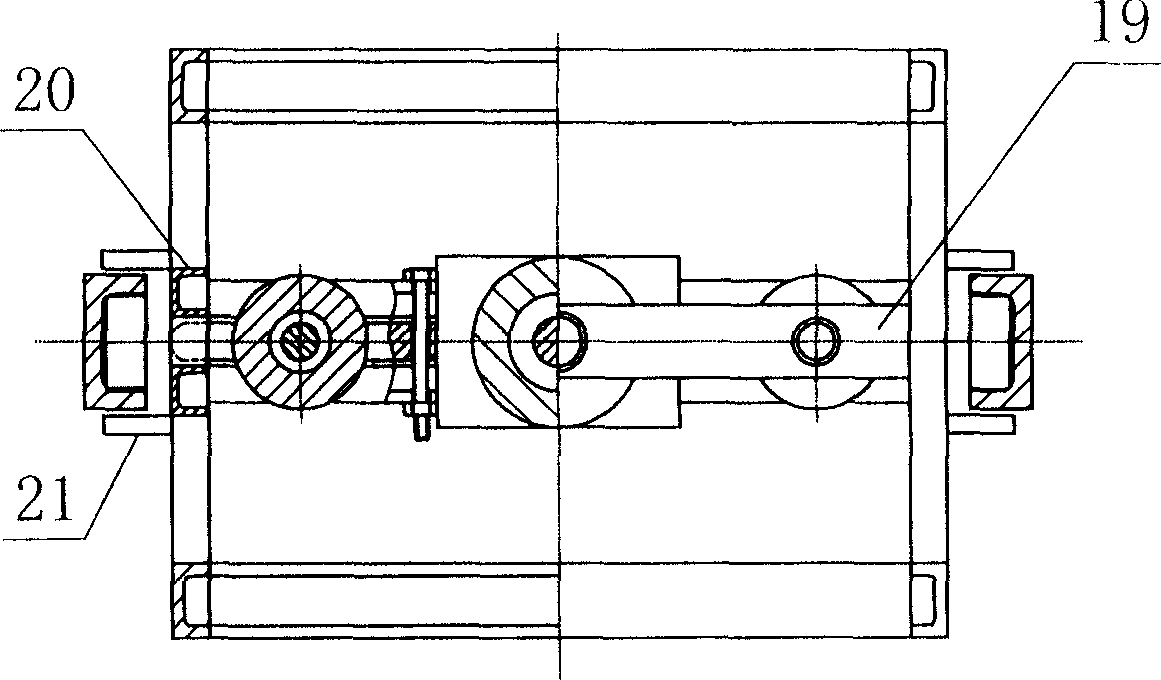

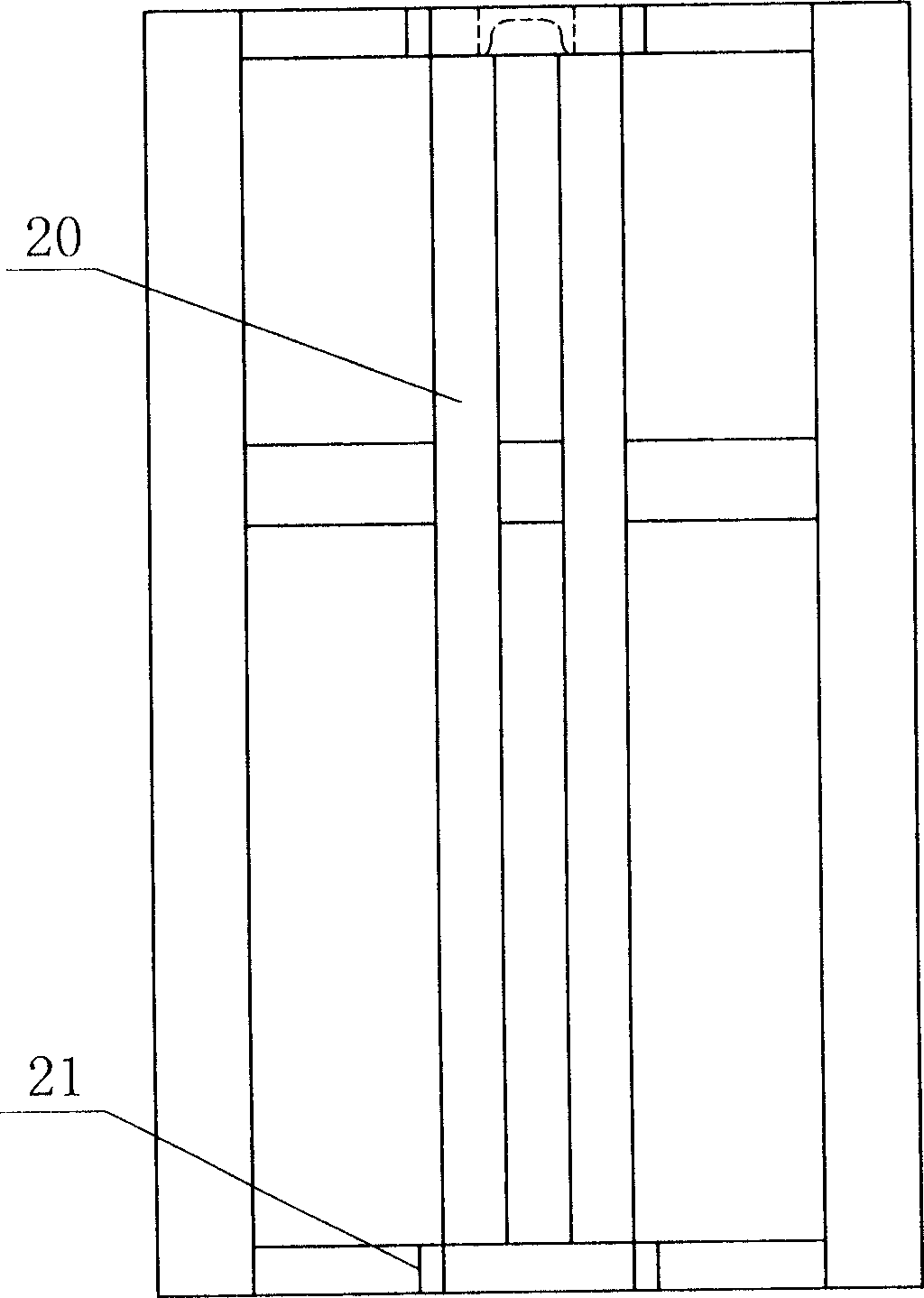

[0017] As shown in the figure, the present invention has a guide rail frame 14 made of channel steel, and a car 13 is arranged in the guide rail frame 14. The car 13 is welded by channel steel. The middle part is respectively symmetrically provided with two vertical beams 20, and the upper and lower ends of the vertical beams 20 are respectively provided with guide shoes 21, and the guide shoes 21 are stuck in the guide rail frame 14 to prevent the car 13 from rocking back and forth when lifting. The inner top surface of the car 13 is provided with a beam 19, and the upper part of the car 13 is provided with a brake. Two brake levers 11 arranged on both sides of the brake beam 12 constitute. The two ends of the brake beam 12 are respectively welded on the vertical beam 20, and the brake shaft 10 passes through the two brake beams 12 and is fixed by a nut and a latch to prevent the nut from falling off; the brake lever 11 The brake shaft 10 can be rotated as a shaft, so that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com