Ash-scraping waste-heat-recovering coal-saving device

A technology of waste heat recovery and economizer, applied in heat exchanger types, indirect heat exchangers, clean heat transfer devices, etc., can solve problems affecting heat recovery, airflow velocity or impact velocity decrease, and poor ash cleaning effect, etc. Achieve the effects of high heat recovery rate, low manufacturing cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below utilize accompanying drawing and embodiment to further describe the present invention:

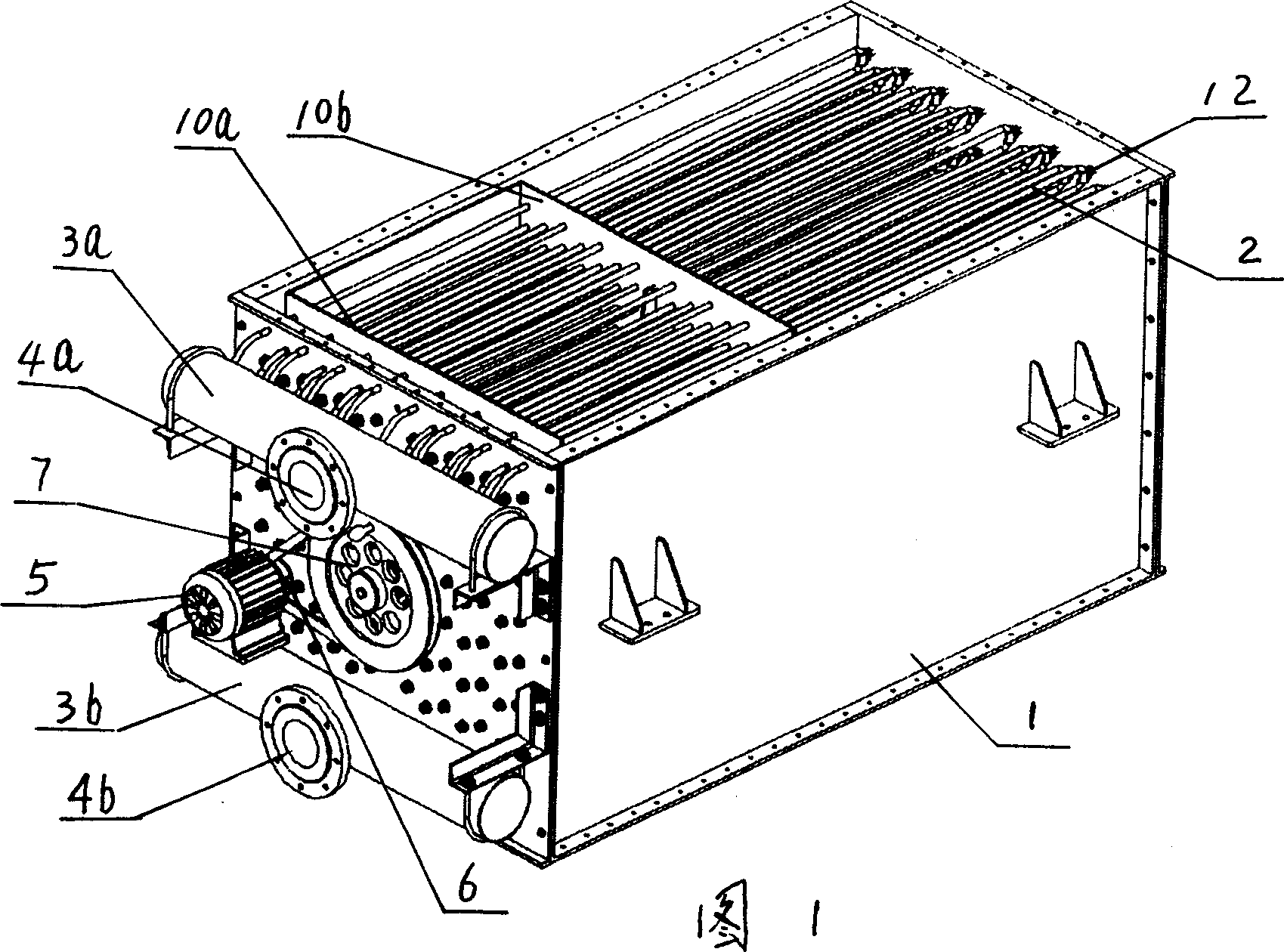

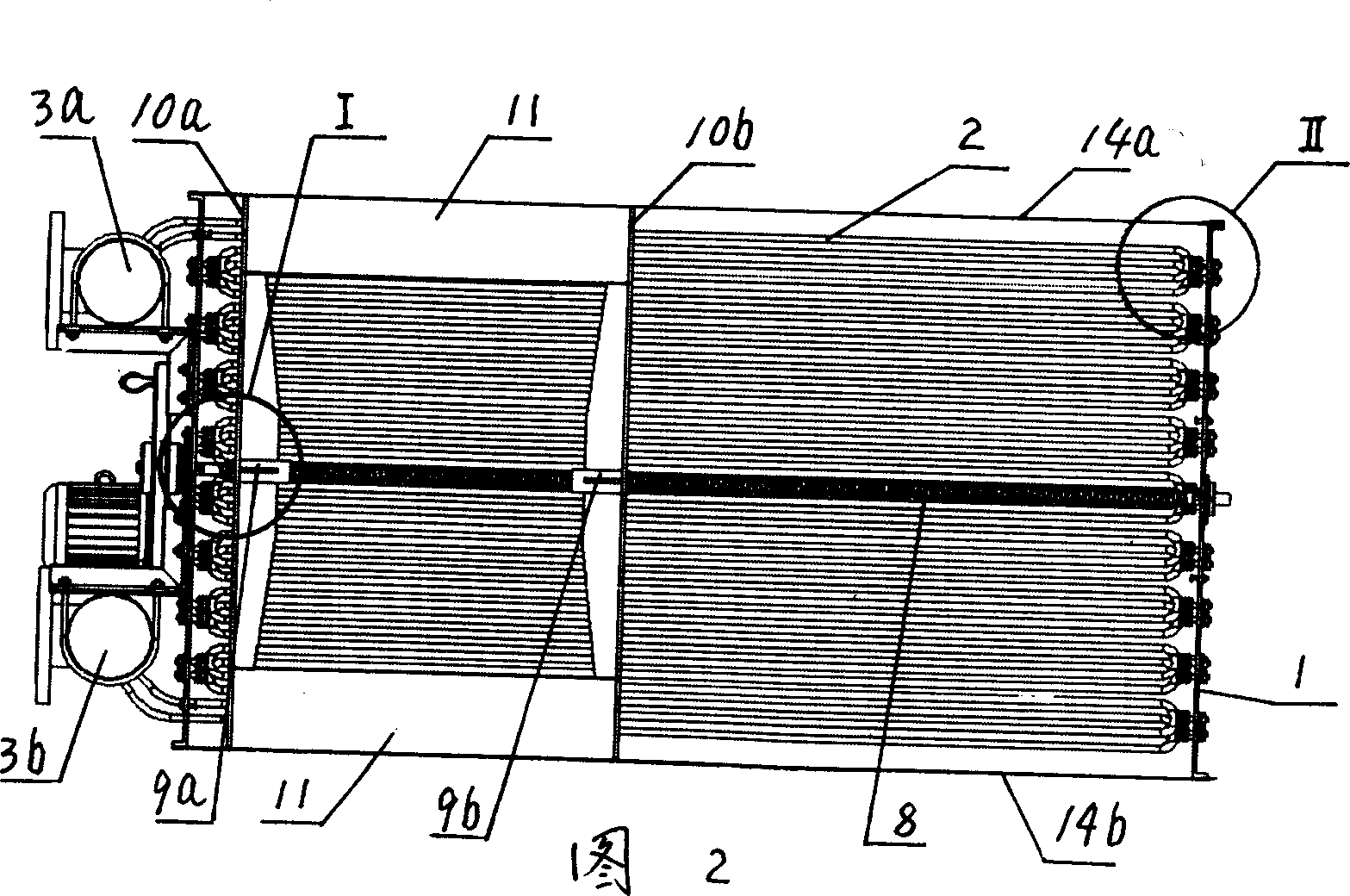

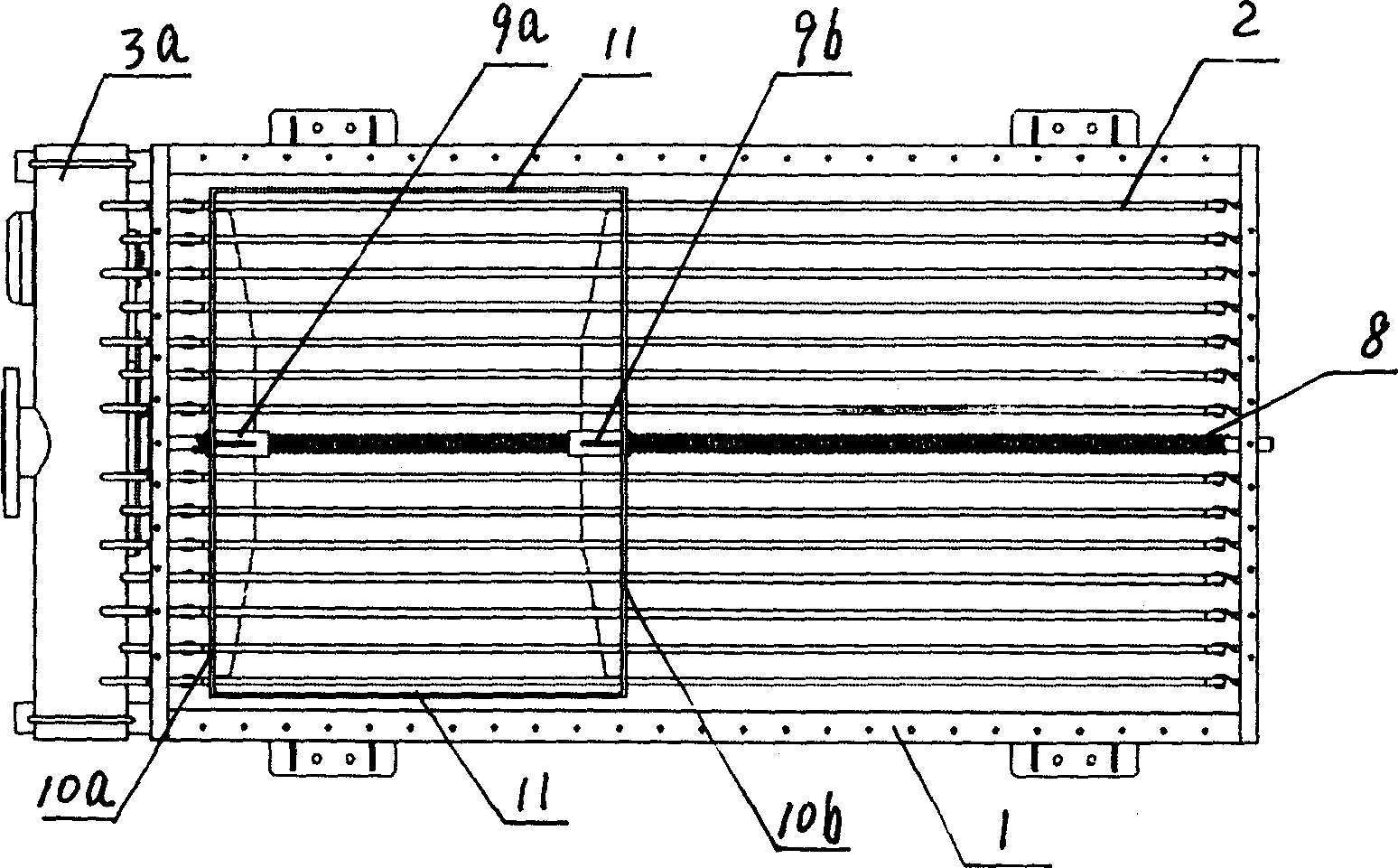

[0014] Referring to Figure 1-4, the ash scraping waste heat recovery economizer is mainly composed of a box body 1, a serpentine tube bundle 2, headers 3a, 3b, ash scraping device and scraper driving device. The box body 1 is surrounded by four steel plates at the front, the rear, the left and the right, and is connected by flanges, bolts and nuts. The welding connection is not used for the convenience of disassembly during maintenance. When using the ash-scraping waste heat recovery economizer, the connection between the ash-scraping waste heat recovery economizer and the flue is also connected by flanges, bolts and nuts.

[0015] refer to Figure 5 and 6 , in order to facilitate the sliding of the scraper along the heated outer surface of the serpentine tube bundle 2, the serpentine tube bundle 2 is hung on the left and right box panels of the box body 1 through the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com