Row-line type integrated jacket pipe heat exchanger detachable scale clean structure

A heat exchanger and determinant technology, applied in the field of heat exchangers, can solve the problem of difficult to physically remove the fouling in the inner tube, and achieve the effects of saving maintenance, convenient disassembly, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

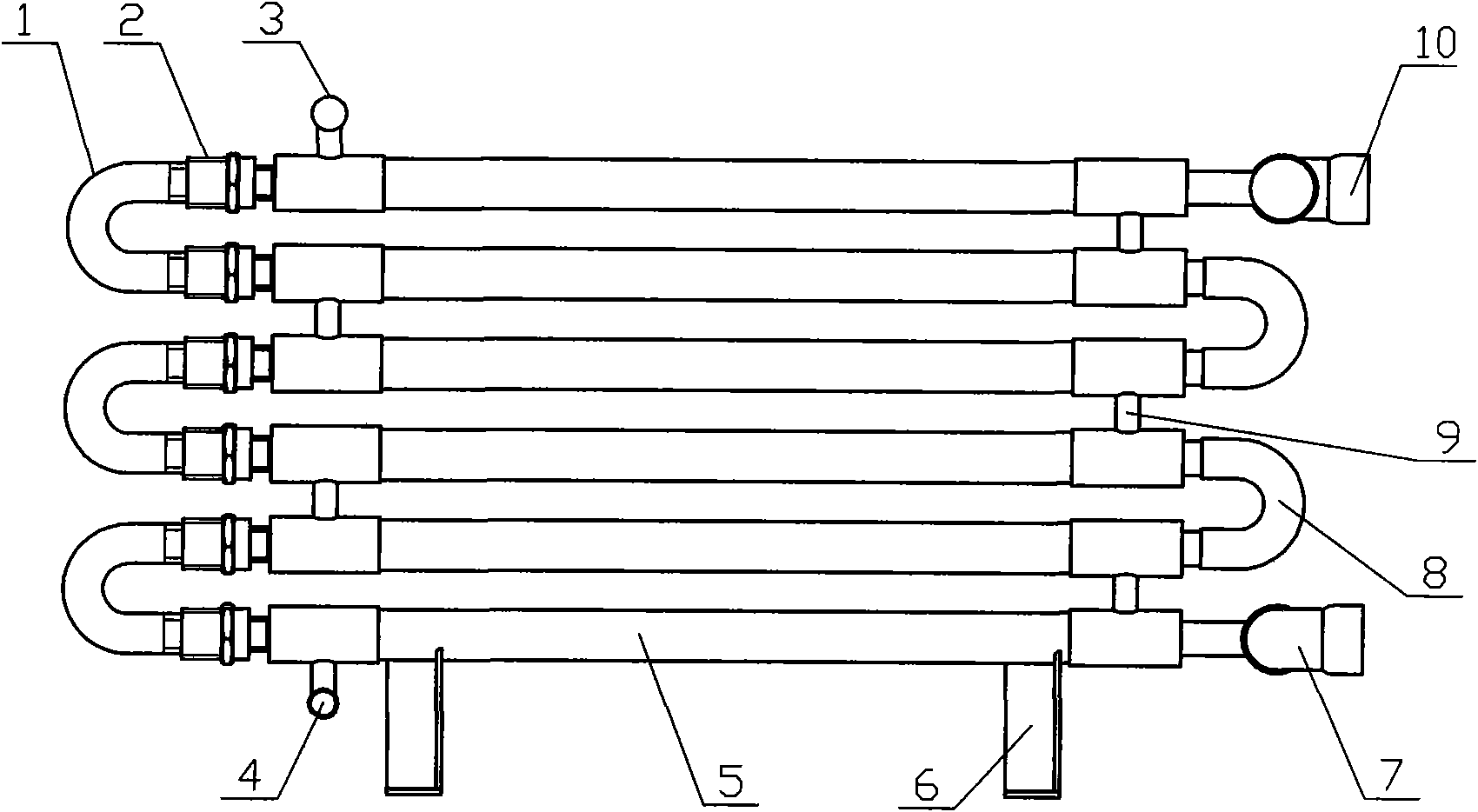

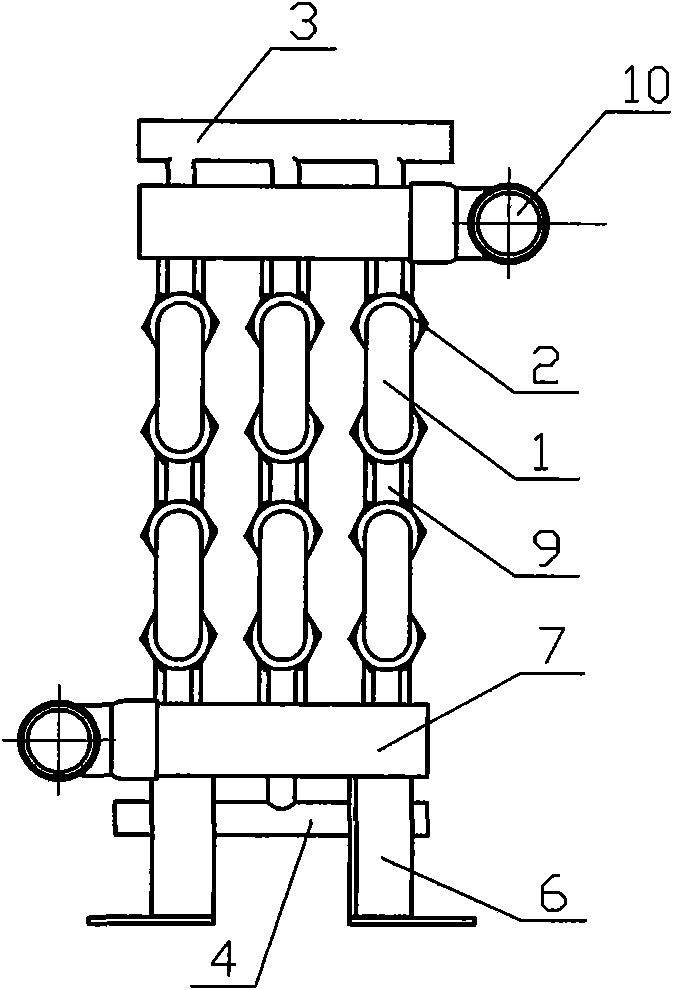

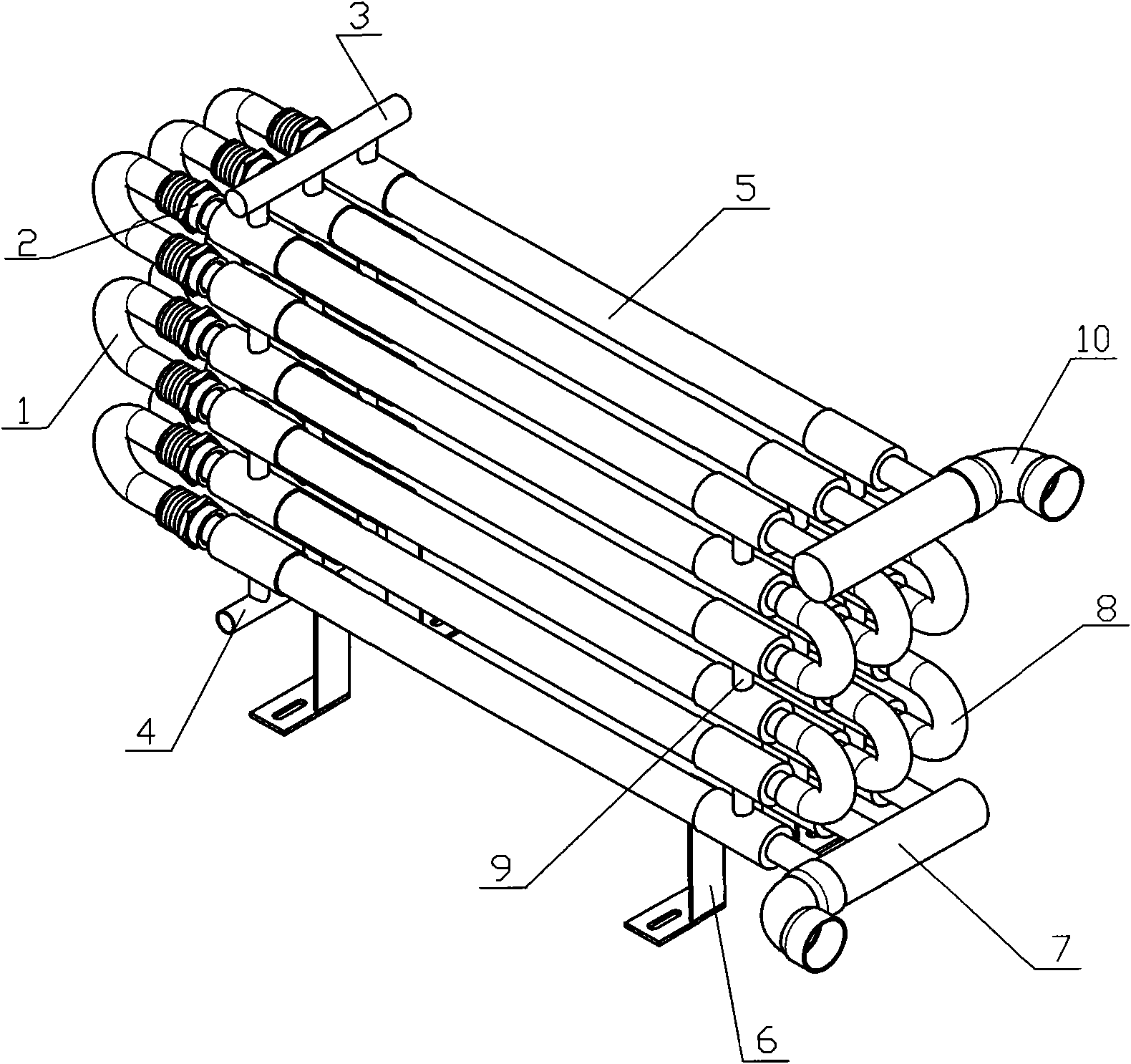

[0015] figure 1 , figure 2 and image 3 The detachment and descaling structure of the determinant integrated casing heat exchanger includes a U-shaped connecting pipe 1 and a C-shaped connecting pipe 8 sequentially connected in series with horizontal casings 5 , short pipes 9 , refrigerant inlet pipe 3 , and refrigerant outlet 4 , water inlet pipe 7, water outlet pipe 10 and foot 6. The rows of casing pipes 5 are connected by short pipes 9 , and the refrigerant inlet pipe 3 , water inlet pipe 7 and water outlet pipe 10 placed vertically are perpendicular to the casing pipes 5 . In this embodiment, there are three rows and three columns of bushings 5, and the refrigerant inlet pipes 3 are respectively connected to the top short pipes 9 of the three rows of bushings 5 to form a parallel structure. Connected, the outlet pipe 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com