Device and method for preparing In2Se3

A vertical placement, quartz tube technology, applied in the methods of chemically changing substances by atmospheric pressure, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low production efficiency and too large feeding amount, etc. To achieve the effect of low equipment requirements, reduce volatilization, and avoid a sharp rise in reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

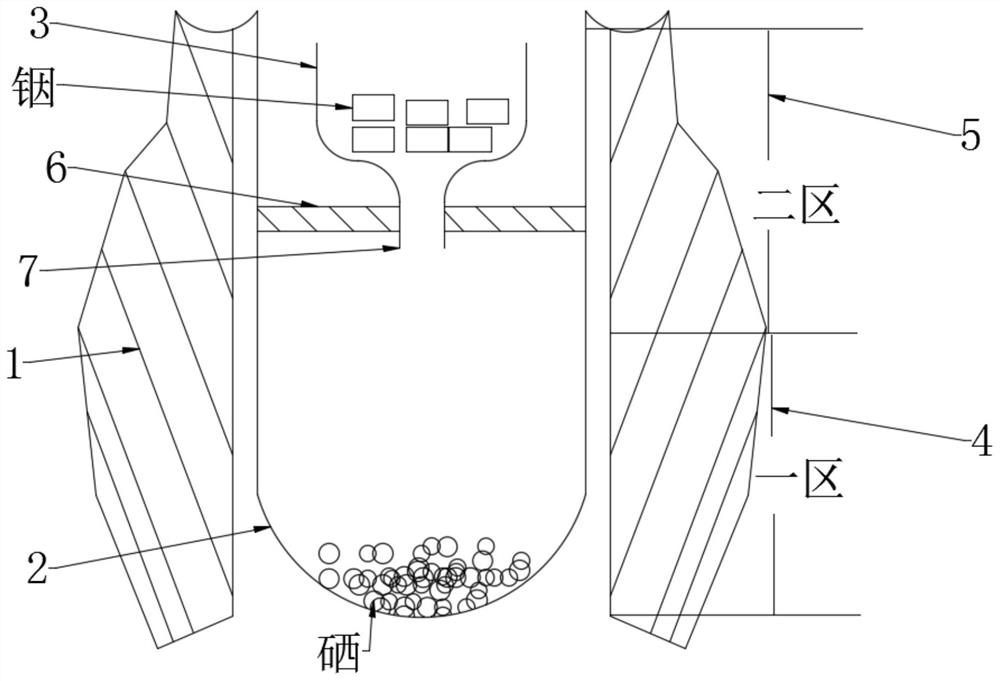

[0031] This example provides a method for preparing In 2 Se 3 A device comprising a rocking furnace 1, a quartz tube 2 and a quartz crucible 3. Wherein, the swing furnace 1 is provided with a first heating zone 4 and a second heating zone 5, the quartz tube 2 is vertically placed in the swing furnace 1, the lower end of the quartz tube 2 corresponds to the first heating zone 4, and the upper end of the quartz tube 2 It corresponds to the second heating zone 5 . The quartz crucible 3 is vertically placed inside the upper end of the quartz tube 2 through the support plate 6 , and the bottom of the quartz crucible 3 is provided with a nozzle 7 passing through the support plate 6 .

[0032] Specifically, the inner diameter of the nozzle 7 is 0.3-1.5 mm. The center of support plate 6 is provided with the jack that allows material nozzle to pass through, and the aperture of jack is 2cm; Support plate 6 is also provided with 4 through holes of symmetrical distribution, and the ape...

Embodiment 2

[0034] This example provides a method for preparing In 2 Se 3 The method adopts the device of embodiment 1 to prepare, and the steps are as follows:

[0035] (1) Preliminary synthesis of In 2 Se 3

[0036] a: According to In 2 Se 3 In order to measure the mass fraction of In and Se in the medium, weigh 4.922kg of In bars and put them into a quartz crucible. The inner diameter of the nozzle of the quartz crucible is 0.3mm. In the quartz tube, the quartz crucible is placed on the support plate, and the nozzle of the quartz crucible passes through the support plate;

[0037] b: Introduce nitrogen gas into the quartz tube to replace the air in the quartz tube. The flow rate of nitrogen gas is 6L / min, and the ventilation time is 1h. After the ventilation is completed, cover the tail cap of the quartz tube and place the quartz tube vertically in the swing furnace;

[0038] c: First turn on the first heating zone of the swing furnace, raise the temperature to 250°C, and keep i...

Embodiment 3

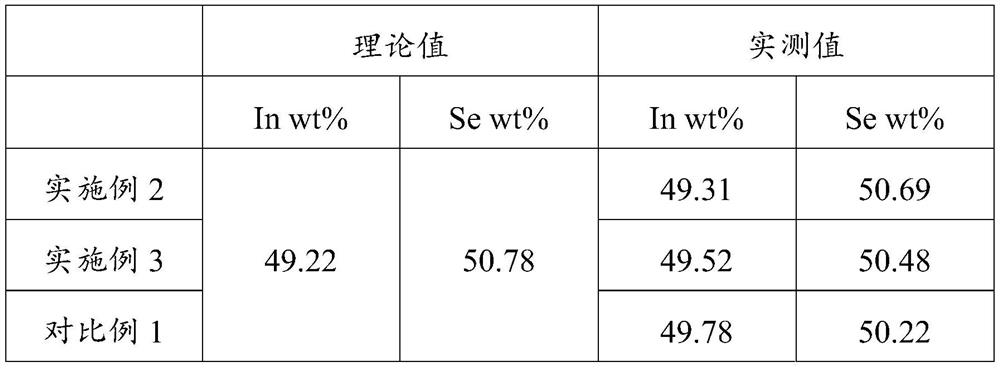

[0043] This example provides a method for preparing In 2 Se 3 The method also adopts the device of embodiment 1 to prepare, and the steps are similar to the steps of embodiment 2, the difference is only: the inner diameter of the nozzle of the quartz crucible is different, and the inner diameter of the nozzle of the quartz crucible of the present embodiment is 1.5 mm. Specific steps are as follows:

[0044] (1) Preliminary synthesis of In 2 Se 3

[0045] a: According to In 2 Se 3 In the mass fraction of In and Se, weigh 4.922kg of In bar and put it into the quartz crucible. The inner diameter of the nozzle of the quartz crucible is 1.5mm. In the quartz tube, the quartz crucible is placed on the support plate, and the nozzle of the quartz crucible passes through the support plate;

[0046] b: Introduce nitrogen gas into the quartz tube to replace the air in the quartz tube. The flow rate of nitrogen gas is 6L / min, and the ventilation time is 1h. After the ventilation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com