Hole sealing device for drilled hole

A technology of sealing device and sealing pipe, which is applied in the directions of safety device, earthwork drilling, sealing/isolation, etc., can solve the problems of unsatisfactory sealing effect, inconvenient extraction work, and no sealing device, etc. Good sealing effect, improve work efficiency and safety, and save materials

Inactive Publication Date: 2016-08-03

CHNA ENERGY INVESTMENT CORP LTD +1

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the different geological conditions of high outburst mines, gas permeability of coal seams, development of coal seam fissures, gas content, gas pressure and other conditions, different sealing methods are selected, which bring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

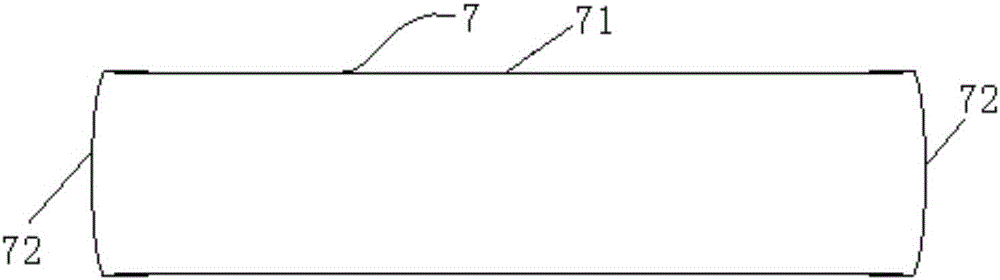

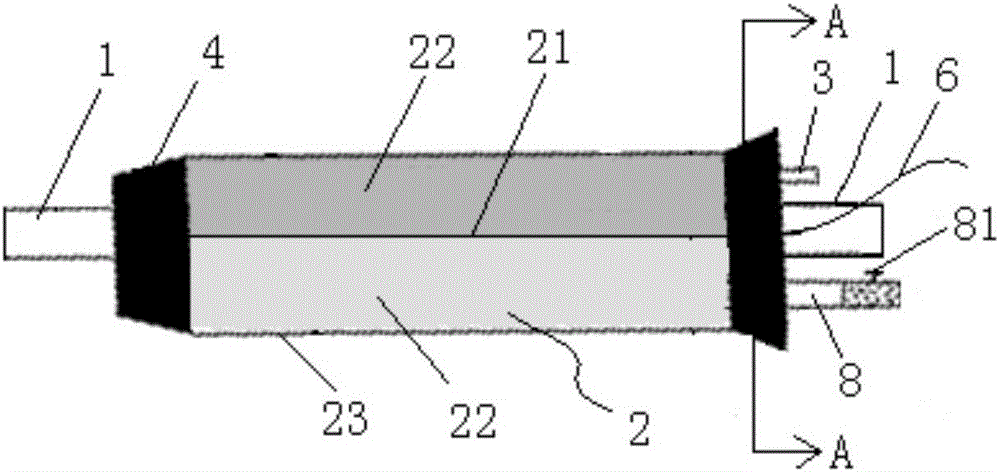

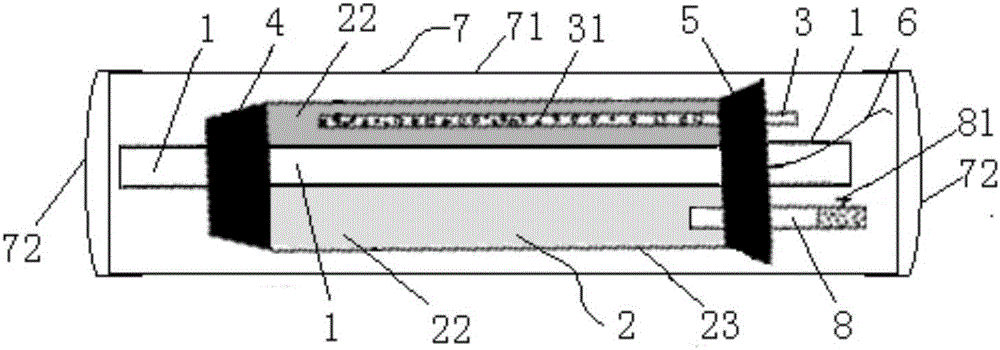

The invention discloses a hole sealing device for a drilled hole. The device comprises a hole sealing pipe, a bag, an inner leaking stoppage plug, an outer leaking stoppage plug and a pull rope. The two ends of the hole sealing pipe are sleeved with the inner leaking stoppage plug and the outer leaking stoppage plug respectively and penetrate out of the inner leaking stoppage plug and the outer leaking stoppage plug respectively. The bag comprises a bag film. The bag film coaxially surrounds and is arranged outside the hole sealing pipe. The sealed annular bag is formed by the bag film and the outer wall of the hole sealing pipe. The thickness of the bag film is smaller than or equal to 1 mm. At least two barriers are arranged in the bag and divide the bag into at least two bag chambers which are not communicated. One end of the pull rope is fixedly connected to at least one barrier, and the other end of the pull rope penetrates out of the outer leaking stoppage plug. The bag contains hole sealing materials comprising various kinds of components. Each bag chamber contains one kind of component of the hole sealing materials. According to the hole sealing device, the barriers can be removed or torn open by pulling the pull rope, the hole sealing materials in the bag chambers are mixed, reacted and expanded, and therefore the drilled hole is sealed; operation is simple, and the hole sealing effect is good.

Description

technical field [0001] The invention belongs to the field of coal mines, in particular to a hole sealing device for drilling. Background technique [0002] "One connection and three defenses" in mines is the top priority of coal mine safety, and gas prevention and control is the top priority of "one connection and three preventions". Gas control work is an important means to prevent accidents, and gas accidents are the most serious in coal mine production. one of the natural disasters. Gas drainage is the most fundamental measure to solve the problems of high gas content and large gas emission in mines. There are many factors that affect the effect of mine gas drainage. The most basic security measures for work. Gas control focuses on drainage, and the drainage effect depends on factors such as the sealing effect. In order to give full play to the role of drilling drainage and achieve the expected drainage effect, the sealing effect of drilling is an important content to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B33/13E21F7/00

CPCE21B33/13E21F7/00

Inventor 赵威宋文义石银斌李国强

Owner CHNA ENERGY INVESTMENT CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com