Mesoporous carbon material preparation method

A technology of mesoporous carbon and sodium-potassium alloy, which is applied in the preparation/purification of carbon, etc., can solve the problems that it is difficult to meet the requirements of synthetic substances, and the chemical and physical properties of carbon materials are quite different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Chemical materials are: metal sodium, metal potassium, carbon tetrachloride, toluene, ethanol, deionized water, and the preparation dosage of the combination is as follows: in grams and milliliters

[0029]

[0030] (1) Selected chemical substances and materials

[0031] The chemical substances and materials used in the preparation should be carefully selected and their quality and purity should be controlled:

[0032]

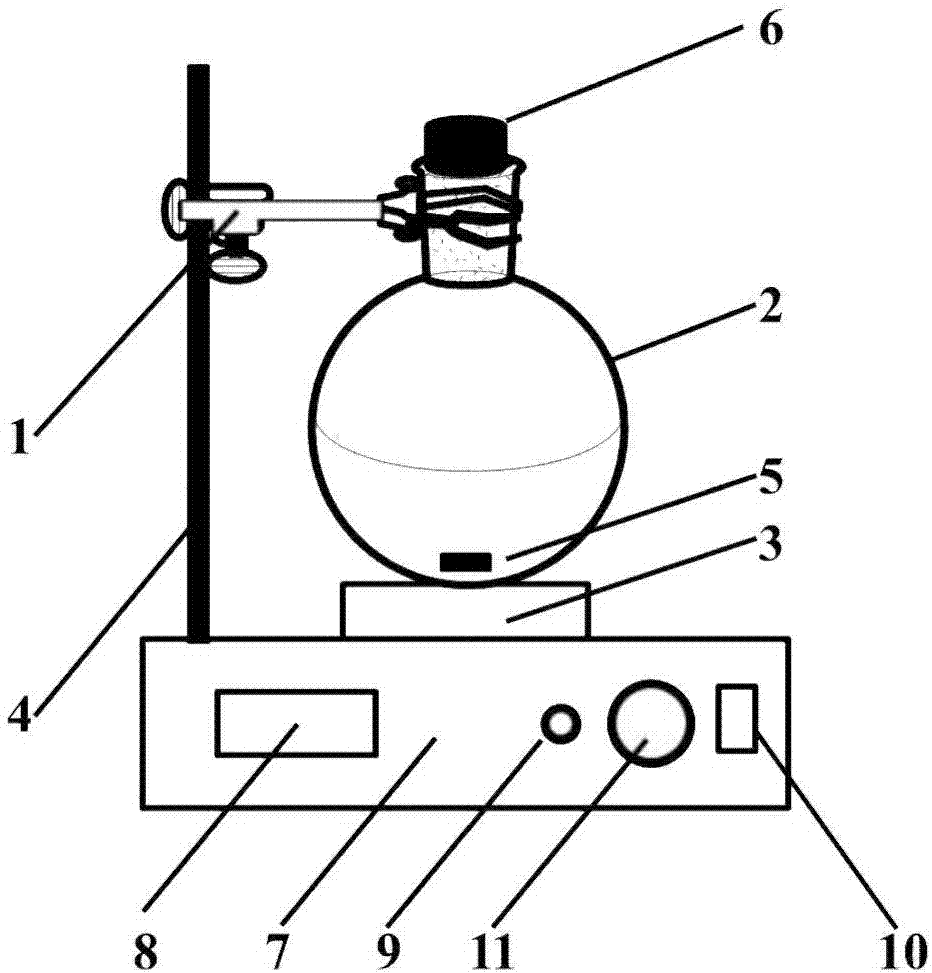

[0033] (2) Preparation of sodium potassium alloy

[0034] Weigh 0.4g±0.03g of sodium metal and 1.6g±0.04g of potassium metal, stir for 1min to form a sodium-potassium alloy;

[0035] (3) Synthesis of mesoporous carbon materials at room temperature

[0036] The synthesis of mesoporous carbon materials is carried out under the protection of nitrogen, and is completed by stirring at room temperature;

[0037] ① Prepare mixed reaction mixture

[0038] Weigh 1.2±0.04g of carbon tetrachloride, 1.8±0.05g of sodium potassium alloy, and 200mL±0.5mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com