Patents

Literature

94 results about "Sodium-potassium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium-potassium alloy, colloquially called NaK (commonly pronounced /næk/), is an alloy of two alkali metals, sodium (Na, atomic number 11) and potassium (K, atomic number 19), and which is usually liquid at room temperature. Various commercial grades are available. NaK is highly reactive with water (like its constituent elements) and may catch fire when exposed to air, so must be handled with special precautions.

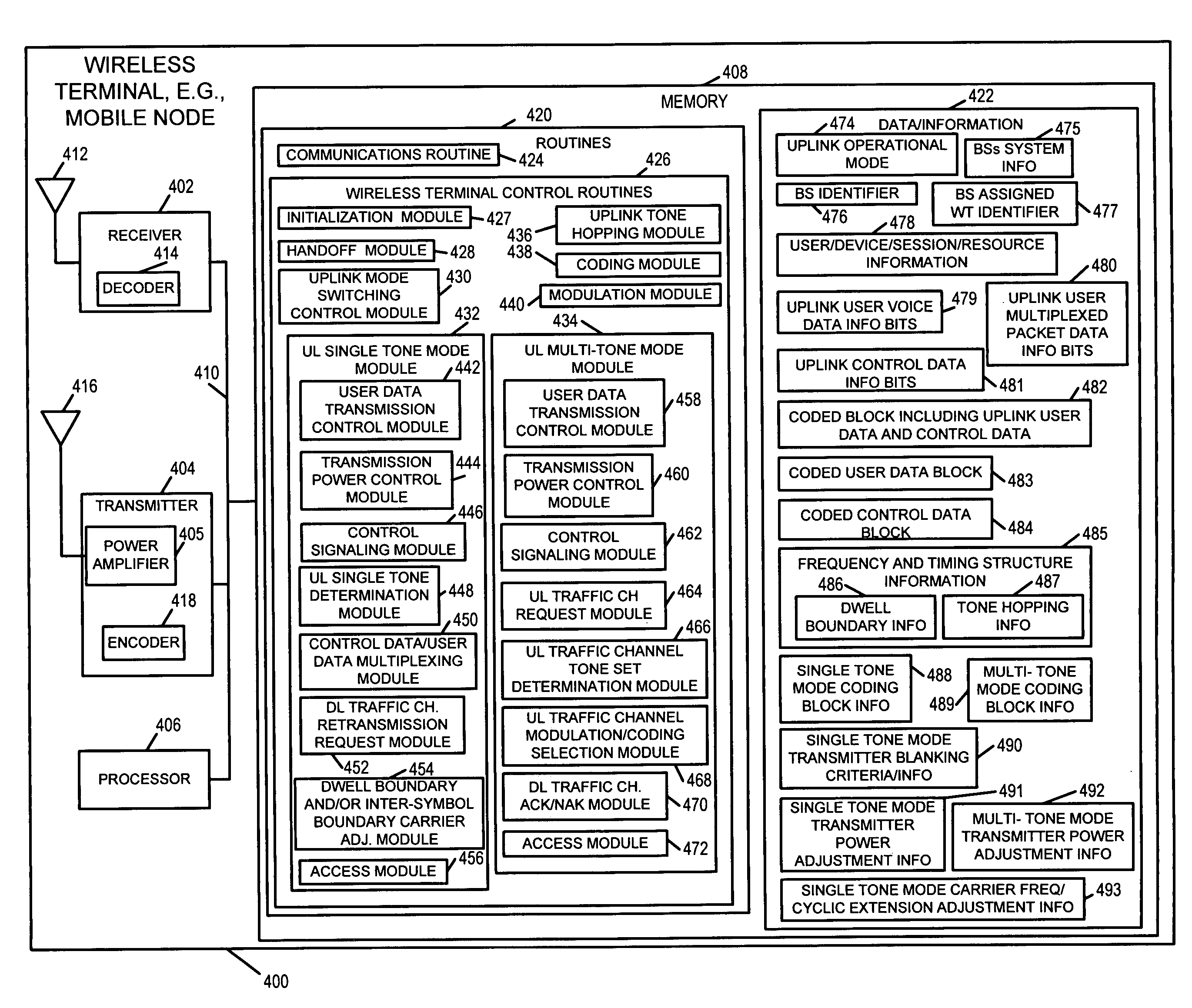

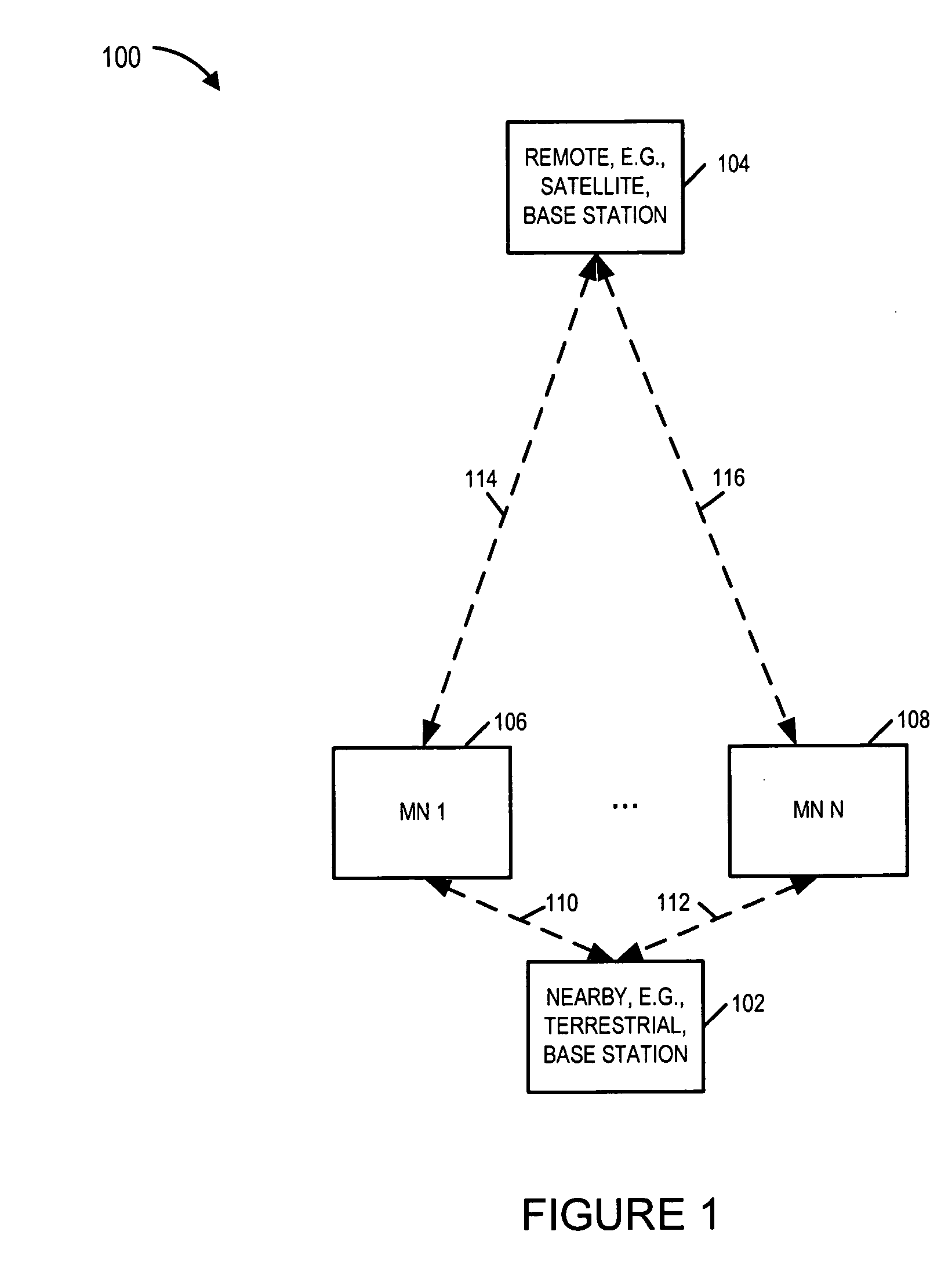

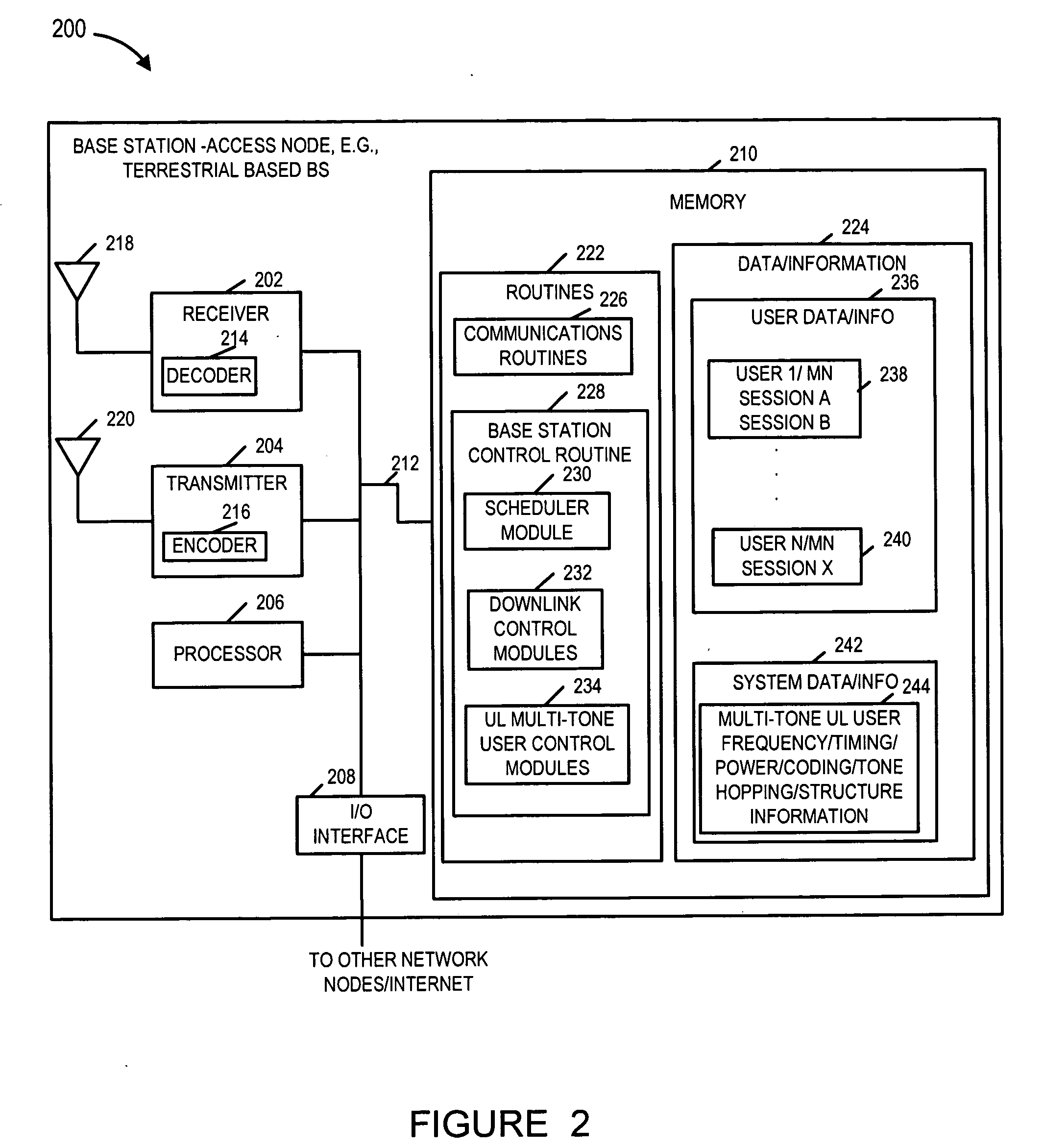

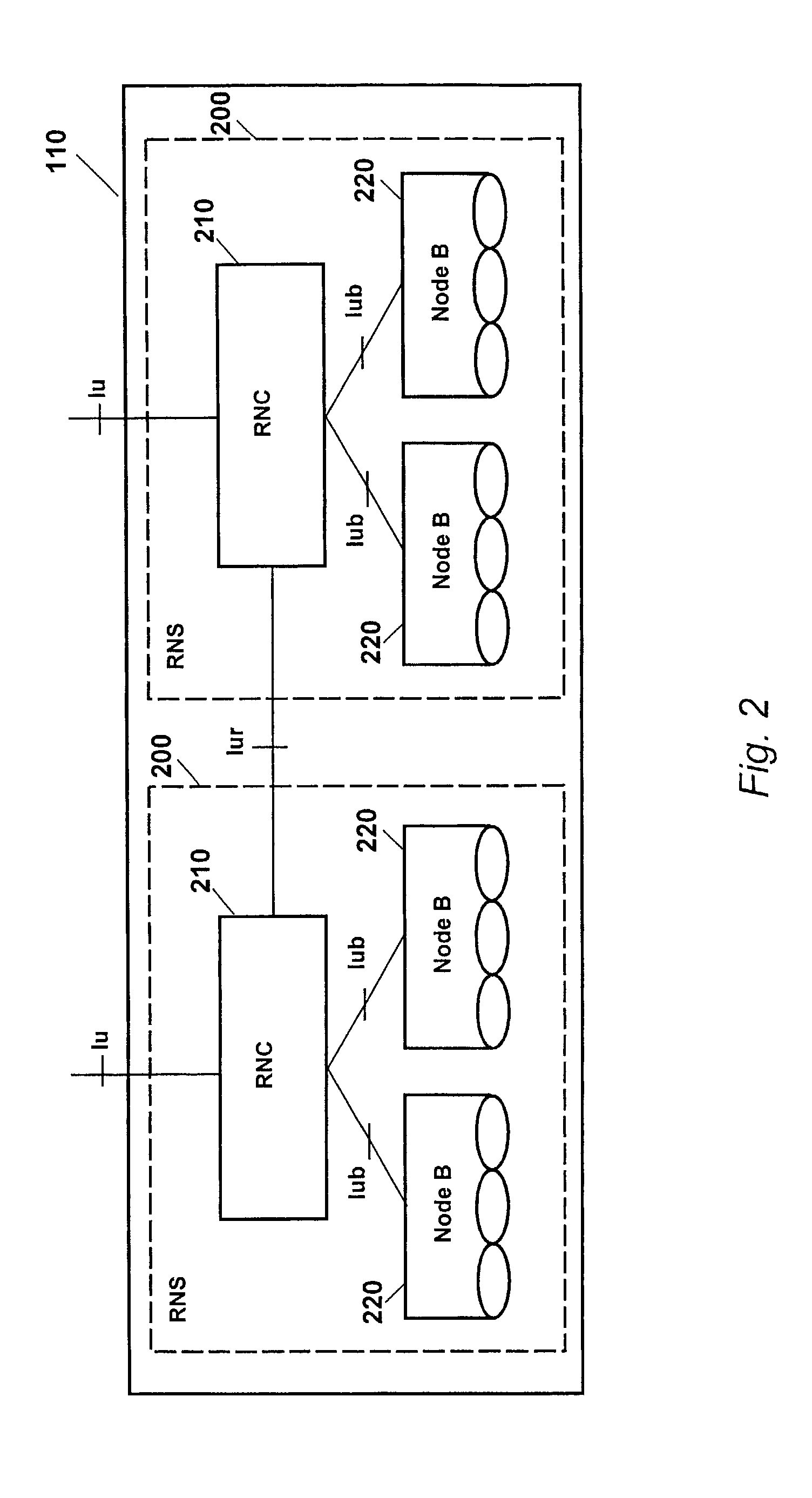

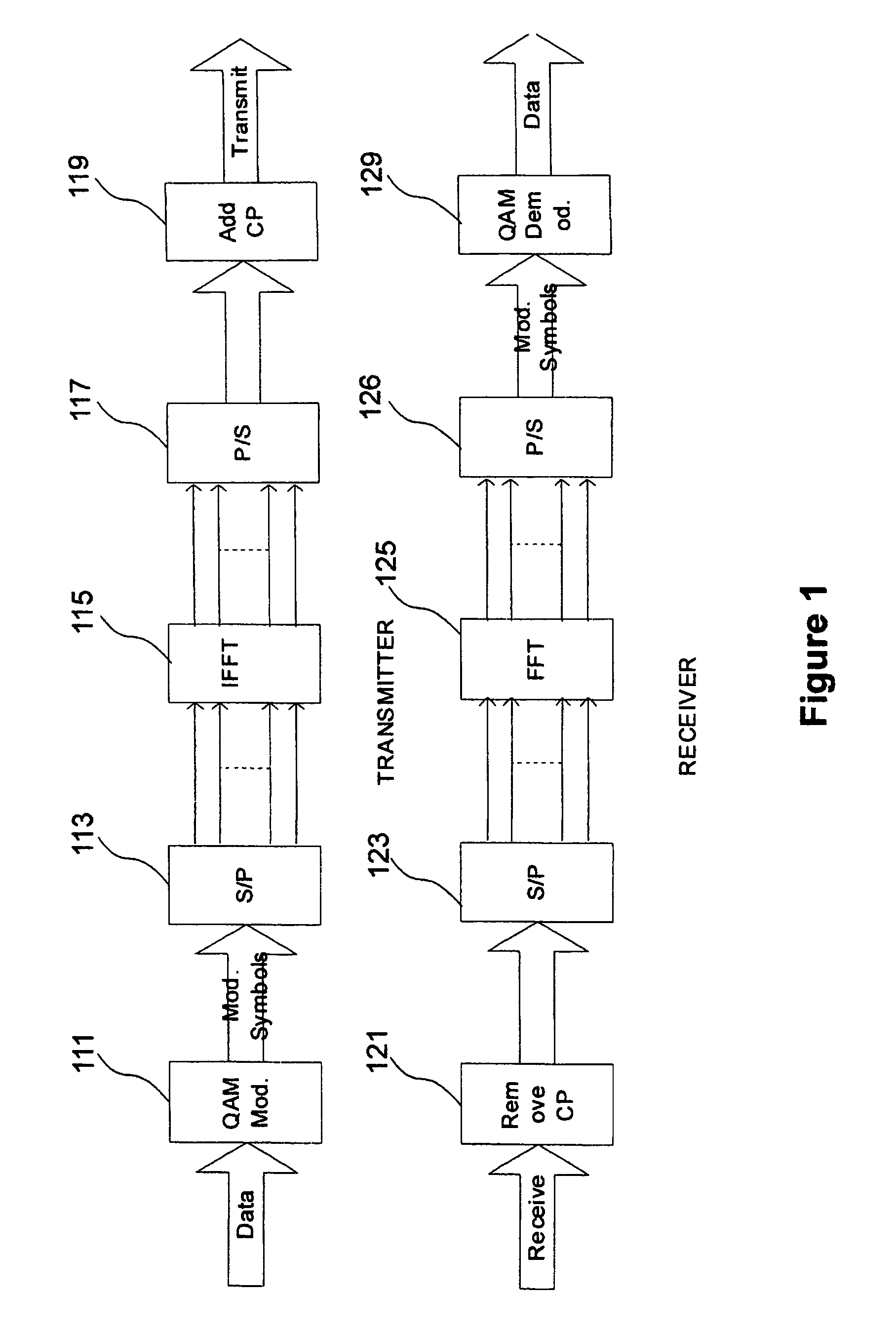

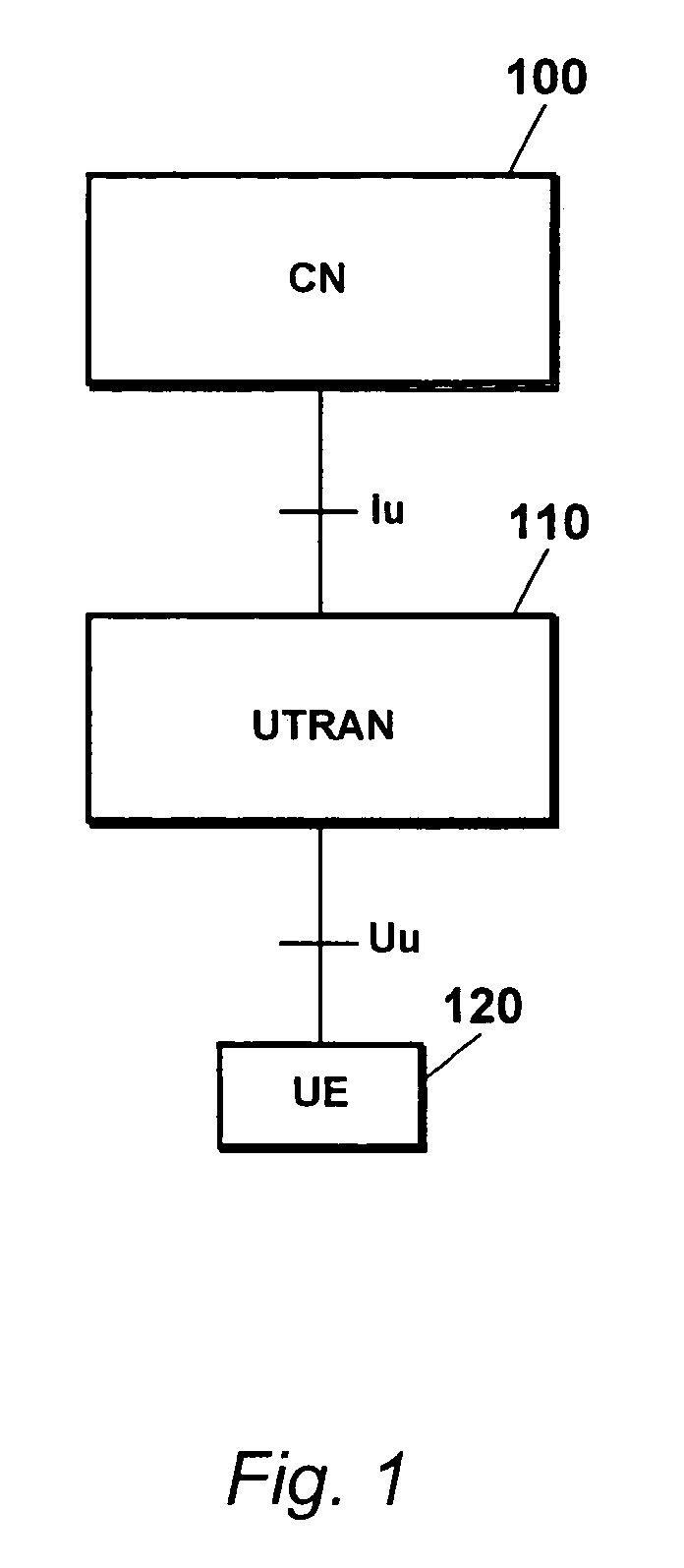

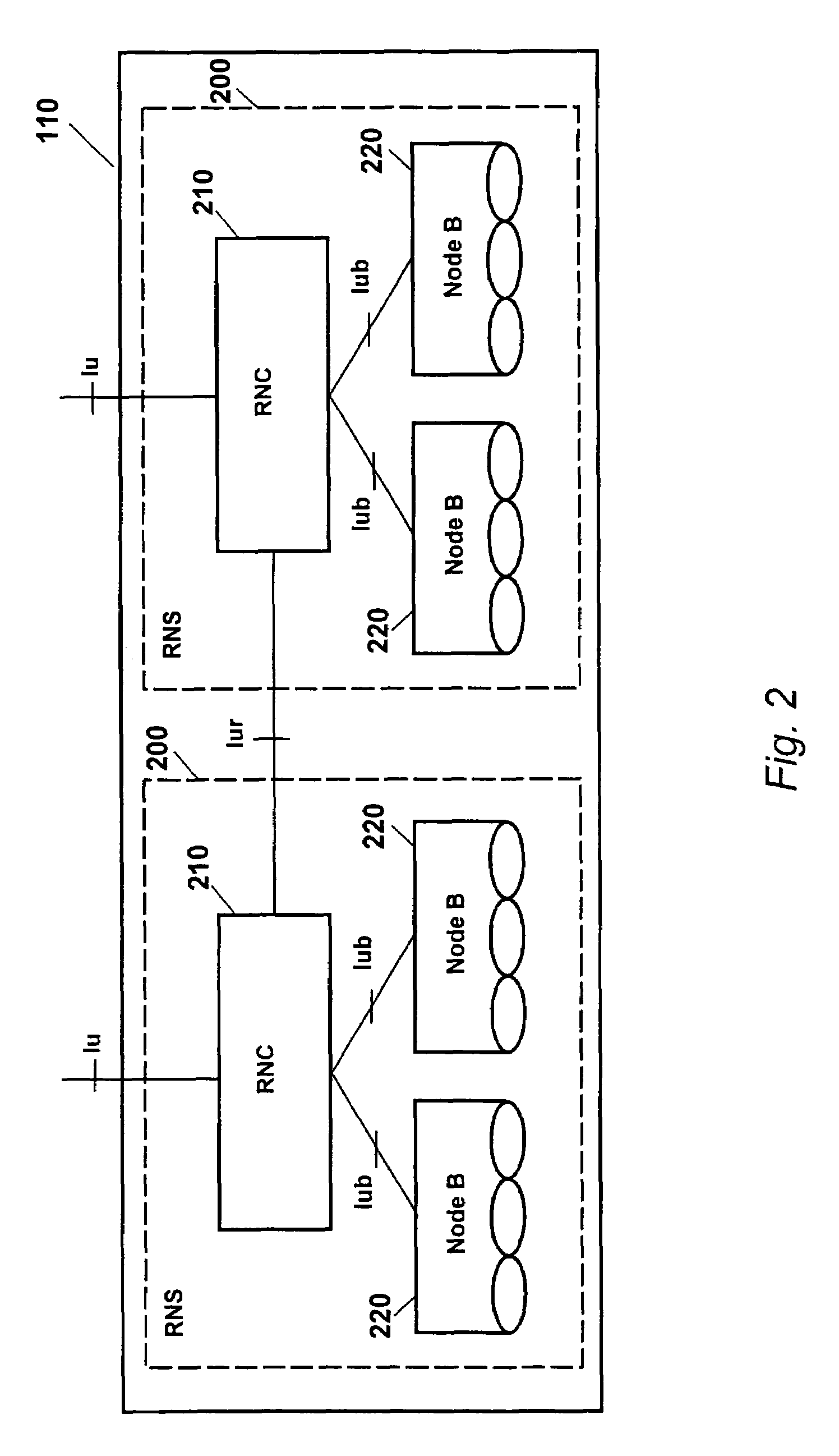

Communications system, methods and apparatus

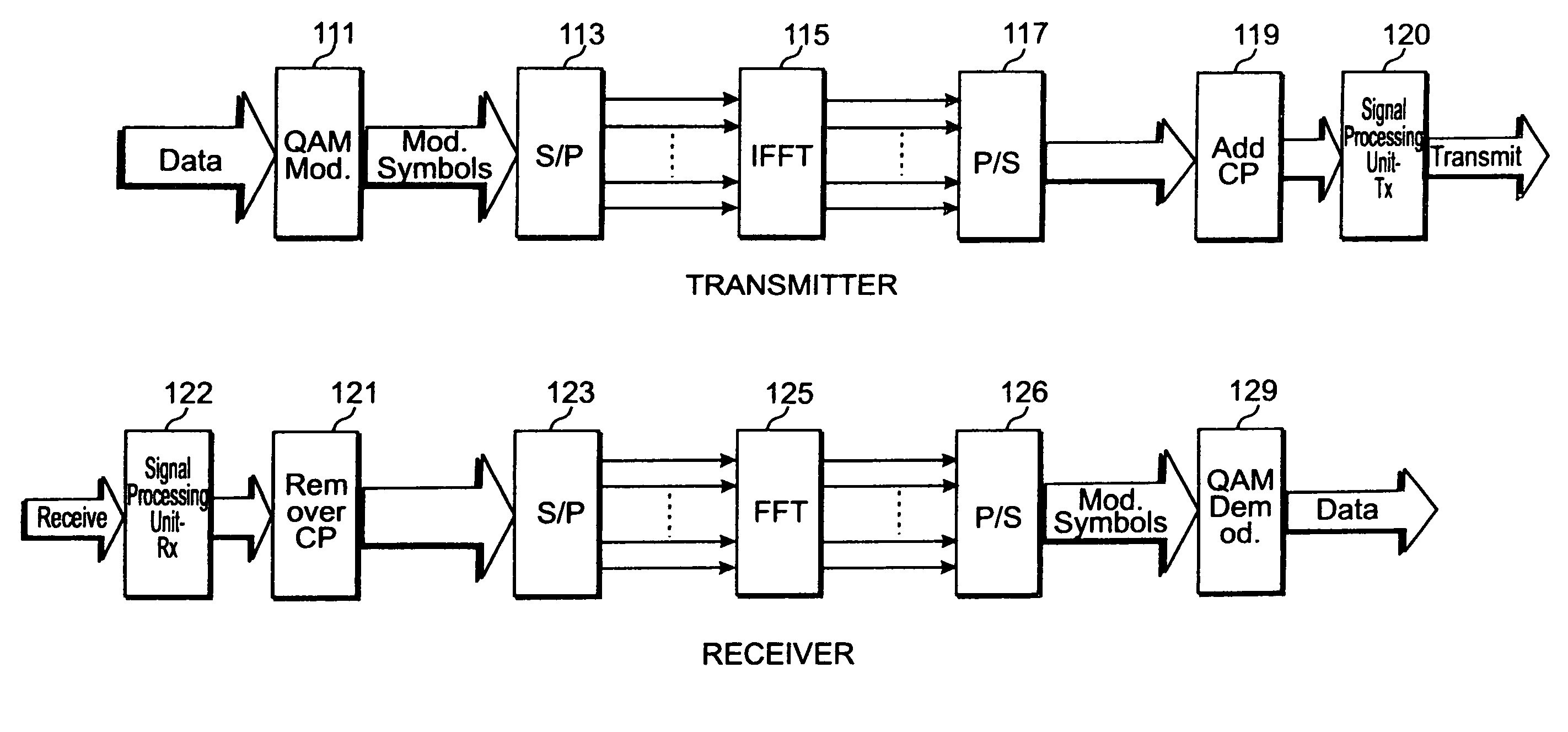

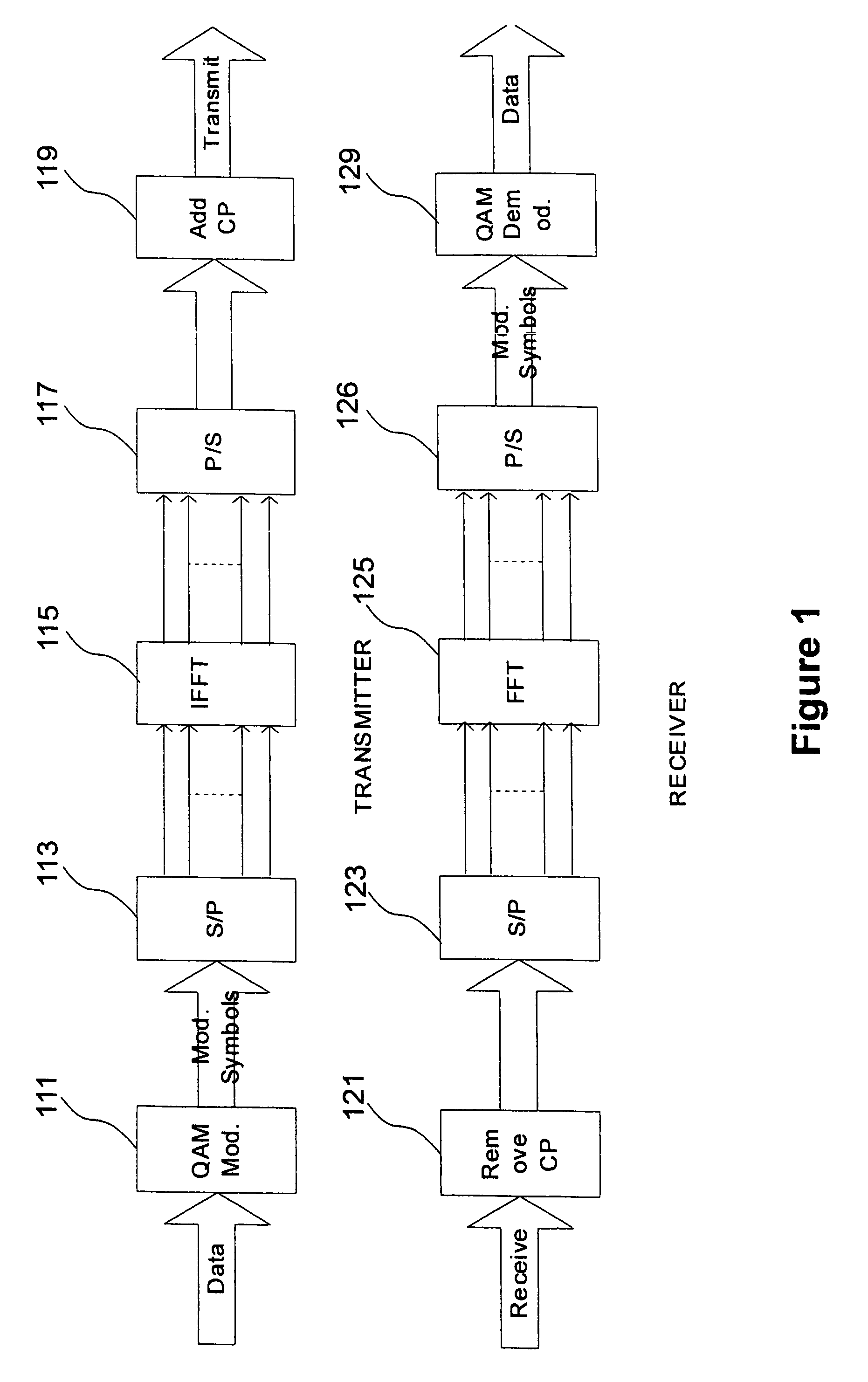

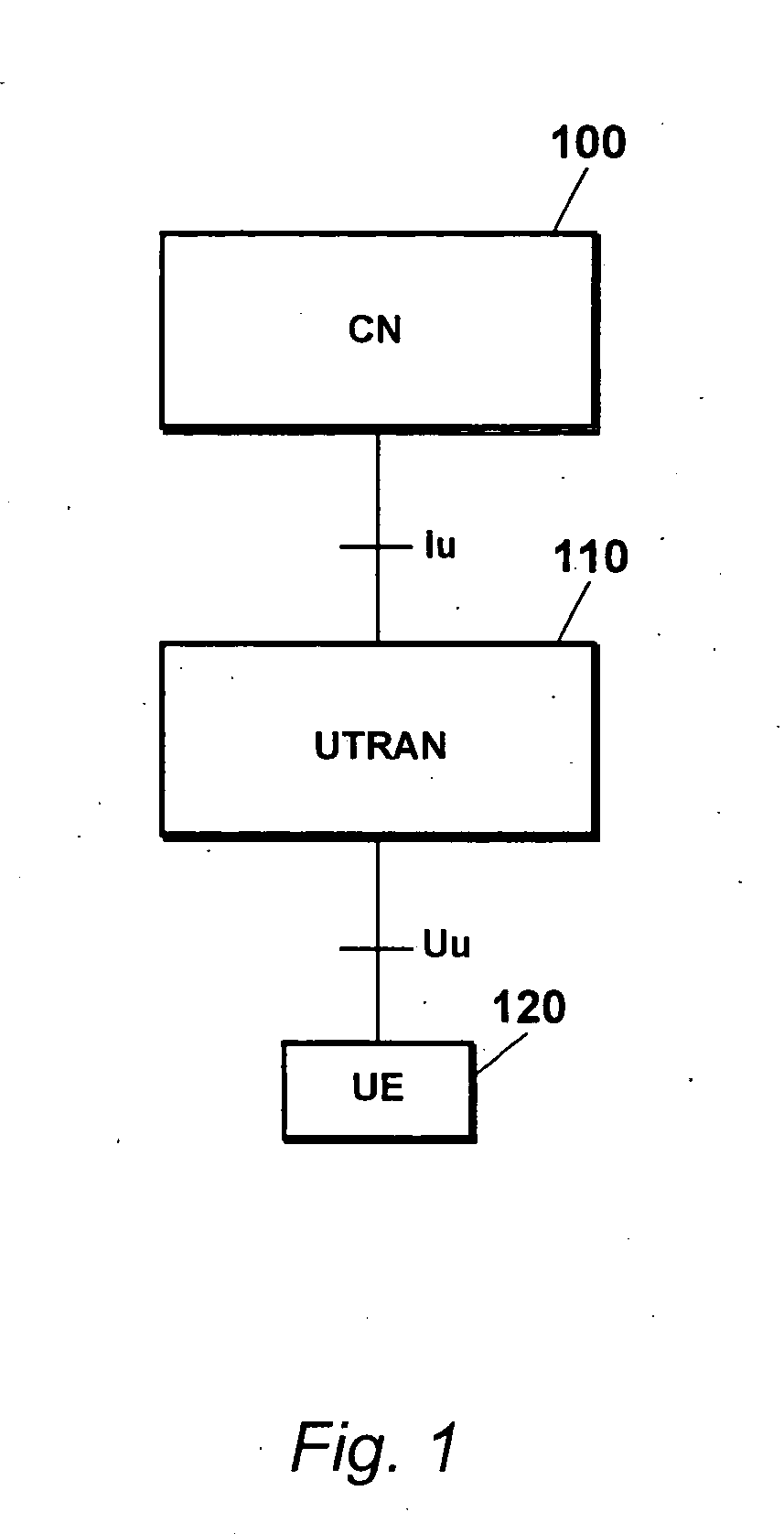

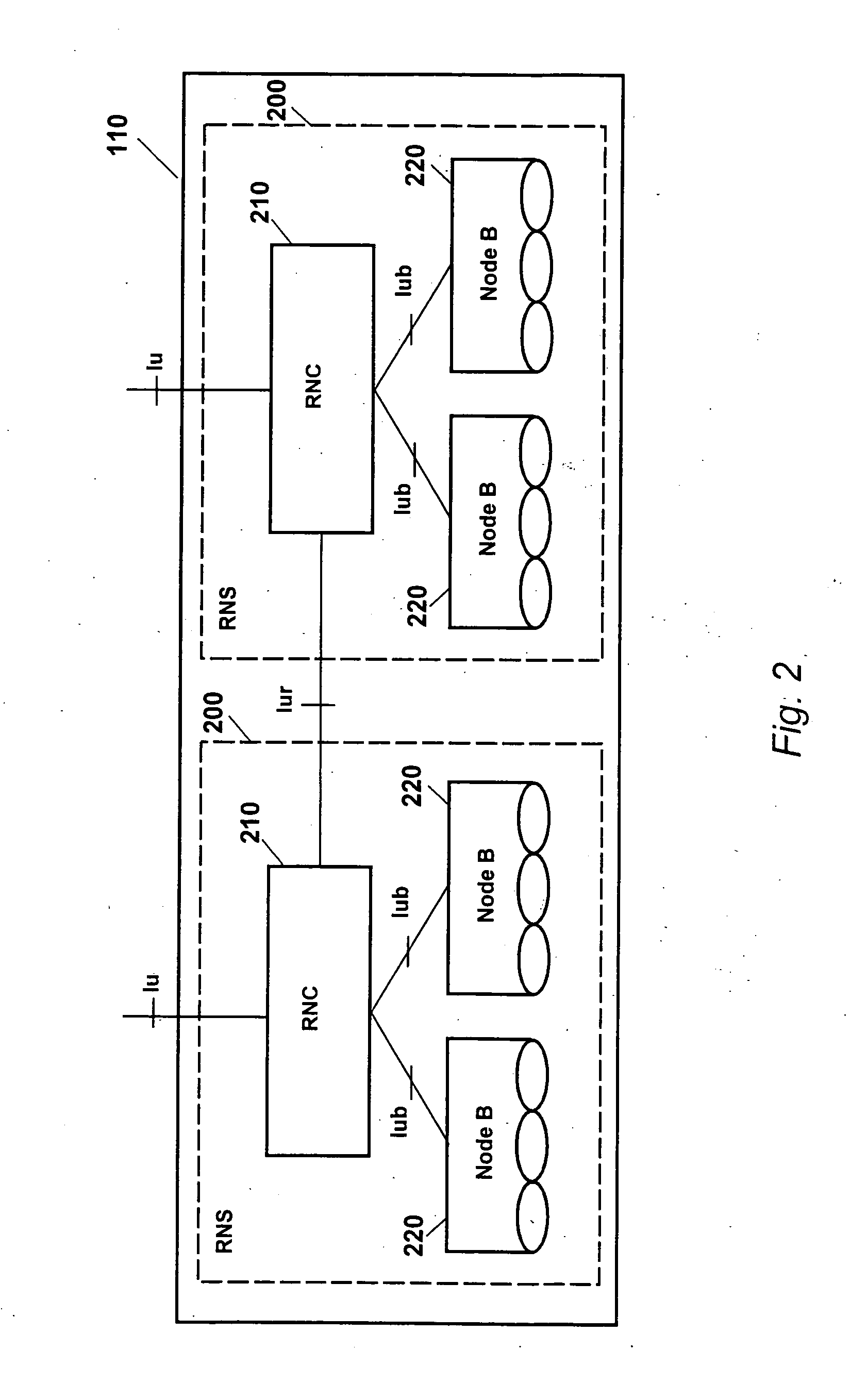

ActiveUS20060285481A1Benefit in transmitted powerIncrease transmit powerEnergy efficient ICTError prevention/detection by using return channelCommunications systemAudio power amplifier

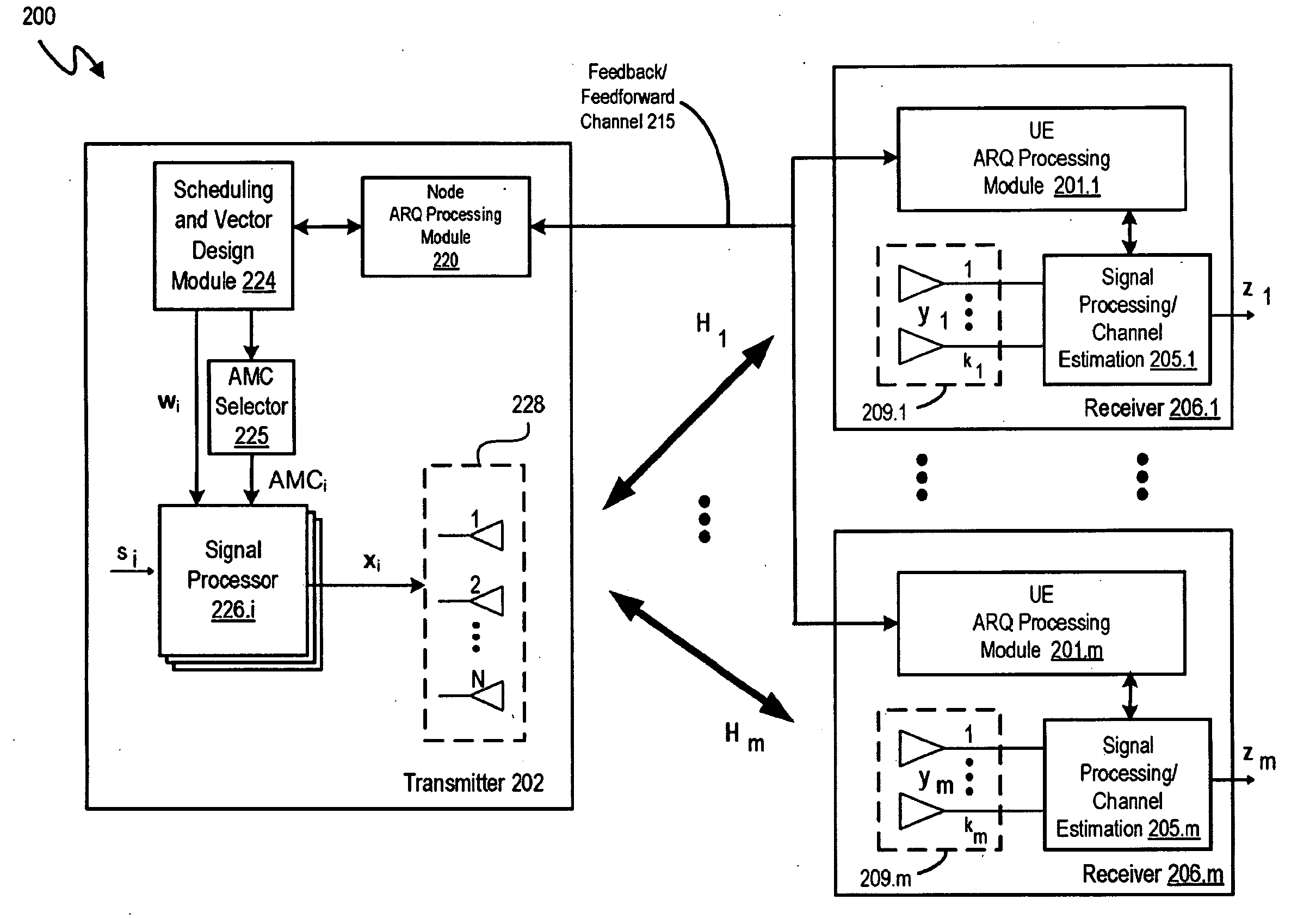

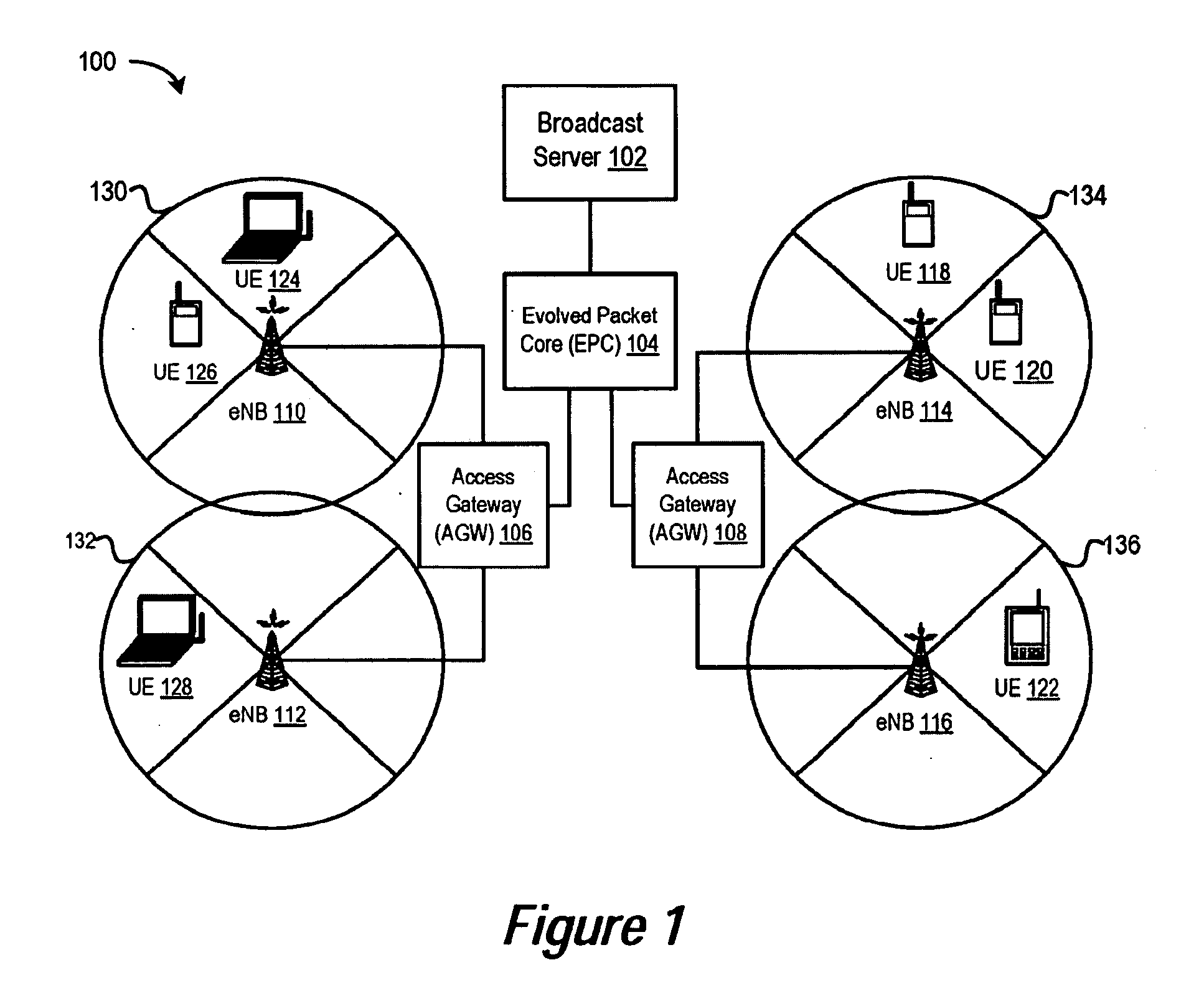

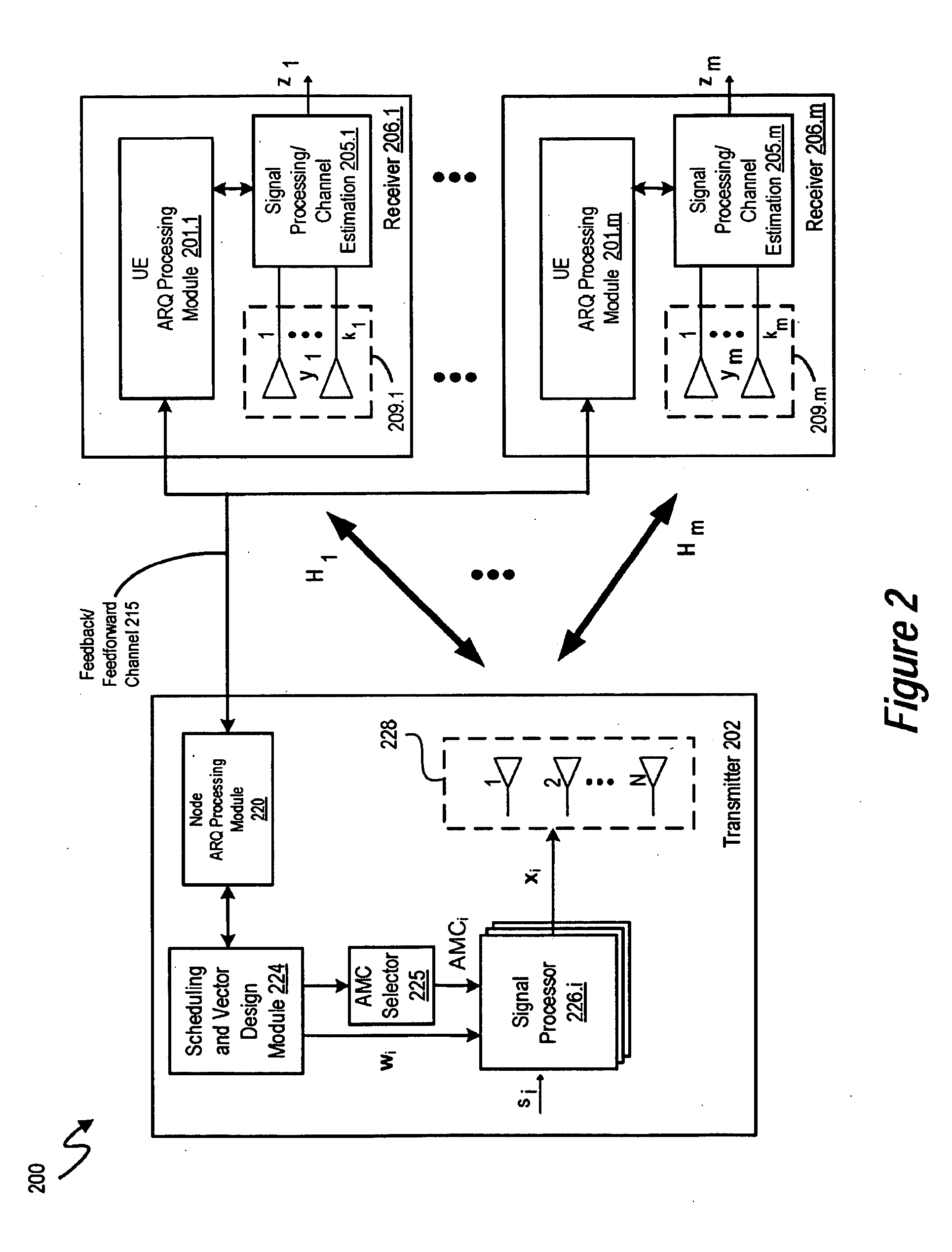

An OFDM wireless communications system includes terrestrial and satellite based base stations. Mobile nodes support two uplink modes of operation, multi-tone mode for terrestrial station interaction and single tone mode for satellite base station interaction. In single tone mode the peak to average power ratio is lower than in the multi-tone mode allowing the same power amplifier to transmit higher average power signals and thus extend range and reach a satellite in geostationary orbit. In multi-tone mode, the mobile node: is temporarily assigned a multi-tone uplink traffic channel segment for user data, is assigned a dedicated control channel for uplink control signals, and supports slaved Ack / Nak for traffic channels. In single tone mode, the mobile node: is assigned a single logical uplink dedicated tone to use for transmitting both user data and control data, and does not use a slaved Ack / Nak mechanism for traffic channels.

Owner:QUALCOMM INC

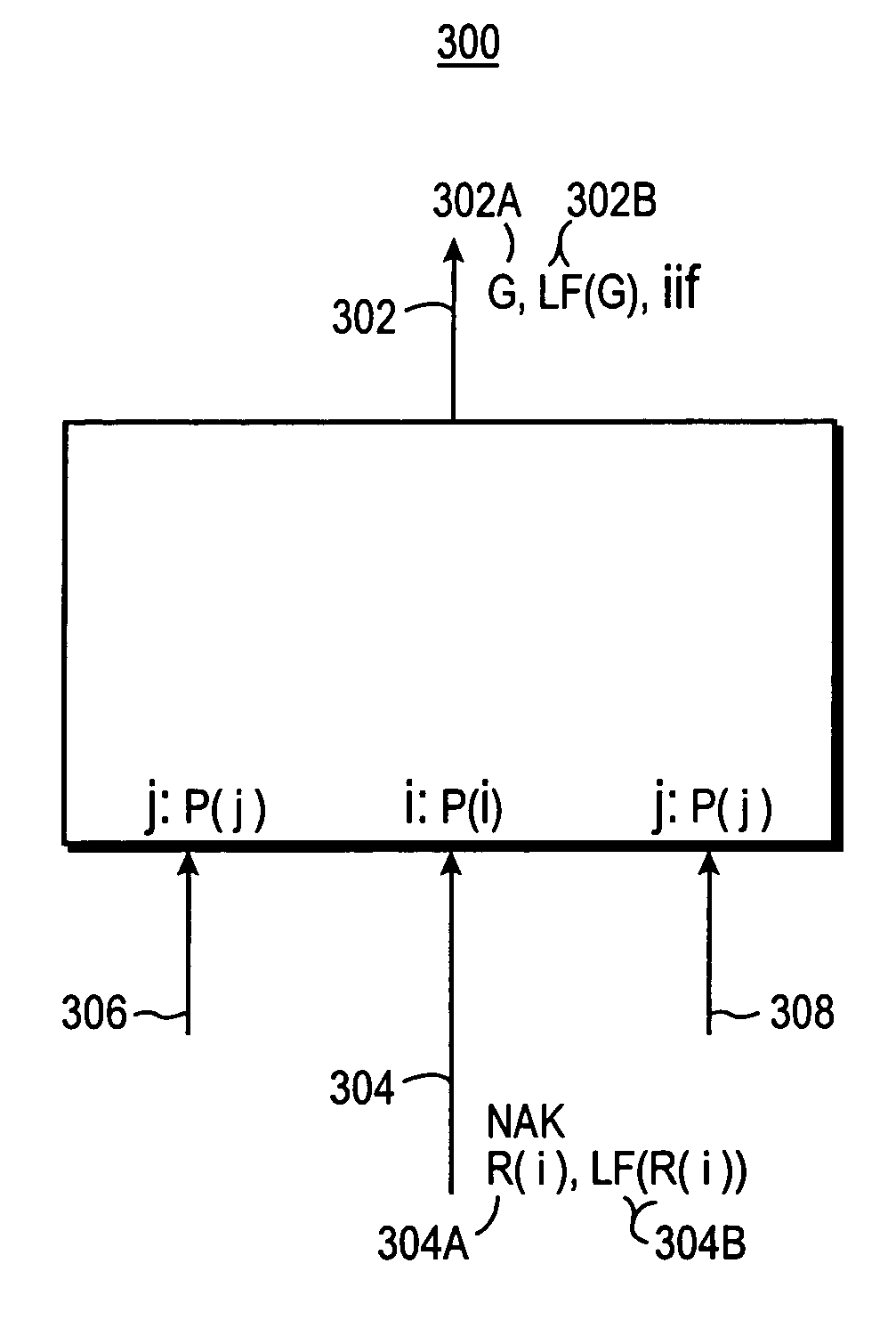

Router-assisted multicast congestion control

InactiveUS7035217B1Convenient and expandable methodError preventionTransmission systemsLoss rateDistribution tree

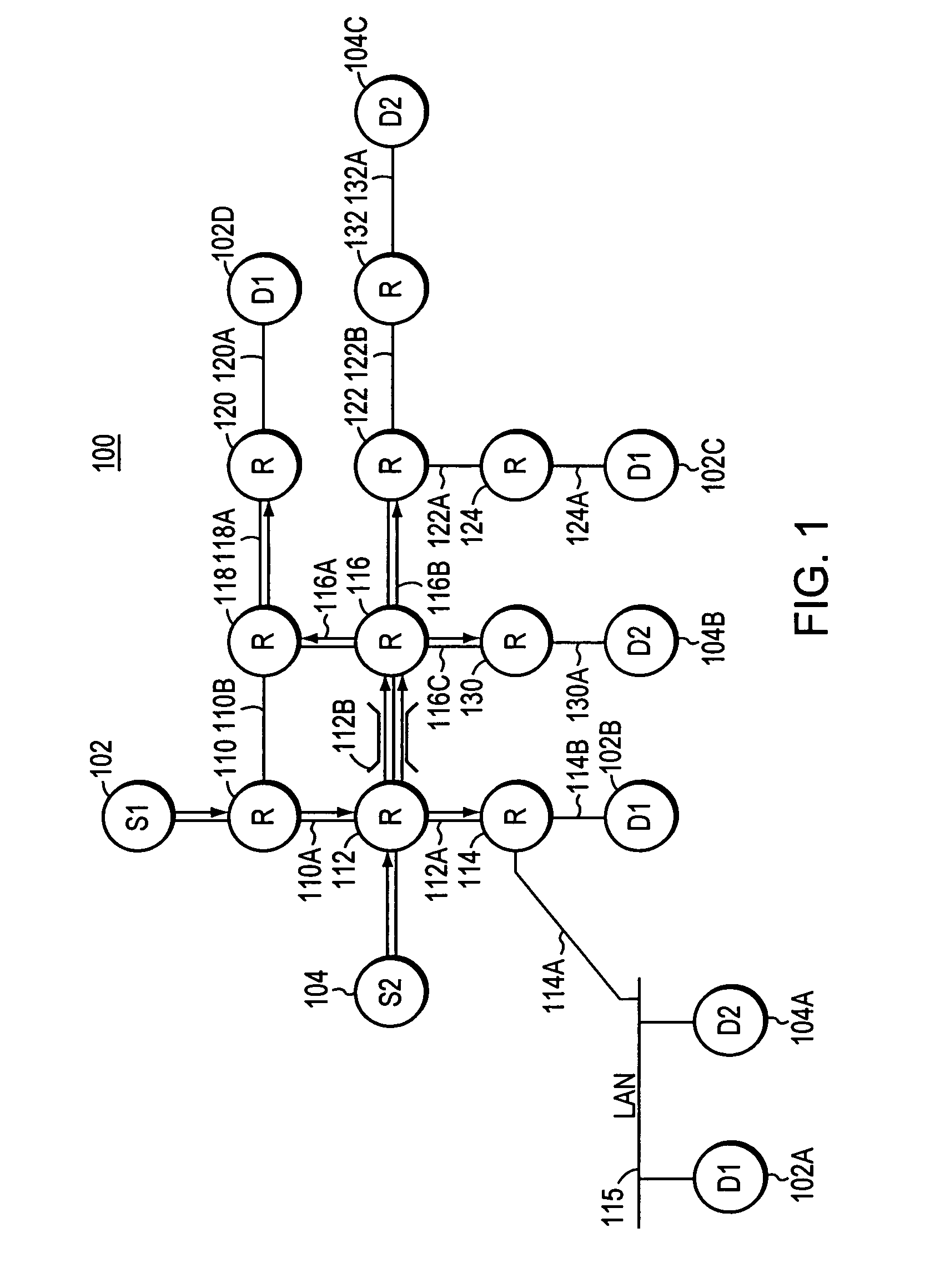

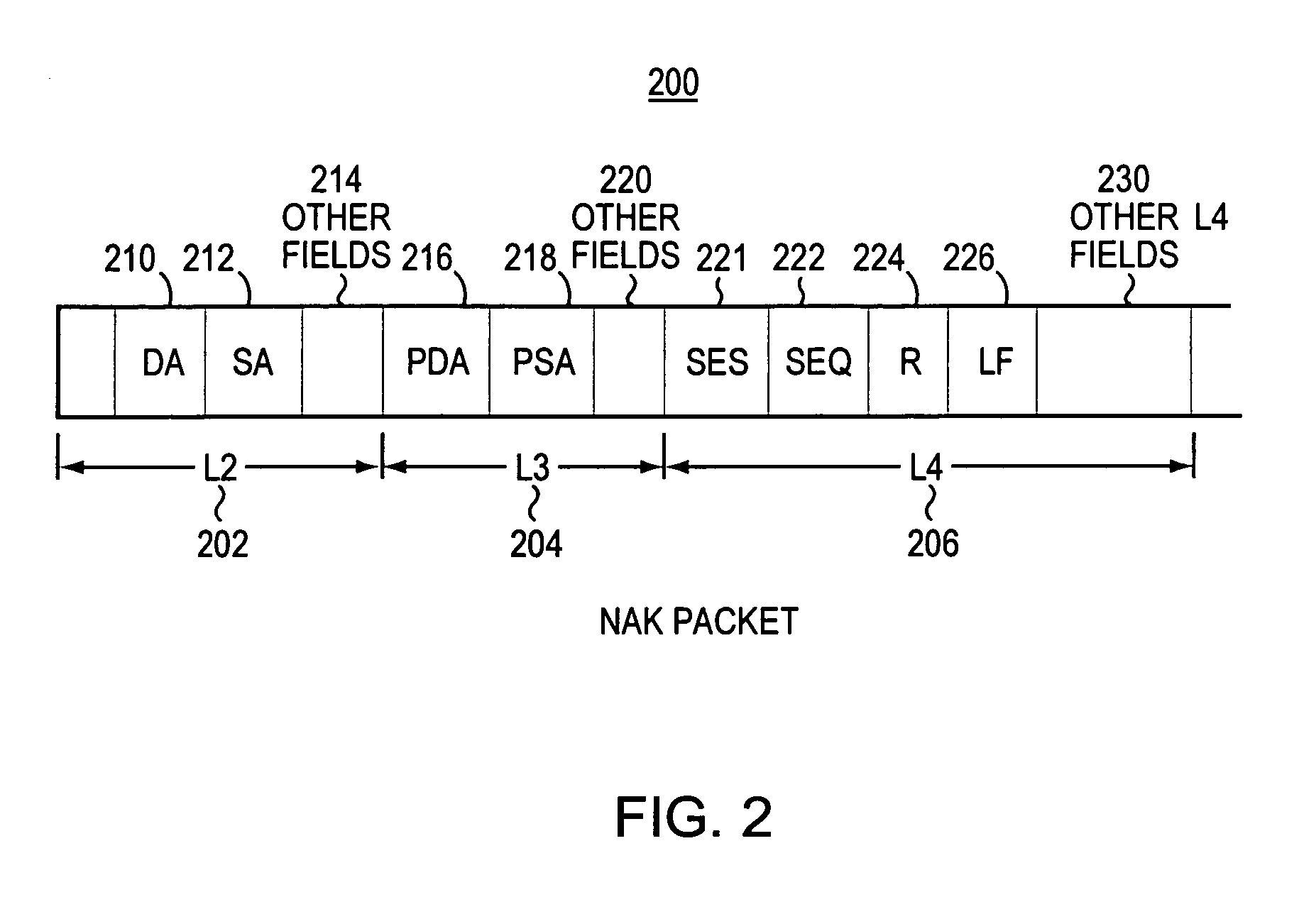

The invention provides a convenient and expandable method for transmitting one or more loss rate statistics determined in a distributed manner from a multicast distribution tree to a source computer. First, the loss rate statistics are collected in a distributed manner from target receiver stations, and from routers in the multicast distribution tree. Second, there is a distributed calculation of statistics on loss rate by routers in the multicast distribution tree. Third, there is transportation of the loss rate statistics back to the source computer in reverse along the multicast distribution tree. For example, congestion information is collected by routers, and the congestion information is sent upstream to the multicast source station in fields of NAK messages. A router may receive a NAK packet in transit from an intended destination station to a source station, the NAK packet indicating loss of a data packet. The router writes a loss rate statistic determined by the router into a “loss rate field” of a message to be sent upstream along the reverse of the distribution tree. The router determines the loss rate statistic to be written into the loss rate field of the message, in response to: analyzing the loss rate statistics on each of its links; the loss rate reported by the incoming NAK packet; and, the elapsed time from the time stamp showing when the various loss rate statistics were determined.

Owner:CISCO TECH INC

Method and apparatus for modulating radio link control (RLC) ACK/NAK persistence to improve performance of data traffic

ActiveUS7181667B2Error prevention/detection by using return channelFrequency-division multiplex detailsAutomatic repeat requestPhysical layer

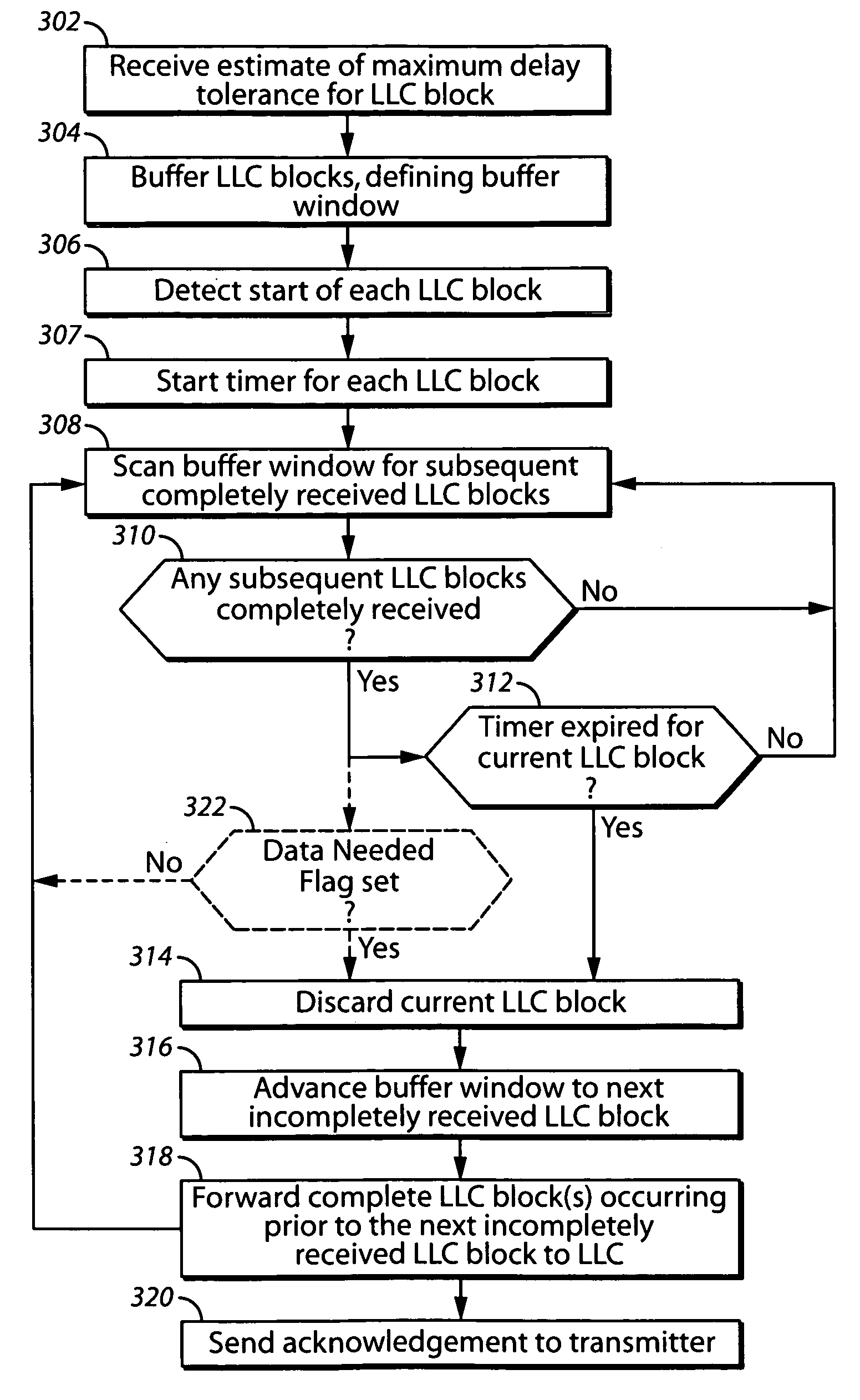

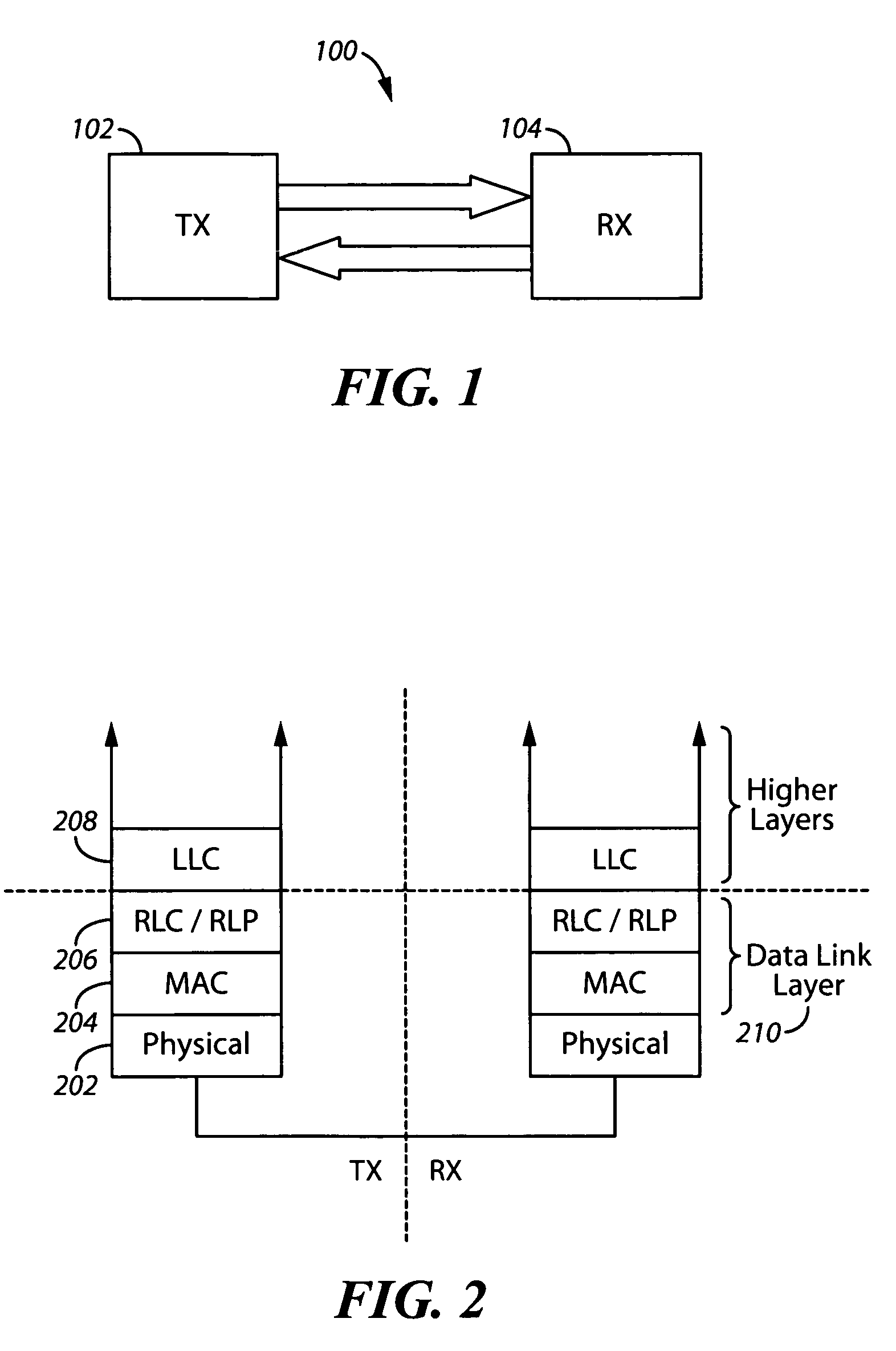

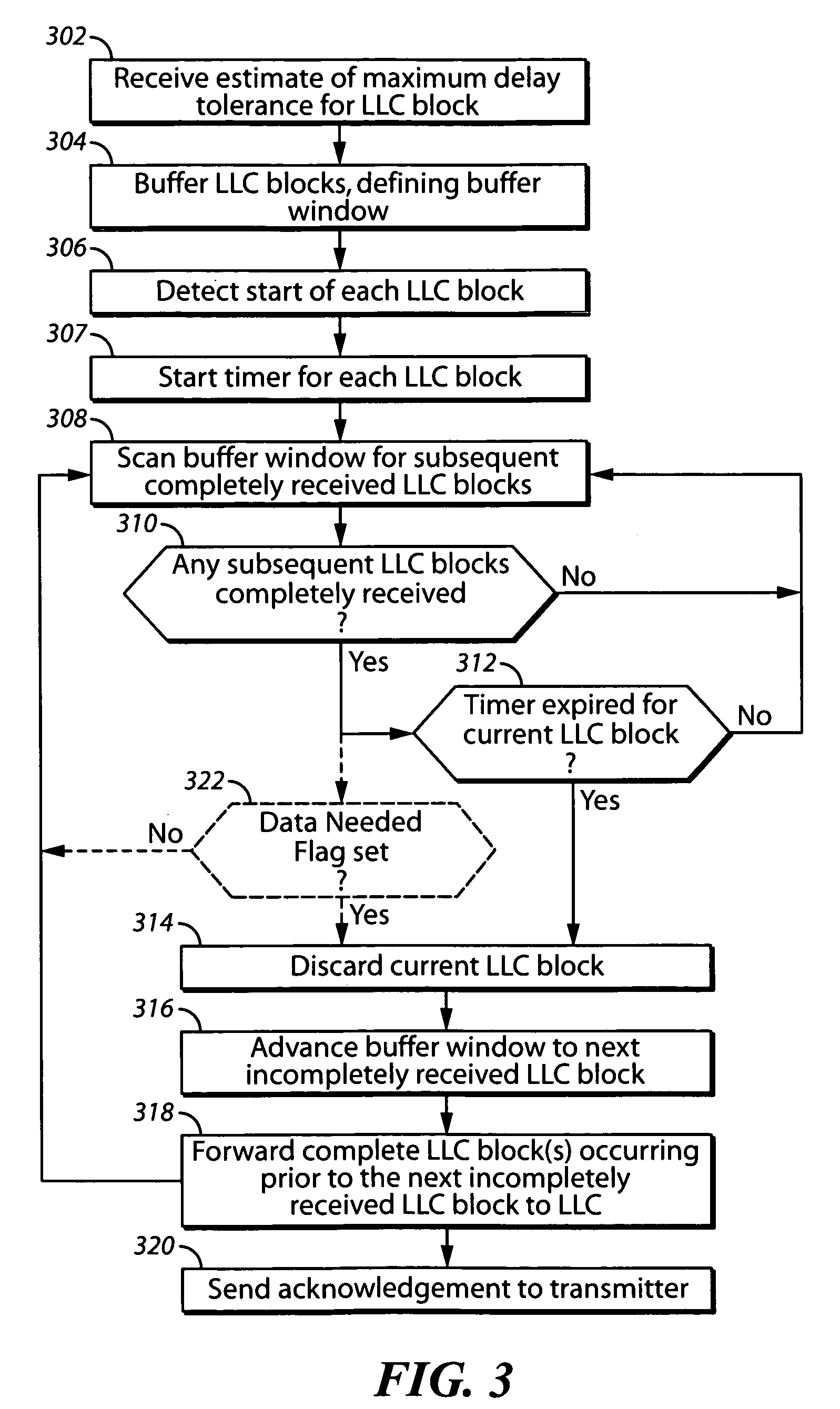

Methods and apparatus are provided for modulating ACK / NACK persistence to improve data traffic performance. In one implementation, a method for control of automatic repeat requests between a transmitting terminal (102) and a receiving terminal (104) comprises: defining (1404) a buffer window of a buffer, the window to buffer multiple higher layer data blocks each segmented into multiple physical layer data blocks, the window beginning at a current higher layer block in which at least one physical layer block has not been received; obtaining (1406) an indication of whether physical layer blocks are completely received; determining (1408), based on the obtaining step, that a subsequent higher layer block within the window has been completely received; and discarding (1410) the current higher layer block when a time delay of the current higher layer block exceeds an estimate of a delay tolerance corresponding to a higher layer application.

Owner:GOOGLE TECH HLDG LLC

Management of ARQ Detection Threshold in Communication Networks

ActiveUS20100042881A1Error prevention/detection by using return channelTransmission systemsQuality of serviceTransmitted power

Embodiments of a system and methodology are disclosed for enabling a network to manage threshold values provided to UEs for use in decoding ACK-NAK signals. In various embodiments described herein, a base station signals an actual fixed threshold value in a semi-static manner for use by UEs to decode ACK / NAK signals. In these embodiments, the threshold value is part of a semi-static but UE-specific threshold value. This allows the base station to accommodate varying UE geometries, and optimize power savings for ACK-NAK transmissions. Embodiments of the invention also allow the base station to enforce a desired quality of service (QoS) without excessive power variations across ACK / NAK which are limited by the transmit power dynamic range.

Owner:APPLE INC

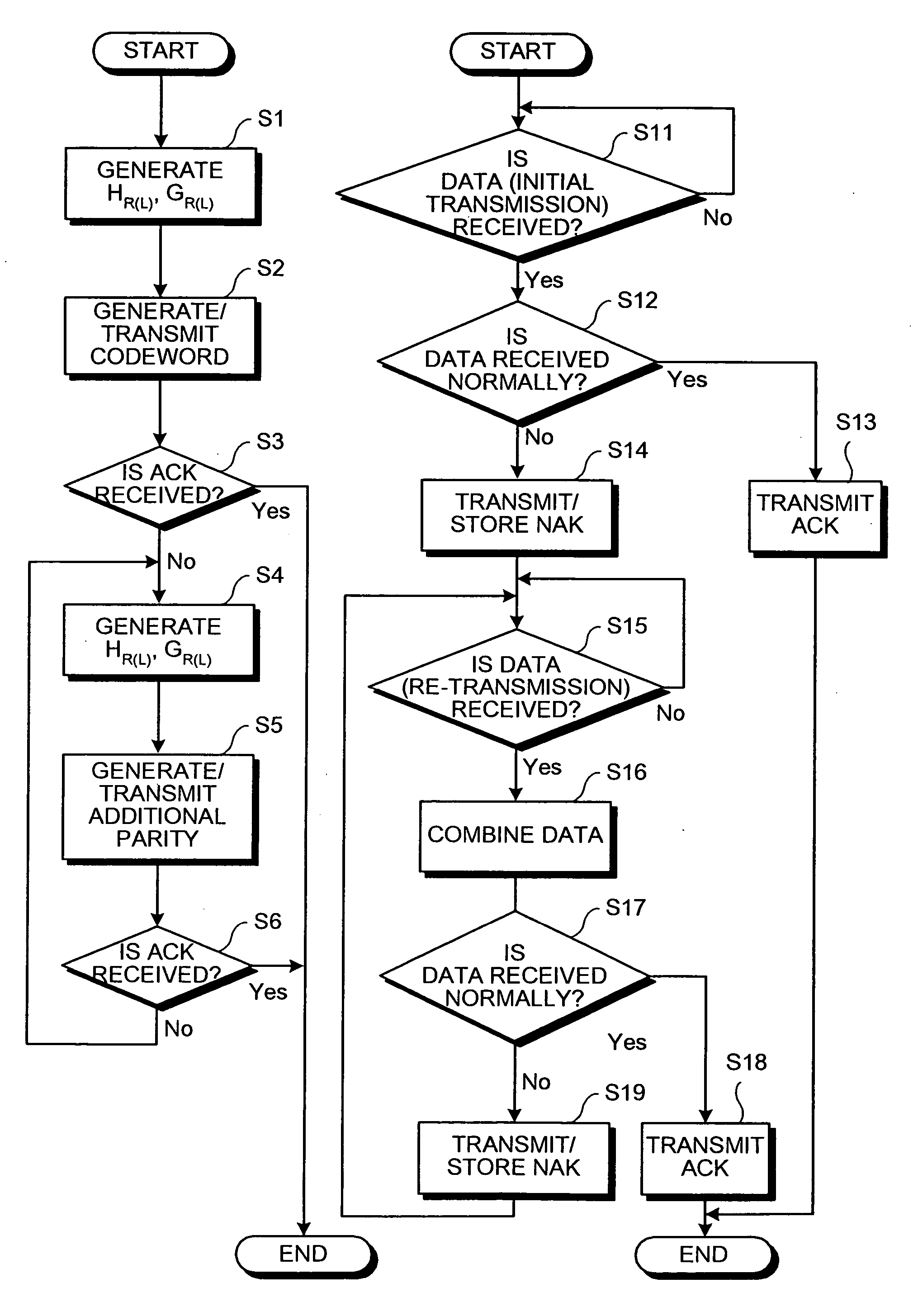

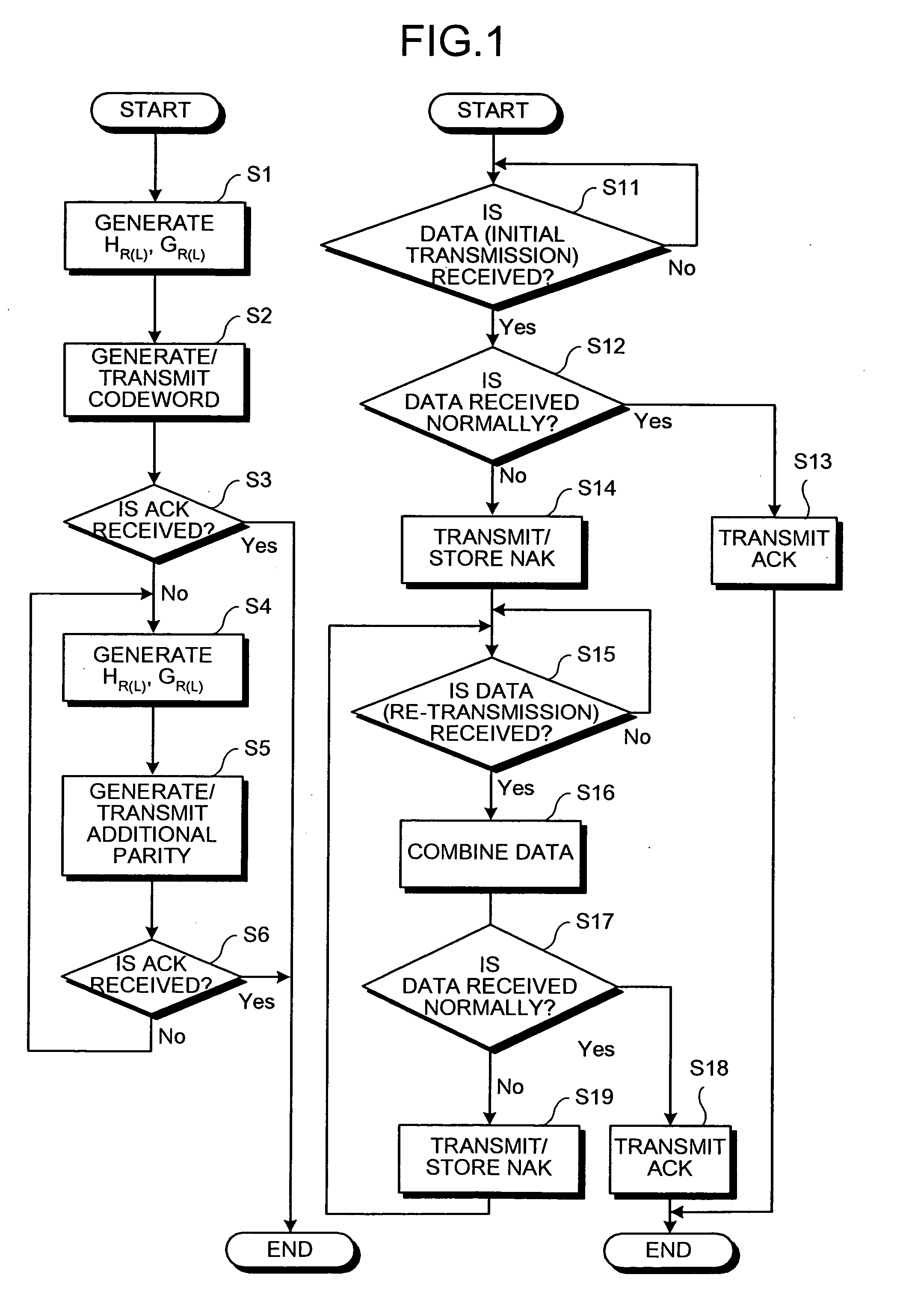

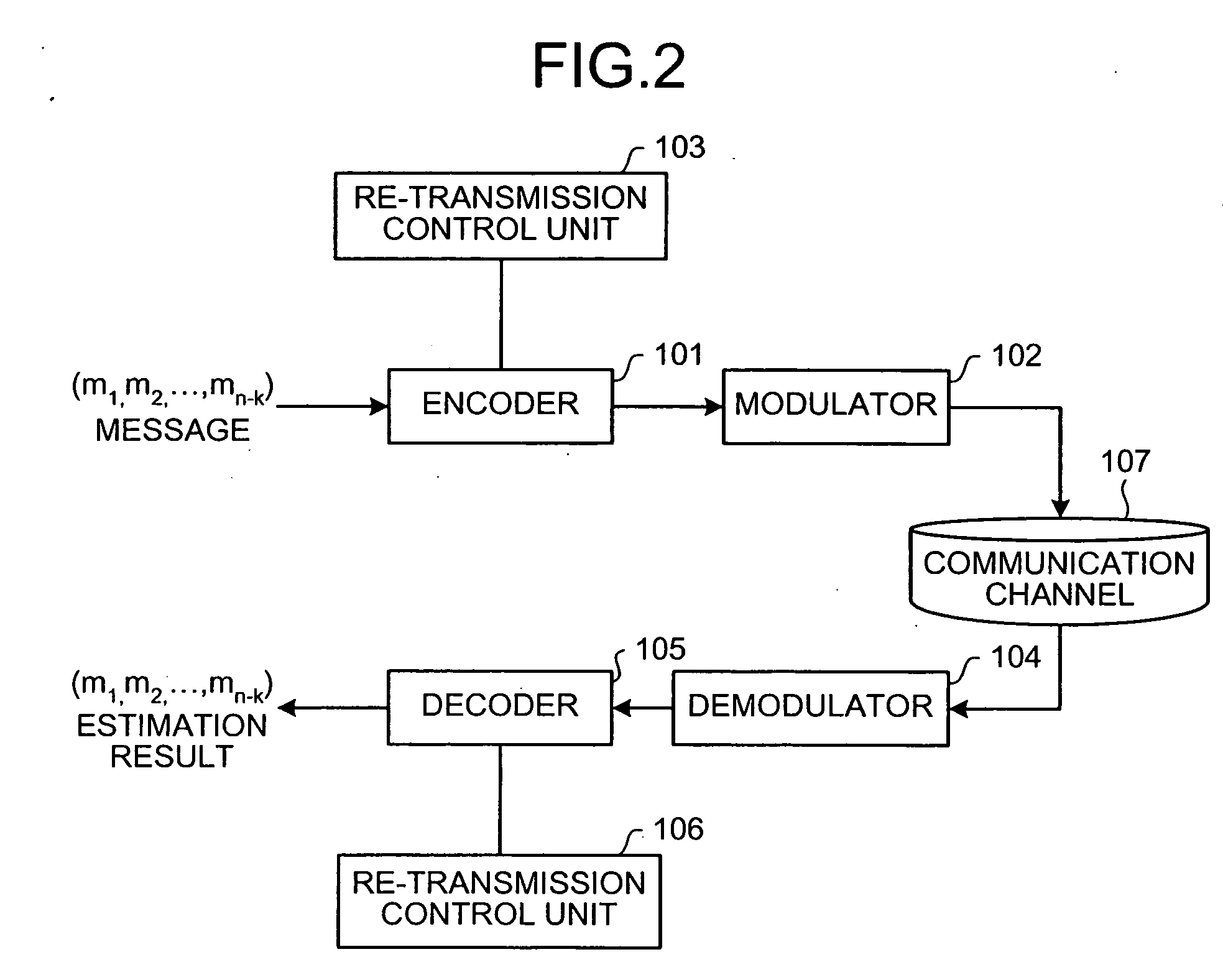

Re-transmission control method and communication device

InactiveUS20070162811A1Improve featuresError prevention/detection by using return channelData representation error detection/correctionParity-check matrixSodium-potassium alloy

A re-transmission control method for a transmitting device that transmits a codeword generated based on a first parity-check matrix to a receiving device, and re-transmits a k-th additional parity generated based on a k-th parity-check matrix to the receiving device when receiving a NAK for the codeword or a (k−1)-th additional parity, comprising: generating a (k+1)-th parity-check matrix based on a k-th parity-check matrix; generating a generator matrix based on the (k+1)-th parity-check matrix; and generating the k-th additional parity based on the generator matrix.

Owner:MITSUBISHI ELECTRIC CORP

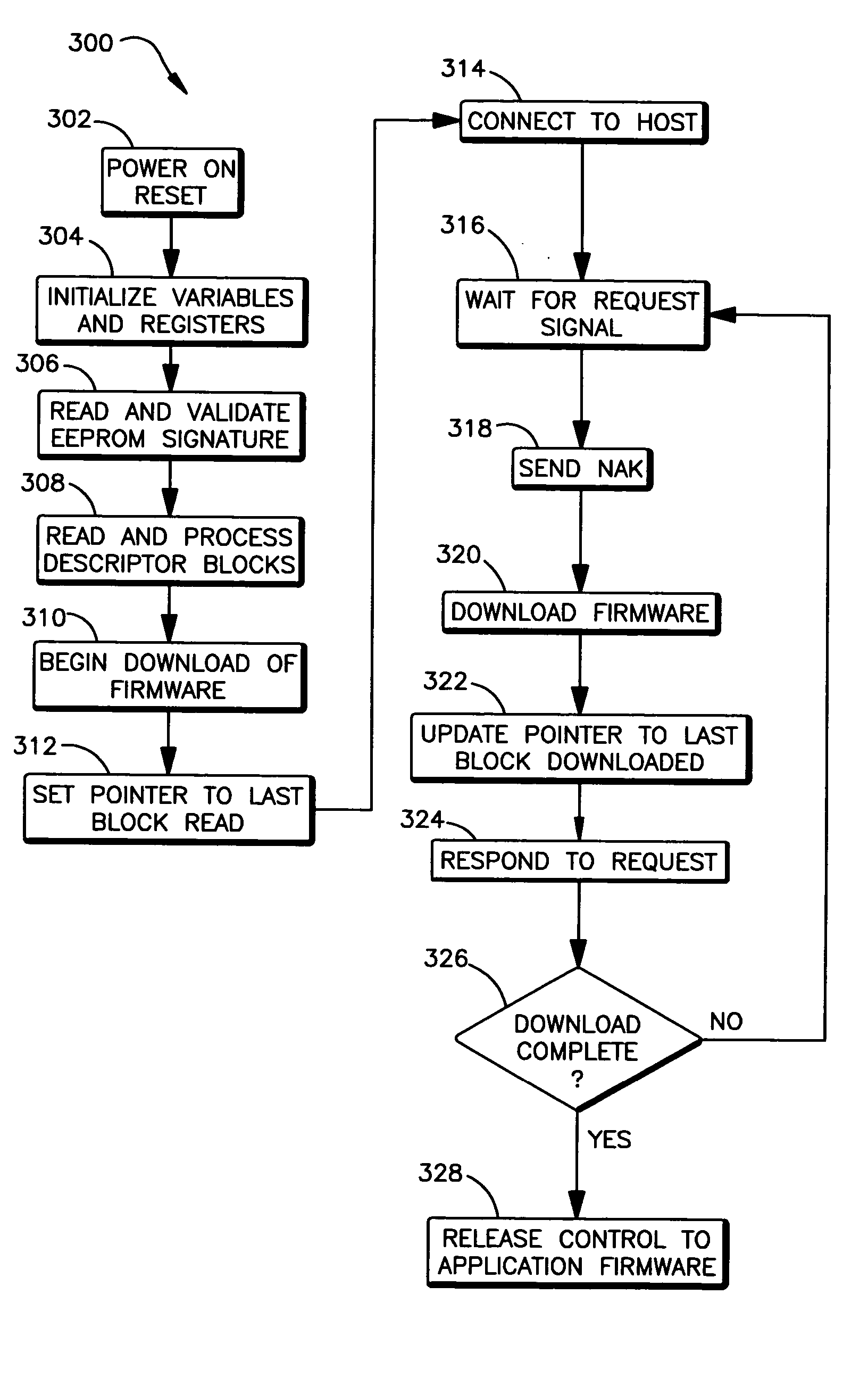

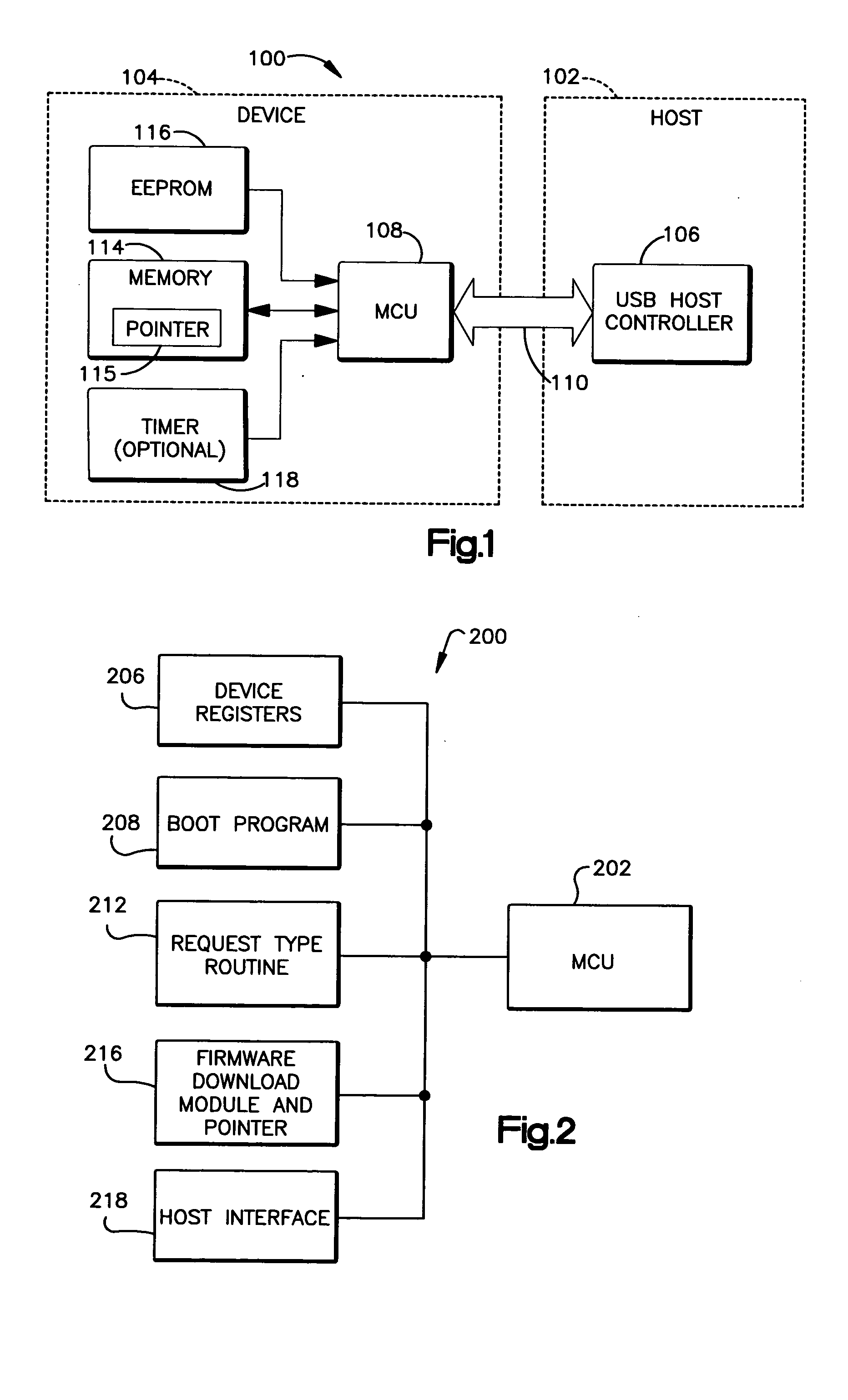

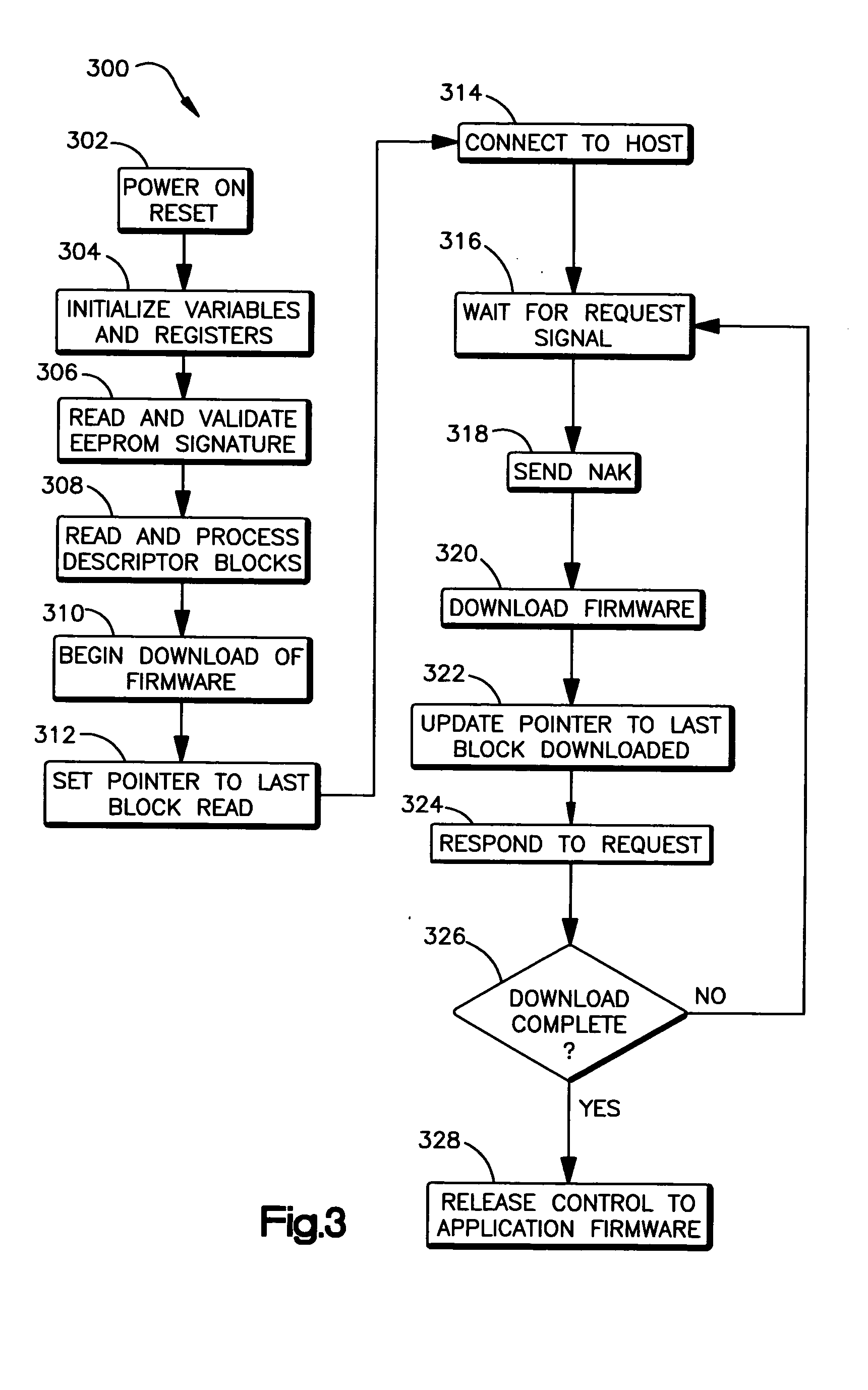

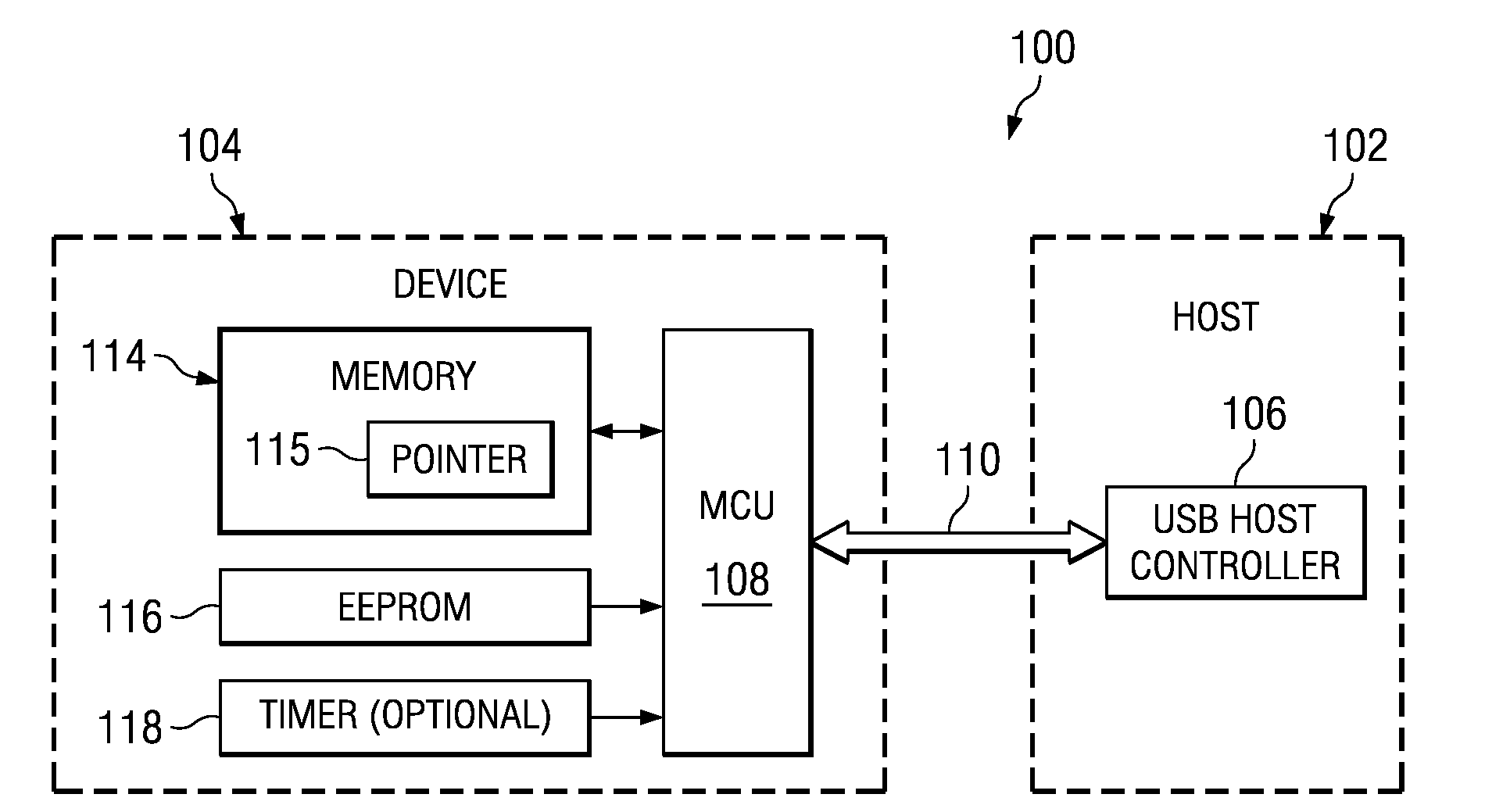

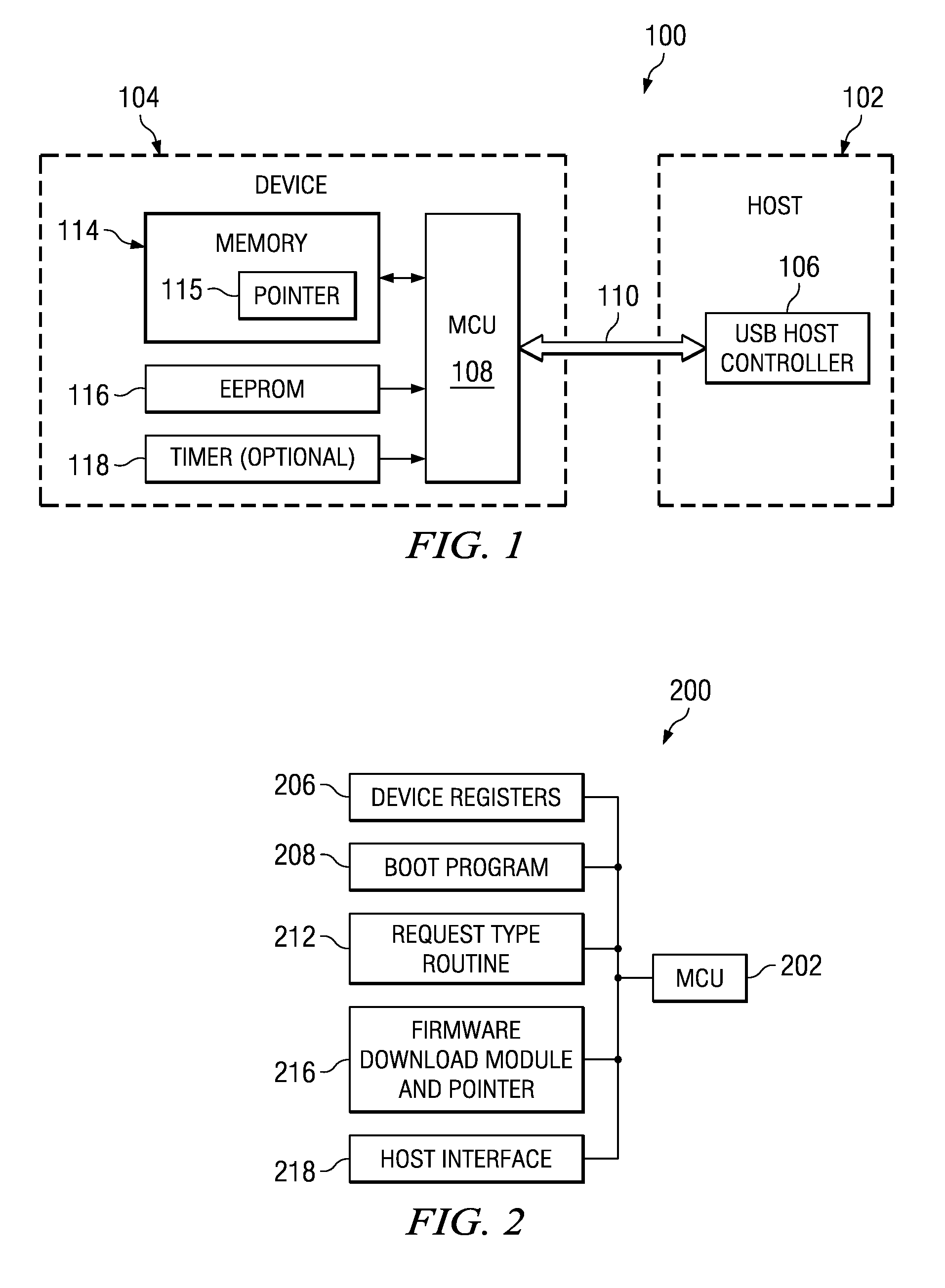

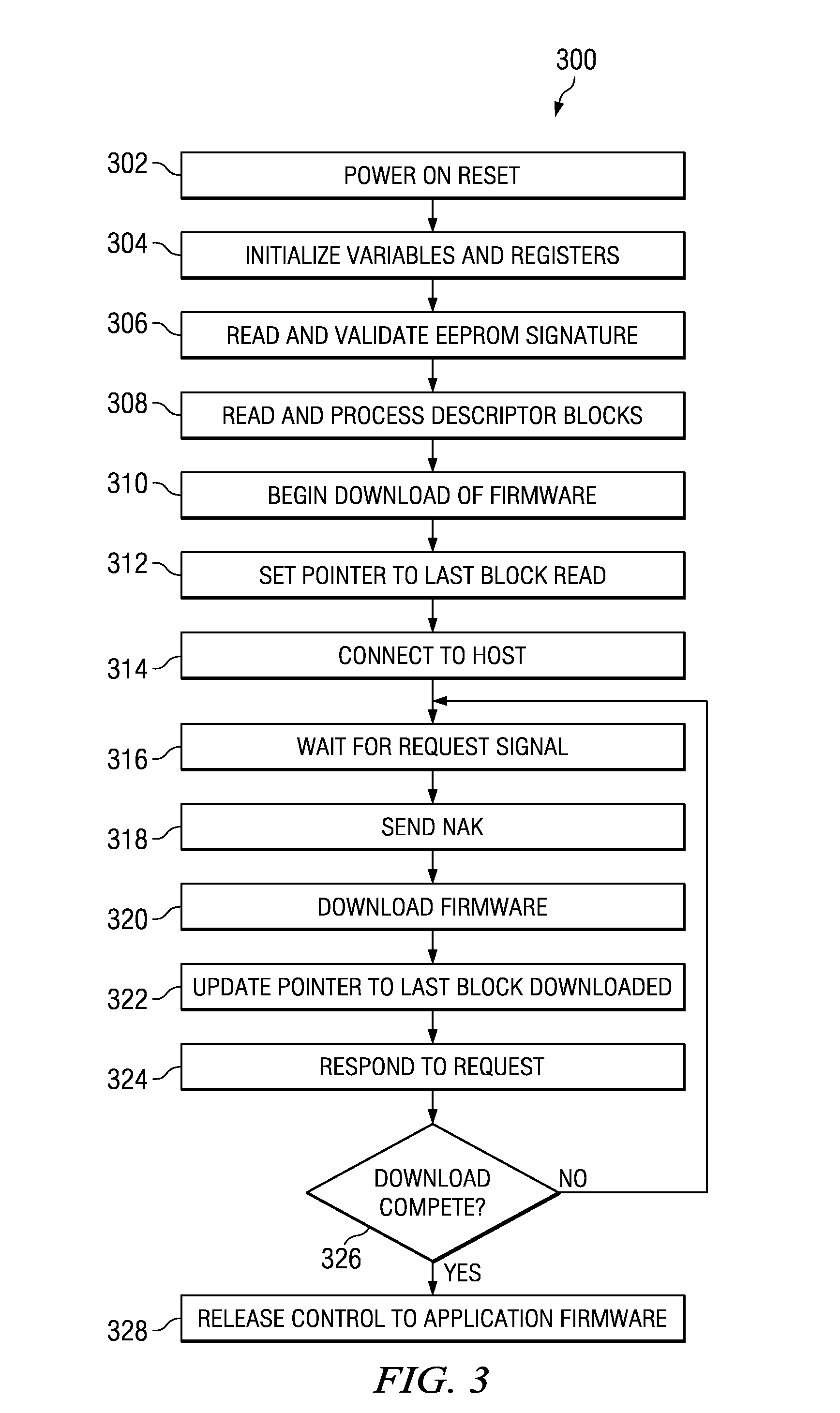

Method and system for firmware downloads

A method and system for downloading firmware by a device controller from a data source while connected to a host. The device controller connects to the host and waits for a signal or communication from the host. The device controller responds to the signal or communication with a negative acknowledgement (NAK), and downloads data for a predetermined period of time based on the request signal or communication type received from the host. The device may use a pointer to track the progress of the download. Once the device has completed the download, the device responds normally to the host.

Owner:TEXAS INSTR INC

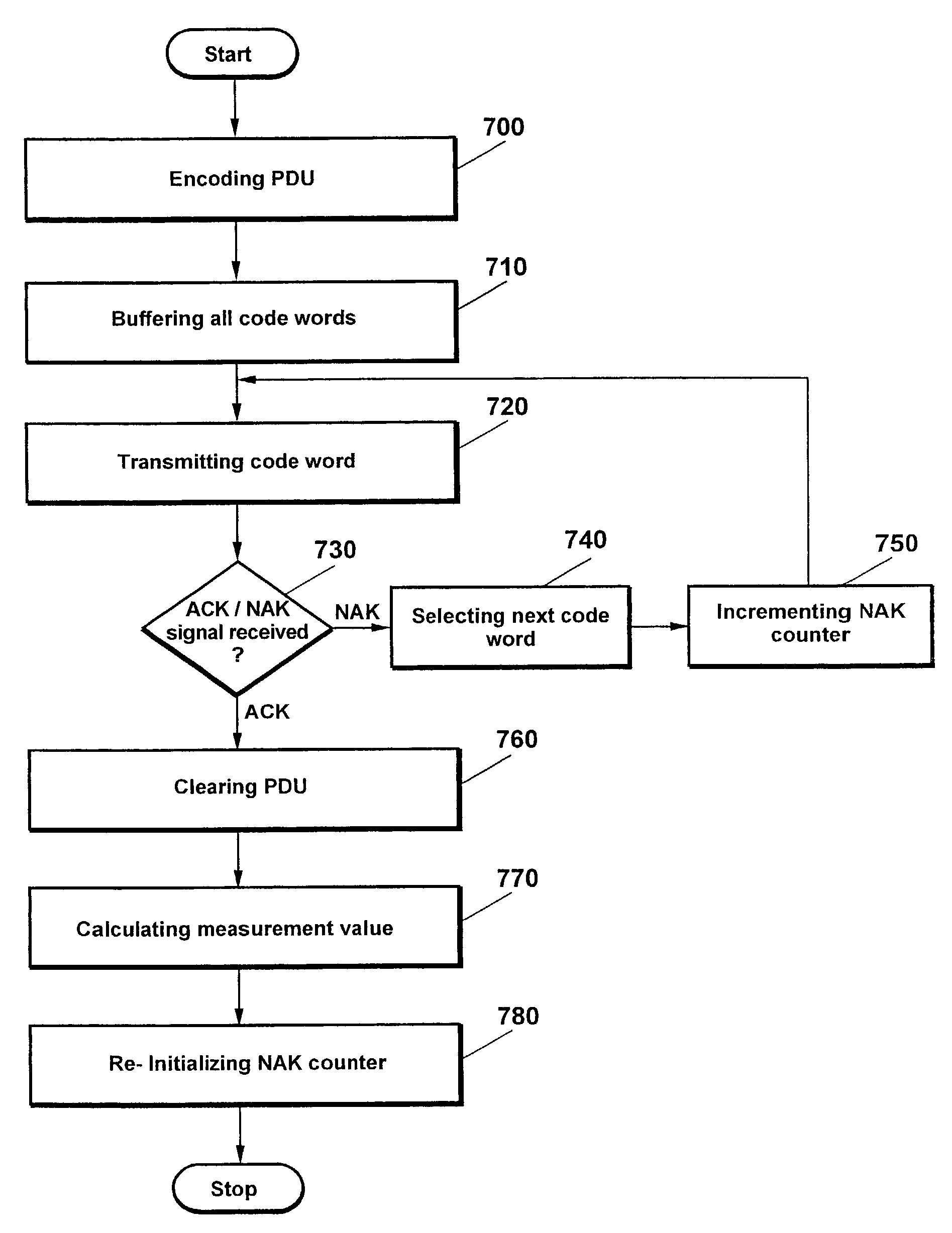

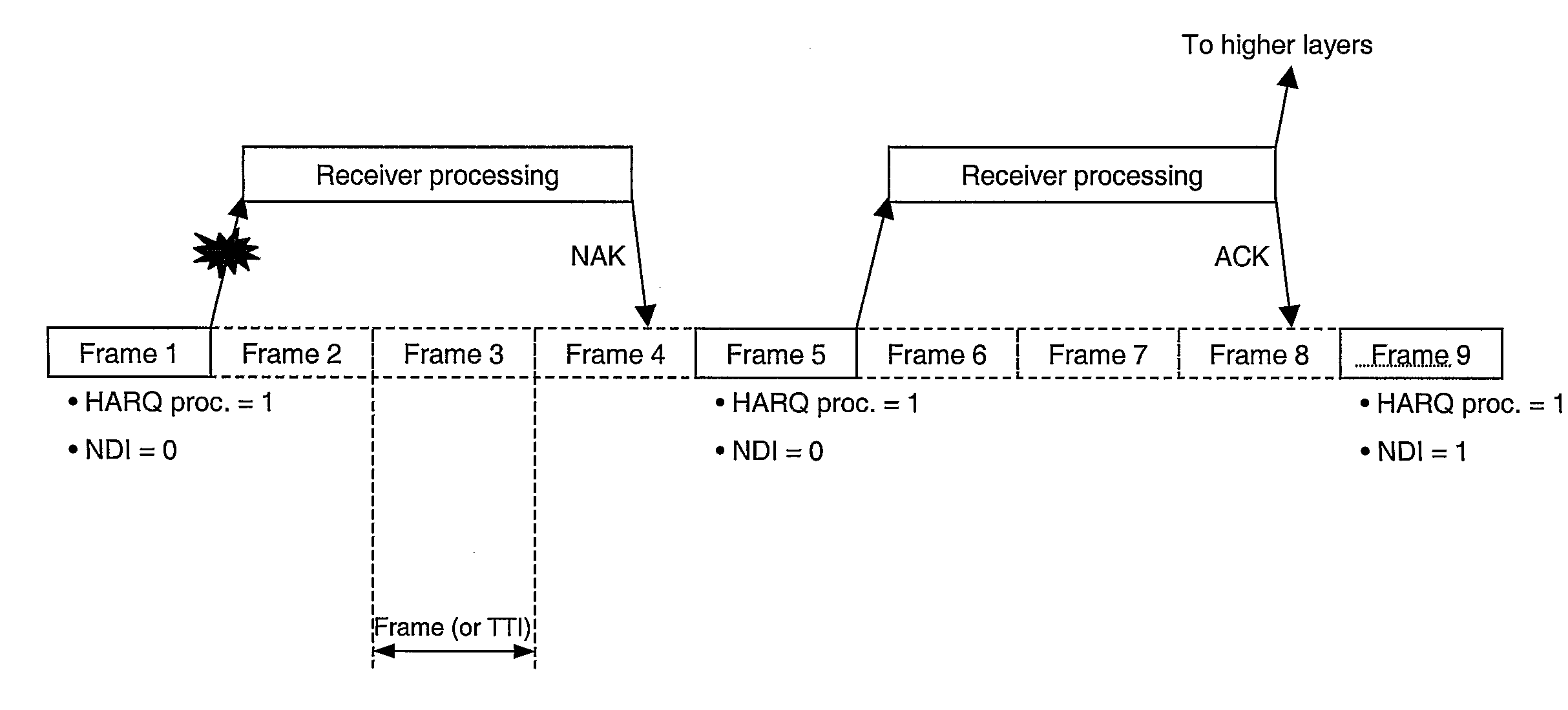

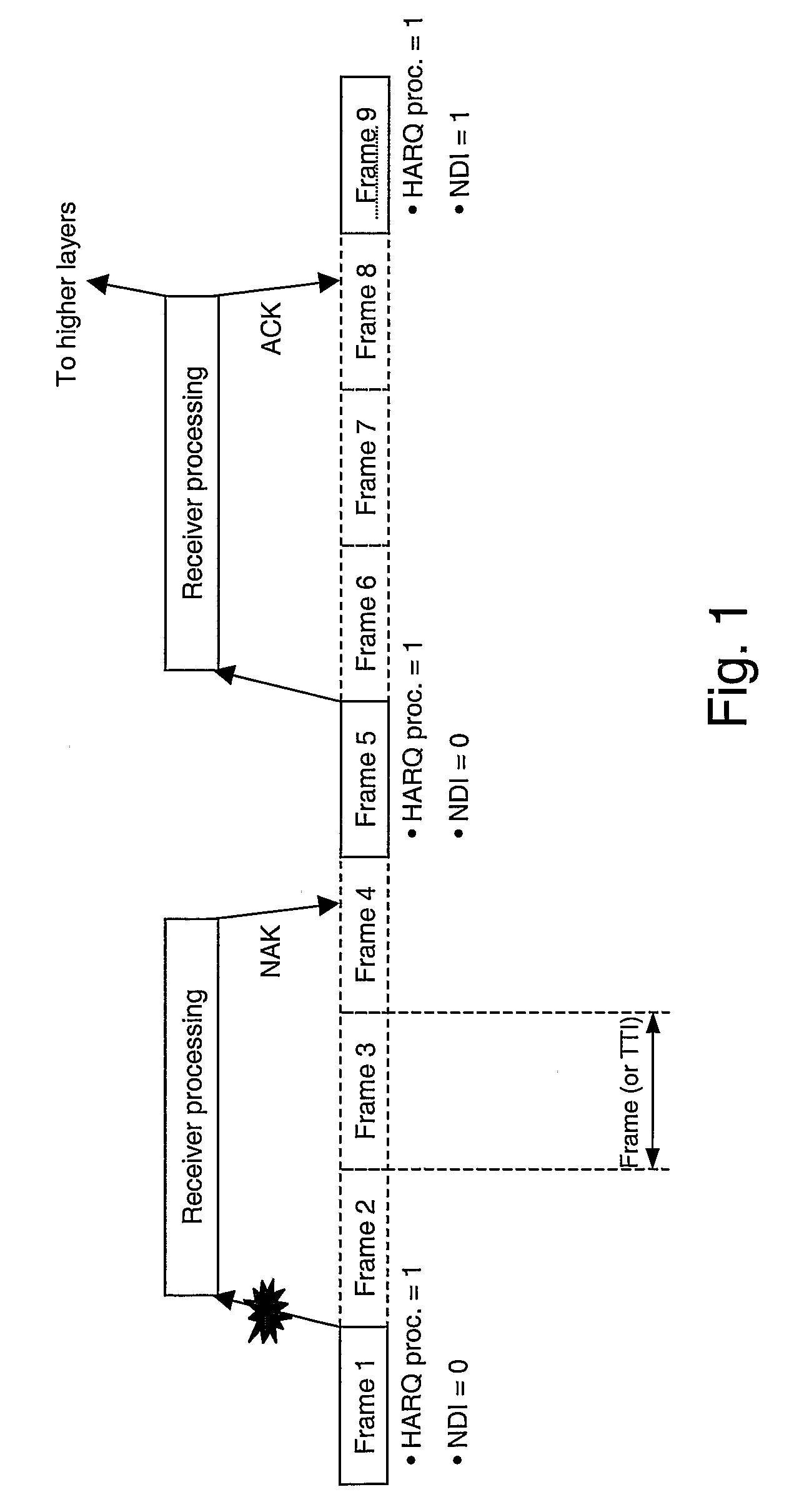

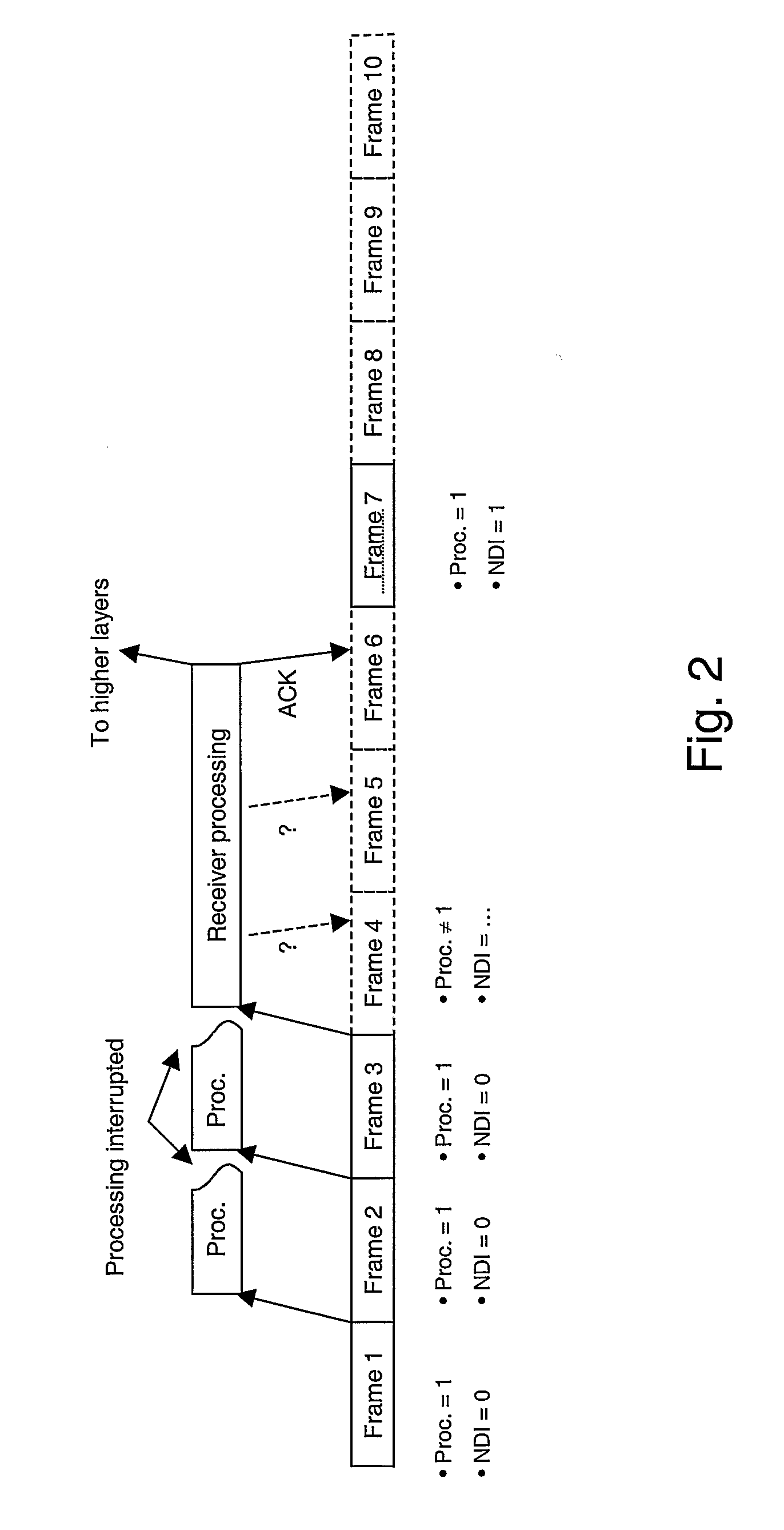

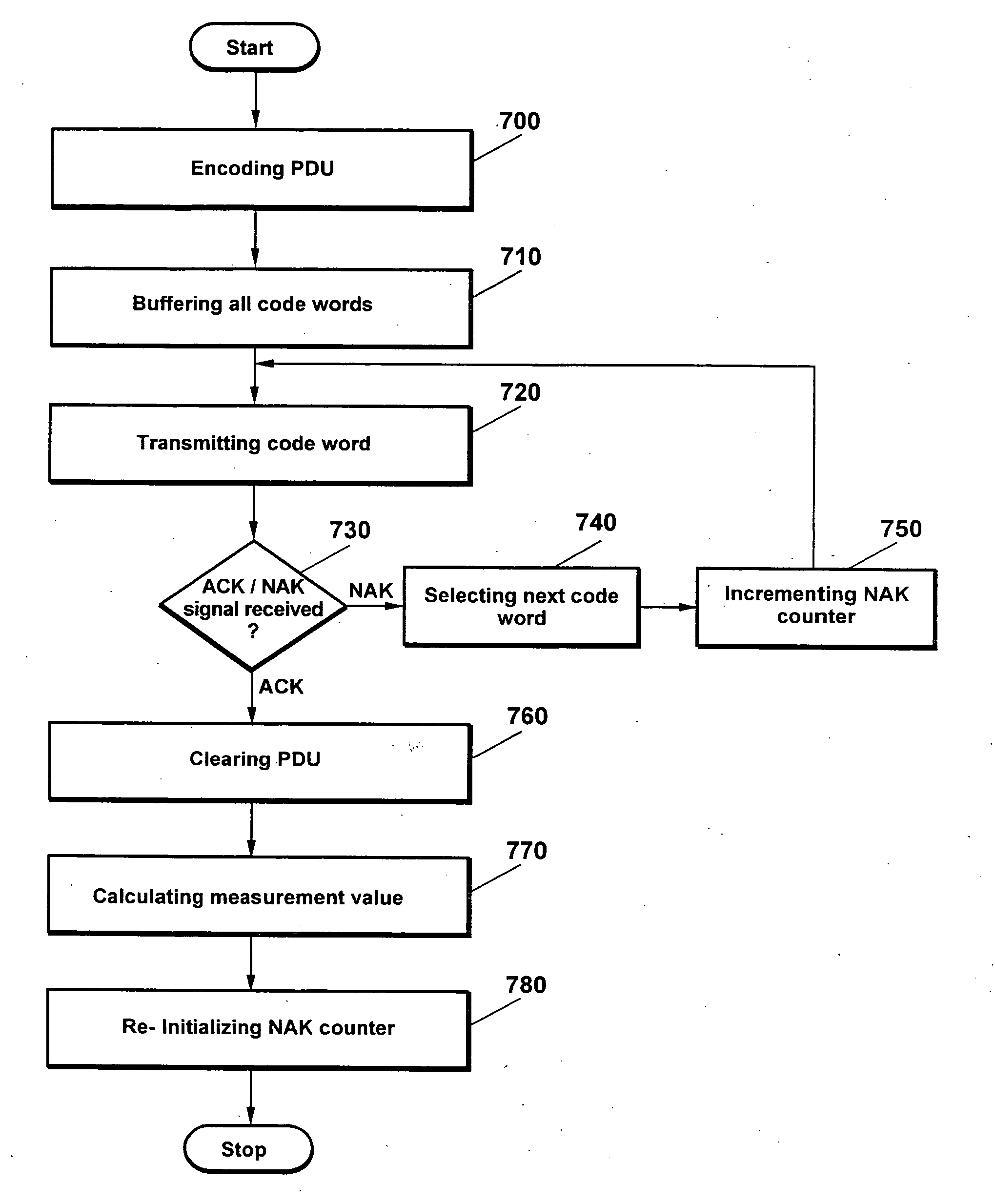

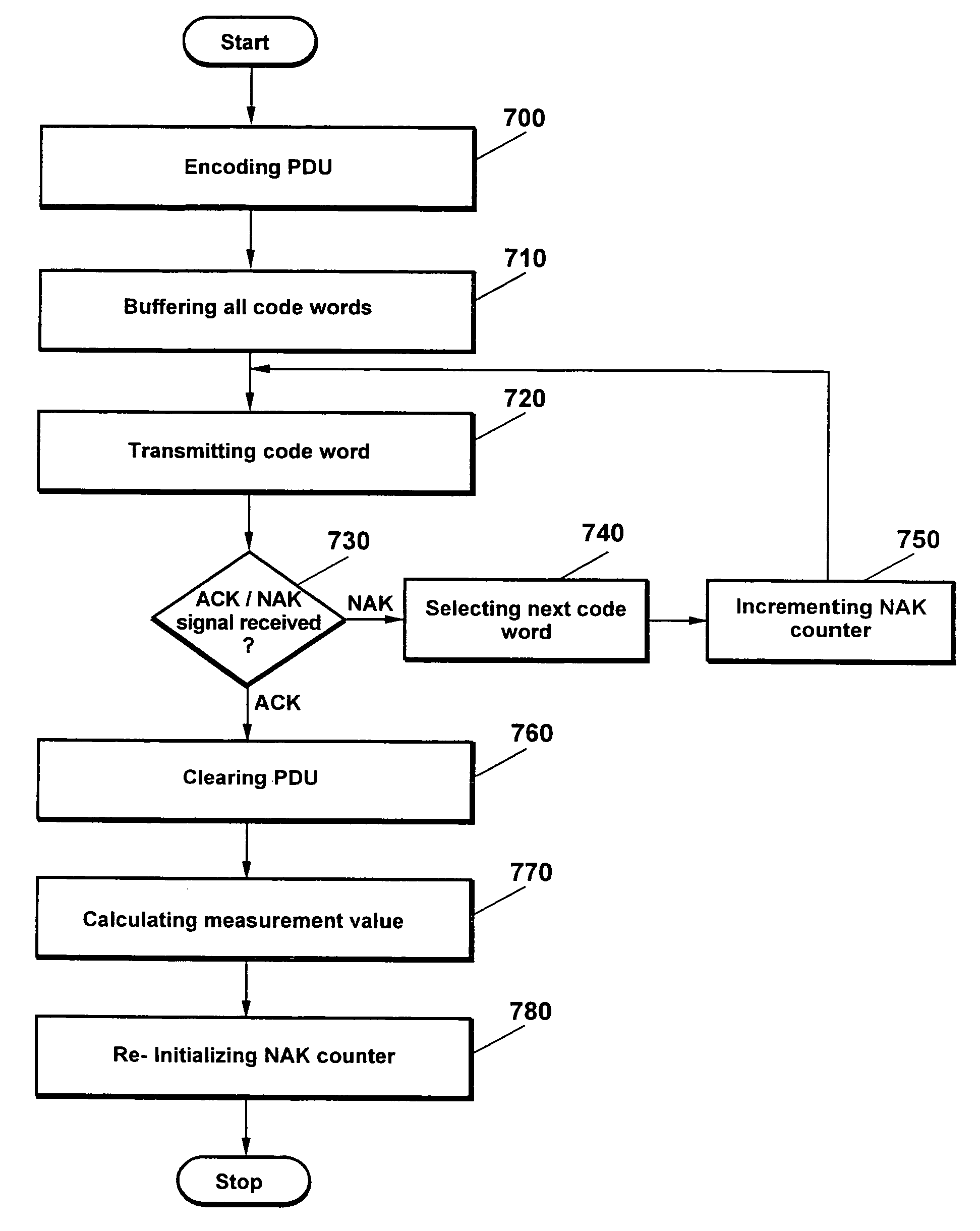

Channel quality measurement in data transmission using hybrid arq

InactiveUS7002923B2Reduce overheadError prevention/detection by using return channelError detection/prevention using signal quality detectorCurrent channelCommunications system

A hybrid ARQ technique for transmitting a data unit on a radio channel in a communication system to a receiver is provided, wherein after the encoding the data unit into a sequence of code words using an encoding parameter, a first code word is transmitted, and an ACK or NAK is received from the receiver. If a NAK is received, the next code word of the sequence is transmitted. A measurement value indicating the current channel conditions is determined by counting the NAK messages and / or evaluating the encoding parameters. The measurement values may be the overall coding rate, the average number of retransmissions per data unit, or the average number of retransmissions per code word. The transmitter may include a NAK counter. The measurement may be used for adaptation purposes.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

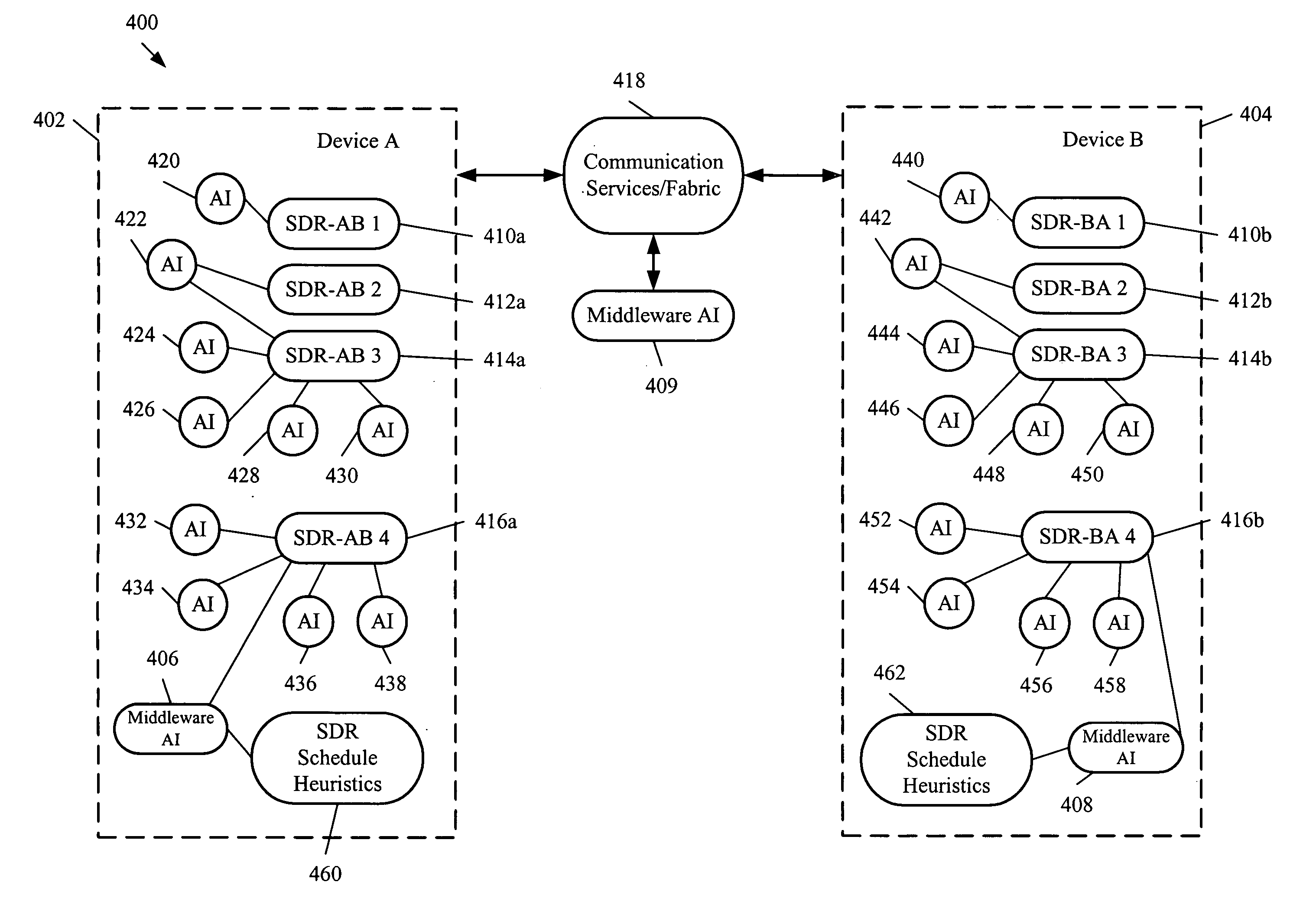

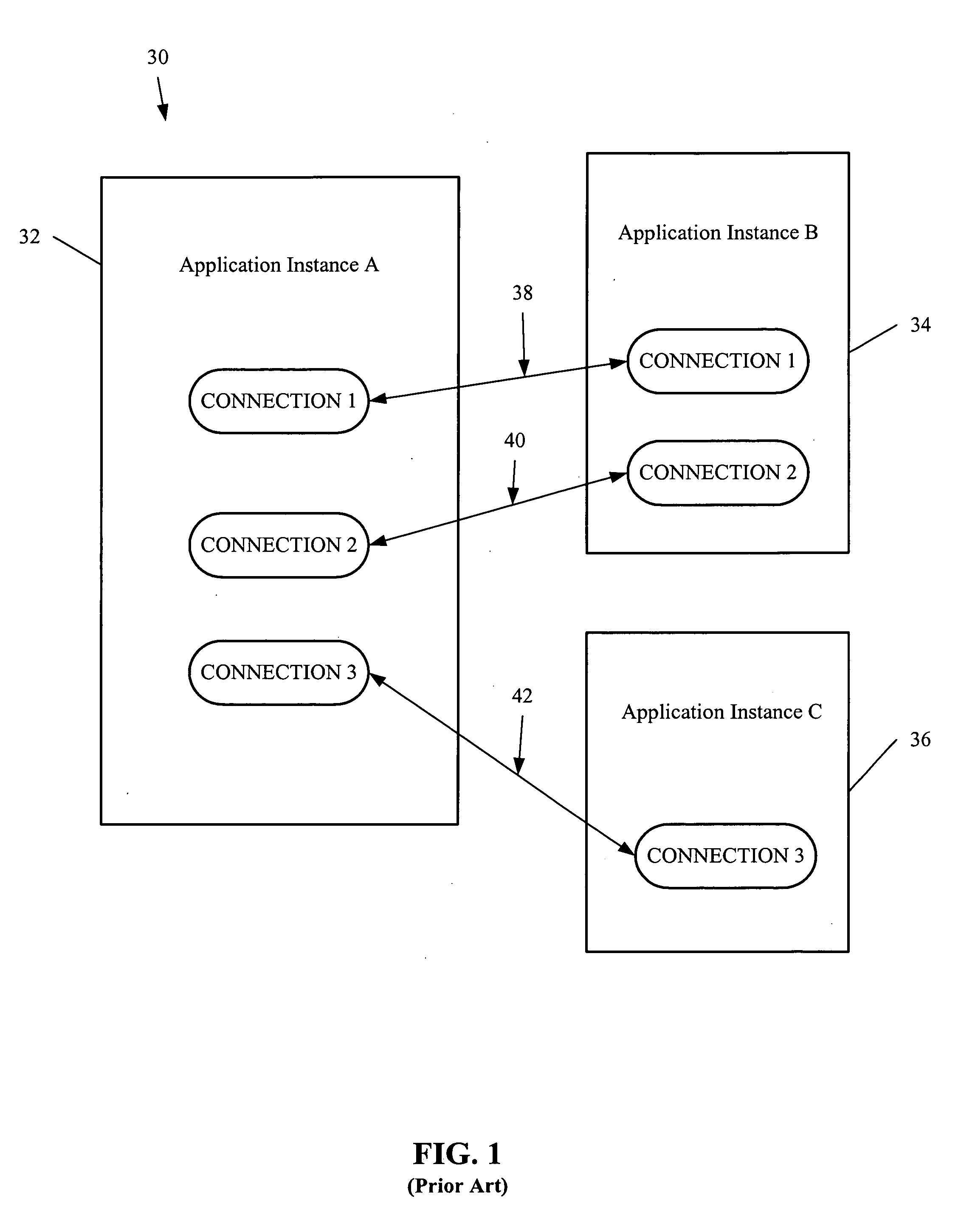

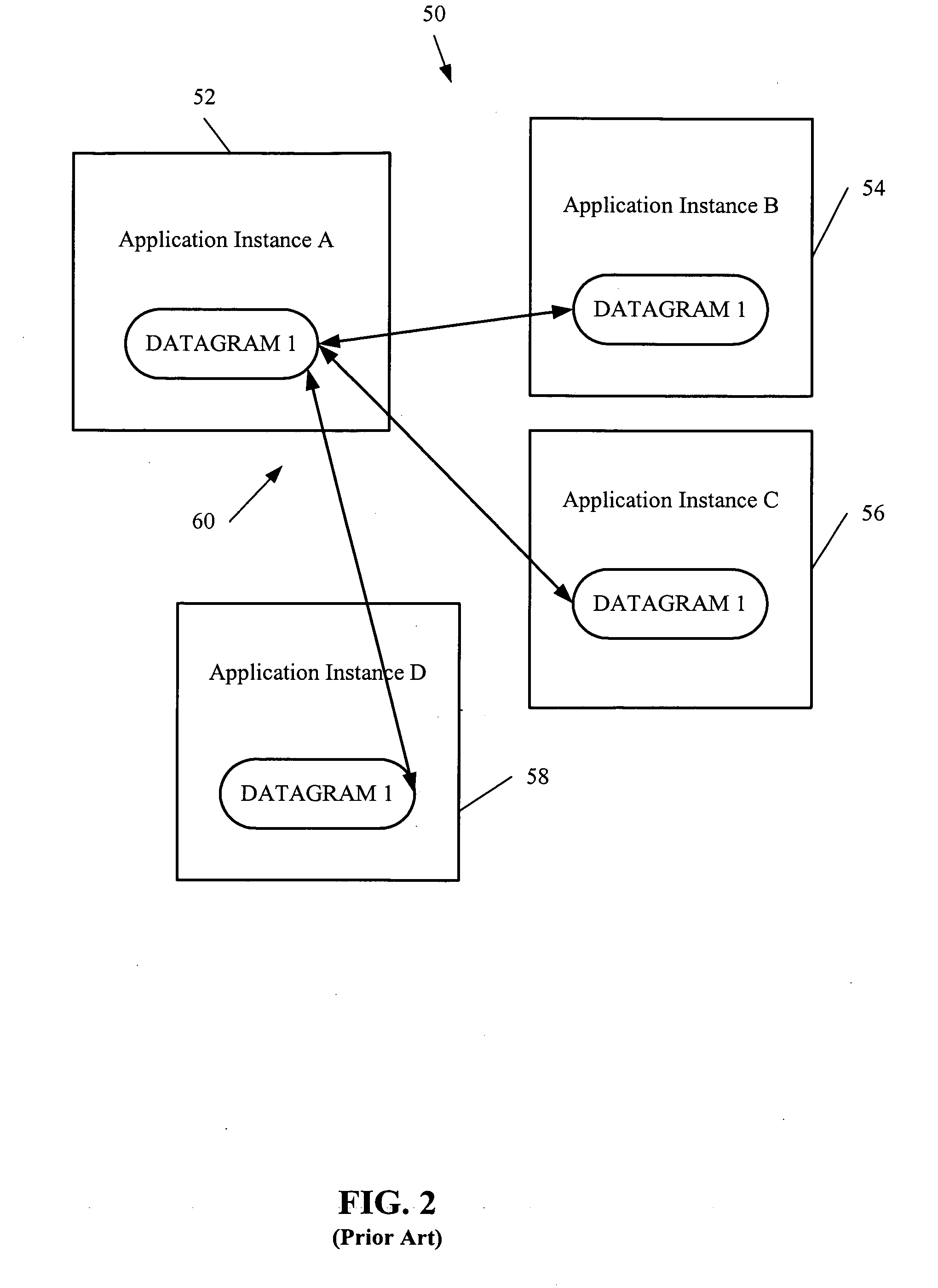

Reliable datagram

InactiveUS7318102B1Reduce in quantityImprove scalabilityError preventionMultiple digital computer combinationsSodium-potassium alloyComputer science

A reliable datagram service is implemented with a source and destination resource (SDR). Source SDR resources, at a source device, multiplex units of work produced by at least one source application instance (AI) into a serial unit of work stream having units of work in a defined order and transmit the serial unit of work stream over a communication services / fabric. Destination SDR resources, at a destination device, receive the serial unit of work stream, demultiplex the serial unit of work stream into units of work provided to at least one destination AI, and provide a negative acknowledgement (NAK) for a unit of work received ahead of its defined order.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Method and system for firmware downloads

A method and system for downloading firmware by a device controller from a data source while connected to a host. The device controller connects to the host and waits for a signal or communication from the host. The device controller responds to the signal or communication with a negative acknowledgement (NAK), and downloads data for a predetermined period of time based on the request signal or communication type received from the host. The device may use a pointer to track the progress of the download. Once the device has completed the download, the device responds normally to the host.

Owner:TEXAS INSTR INC

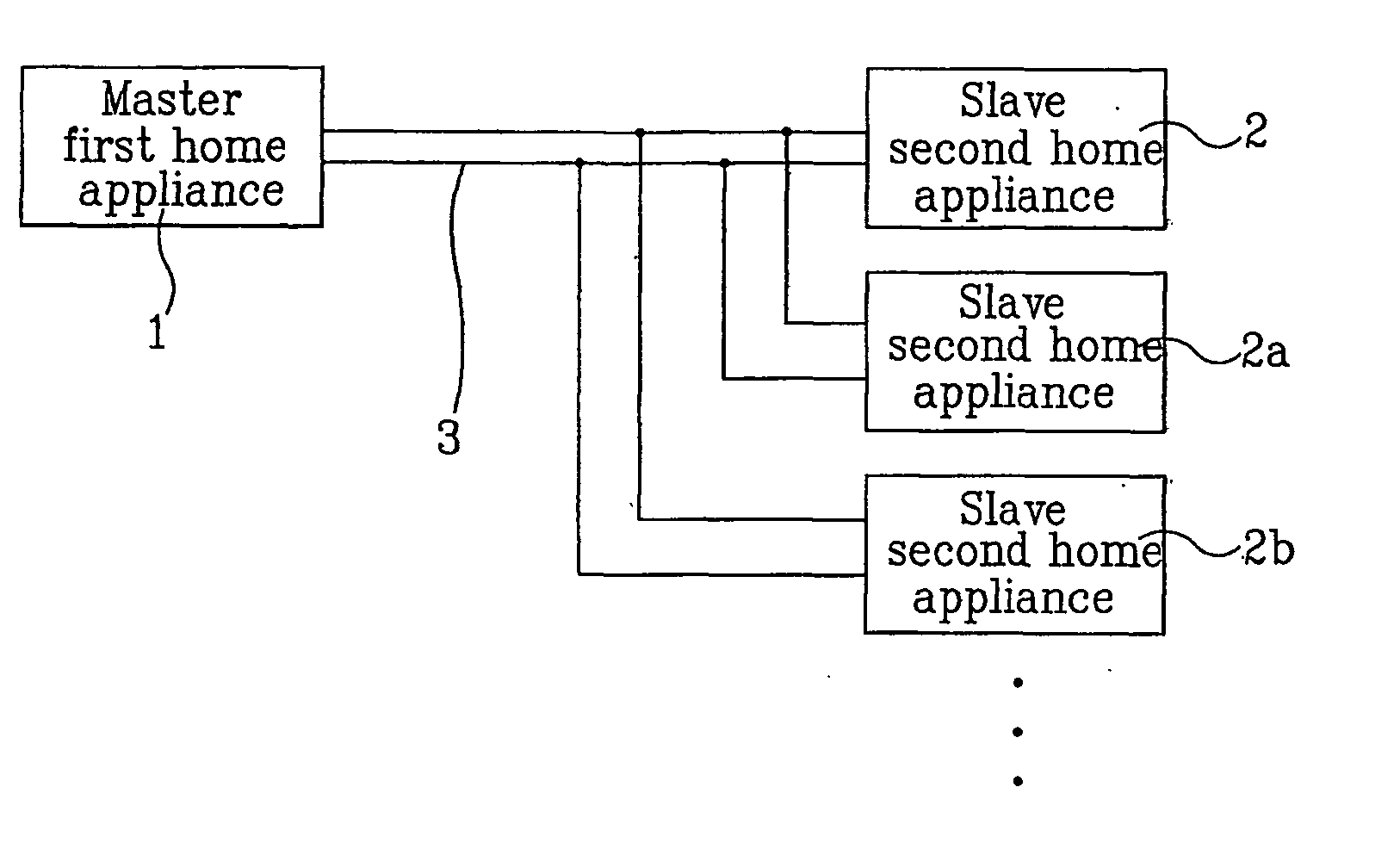

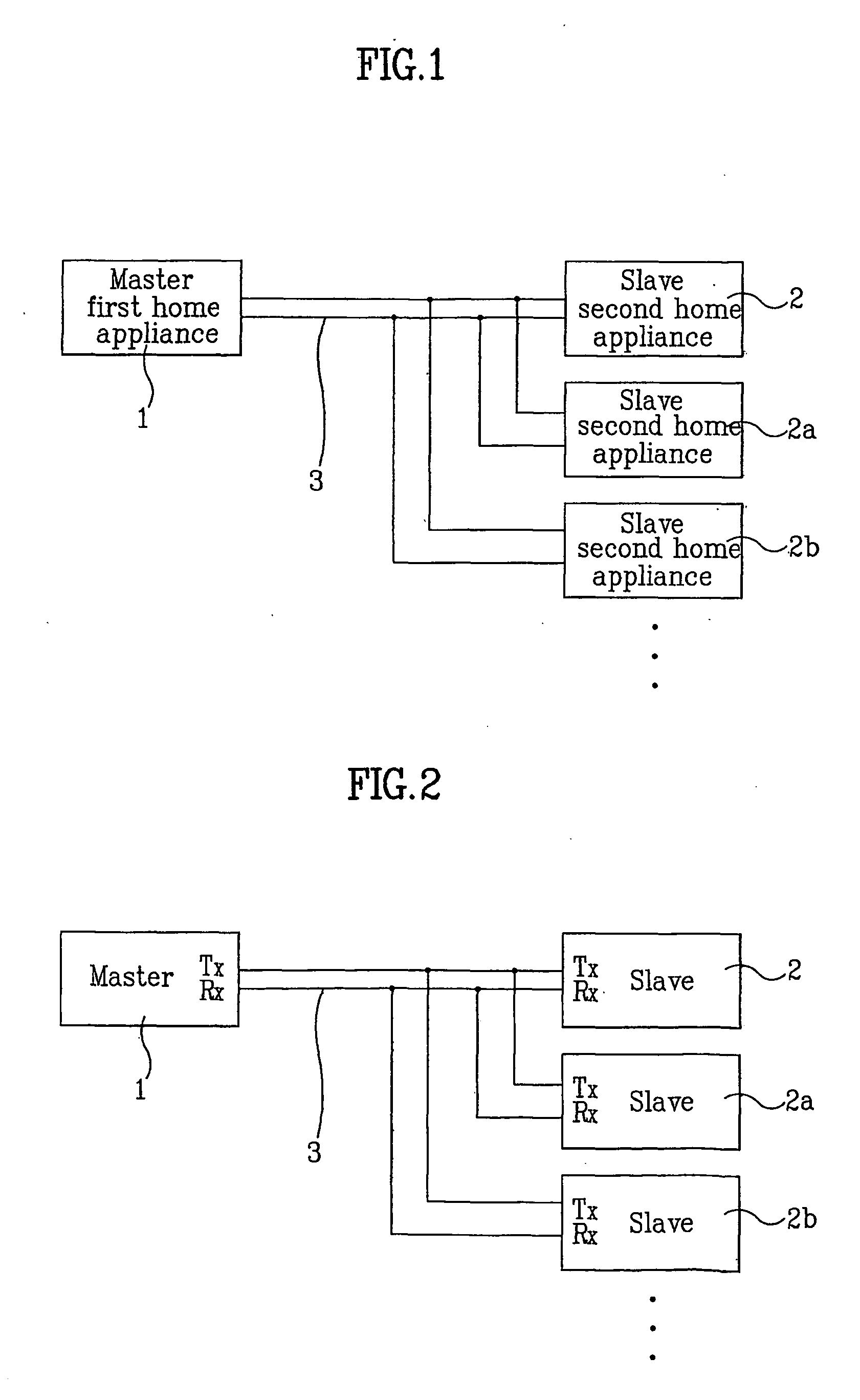

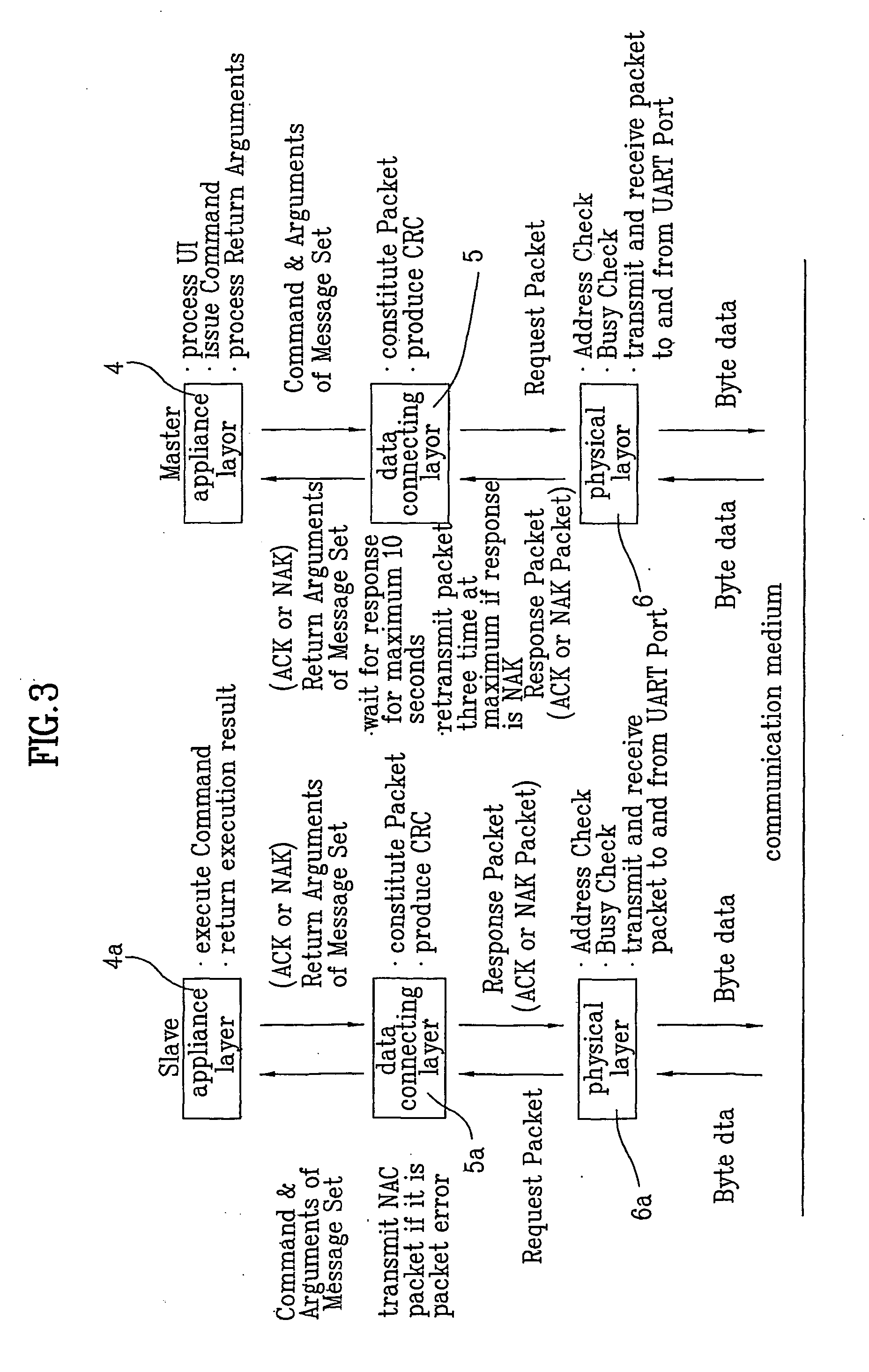

System and method for remote controlling and monitoring electric home appliances

InactiveUS20050225426A1Eliminate the problemError prevention/detection by using return channelComputer controlHome applianceSodium-potassium alloy

A system and a method for remote controlling and monitoring electric home appliance are disclosed. The system includes a first electric home appliance having a master function, a second electric home appliance having a slave function, and a communication line path for communicating between the first and second electric home appliances. The method includes a first s in which the first electric home appliance leads information of the second electric home appliance, sets a corresponding communication speed and a corresponding packet length, and transmits a use command to the second electric home appliance at the preset speed by the preset packet length constituted as one packet; a second step in which the second electric home appliance corresponding to the first packet receives the first packet, checks an error, performs a command of the first packet if an error is not found and a command of the second packet of NAK if an error is found, and constitutes the second packet of ACK if the command is performed, thereby transmitting to the first electric home appliance; and a third step in which the first electric home appliance checks whether the second packet is received or not and then transmits a next packet or retransmits the first packet according to the result.

Owner:LG ELECTRONICS INC

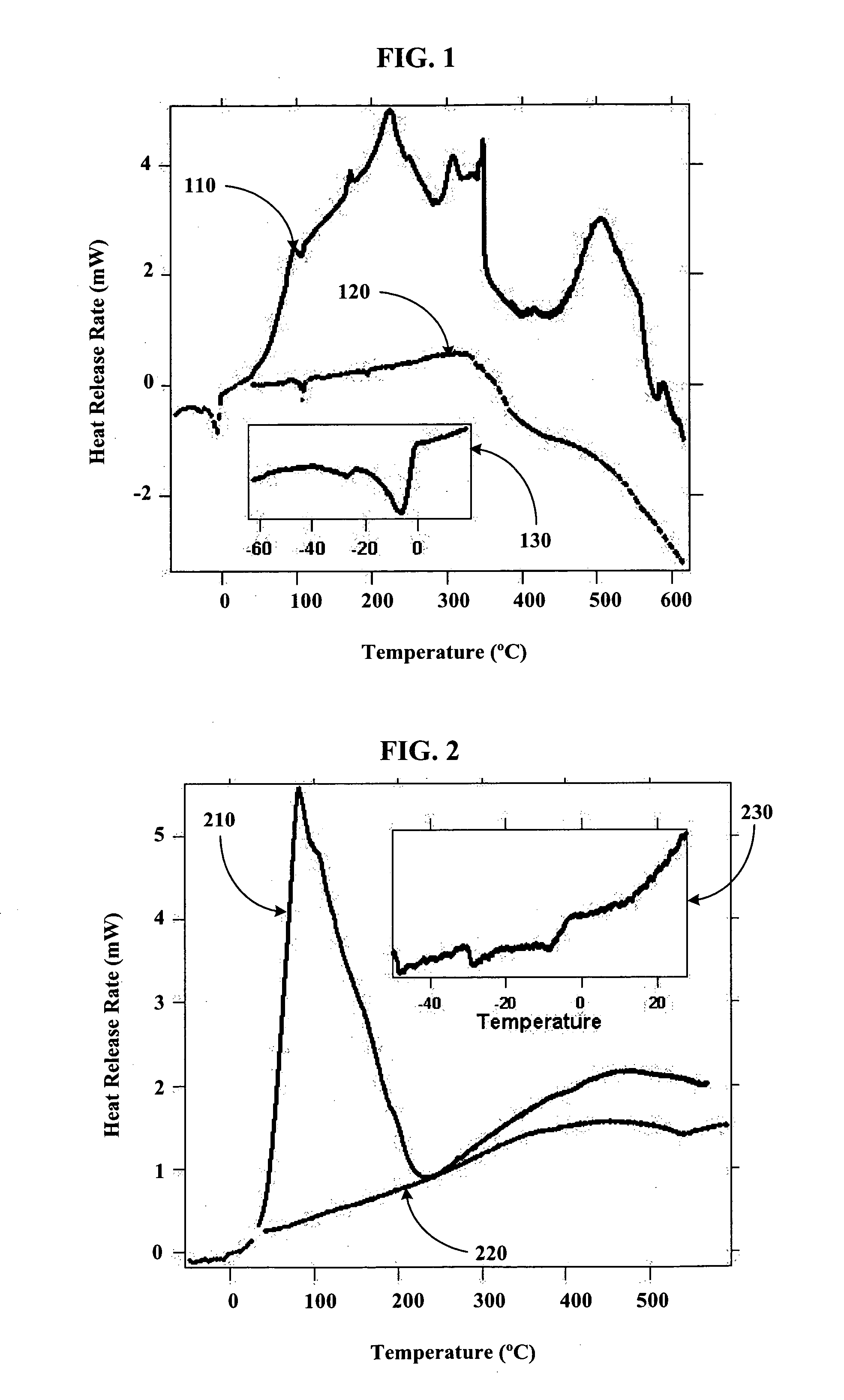

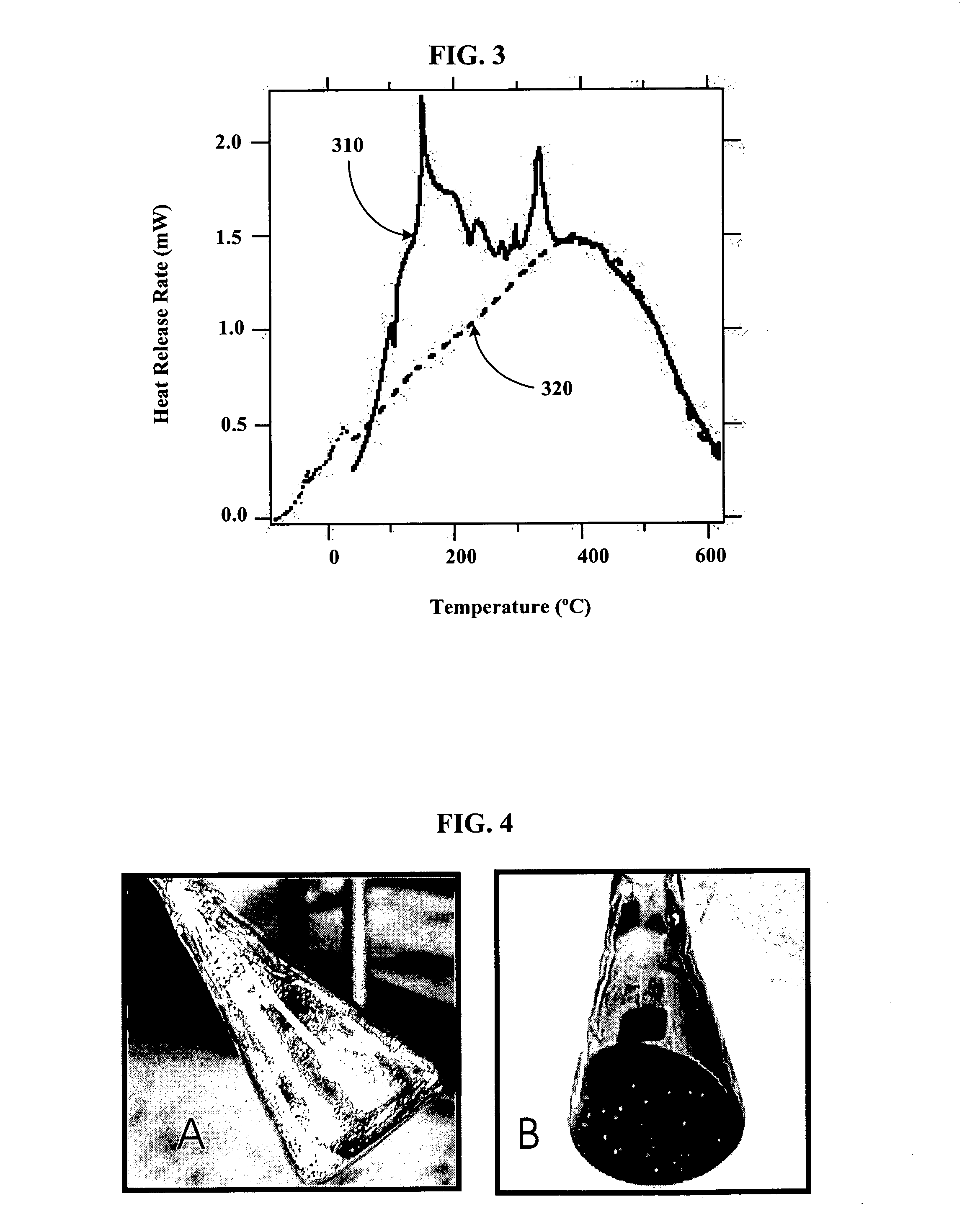

Silica gel compositions containing alkali metals and alkali metal alloy

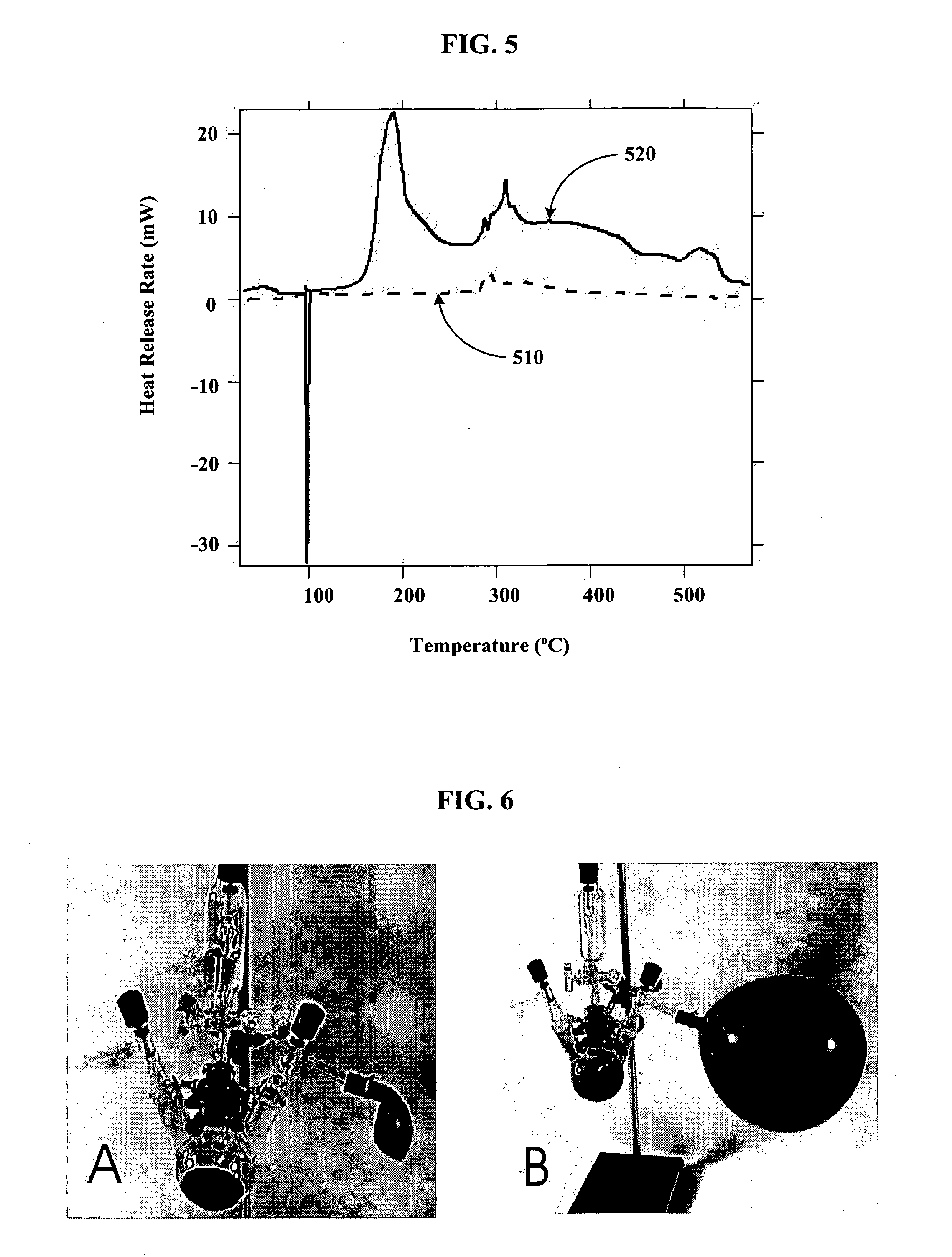

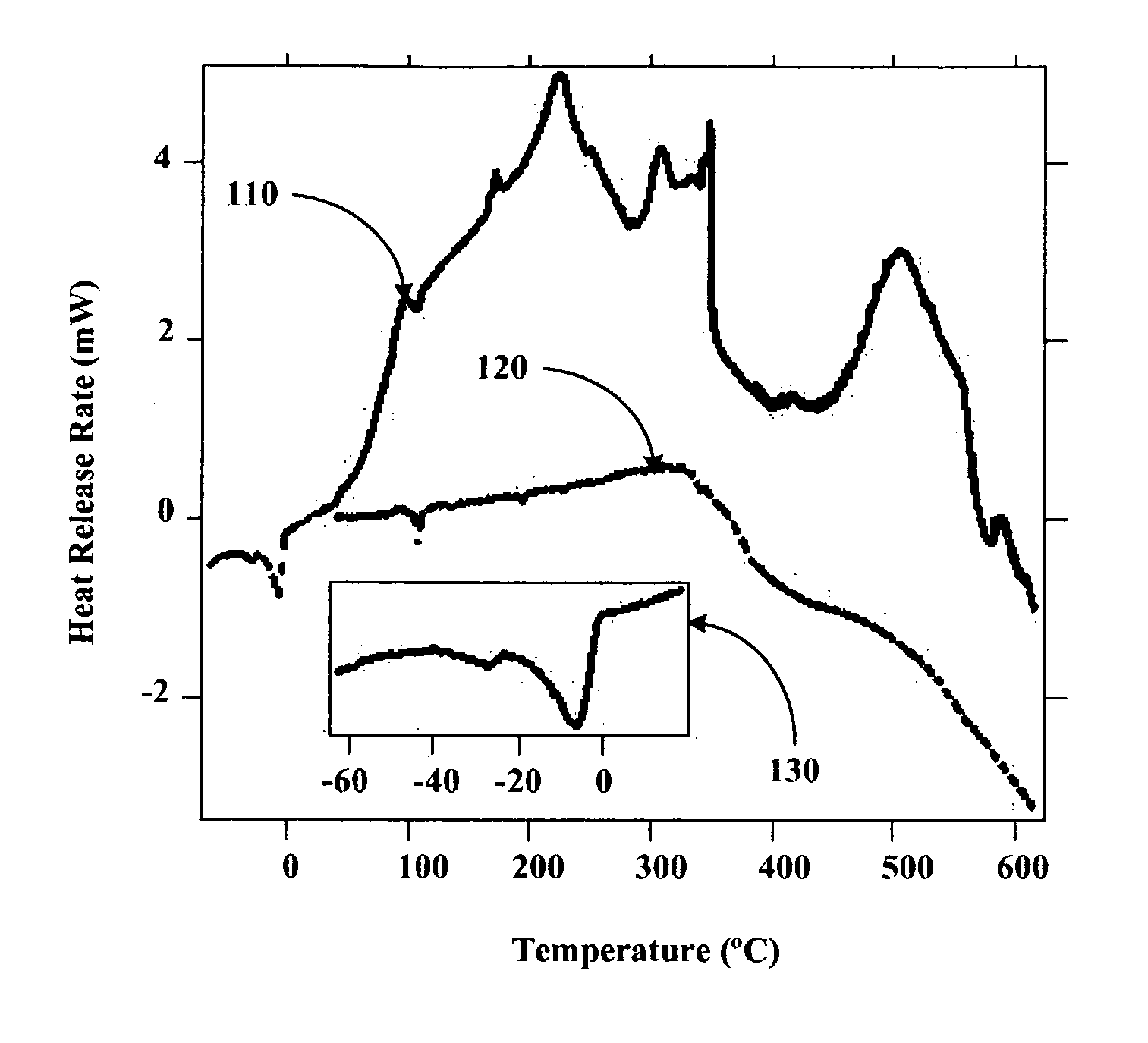

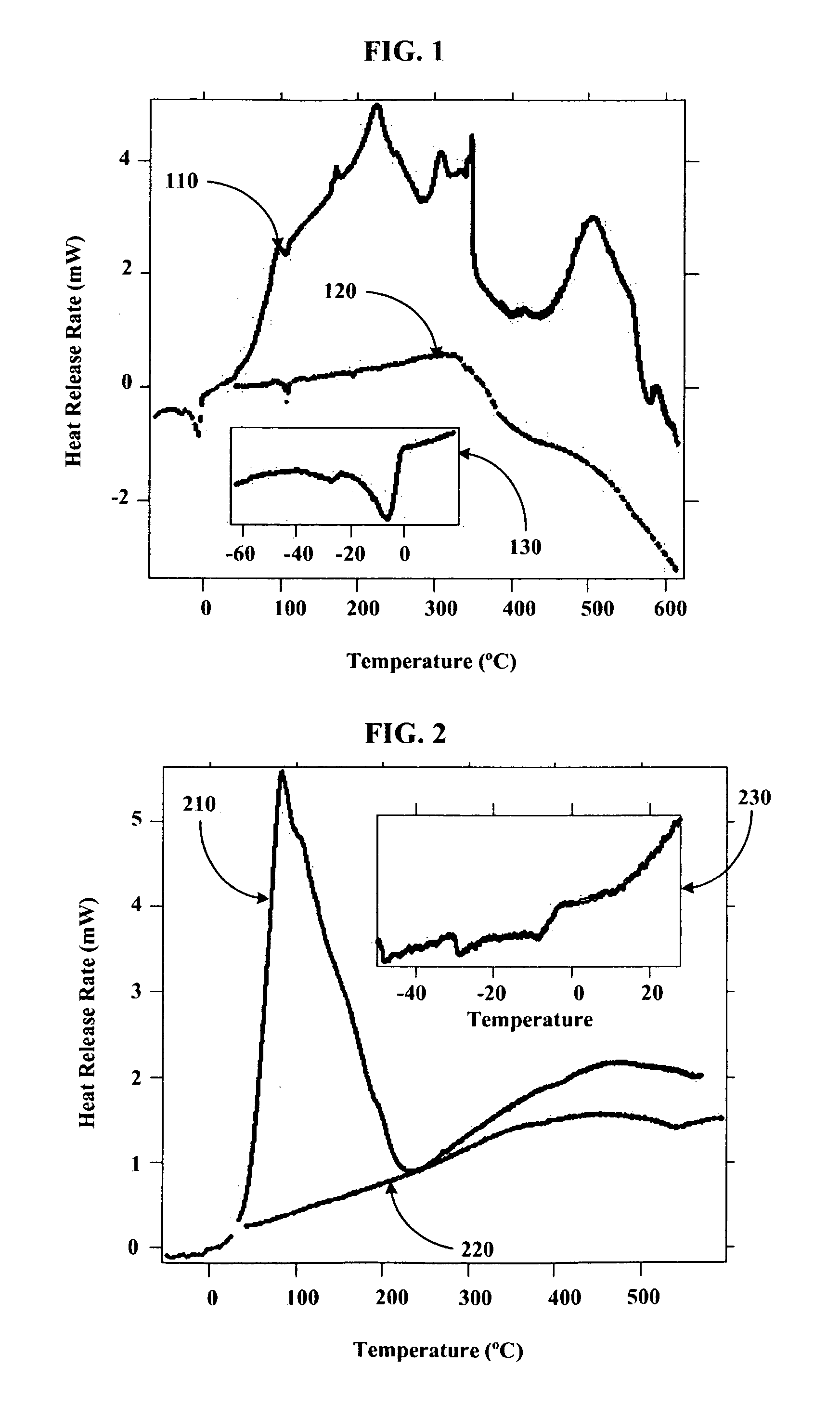

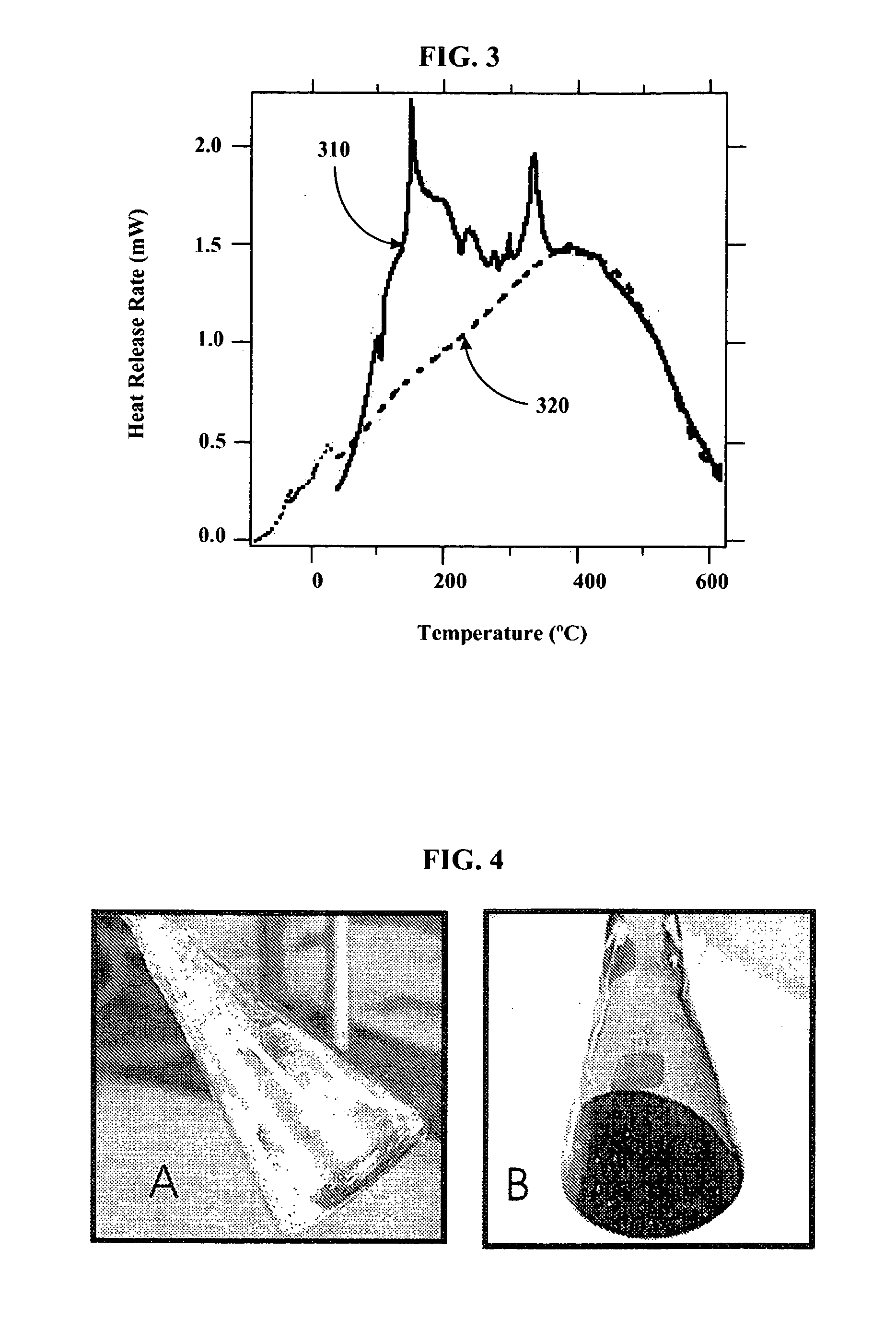

ActiveUS20050151278A1Preparation by hydrogen halide split-offLithium organic compoundsChemical reactionRoom temperature

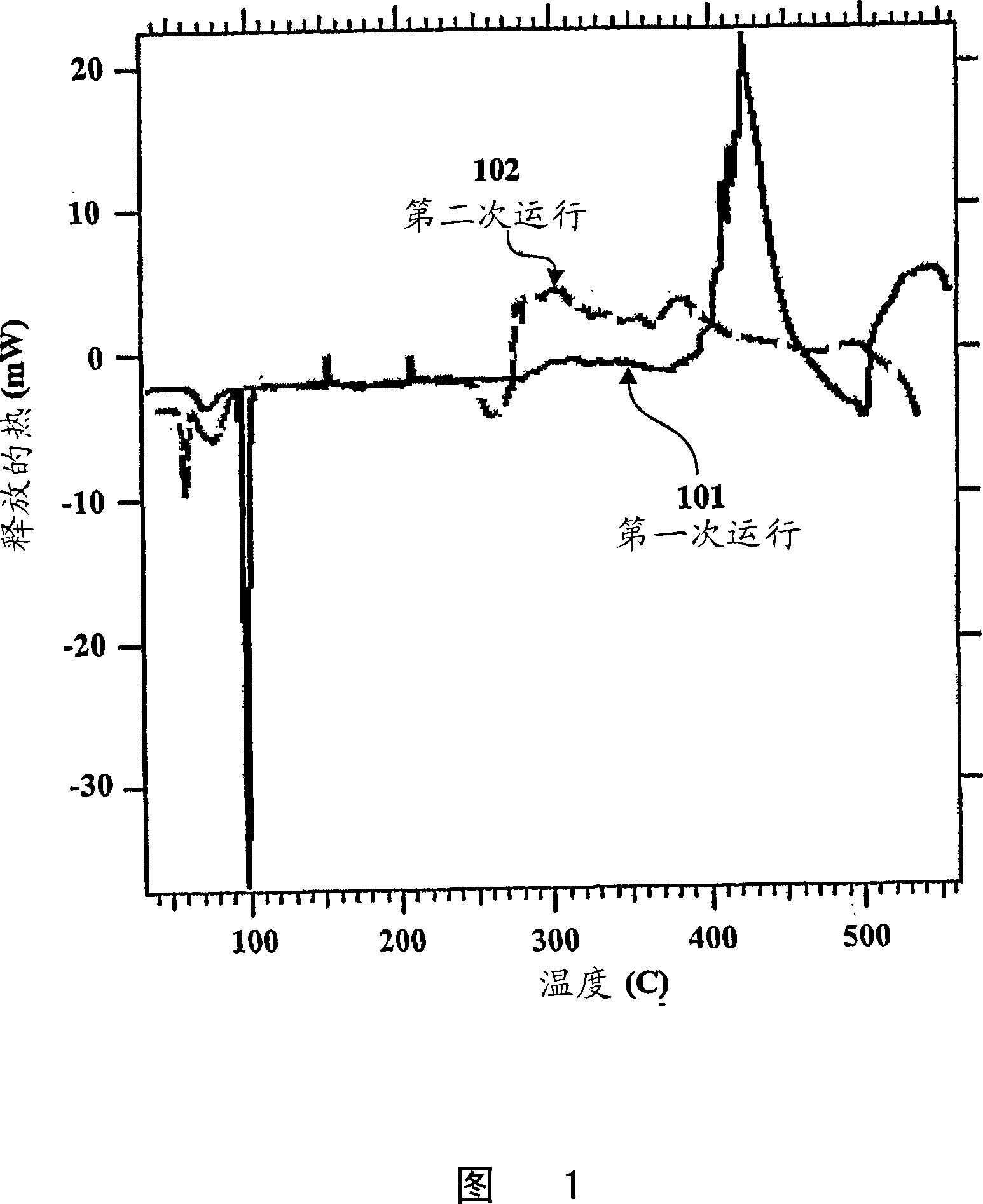

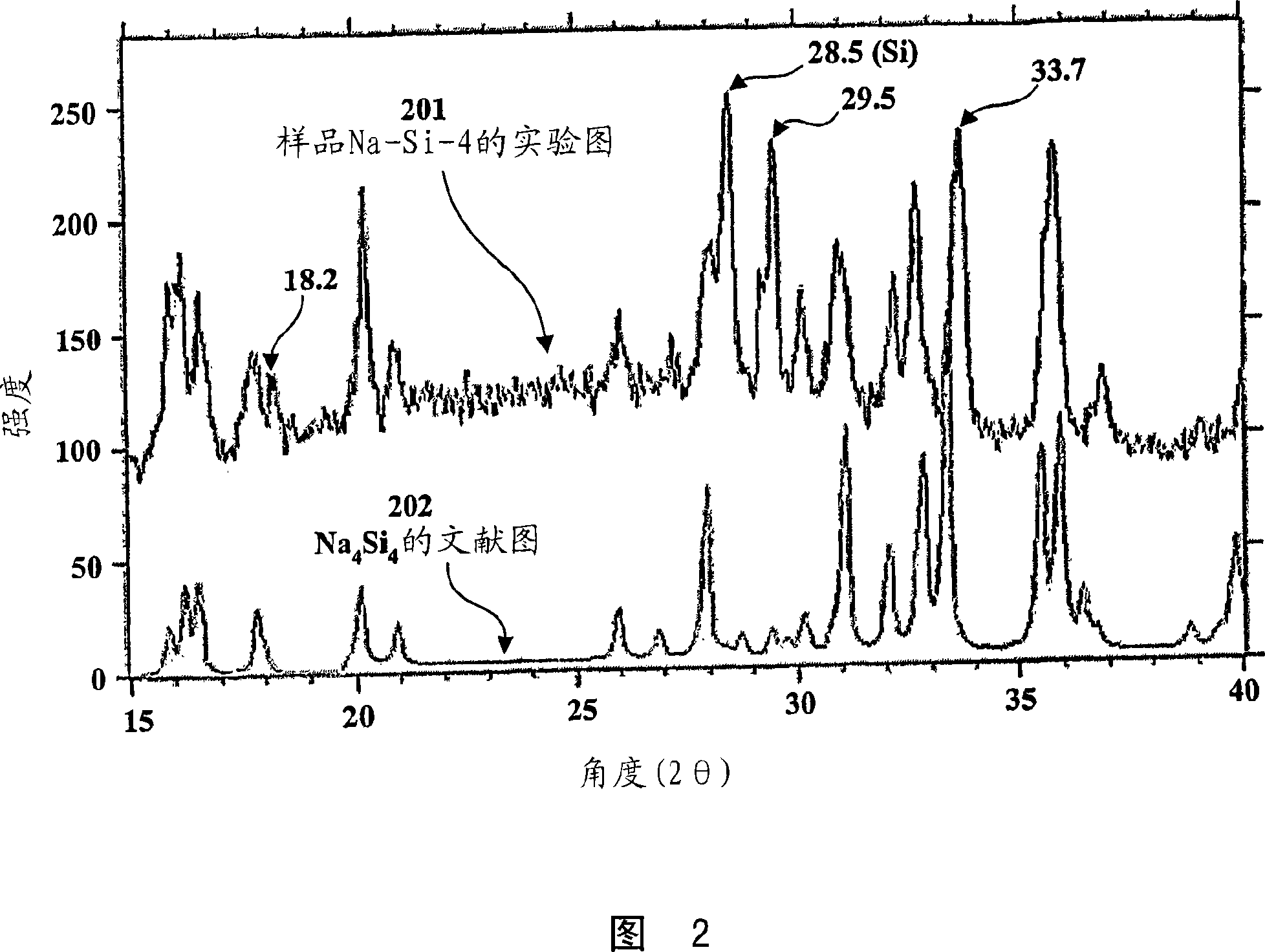

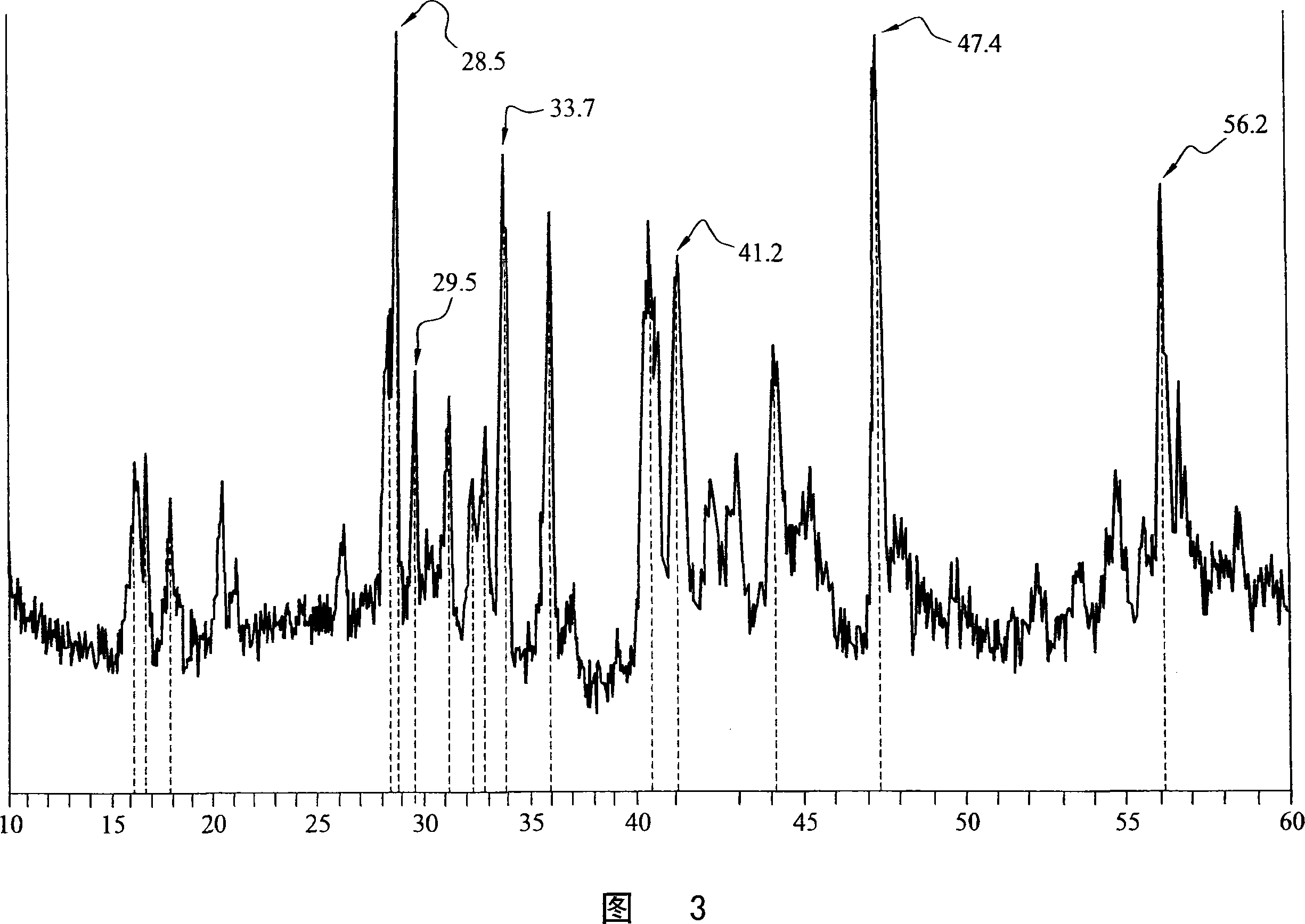

The invention relates to Group 1 metal / silica gel compositions comprising silica gel and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0, I, II, and III materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by silica gel (porous SiO2) under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the silica gel, a mild exothermic reaction produces Stage I material, loose black powders that are indefinitely stable in dry air. Subsequent heating to 400° C. produces Stage II materials, which are also loose black powders. Further heating above 400° C. forms Stage III material with release of some Group 1 metal. It is believed that Stage I, II and III materials represent reductions of the silica gel after absorption of the Group 1 metal. Preferred Group 1 metal / silica gel compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium-potassium alloys being most preferred. Each stage of the Group 1 metal / silica gel composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:SIGNA CHEM INC +1

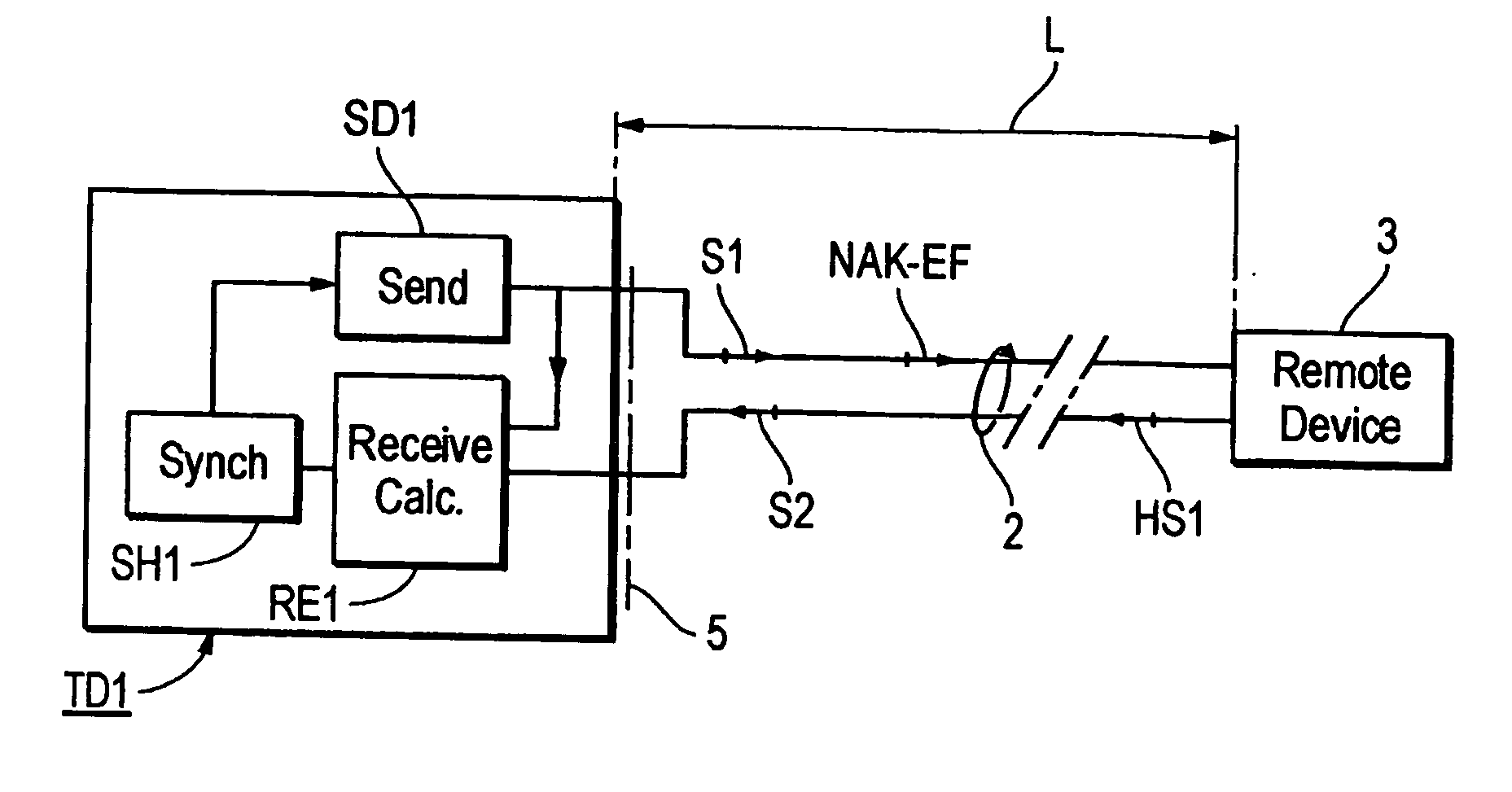

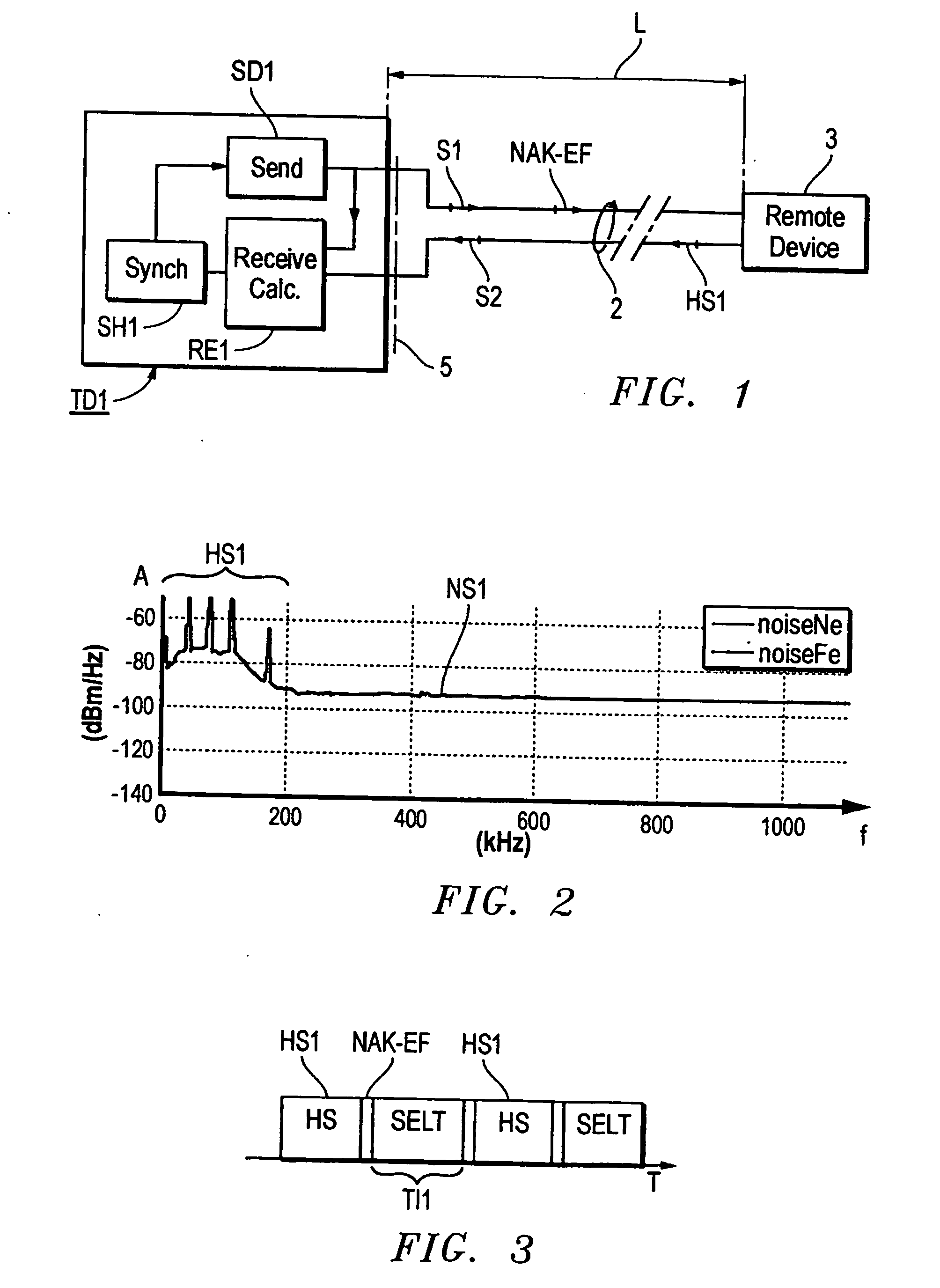

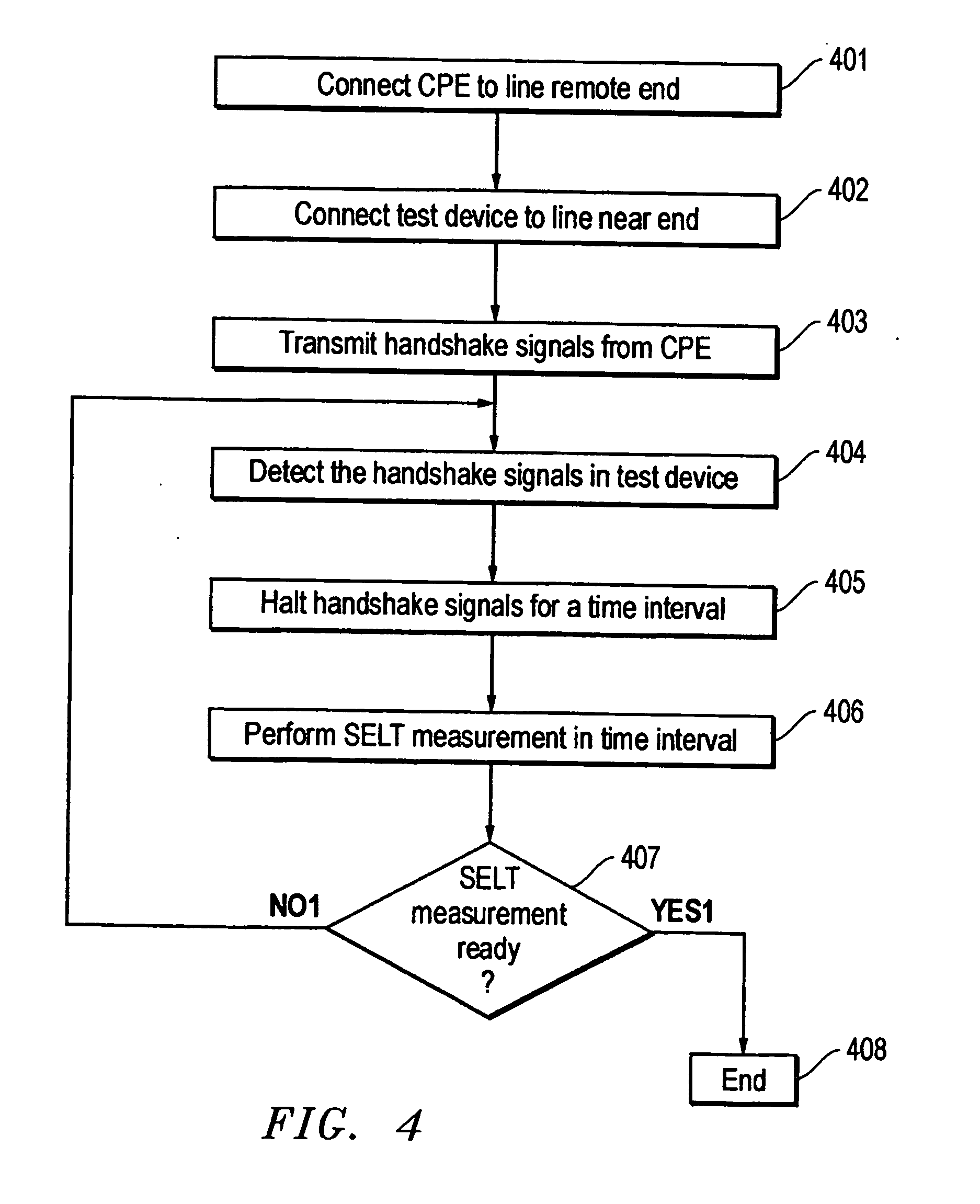

Method and arrangement for loop test of a disturbed line

ActiveUS20060251221A1Procedure is expensiveEasily understandable meaningSupervisory/monitoring/testing arrangementsSubstation equipmentSodium-potassium alloyBroadband

The invention refers to single-ended test of a loop (2, 3). A test device (TD1) is connected to a remote device (3) via a line (2). The remote device is powered on and transmits intermittently handshake signals (HS1), which can disturb the loop test. A receiving and calculating unit (RE1) detects the handshake signals (HS1) and orders a sending unit (SD1) to send a halting signal (NAK-EF) to the remote device. The latter is halted for predetermined silent period of time, during which the test or a part of it is performed. If required the halting of the handshake signals is repeated. The test device sends a broadband loop test signal (S1) and receives a reflected signal (S2) during the silent period. A frequency dependent echo transfer function is generated from the signals (S1, S2) and is used for generating desired properties of the line (2) such as its length (L).

Owner:TELEFON AB LM ERICSSON (PUBL)

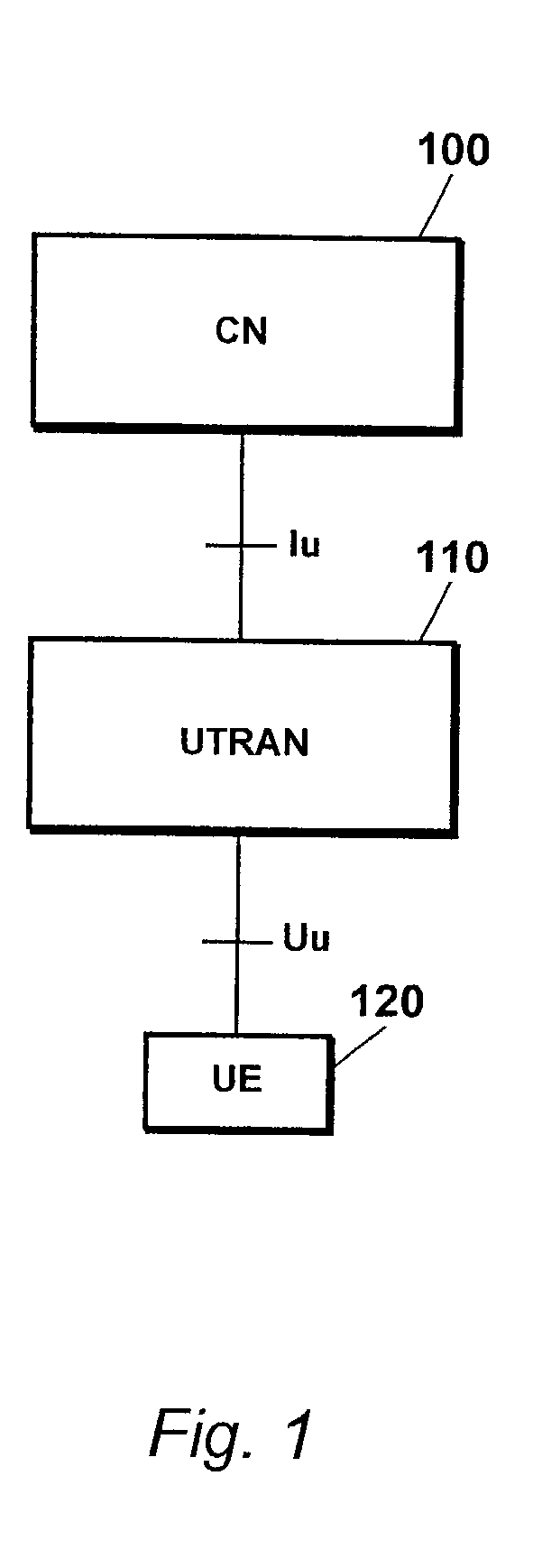

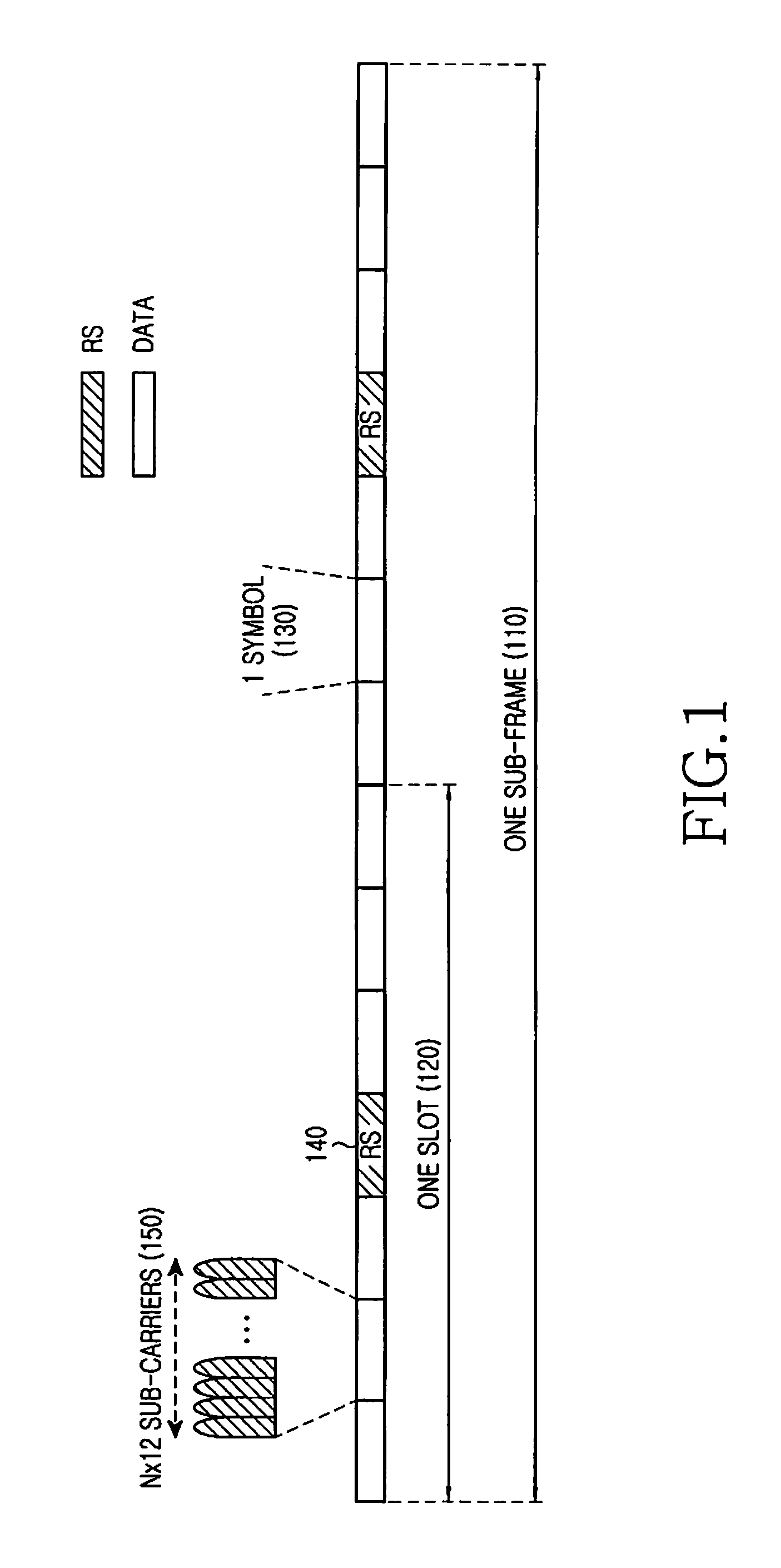

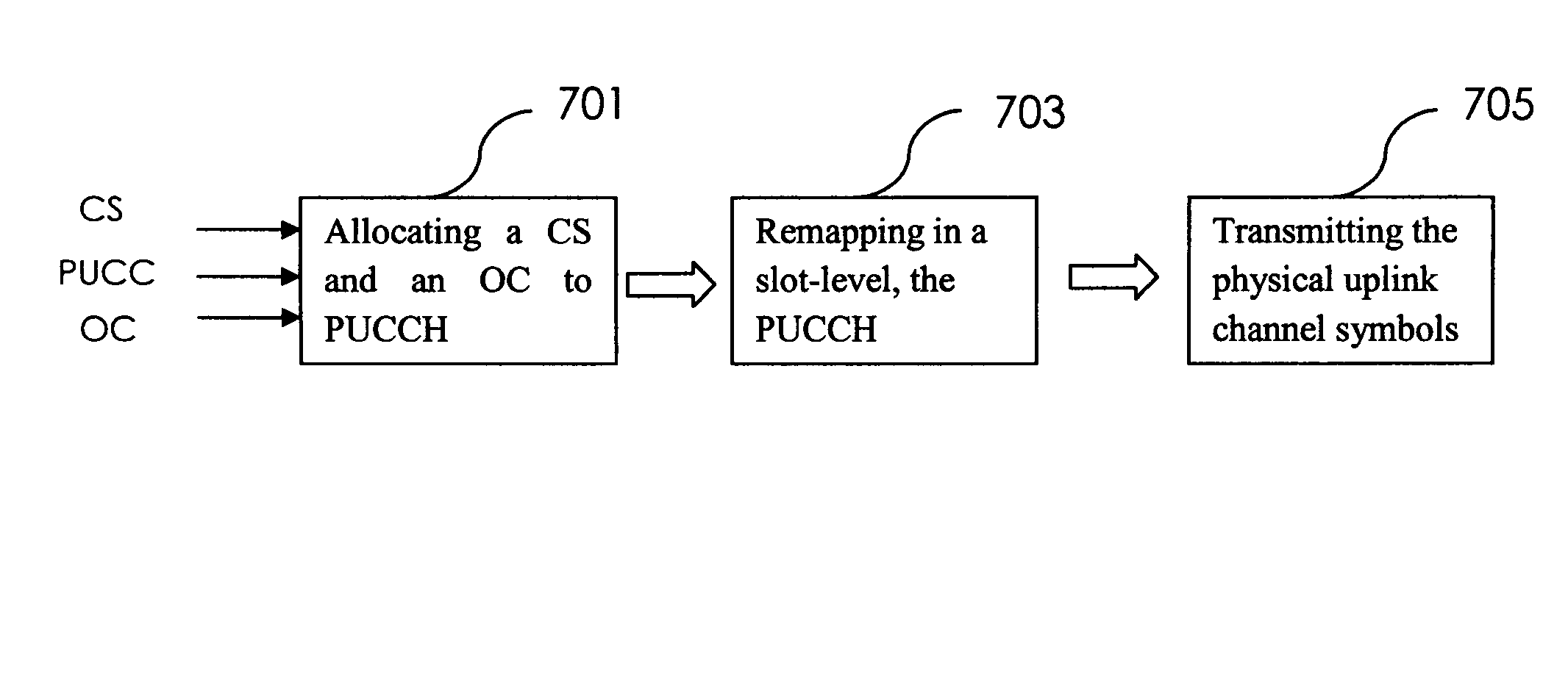

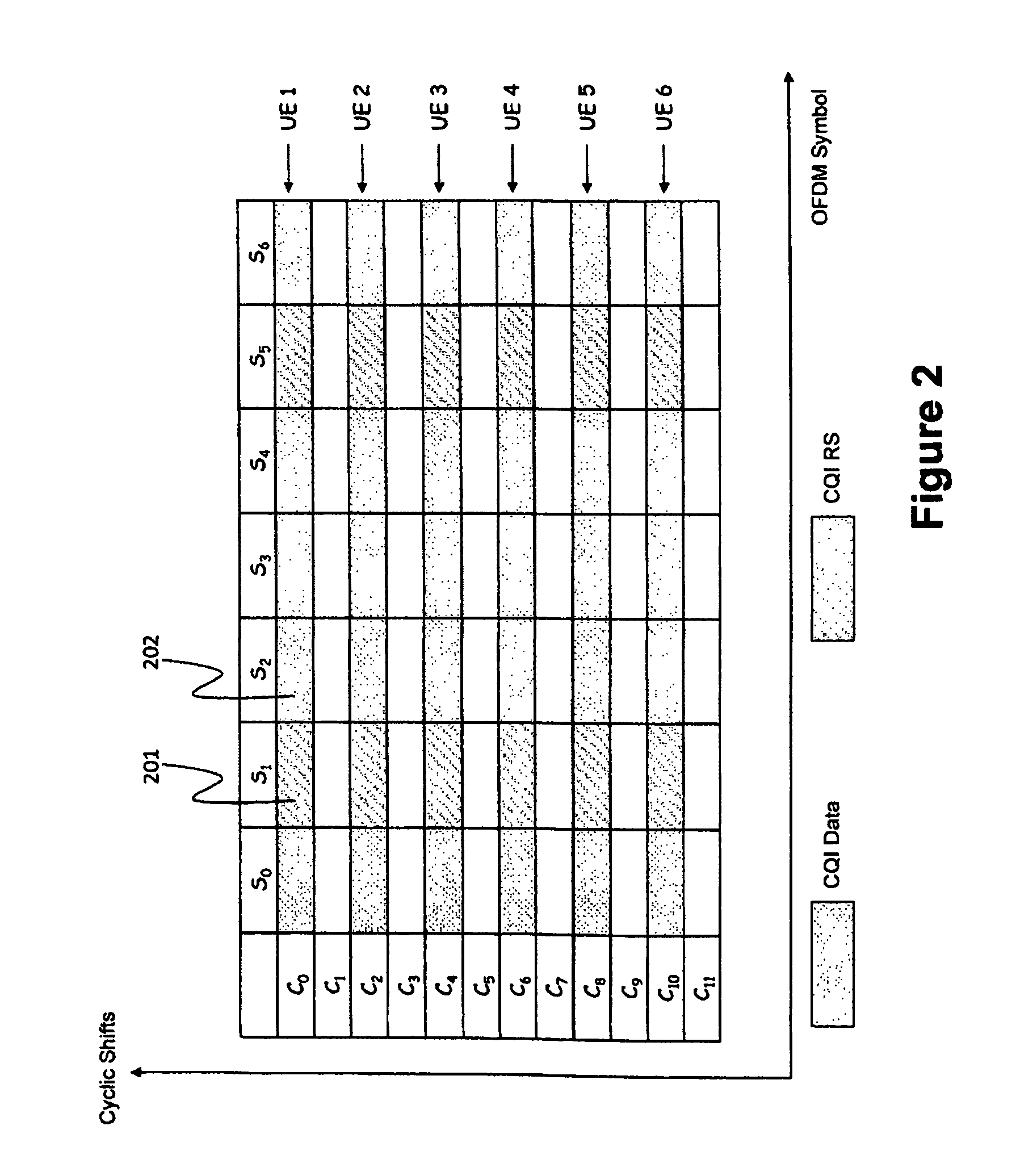

Methods of uplink channelization in LTE

ActiveUS8160018B2Error prevention/detection by using return channelModulated-carrier systemsTelecommunicationsResource block

Methods of a slot-level remapping physical uplink control channels into two resource blocks respectively located at two slots of a subframe, are generally adapted to a 3GPP LTE physical uplink where ACK / NAK resource blocks may be applied by the extended cyclic prefix, adapted to a complex 3GPP LTE physical uplink where mixed resource blocks (where the ACK / NAK and CQI channels coexist) may be applied by the normal cyclic prefix, and adapted to a complex 3GPP LTE physical uplink where mixed resource blocks (where the ACK / NAK and CQI channels coexist) may be applied by the extended cyclic prefix.

Owner:SAMSUNG ELECTRONICS CO LTD

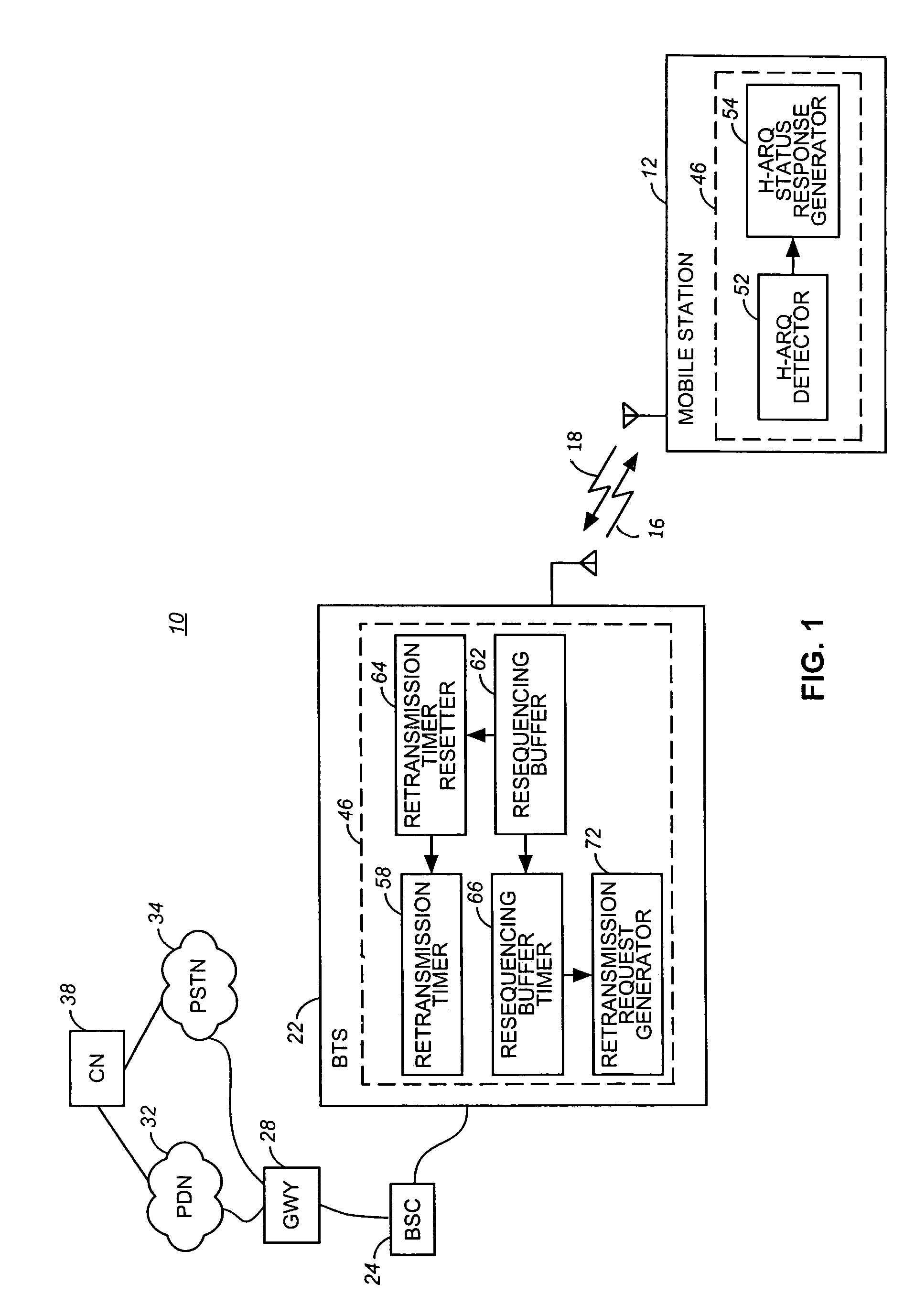

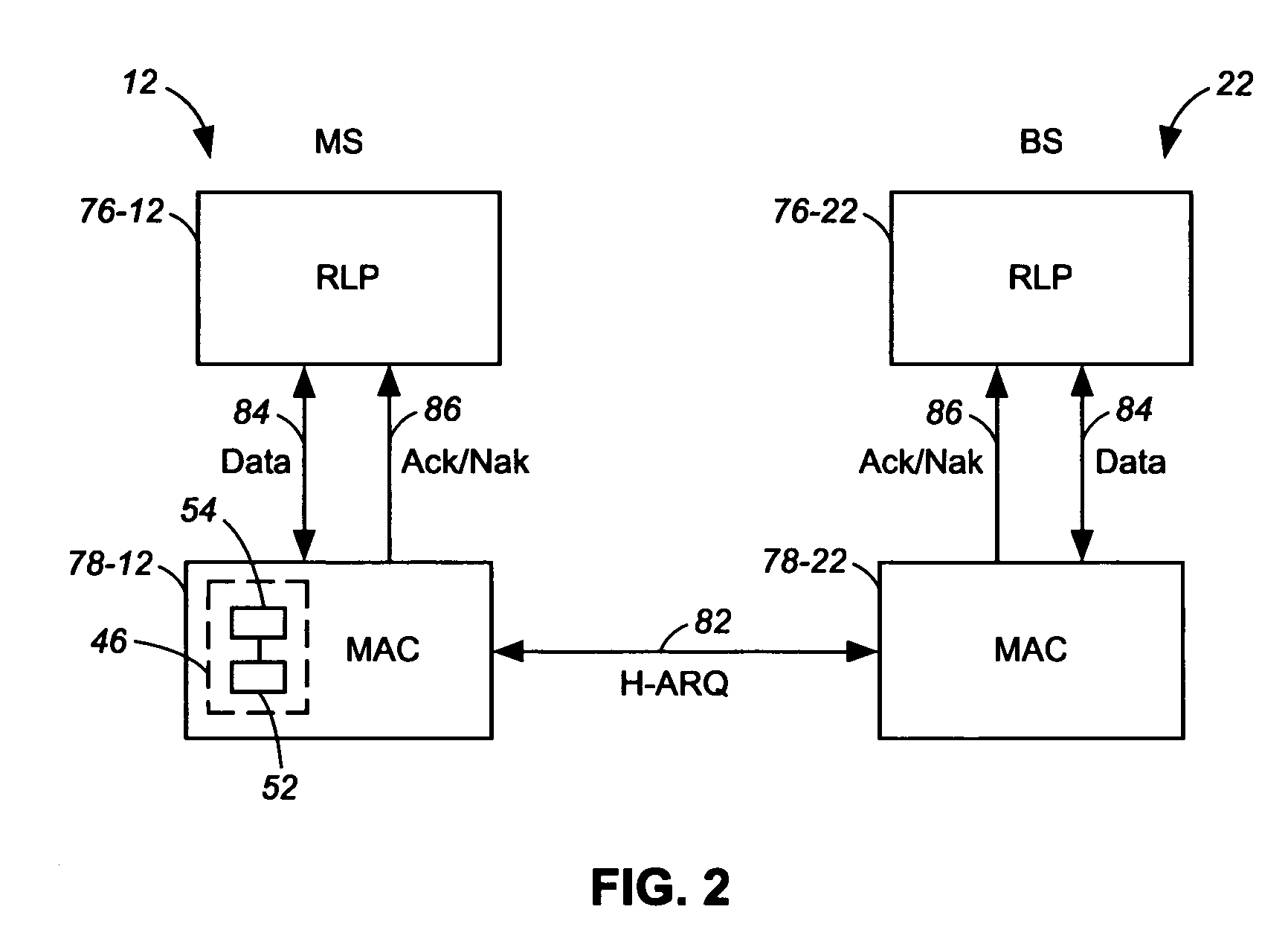

Apparatus, and associated method, for facilitating retransmission of data packets in a packet radio communication system that utilizes a feedback acknowledgement scheme

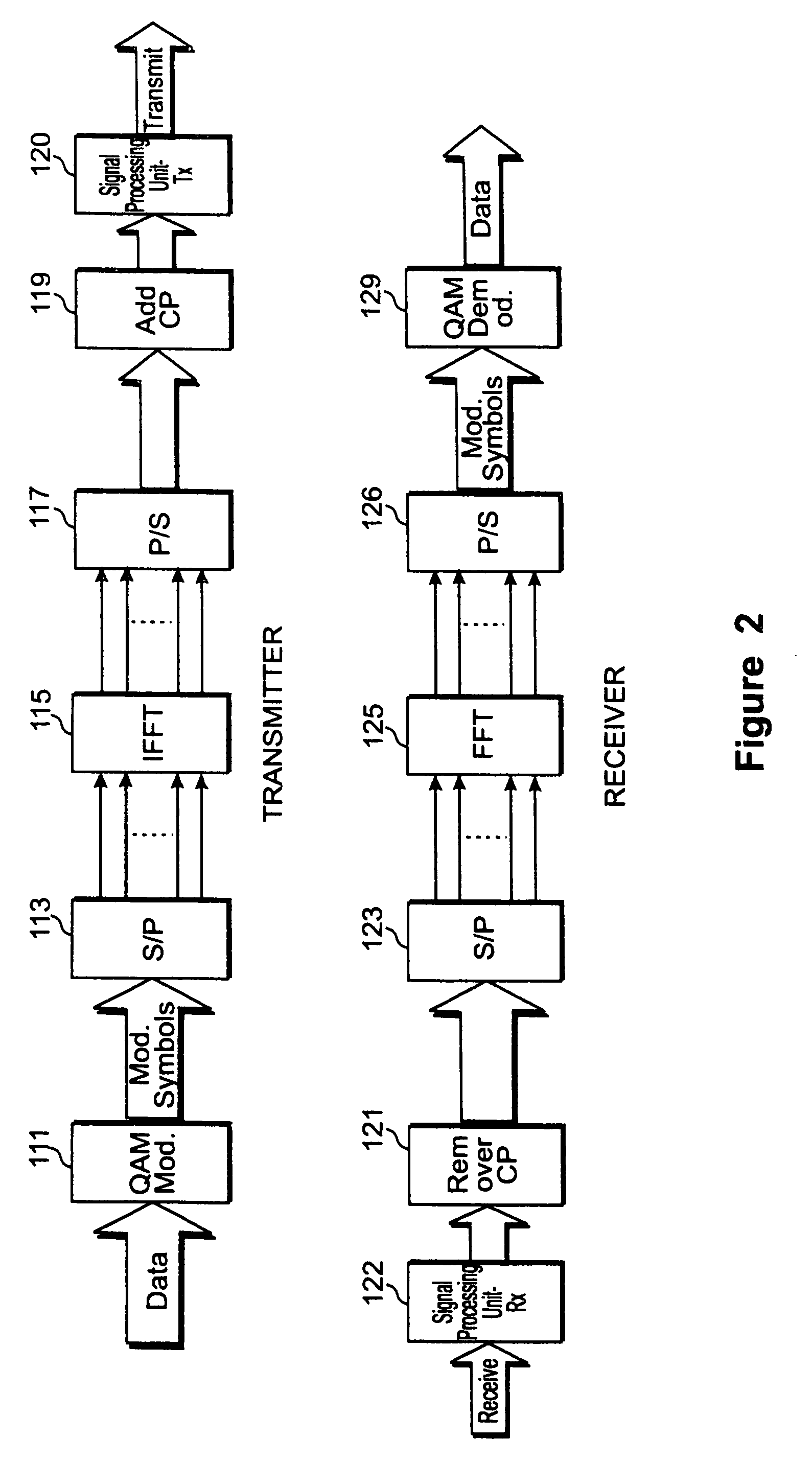

ActiveUS7050397B2Control generationImprove utilizationError prevention/detection by using return channelFrequency-division multiplex detailsCommunications systemSodium-potassium alloy

Apparatus, and an associated method, for a frame-formatted radio communication system. Coordination is provided between MAC and RLP layers of a sending station through use of apparatus embodied at the MAC layer of the sending station. Also, apparatus is provided at a receiving station to reduce the generation of RLP layer NAK during segmented RLP frame retransmissions.

Owner:NOKIA TECH OY

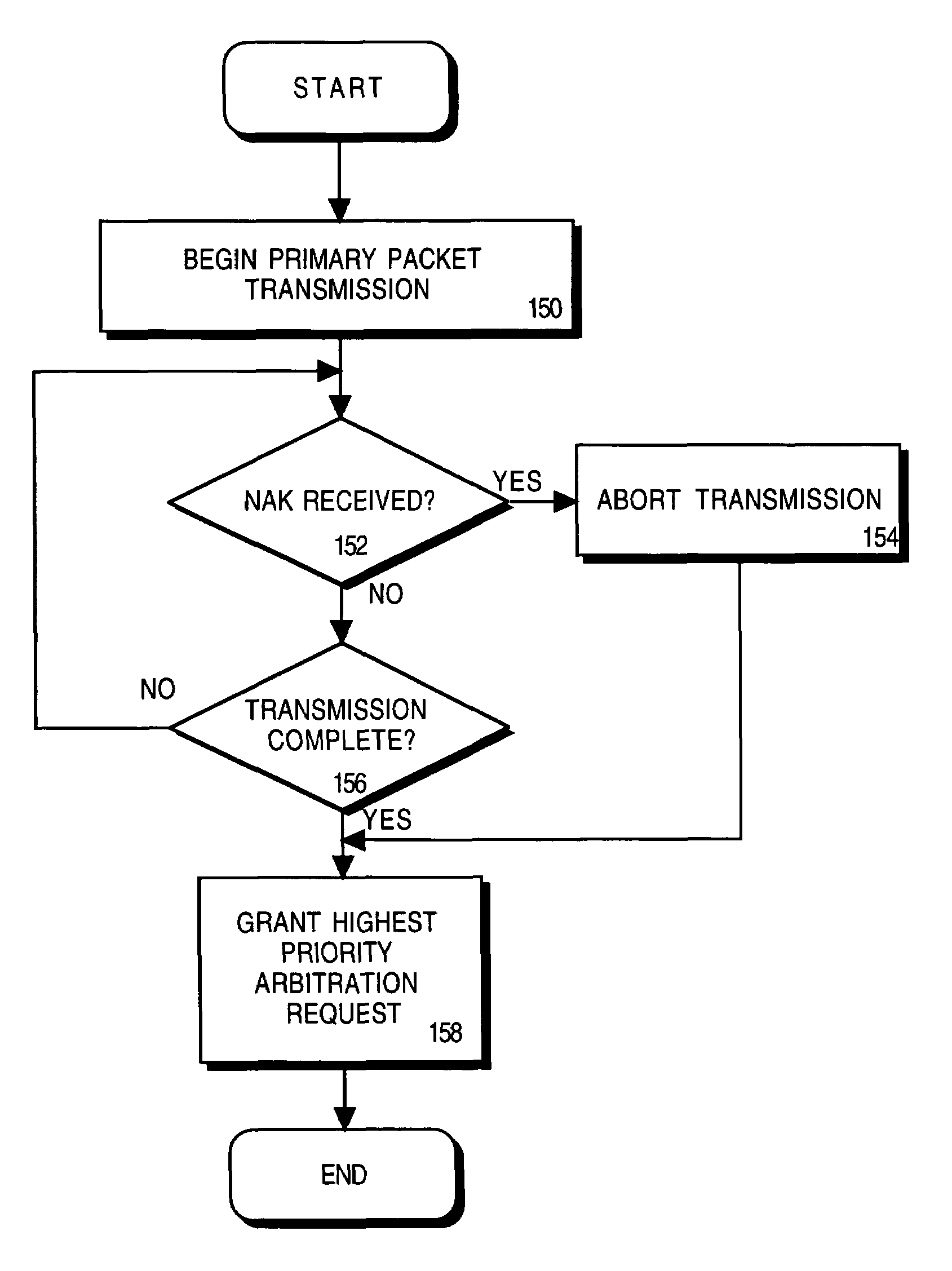

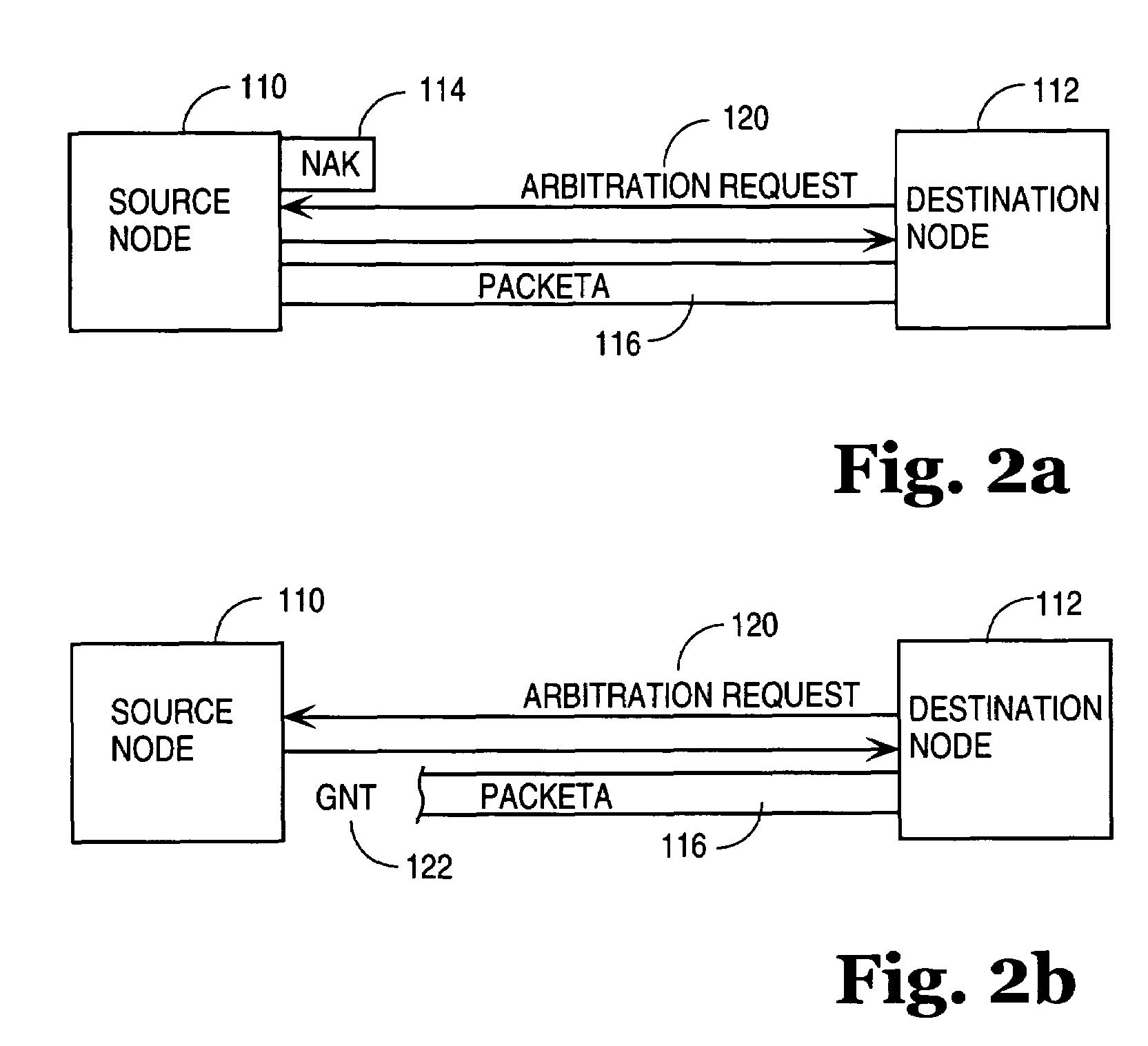

Early acknowledgement of primary packets

InactiveUS7076716B1Improve bus efficiencyError prevention/detection by using return channelTransmission systemsSodium-potassium alloyPacket transmission

A method and apparatus for reclaiming bus bandwidth on a full duplex bus. A source node sends a primary packet toward a destination node along a full duplex bus. If the destination node identifies an inability to accept the primary packet, it sends a NAK in the opposite direction along the full duplex bus towards the source node. Upon receiving the NAK, the source node aborts packet transmission of the primary packet which by virtue of the NAK has been identified as futile. Accordingly, the bandwidth, which would have otherwise have been used for the futile packet transmission, can be reclaimed and used for some other purpose.

Owner:INTEL CORP

Method and System for Providing Autonomous Retransmissions in a Wireless Communication System

InactiveUS20070230516A1Reduce delaysLow rateError prevention/detection by using return channelNetwork traffic/resource managementCommunications systemSodium-potassium alloy

A transmitter that may have marginal power availability is enabled to autonomously retransmit previously transmitted frames containing the same data. The transmitter sends an initial frame to a base transceiver station (BTS) and immediately retransmits the same frame without regard to any ACK / NAK transmission from the BTS. The retransmissions are accumulated in the receiver and decoded after a sufficient quantity of the frame is transmitted. After receiving the last retransmitted frame the BTS sends an ACK / NAK to the transmitter that is accepted.

Owner:TELEFON AB LM ERICSSON (PUBL)

Silica gel compositions containing alkali metals and alkali metal alloys

ActiveUS7211539B2Lithium organic compoundsPreparation by hydrogen halide split-offChemical reactionLiquid state

The invention relates to Group 1 metal / silica gel compositions comprising silica gel and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0, I, II, and III materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by silica gel (porous SiO2) under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the silica gel, a mild exothermic reaction produces Stage I material, loose black powders that are indefinitely stable in dry air. Subsequent heating to 400° C. produces Stage II materials, which are also loose black powders. Further heating above 400° C. forms Stage III material with release of some Group 1 metal. It is believed that Stage I, II and III materials represent reductions of the silica gel after absorption of the Group 1 metal. Preferred Group 1 metal / silica gel compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium-potassium alloys being most preferred. Each stage of the Group 1 metal / silica gel composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:SIGNA CHEM INC +1

Method for reducing contact resistance based on low-melting-point metal and oxide thereof

ActiveCN103066475AReduce contact resistanceImprove efficiencyLine/current collector detailsMetal/alloy conductorsIndiumRubidium

The invention relates to a method for reducing contact resistance based on low-melting-point metal and an oxide thereof. By coating the low-melting-point metal and the oxide thereof between electric terminals connected with machinery, the contact resistance between the mechanical electric terminals is reduced effectively. The invention further relates to a conductive paste composing of the low-melting-point metal and the oxide thereof. The oxide takes 0.05% to 50% of the total weight of the conductive paste. The low-melting-point metal is one type or a combination of any two types selected from sodium, potassium, lithium, rubidium, cesium, gallium, indium, mercury, lead bismuth alloy, gallium-base binary alloy, gallium-base complex alloy, indium-base alloy, bismuth-base alloy, mercury-base alloy and sodium-potassium alloy which are lower than 200 DEG C in melting point. With the compound of the low-melting-point metal and the oxide thereof as the conducting medium, the method for reducing contact resistance can effectively reduce the contact resistance between the electric terminals connected with the machinery, significantly reduce the contact resistance heat effect, improve transmission efficiency of electric energy and prolong the service life of the machinery. The method for reducing contact resistance based on the low-melting-point metal and the oxide thereof can be widely applied to the technical fields of electric power and energy.

Owner:郭瑞

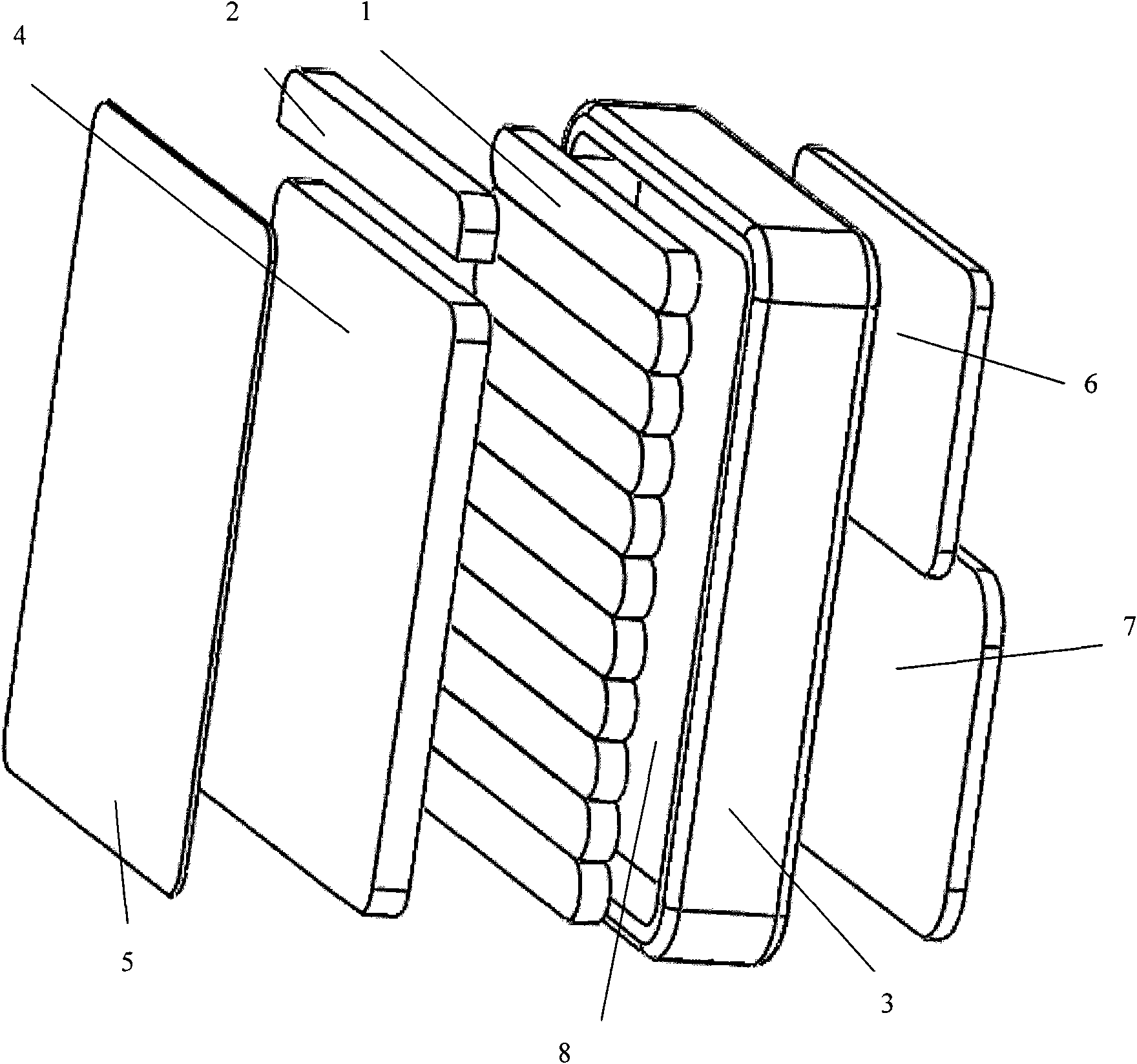

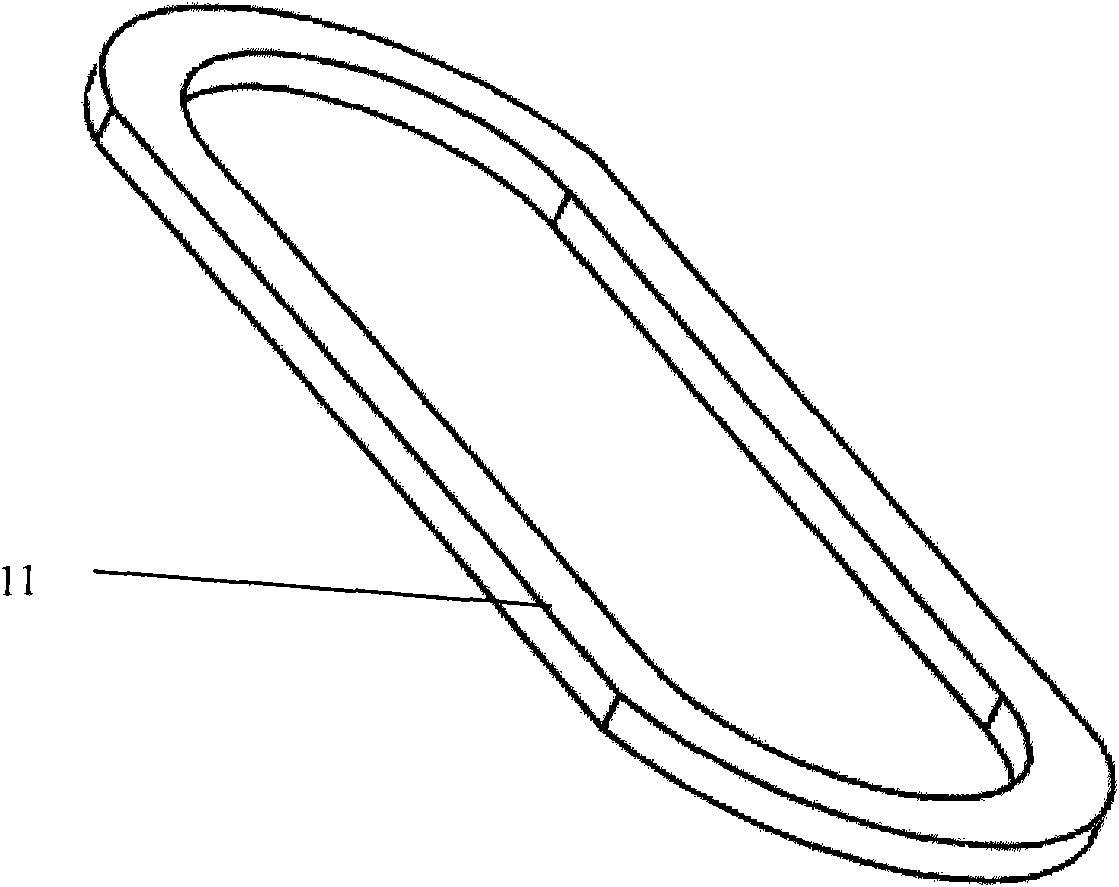

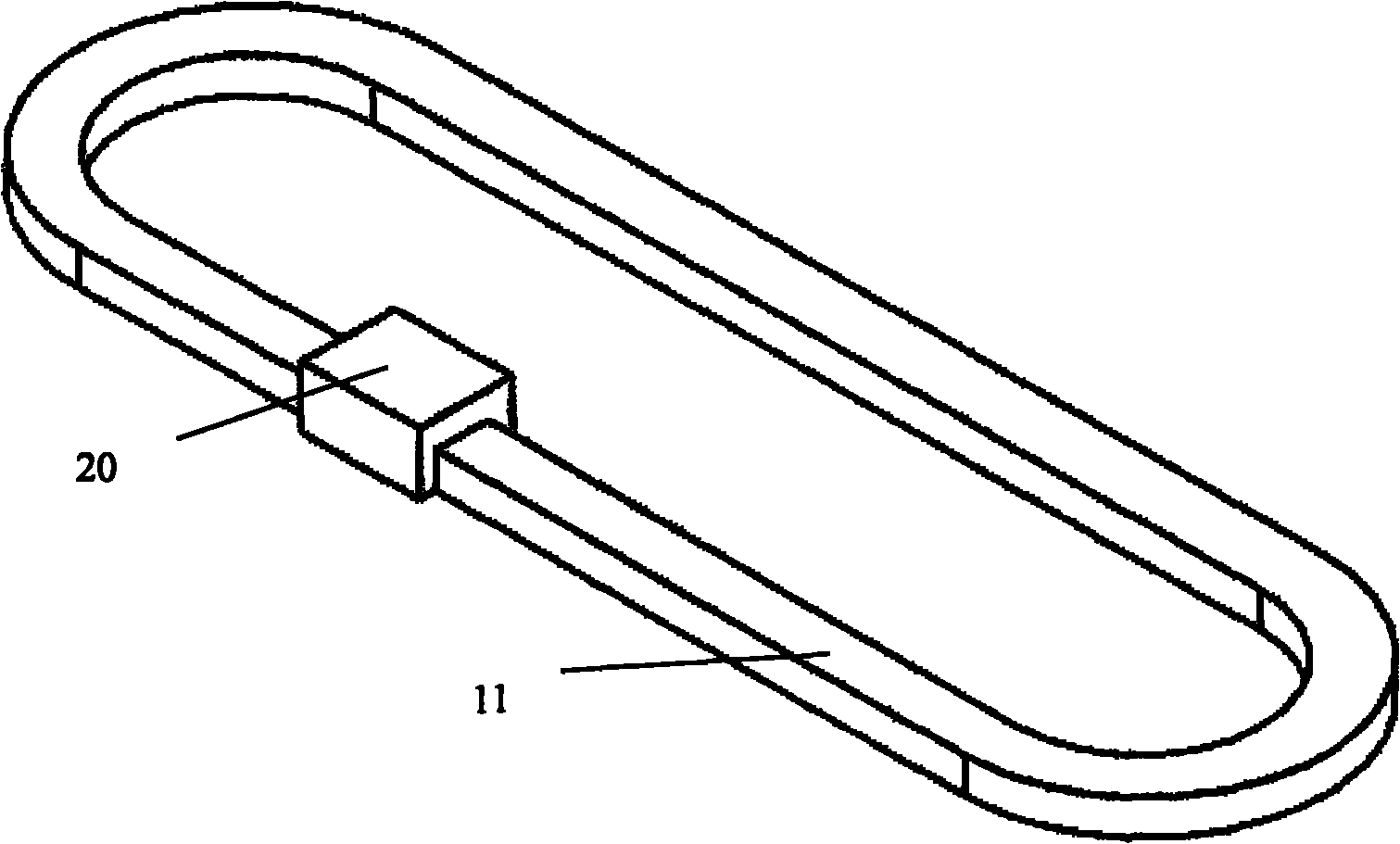

Mobile phone with liquid metal radiating module group

ActiveCN102377847AComputing faster thanSpeed up the flowTelephone set constructionsIndiumWork performance

The invention relates to a mobile phone with a liquid metal radiating module group. The mobile phone comprises a mobile phone chip set, a mobile phone battery and a mobile phone cover which are positioned in a base on the back of the mobile phone and arranged in turn, and a mobile phone display screen and a mobile phone keyboard which are positioned in a base on the front of the mobile phone. The mobile phone is characterized by also comprising the liquid metal radiating module group positioned between the mobile phone chip set and the mobile phone battery which are positioned in the base on the back of the mobile phone, wherein the liquid metal radiating module group consists of at least one liquid metal radiating module; the liquid metal radiating module comprises a hollow sealed annular channel and liquid metal filled in the hollow sealed annular channel; and the liquid metal is gallium, sodium, potassium, mercury, indium-gallium alloy, sodium-potassium alloy or gallium- indium-tin alloy which are in a liquid state at normal temperature. The mobile phone can solve the problem of radiation of the mobile phone chip set by means of the flowing of the liquid metal, and the working performance of the mobile phone is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Hybrid ARQ technique for data transmission

InactiveUS20060062167A1Reduce overheadError prevention/detection by using return channelError detection/prevention using signal quality detectorCurrent channelCommunications system

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

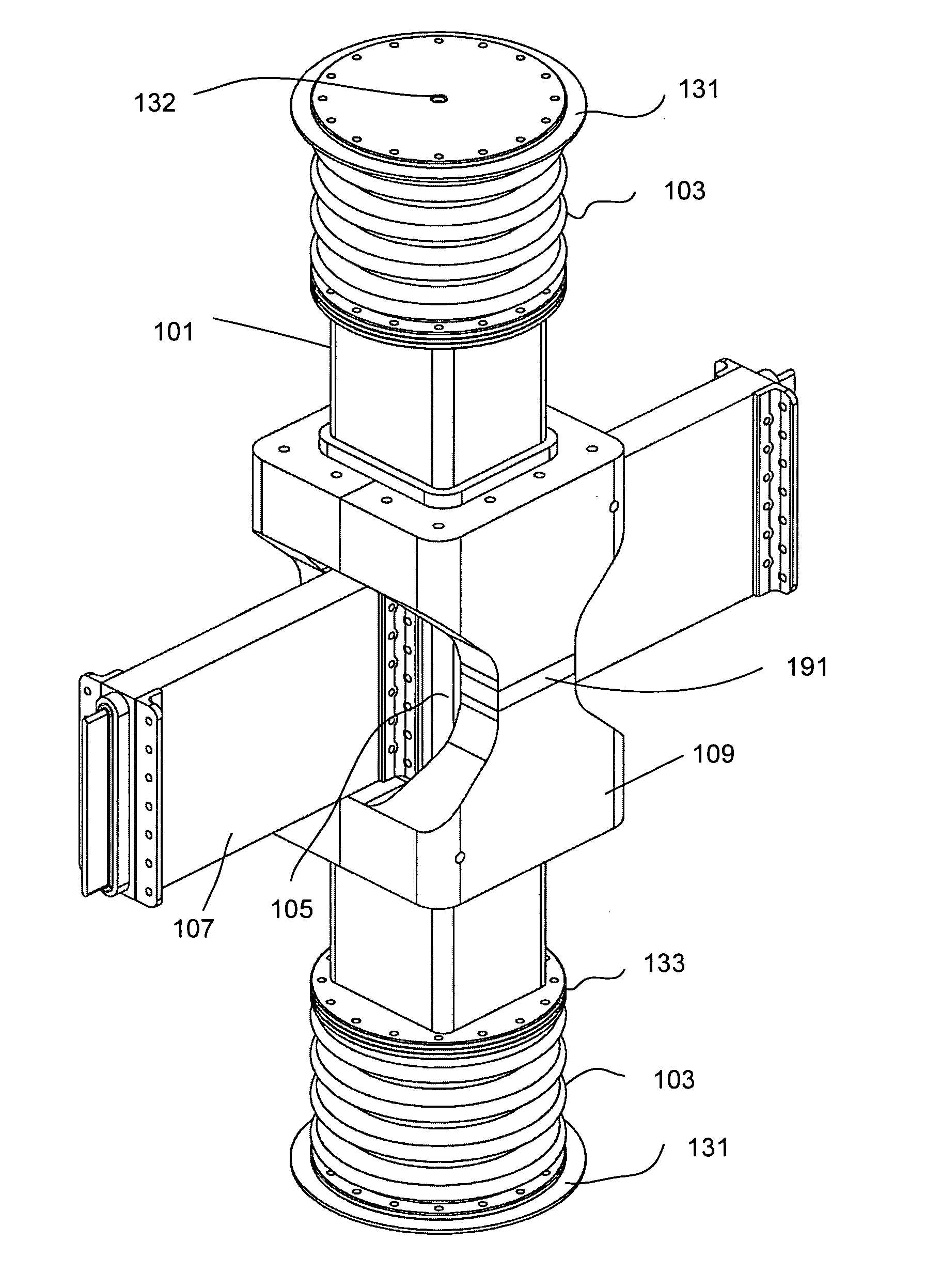

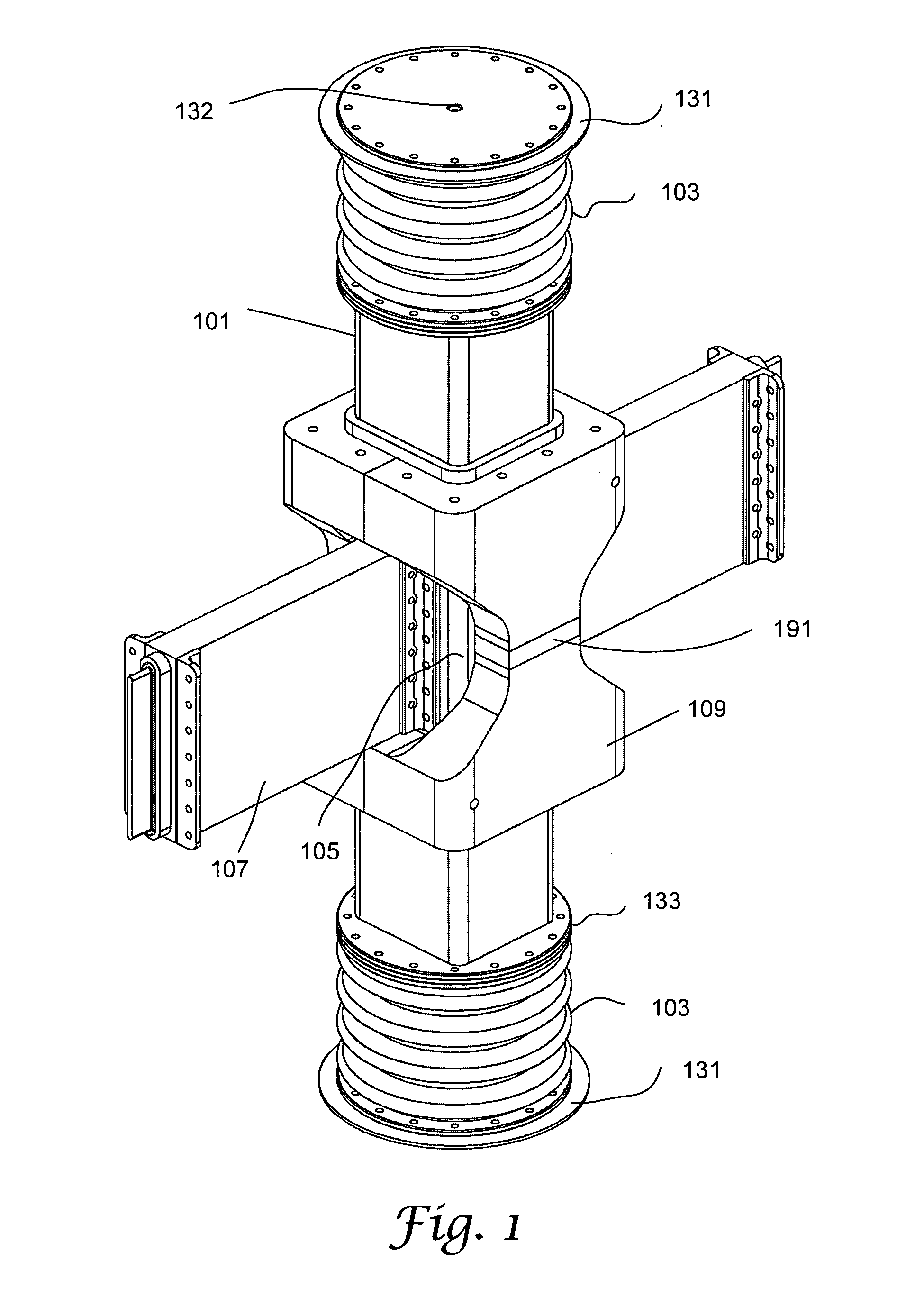

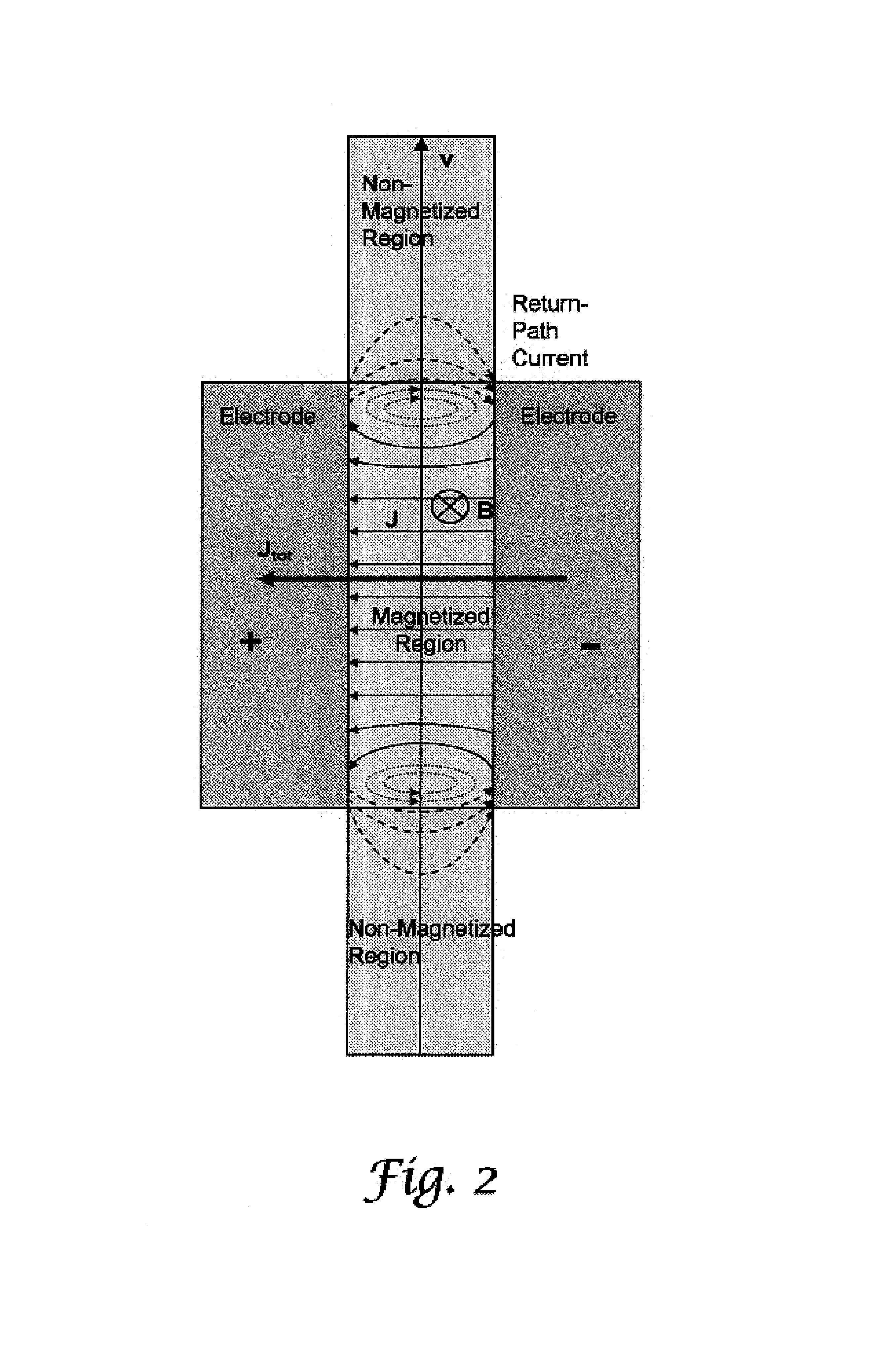

Modular liquid-metal magnetohydrodynamic (LMMHD) power generation cell

InactiveUS7166927B2Facilitate efficient, practical, and economical conversion of appliedEnergy production using magneto-hydrodynamic generatorsMachines/enginesElectrical batteryLiquid metal

A LMMHD power generation cell, having a fluid channel in which a conductive fluid is forced to flow in response to an external force. A pair of pressure conveying members such as bellow reservoirs can be used for conveying the external force to the conductive flow. A magnetic field is established across the fluid channel by a pair of magnets. A pair of electrodes is disposed with respect to the fluid channel to collect the electric current induced by the conductive fluid flowing through the magnetic field. The magnets are selected from either permanent magnets or electromagnets. Preferably, the conductive fluid is selected from low-density, low-viscosity, high-conductivity liquid metal such as NaK-78.

Owner:SCI APPL & RES ASSOCS

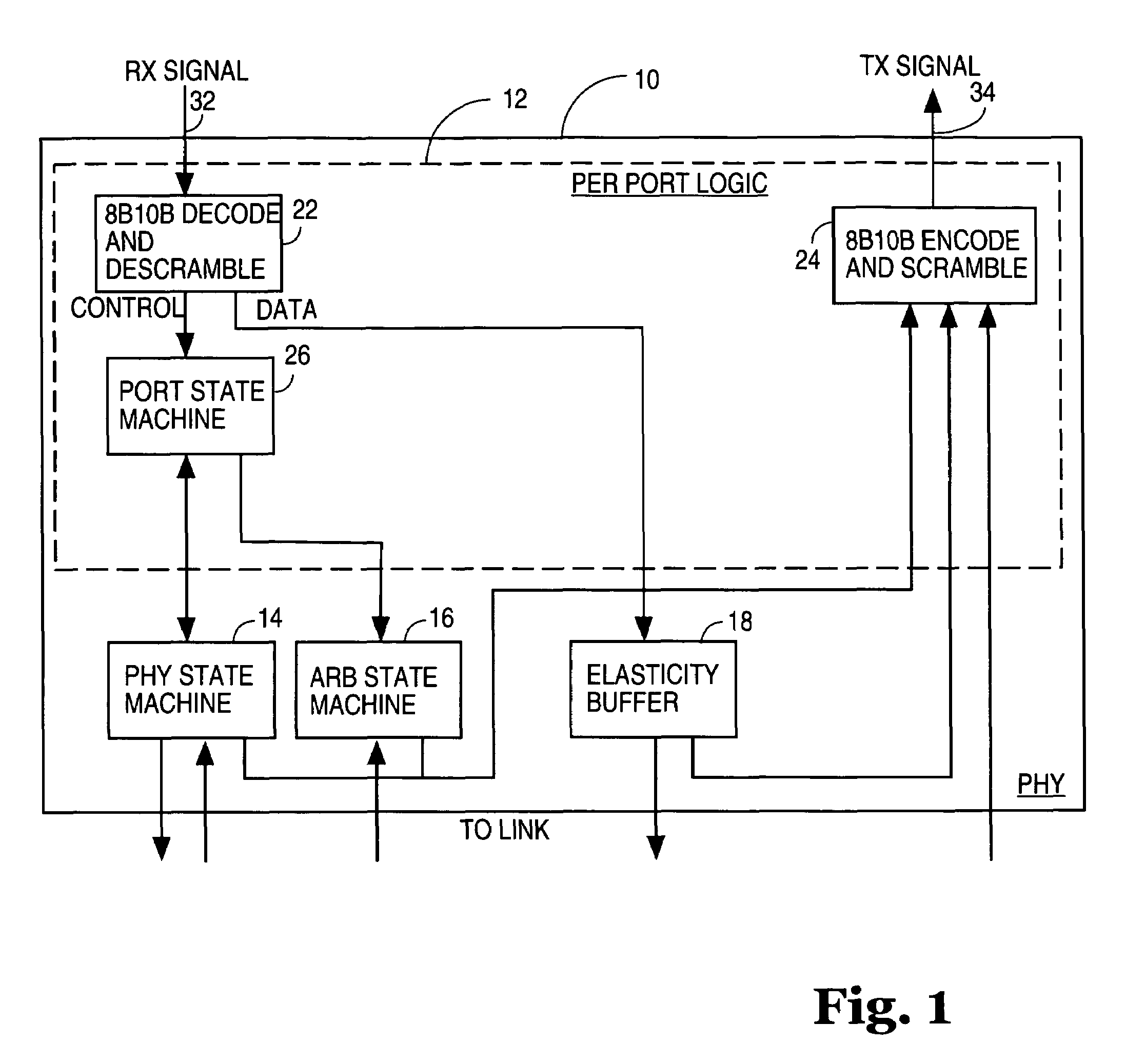

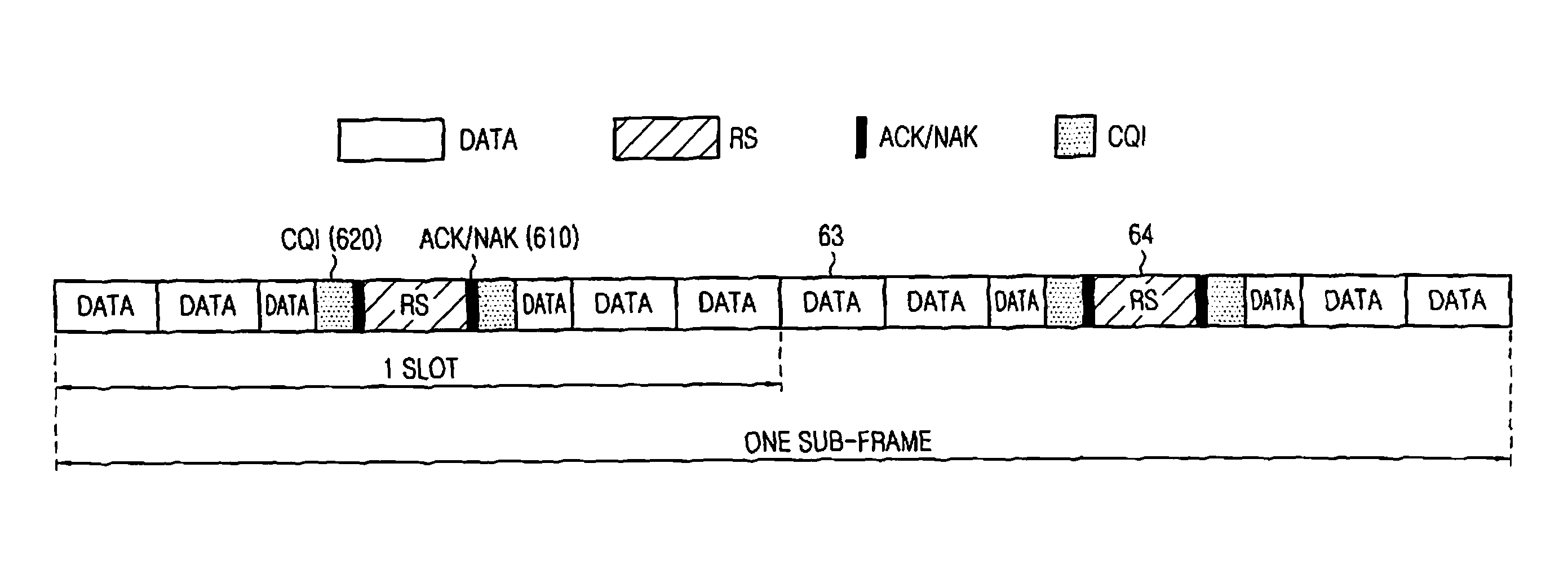

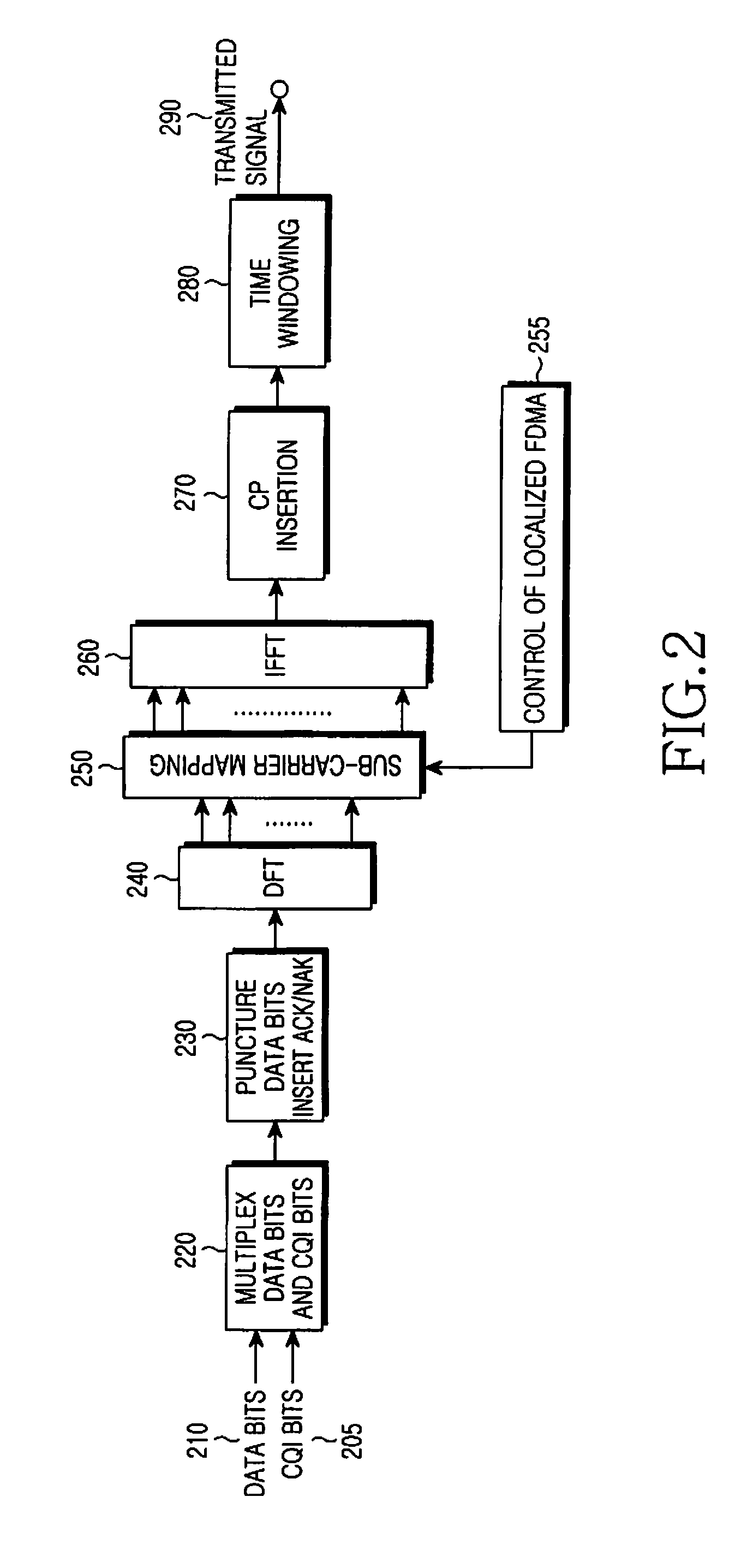

Control and data signaling in SC-FDMA communication systems

ActiveUS8331328B2Improve reliabilityRaise priorityTransmission path divisionSignal allocationMultiplexingCommunications system

Apparatus and method for multiplexing control information bits and data information bits into sub-frame symbols depending on the location of symbols carrying a reference signal (RS), to provide an estimate for the channel medium and enable coherent demodulation for signals carrying information bits. The control information bits include ACK or NAK and / or channel CQI bits. The ACK / NAK bits are placed with priority in symbols around the symbols carrying the RS, to allow for improved accuracy of the channel estimate, followed by the CQI bits when both ACK / NAK and CQI bits exist. Moreover, the sub-frame resources required to achieve the desired reception reliability for the control information depend on the operating conditions and can varied to minimize the associated control overhead.

Owner:SAMSUNG ELECTRONICS CO LTD

Silicide compositions containing alkali metals and methods of making the same

The invention relates to Group 1 metal / silica gel compositions comprising silica gel and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0, I, II, and III materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by silica gel (porous Si02) under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the silica gel, a mild exothermic reaction produces Stage I material, loose black powders that are indefinitely stable in dry air. Subsequent heating to 400 DEG C produces Stage II materials, which are also loose black powders. Further heating above 400 DEG C forms Stage III material with release of some Group 1 metal. It is believed that Stage I, II and III materials represent reductions of the silica gel after absorption of the Group 1 metal. Preferred Group 1 metal / silica gel compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium- potassium alloys being most preferred. Each stage of the Group 1 metal / silica gel composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:SIGNA CHEM INC +1

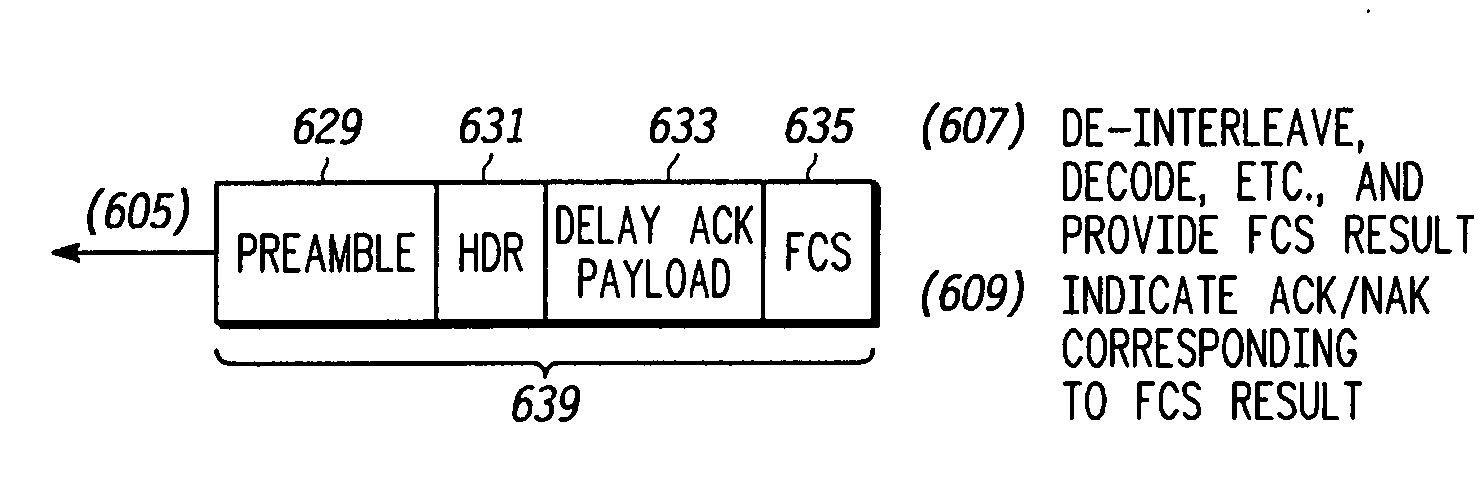

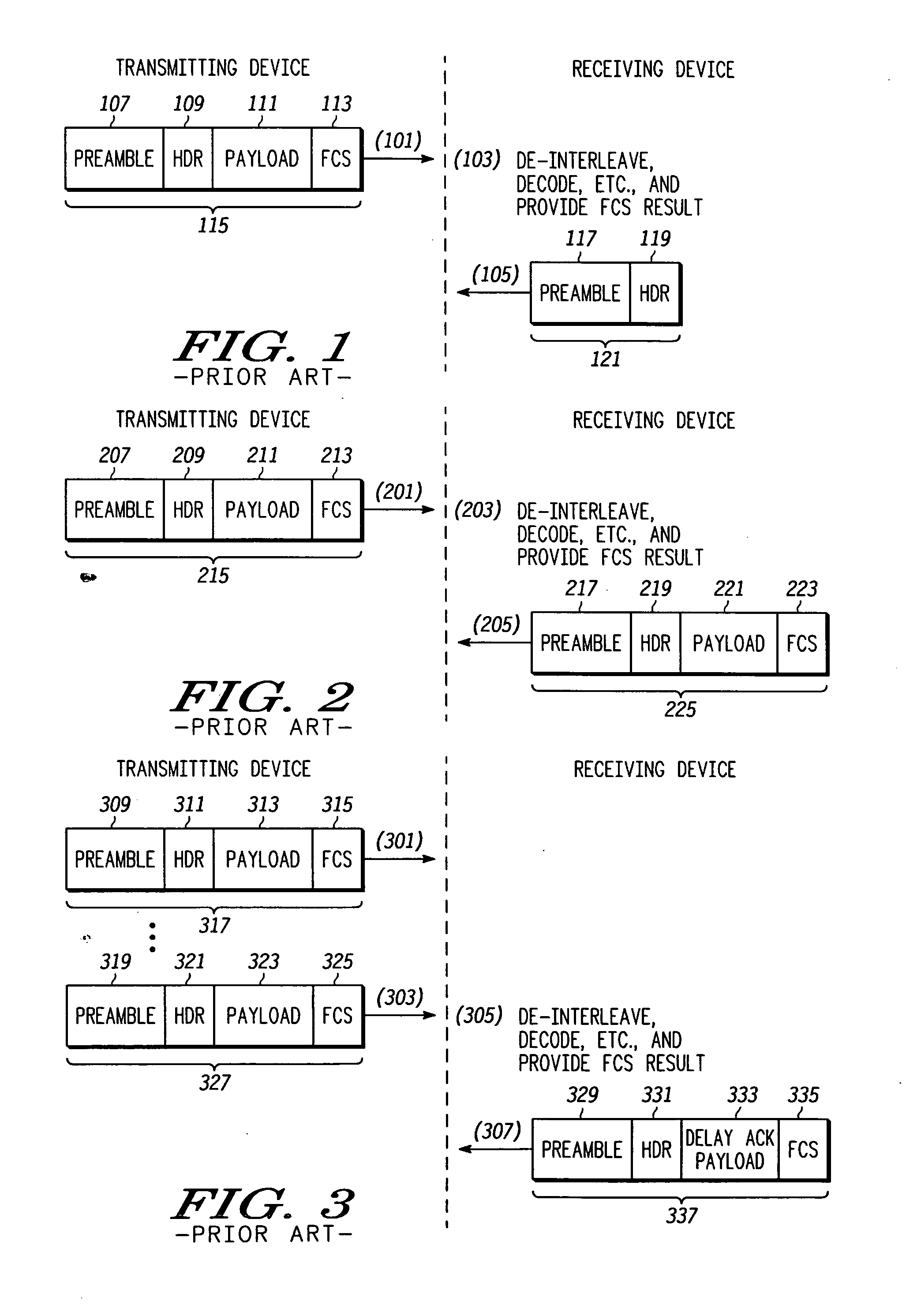

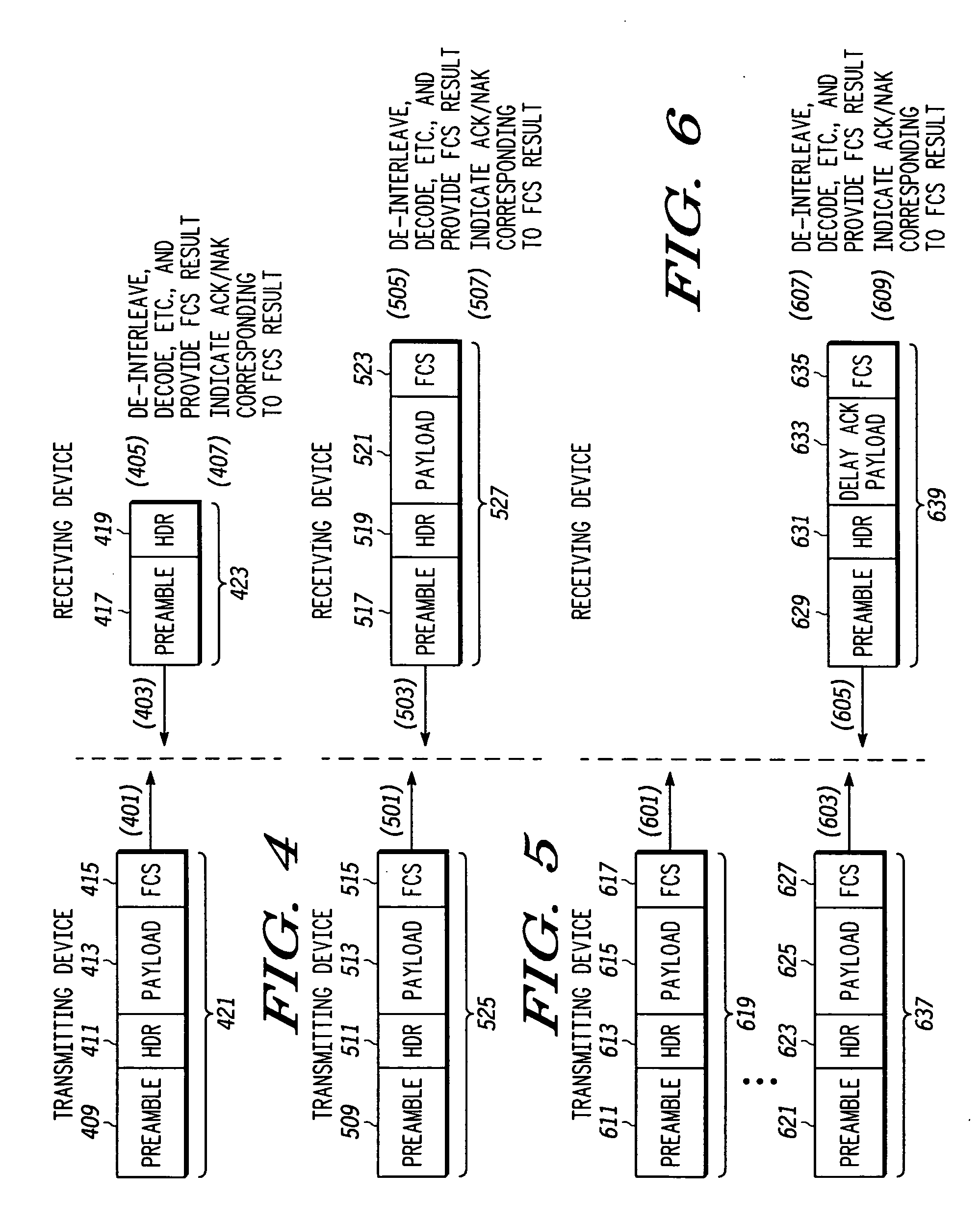

Method and system for acknowledging frames in a communication network

InactiveUS20070079208A1Error prevention/detection by using return channelFrequency-division multiplex detailsTransceiverSodium-potassium alloy

A communication device (1001) is provided. The communication device (1001) can include a transceiver (1003), for transmitting and receiving communications when operably connected to a communication network. Also, the communication device (1001) can include a processor (1009) cooperatively operable with the transceiver (1003). The processor (1009) can facilitate receiving (1015) one or more frames from a transmitting device. Also, the processor (1009) can obtain a frame check sequence result (1019). Before obtaining the frame check sequence result, the processor can initiate (1017) a transmission of a responsive frame corresponding to the one or more frames. The responsive frame will explicitly indicate an acknowledgement (ACK) or negative acknowledgement (NAK) of the one or more frames.

Owner:NORTH STAR INNOVATIONS

Methods of assigning resources for the uplink control channel in LTE

A method of a slot-level remapping physical uplink control channels into two resource blocks respectively located at two slots of a subframe, is generally adapted to a complex 3GPP LTE physical uplink where ACK / NAK recourse blocks may be applied by the extended cyclic prefix, mixed resource blocks (where the ACK / NAK and CQI channels coexist) may be applied by the normal cyclic prefix, or mixed recourse blocks (where the ACK / NAK and CQI channels coexist) may be applied by the extended cyclic prefix.

Owner:SAMSUNG ELECTRONICS CO LTD

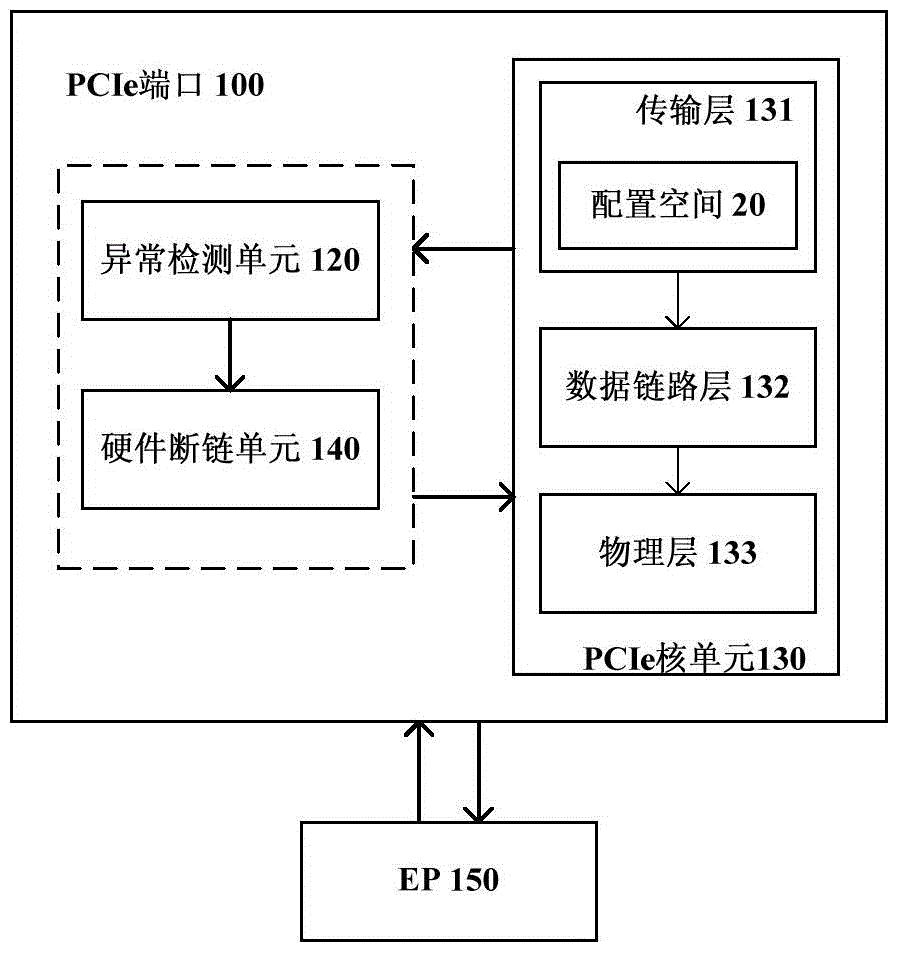

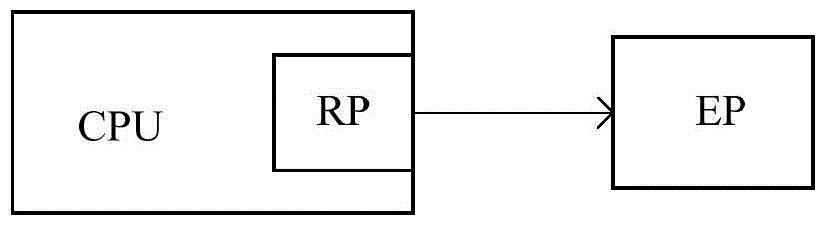

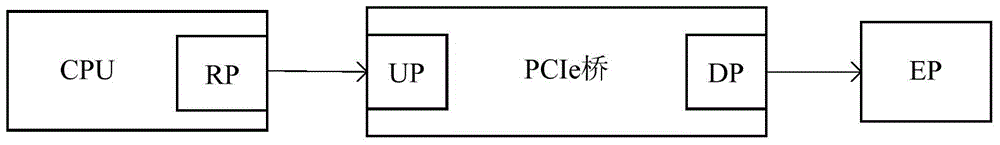

PCIe (Peripheral Component Interconnect Express) equipment and detection method thereof

InactiveCN105700967AGuaranteed to workImprove reliabilityNon-redundant fault processingEmbedded systemSodium-potassium alloy

The invention relates to PCIe (Peripheral Component Interconnect Express) equipment and a detection method thereof. The PCIe equipment comprises a PCIe port, wherein the PCIe port can be in a DP (Downstream Port) of a PICe bridge and also can be in a RP (Root Point) of a CPU (Central Processing Unit). One example comprises the following steps: a PCIe kernel unit receives a transmission layer message issued from the CPU or an UP (Upstream Port) and issues the message to an EP (End Point); an exception detection unit detects a process that the port issues the message to the EP, identifies whether the process has message retransmission exception, such as ACK / NAK (Acknowledge / Negative Acknowledge) message exception or fluid control credit value update exception or not, and the exception detection unit outputs a hardware chain scission enable signal when no credit value exception is in the presence; and a hardware chain scission unit disconnects the link of the PCIe port and the EP according to the signal. The embodiment of the invention detects and processes ACK / NAK message or fluid control credit value update which can not be perceived but can cause the exception including CPU crash so as to guarantee that the CPU can normally work, and the reliability of the PCIe system and the compatibility of the system on a drive program can be improved.

Owner:HUAWEI TECH CO LTD

Hybrid ARQ technique for data transmission

InactiveUS7583614B2Reduce overheadError prevention/detection by using return channelError detection/prevention using signal quality detectorCommunications systemCurrent channel

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

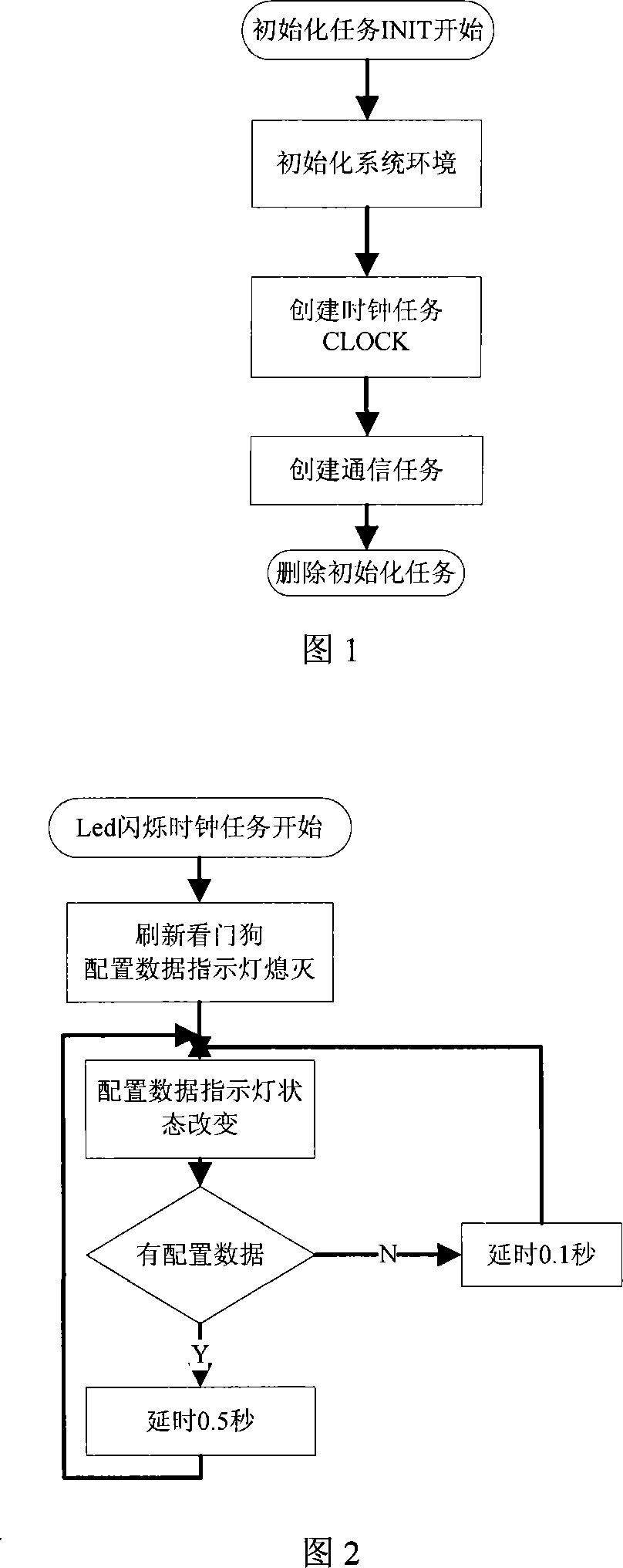

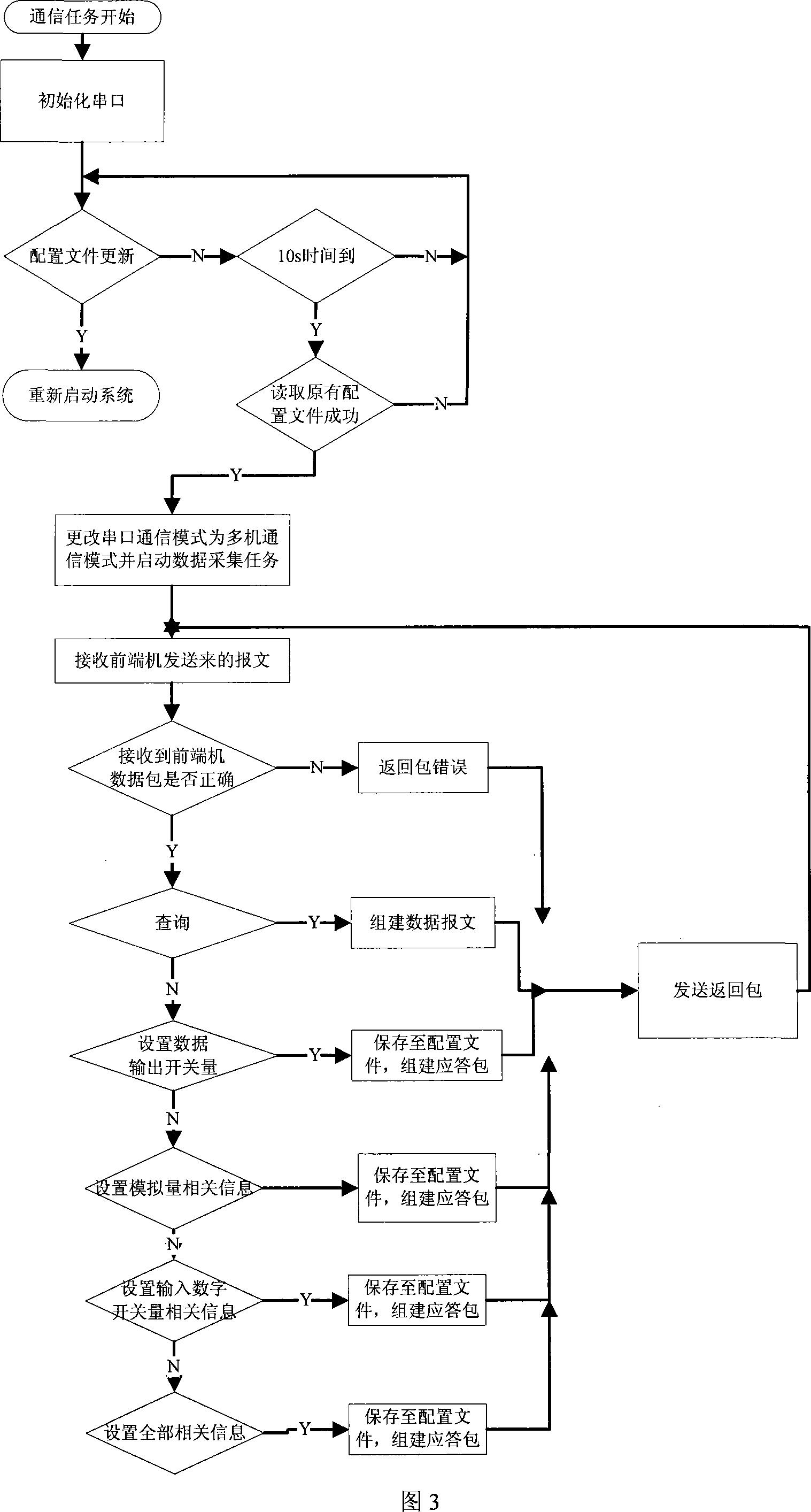

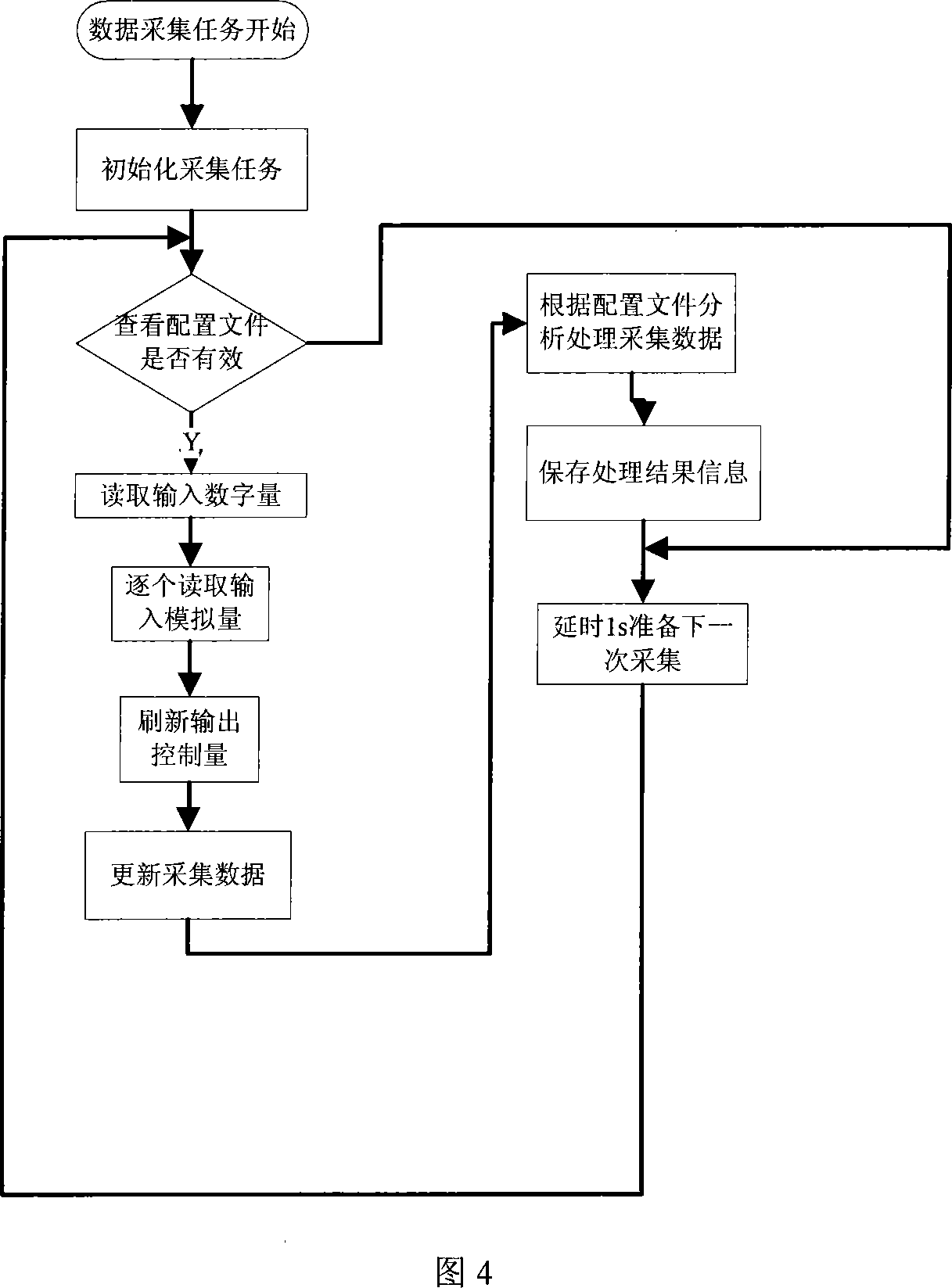

Universal monitoring system collection end control system

InactiveCN101241360AImprove scalabilityLow costComputer controlSimulator controlExtensibilityMulti machine

A gathering end control system for a general supervisory control system is disclosed. The gathering end is a build-in micro-processor which can generate complex time sequence needed by a performer or numerous controlling operation. If the gathering end internal FLASH has no configuration information, the gathering end waits for configuration commands from RS232; the gathering end answers with an ACK signal after obtaining the accurate configuration; the gathering end answers with a NAK signal after receiving an error configuration; if the gathering end internal FLASH has configuration information, the gathering end waits for a reconfiguration command in preset time after each startup; the gathering end woks according to the internal configuration information after the preset time; data is transferred by RS485 half-duplex with a multi-machine communication mode; normal data query is performed, output digit on-off value, alarm parameter fluctuating value, entry switch state quantity and all parameter configuration of the gathering end are set. The invention is provided with good extendibility and reduced cost, and waste is avoided when packing ability is increased.

Owner:ZHEJIANG UNIV OF TECH

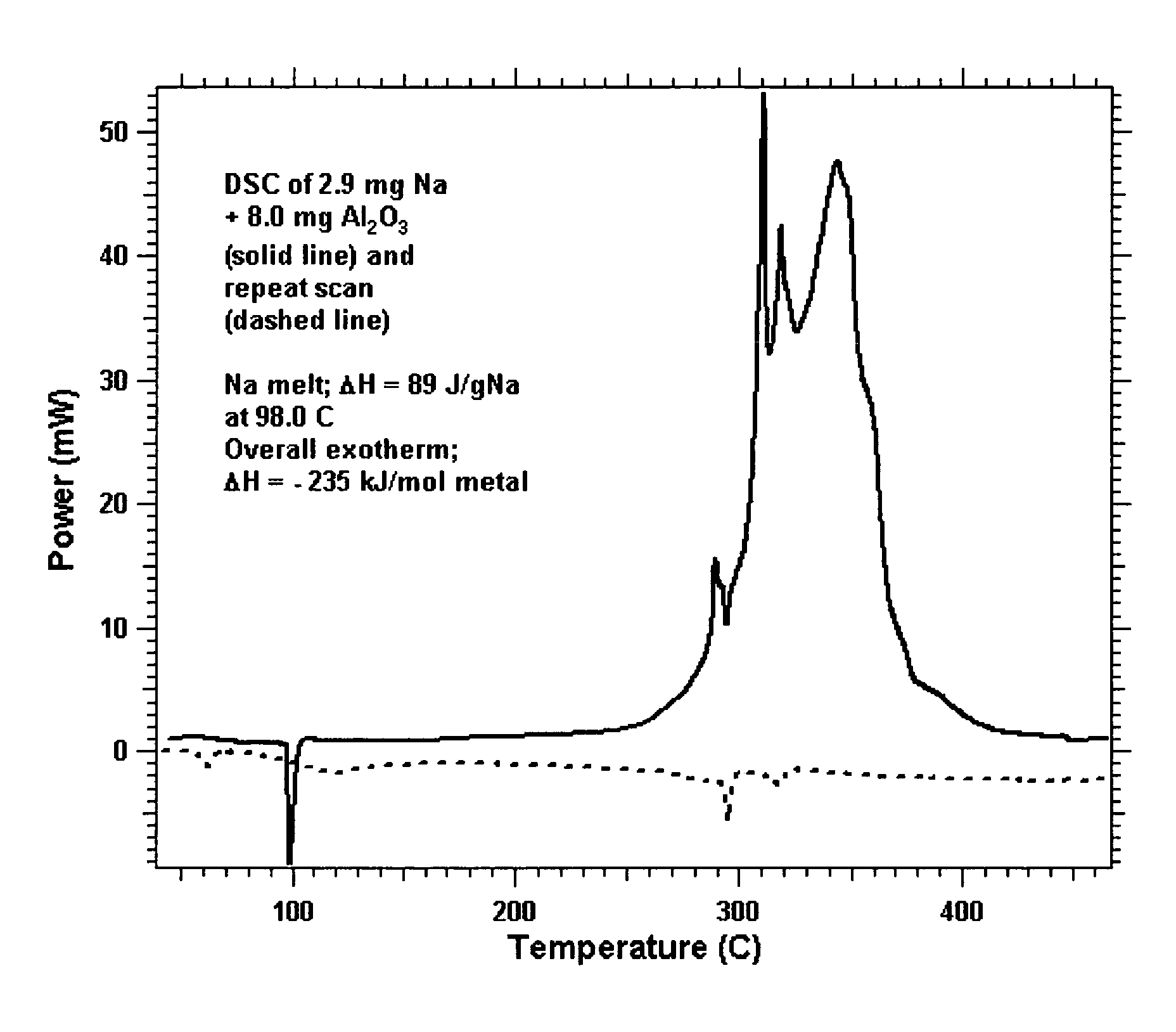

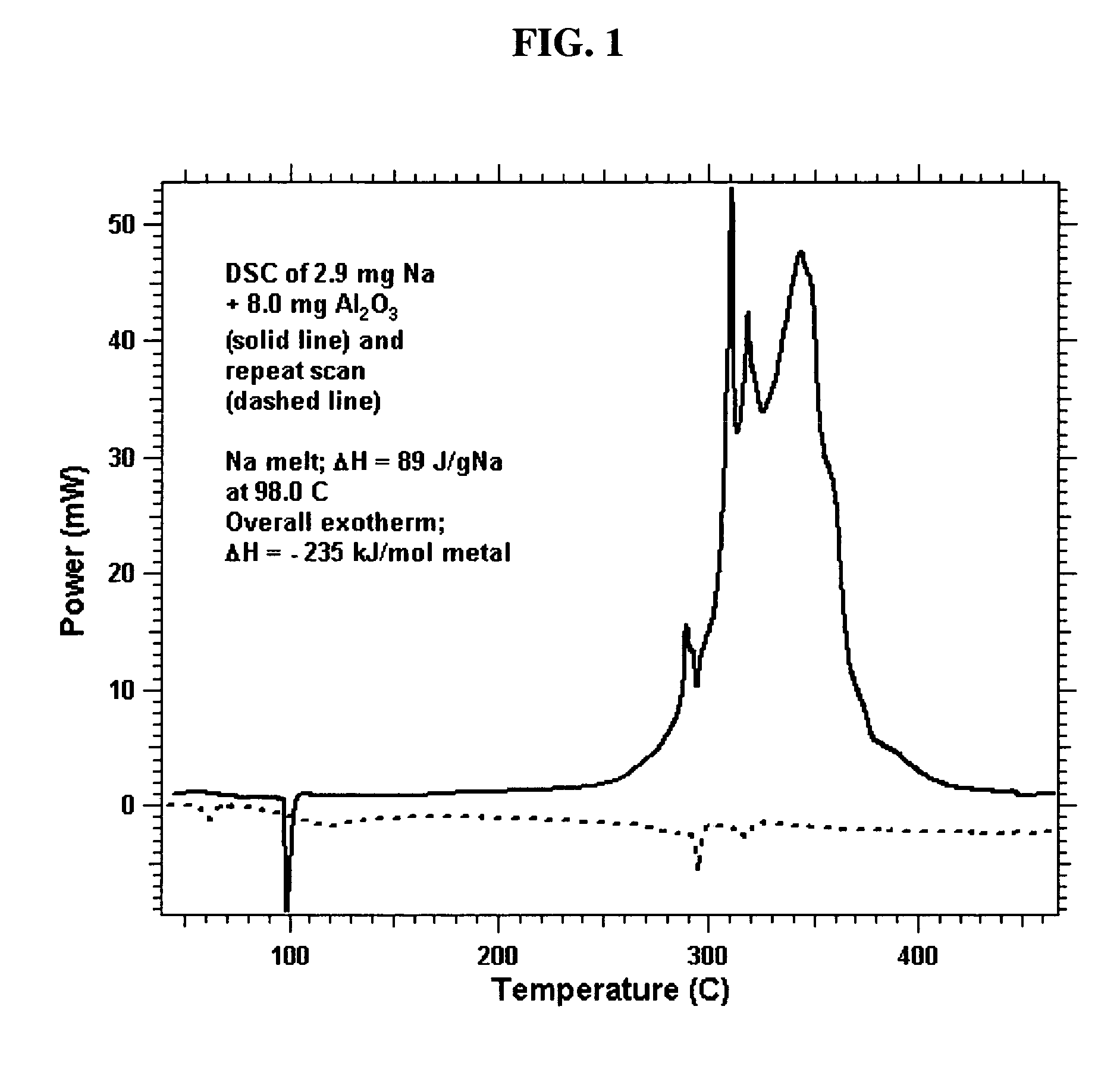

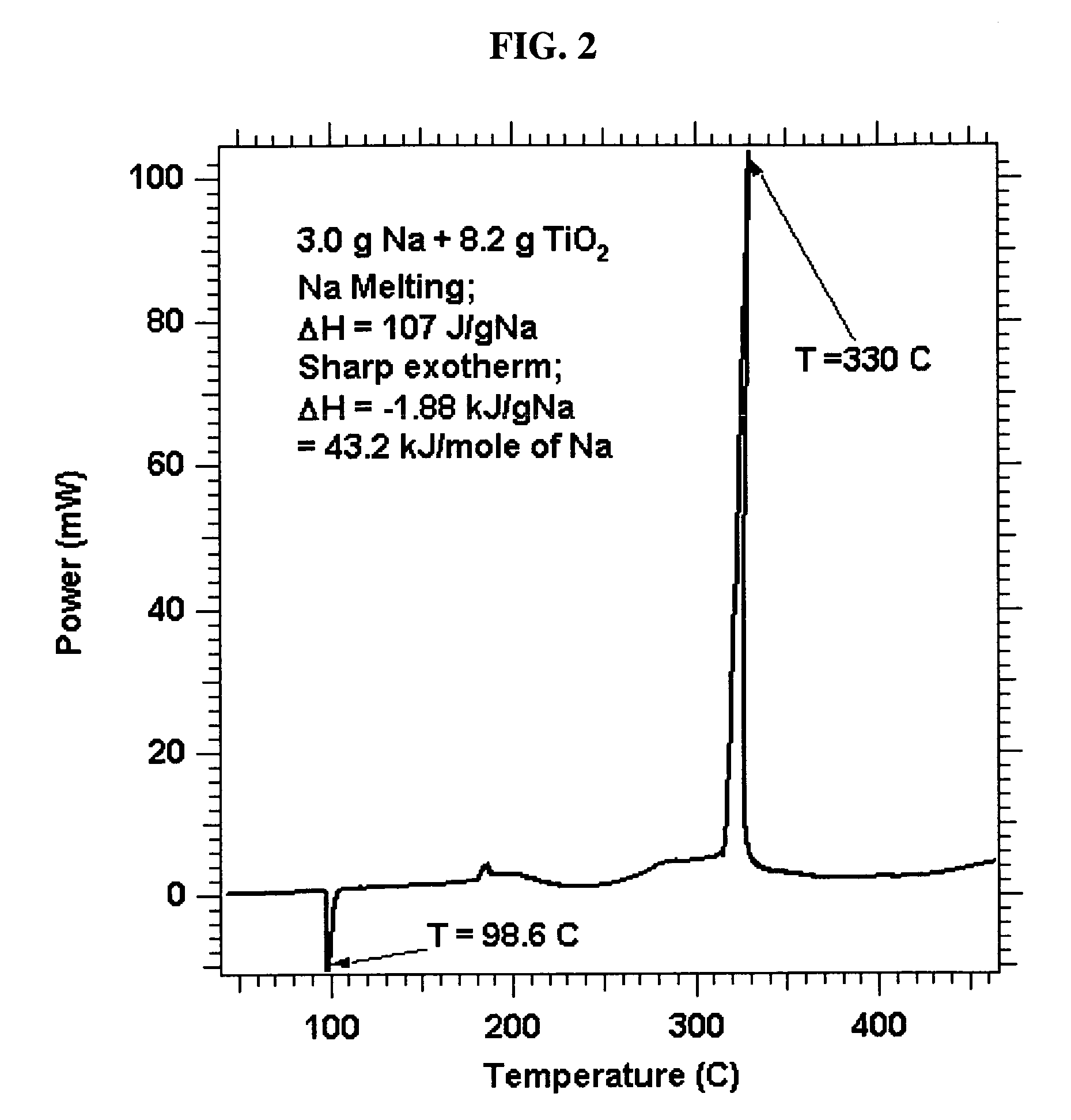

Titanium oxide and alumina alkali metal compositions

ActiveUS7259128B2Preparation by dehalogenationOther chemical processesChemical reactionSodium-potassium alloy

The invention relates to Group 1 metal / porous metal oxide compositions comprising porous metal oxide selected from porous titanium oxide and porous alumina and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0 and I materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by porous metal oxide under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the porous metal oxide at about 150° C., an exothermic reaction produces Stage I material, loose black powders that are stable in dry air. Further heating forms higher stage materials of unknown composition. It is believed that Stage I higher materials represent reductions of the porous metal oxide after absorption of the Group 1 metal. Preferred Group 1 metal / porous metal oxide compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium-potassium alloys being most preferred. Each stage of the Group 1 metal / porous metal oxide composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +1

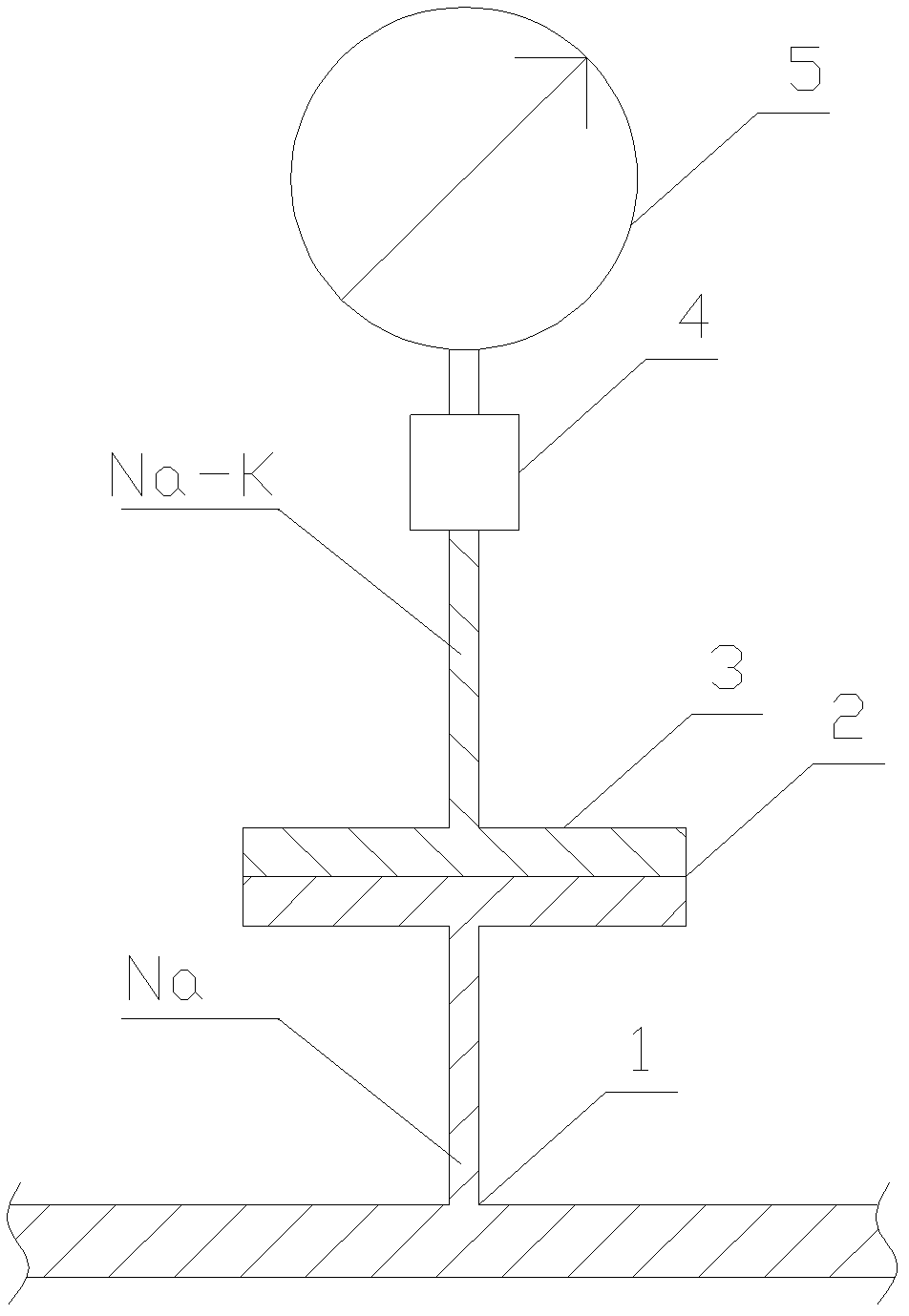

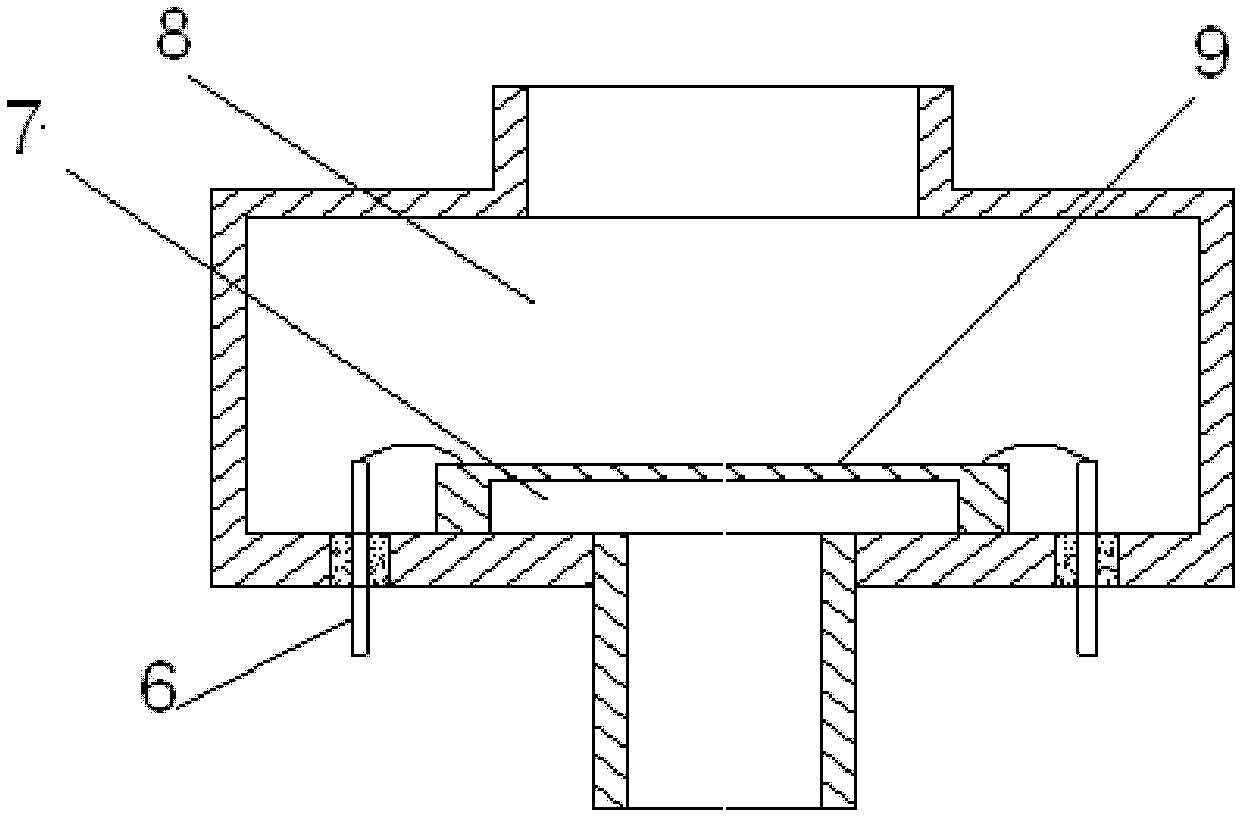

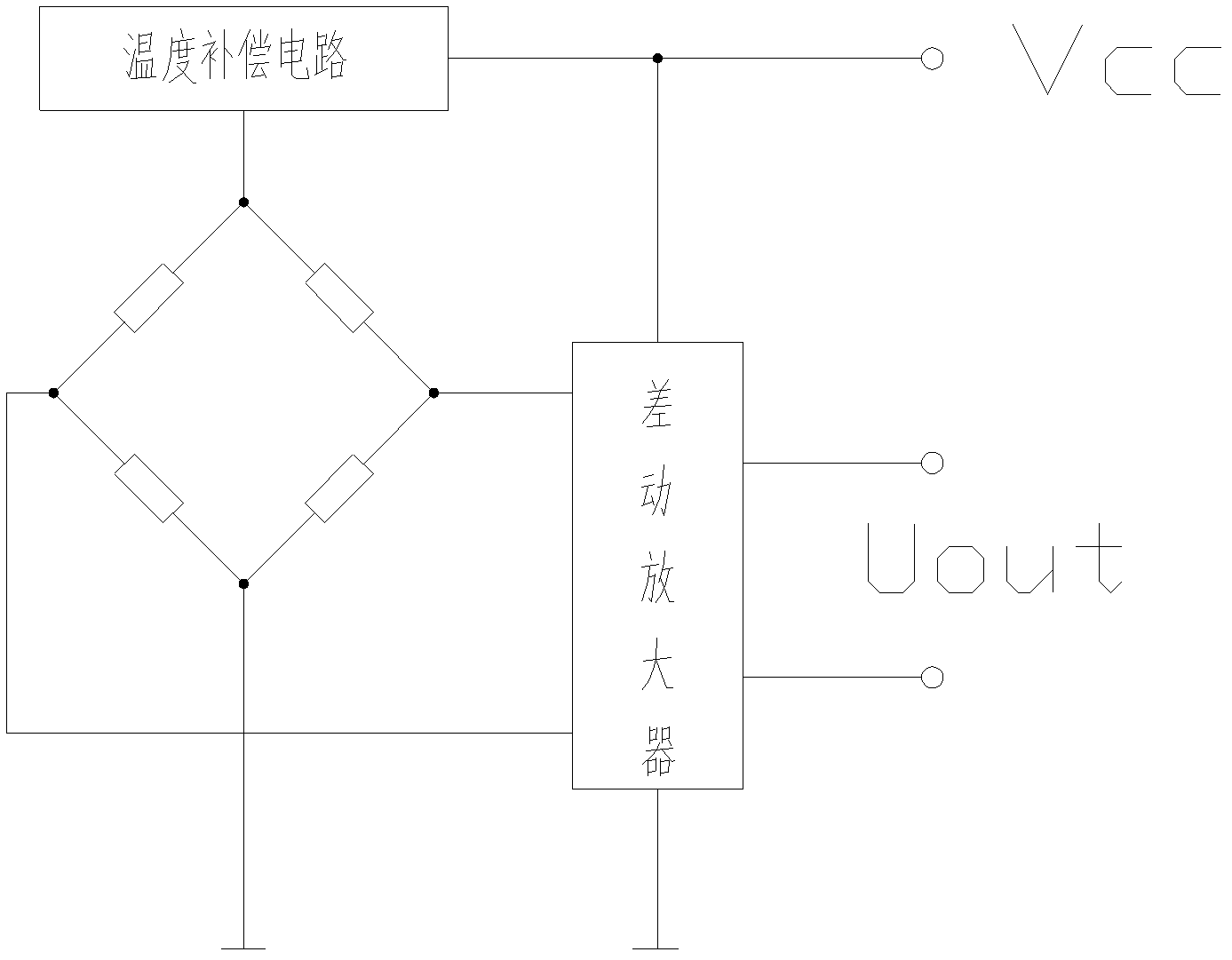

Liquid-state metallic sodium experiment loop pressure sensor

InactiveCN102435381AAvoid contactReduce riskFluid pressure measurement using ohmic-resistance variationLiquid stateLiquid metal

The invention discloses a liquid-state metallic sodium experiment loop pressure sensor. The pressure sensor comprises: a sodium adapter, an elastic strain gauge, a sodium-sodium potassium alloy pressure sensor box, a sodium potassium alloy-air pressure sensor and a pressure gauge. The sodium adapter is connected with a main pipe. Liquid state sodium can enter into the sodium-sodium potassium alloy pressure sensor box through the sodium adapter. The elastic strain gauge is in the middle of the pressure sensor box. Two sides of the strain gauge are the liquid state sodium and liquid-state sodium potassium alloy. The liquid-state sodium potassium alloy enters into the sodium potassium alloy-air pressure sensor through the pipe. A pressure signal is converted into an electric signal in the pressure sensor. The converted electric signal is displayed through the pressure gauge. Two-stage sensing is used so that the sodium can not contact with the air. A sealing property is good. A temperature compensation circuit is used in a bridge circuit of the sodium potassium alloy-air pressure sensor. An error generated by temperature can be avoided and overall measurement accuracy can be increased.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com