Liquid-state metallic sodium experiment loop pressure sensor

A technology of pressure sensor and liquid metal sodium, which is applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve the problems of unsuitable liquid metal sodium pressure sensor, sodium and air contact, etc., and achieve small structure size, reduce risk, and seal performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings:

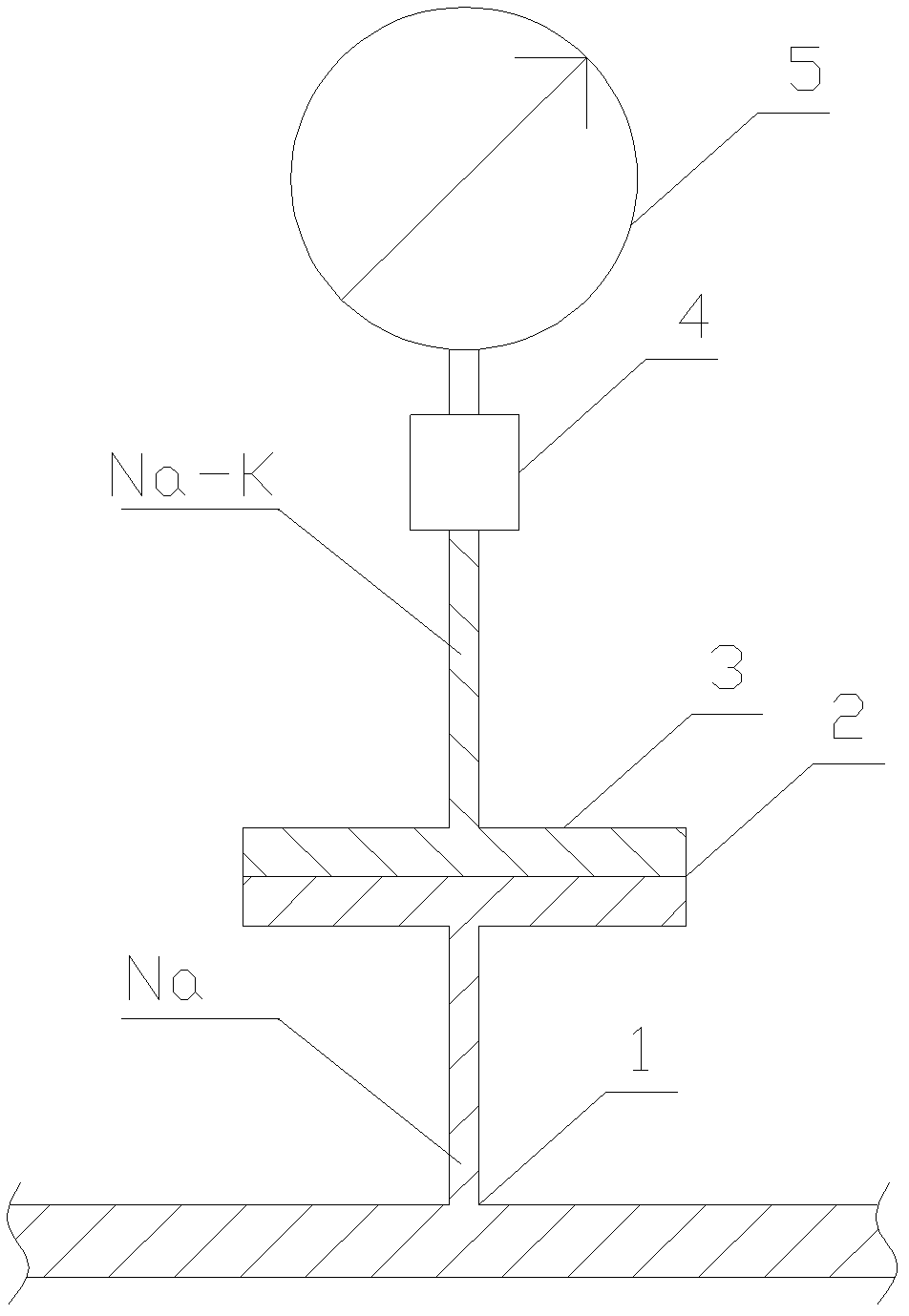

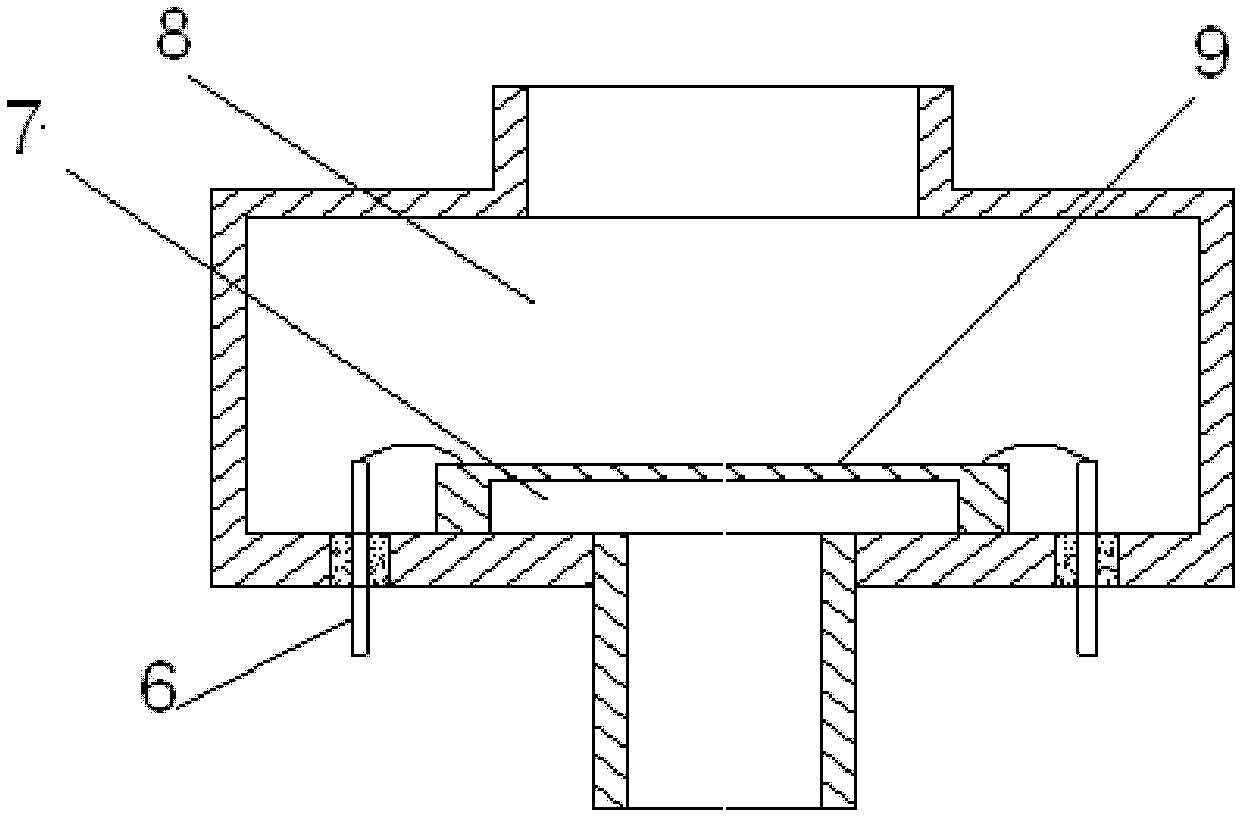

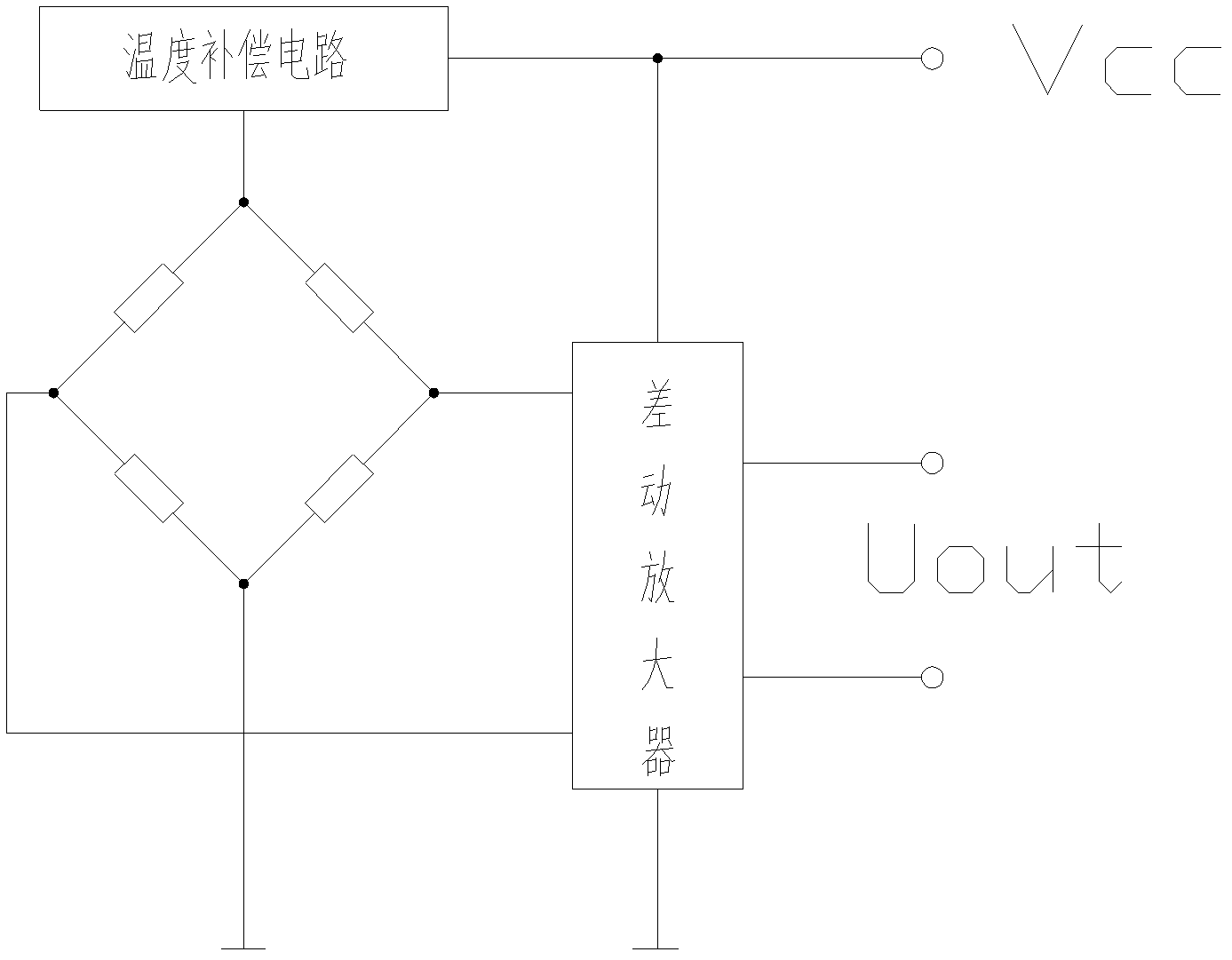

[0023] See figure 1 , The present invention includes sodium connector, elastic stress sheet, sodium-sodium-potassium alloy pressure sensing box, sodium-potassium alloy-air pressure sensor and pressure gauge. The sodium connection pipe is connected from the main pipe where the pressure needs to be measured, and is connected to the sodium-sodium-potassium alloy pressure sensing box. There is an elastic stress sheet in the middle of the sodium-sodium potassium alloy pressure sensing box, and the elastic stress sheet transmits the pressure of sodium from one side to the other One side of sodium potassium alloy makes the pressure on both sides consistent. After the sodium-potassium alloy in the sodium-sodium-potassium alloy pressure sensing box is connected, connect a sodium-potassium alloy-air pressure sensor, and the pressure signal is changed into an electrical signal in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com