ZnFe2O4/Bi7O9I3 magnetic composite photocatalytic material and preparation method thereof

A composite photocatalysis, bi7o9i3 technology, applied in chemical instruments and methods, physical/chemical process catalysts, water/sludge/sewage treatment, etc., can solve problems such as high price, increased energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a ZnFe 2 o 4 / Bi 7 o 9 I 3 The magnetic composite photocatalytic material is prepared according to the following steps:

[0034] S1, ZnFe 2 o 4 Preparation of:

[0035] (1) ZnCl 2 and FeCl 3 ·6H 2 O was dissolved in deionized water at a molar ratio of 1:4, and stirred until completely dissolved to obtain solution A;

[0036] (2) A certain amount of NaAc (with ZnCl 2 The molar ratio is 1:8) into the above-mentioned solution A, stirred at room temperature until completely dissolved to obtain solution B;

[0037] (3) Transfer the solution B into a three-neck flask and incubate at 80° C. for 8 hours to obtain the product solution C;

[0038] (4) After the solution C was left to stand for 2 hours, the product solution C was centrifuged, and the rotation speed was controlled at 7000-9000r / min for 5-9 minutes to separate the product solution C and obtain a precipitate D, which was washed and dried. Said precipitation D, said precipitation ...

Embodiment 2

[0049] To the ZnFe prepared in embodiment 1 2 o 4 / Bi 7 o 9 I 3 Structural characterization of magnetic composite photocatalytic materials.

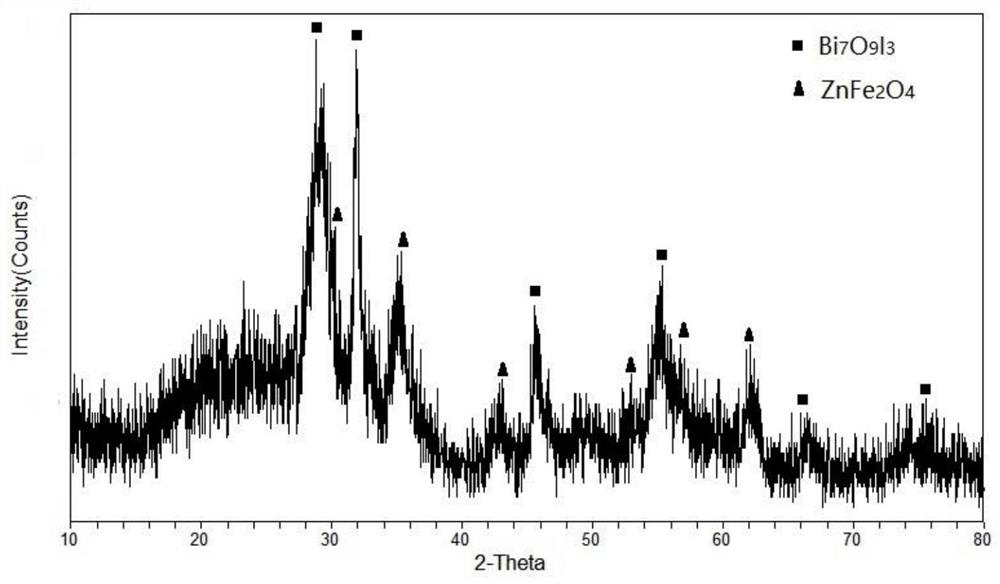

[0050] Depend on figure 1 Known: ZnFe 2 o 4 with Bi 7 o 9 I 3 The characteristic peaks all exist, indicating that ZnFe 2 o 4 / Bi 7 o 9 I 3 Successfully compounded to form a magnetic composite photocatalytic material;

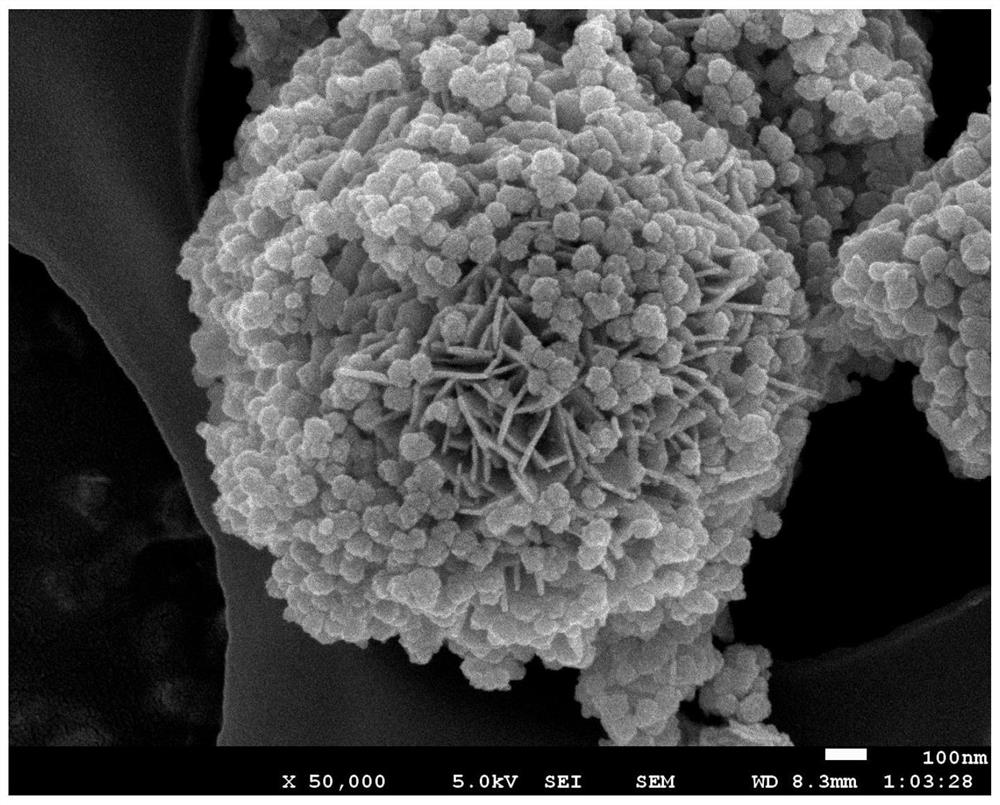

[0051] Depend on figure 2 Known: ZnFe 2 o 4 It is a spherical nanoparticle with a size of 20-80nm; Bi 7 o 9 I 3 The nanosheets (thickness 5-10nm) are inserted into a micron-scale flower shape, and ZnFe after compounding 2 o 4 Spherical nanoparticles interspersed with Bi 7 o 9 I 3 In the micron-scale flower-like structure composed of nanosheets, a composite structure is formed.

Embodiment 3

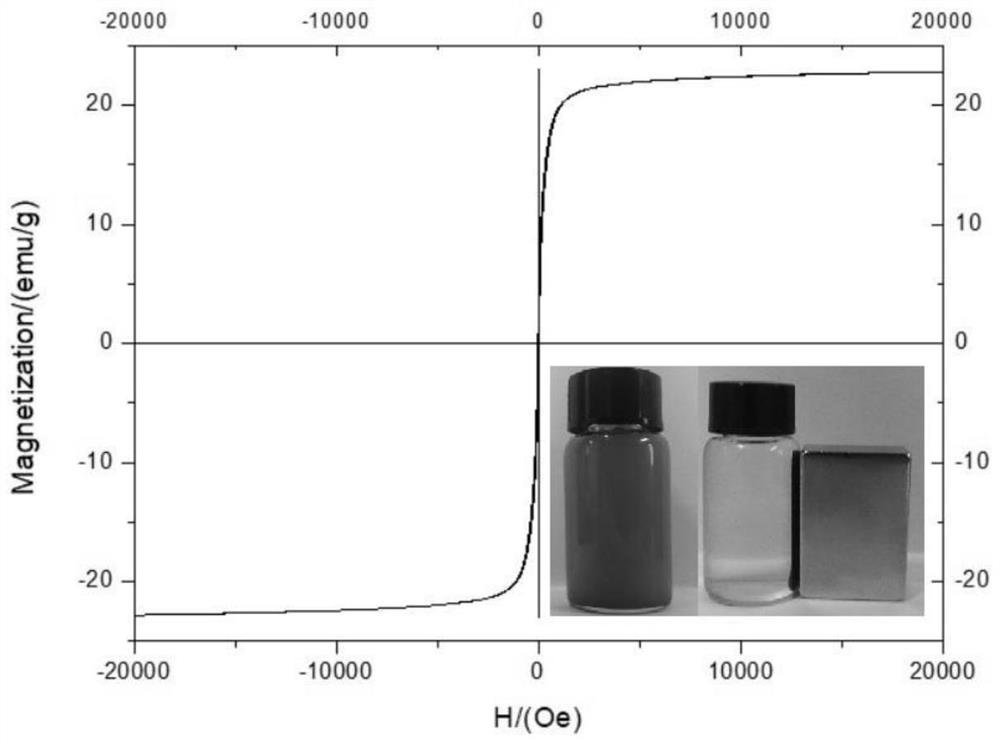

[0052] The test of embodiment 3-saturation magnetization

[0053] Utilize vibration magnetometer to measure the ZnFe that embodiment 1 prepares 2 o 4 / Bi 7 o 9 I 3 Magnetic properties of magnetic composite photocatalytic materials.

[0054] Depend on image 3 Know, ZnFe 2 o 4 / Bi 7 o 9 I 3 The magnetic composite photocatalytic material exhibits superparamagnetism, the saturation magnetization is 23.1emu / g, and has good magnetic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com