Composite thermal insulation structure of thermal battery and application of composite thermal insulation structure in thermal battery preparation

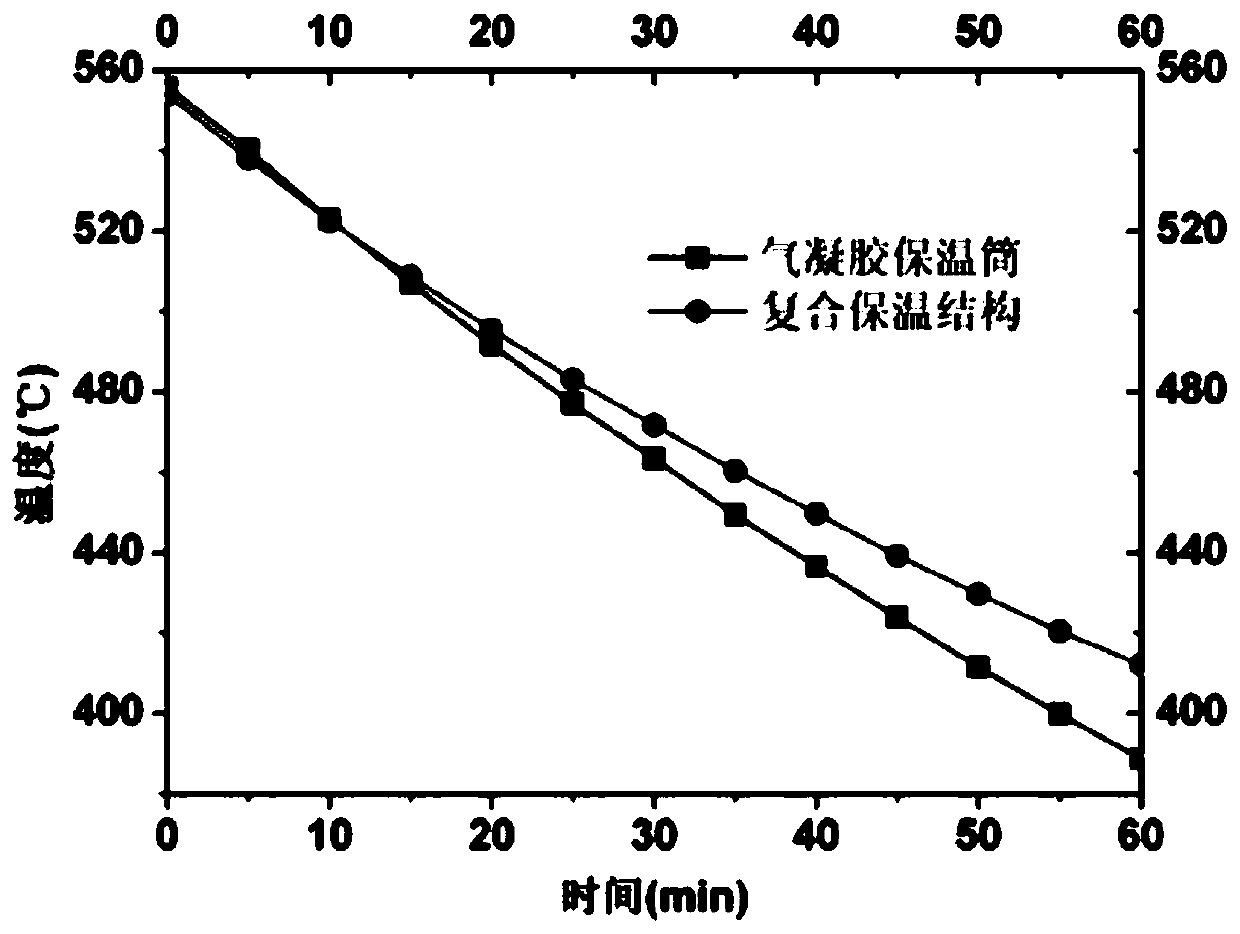

A composite thermal insulation and thermal battery technology, applied in structural parts, secondary batteries, battery pack components, etc., can solve the problems of poor thermal insulation effect and short life of thermal batteries, and achieve excellent thermal insulation effect, low surface temperature, and extended transmission. The effect of thermal paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

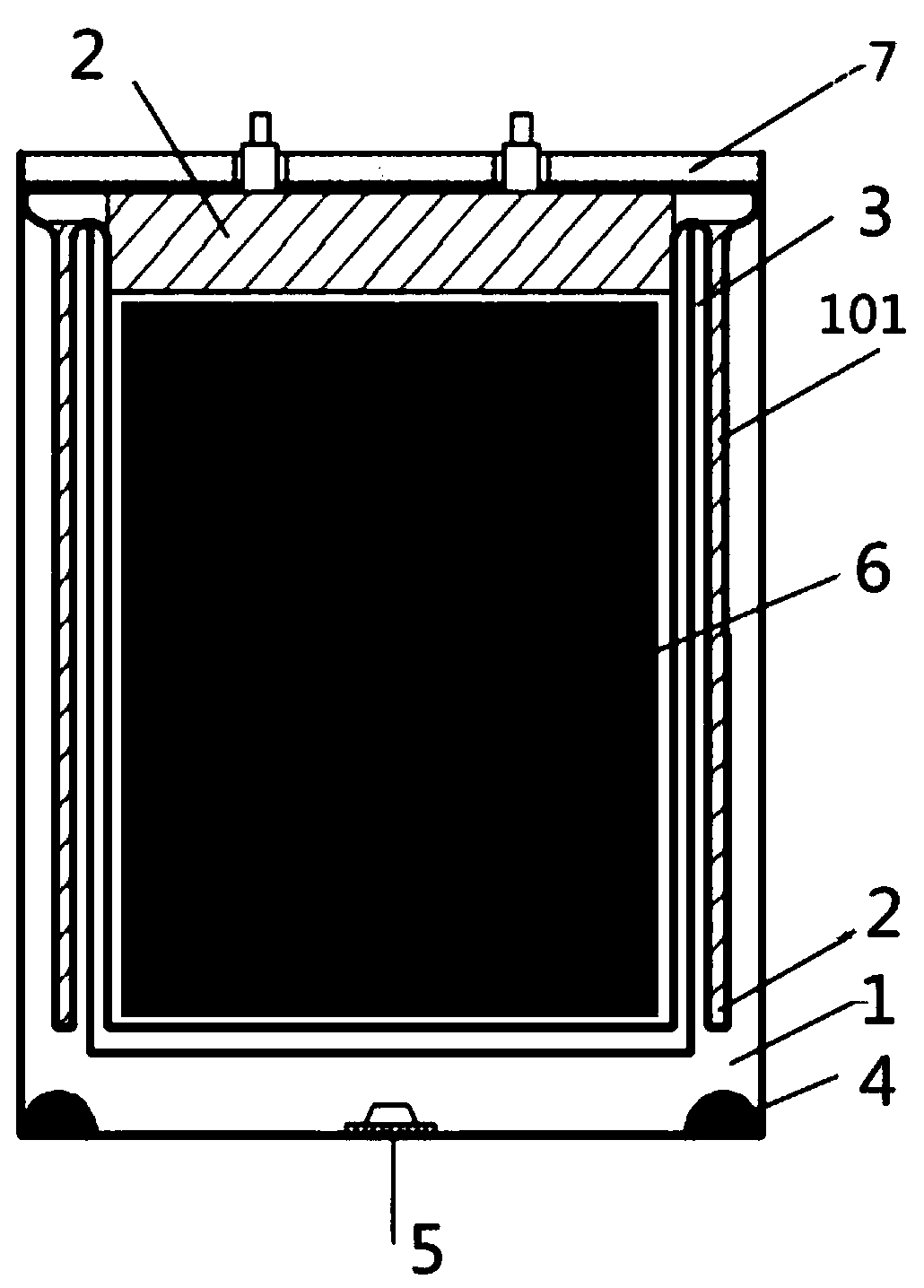

Embodiment 1

[0038] The vacuum insulation cavity 1 is made of stainless steel 304 material as the shell material of the vacuum insulation layer, and the copper foil and the Ti-Zr-V getter material are fixed inside the vacuum insulation cavity 1 by welding to ensure that the copper foil does not trap the vacuum The inner and outer walls of the shell of the thermal insulation cavity are overlapped, the copper foil is used as the infrared radiation reflection layer 3, and the structure of the groove 101 is set on the side wall of the shell to extend the heat conduction path of the stainless steel shell, and then sealed with a vacuum furnace The shell of the vacuum insulation cavity 1 is pumped and sealed. After the vacuum sealing process is completed, the groove 101 on the side of the shell of the vacuum insulation cavity 1 is filled with nano-silica airgel material, and then installed Insert the thermal battery stack 6, put in the airgel plug and cover the battery cover 7 to complete the asse...

Embodiment 2

[0040] The vacuum insulation cavity 1 is made of Kovar 4j29 material as the shell material of the vacuum insulation layer, and the silver foil and the Zr-V-Fe getter material are fixed in the vacuum insulation cavity 1 by welding to ensure that the silver foil does not The inner and outer walls of the shell of the vacuum insulation cavity are overlapped, the silver foil is used as the infrared radiation reflection layer 3, and the structure of the groove 101 is set on the side wall of the shell to extend the heat conduction path of the Kovar shell, and then use The vacuum sealing furnace pumps and seals the shell of the vacuum insulation chamber 1. After the vacuum sealing process is completed, the groove 101 on the side of the shell of the vacuum insulation chamber 1 is sealed with nano-sized zirconia airgel material. Filling, and then put into the thermal battery stack 6, put in the airgel plug and cover the battery cover 7, and complete the assembly of the thermal battery. ...

Embodiment 3

[0042] The vacuum insulation cavity 1 is made of titanium alloy TC4 material as the shell material of the vacuum insulation layer, and the gold foil and the Y-Mn-Al getter material are fixed by welding in the vacuum insulation cavity 1 to ensure that the gold foil does not insulate the vacuum insulation. The inner and outer walls of the shell of the cavity are overlapped, the gold foil is used as the reflective infrared radiation layer 3, the structure of the groove 101 is set on the side wall of the shell to extend the heat conduction path of the titanium alloy shell, and then the vacuum sealing furnace is used to seal the The shell of the vacuum insulation cavity 1 is pumped and sealed. After the vacuum sealing process is completed, the groove 101 on the side of the shell of the vacuum insulation cavity 1 is filled with nano-zirconia airgel material, and then loaded Put the airgel plug into the thermal battery stack 6 and cover the battery cover 7 to complete the assembly of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com