Nanometer micropore heat insulation board and manufacturing method thereof

A technology of heat insulation and nano-micropores, which is applied in the direction of heat preservation, heat exchange equipment, and pipeline protection through heat insulation, can solve the problems of inability to achieve heat preservation and heat insulation, achieve good heat preservation, improve refractoriness and surface mechanical strength, Strong high temperature resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

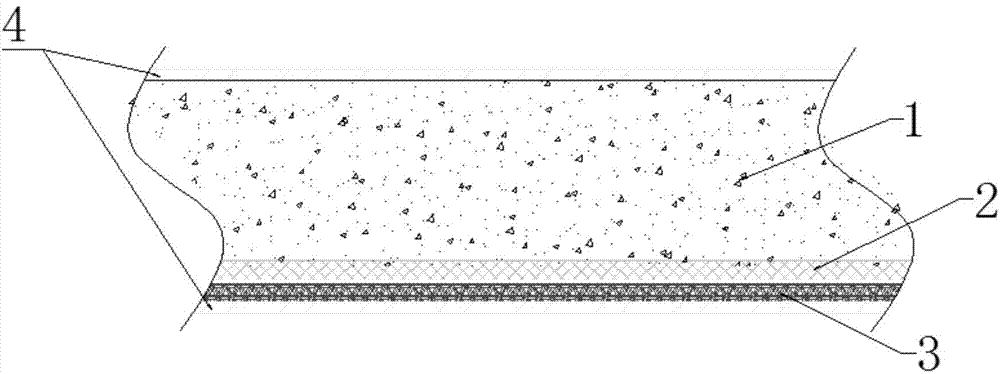

[0030] This embodiment provides a nano-microporous thermal insulation board with a structure such as figure 1 As shown, from the cold side to the hot side (from top to bottom in the figure) are the thermal insulation layer, the anti-radiation layer and the reinforcement layer. The thickness of the thermal insulation layer, the anti-radiation layer and the reinforcement layer are 3mm, 1.5mm, and 1.5 respectively. mm; wherein the material composition of the thermal insulation layer is 550g fumed silica and 30g glass fiber; the material composition of the anti-radiation layer is 30g nanometer silicon carbide, 15g nanometer titanium dioxide; the material composition of the reinforcement layer It is 30g aluminum oxide and 6g zirconium oxide;

[0031] It is prepared by the following method:

[0032] (1) Weigh the material components of the reinforcement layer and inject it into the mold, and spread it flat on the bottom of the mold as the bottom layer;

[0033] (2) Weigh the material com...

Embodiment 2

[0038] This embodiment provides a nanoporous heat-insulating and heat-preserving board, which is composed of an insulation layer, an anti-radiation layer, and an enhanced layer from the cold side to the hot side. The thickness of the insulation layer, the anti-radiation layer and the enhanced layer are 15 mm and 0.5, respectively. mm, 0.5mm; wherein the material composition of the thermal insulation layer is 2400g of fumed silica and 150g of ceramic fiber; the material composition of the anti-radiation layer is 100g of nanometer silicon carbide and 30g of nanometer titanium dioxide; The material components are 100g aluminum oxide and 50g inorganic clay;

[0039] It is prepared by the following method:

[0040] (1) Weigh the material components of the reinforcement layer and inject it into the mold, and spread it flat on the bottom of the mold as the bottom layer;

[0041] (2) Weigh the material components of the thermal insulation layer into the mold, and spread them evenly on the b...

Embodiment 3

[0046] This embodiment provides a nanoporous thermal insulation board, which is composed of an insulation layer, an anti-radiation layer, and an enhanced layer from the cold side to the hot side. The thickness of the insulation layer, the anti-radiation layer and the enhanced layer are 4mm and 2mm, respectively. , 2mm; wherein the material composition of the thermal insulation layer is 650g fumed silica, 20g glass fiber, 10g ceramic fiber, 10g alumina fiber, 5g carbon fiber; the material composition of the anti-radiation layer is 60g nano silicon carbide The material component of the reinforcement layer is 60g aluminum oxide;

[0047] It is prepared by the following method:

[0048] (1) Weigh the material components of the reinforcement layer and inject it into the mold, and spread it flat on the bottom of the mold as the bottom layer;

[0049] (2) Weigh the material components of the thermal insulation layer into the mold, and spread them evenly on the bottom layer of step (1) to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com