Vacuum low-temperature ball valve

A technology of vacuum cryogenic and ball valves, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of short service life, poor heat insulation effect, etc., achieve small cold loss, reduce metal heat conduction, and self-centering sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

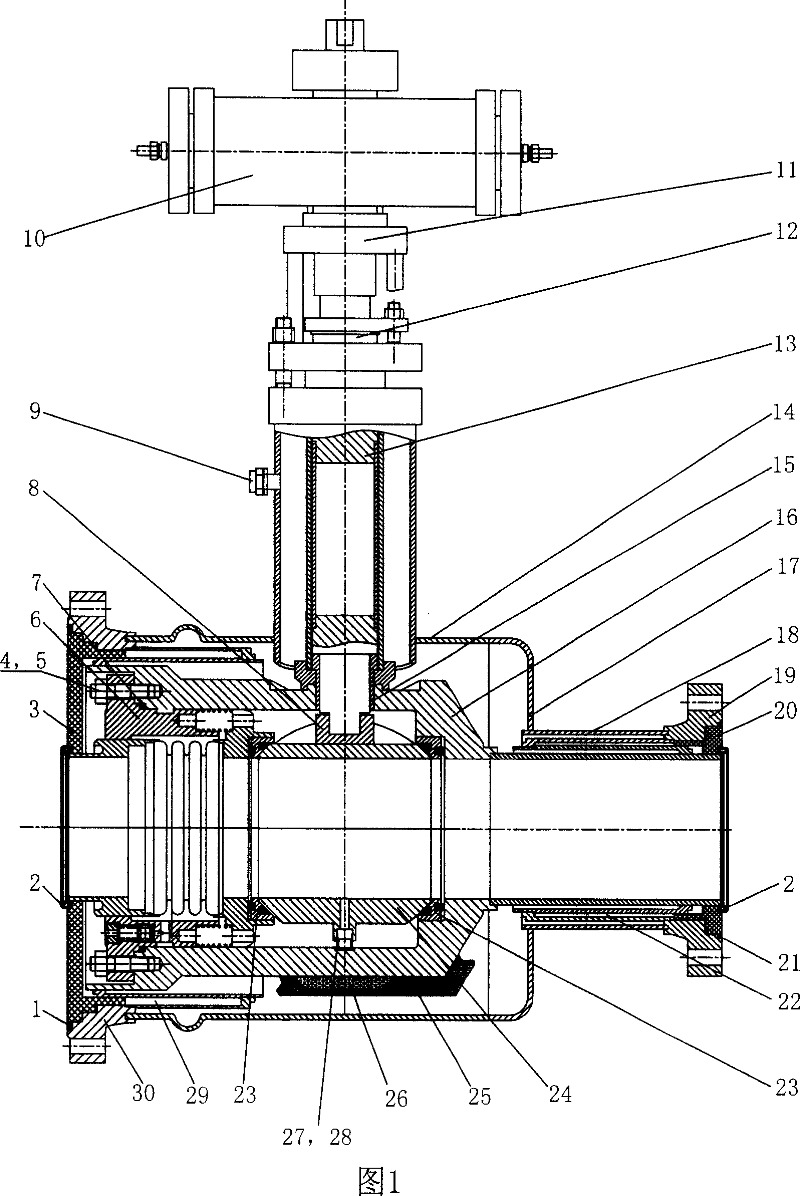

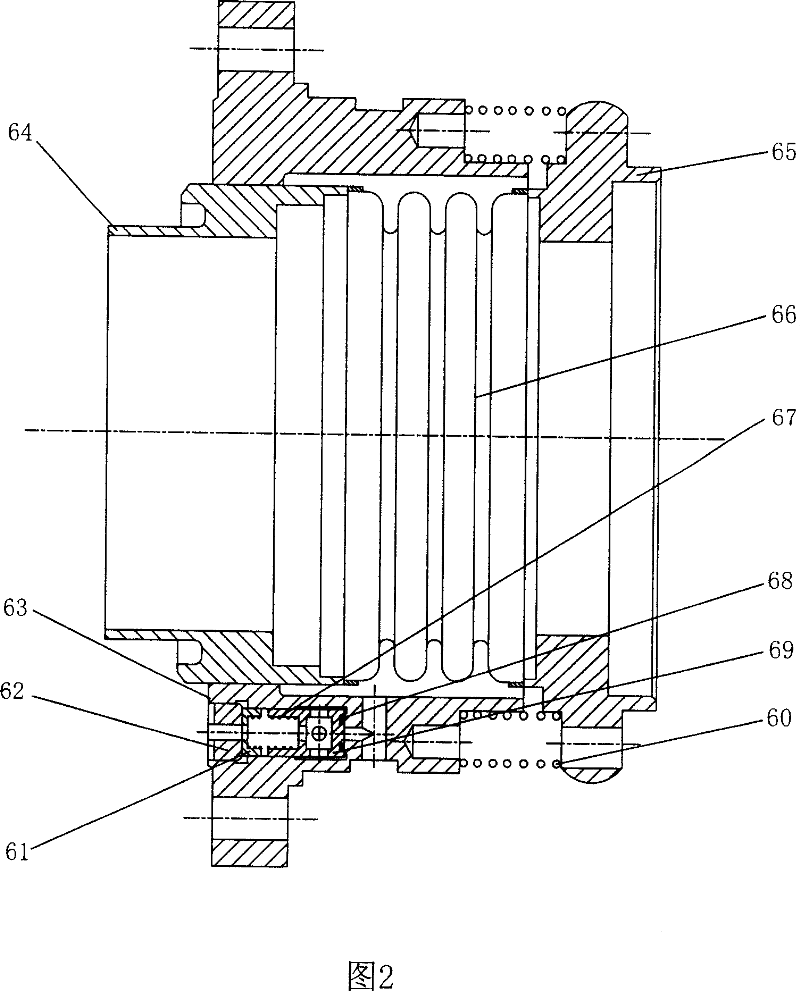

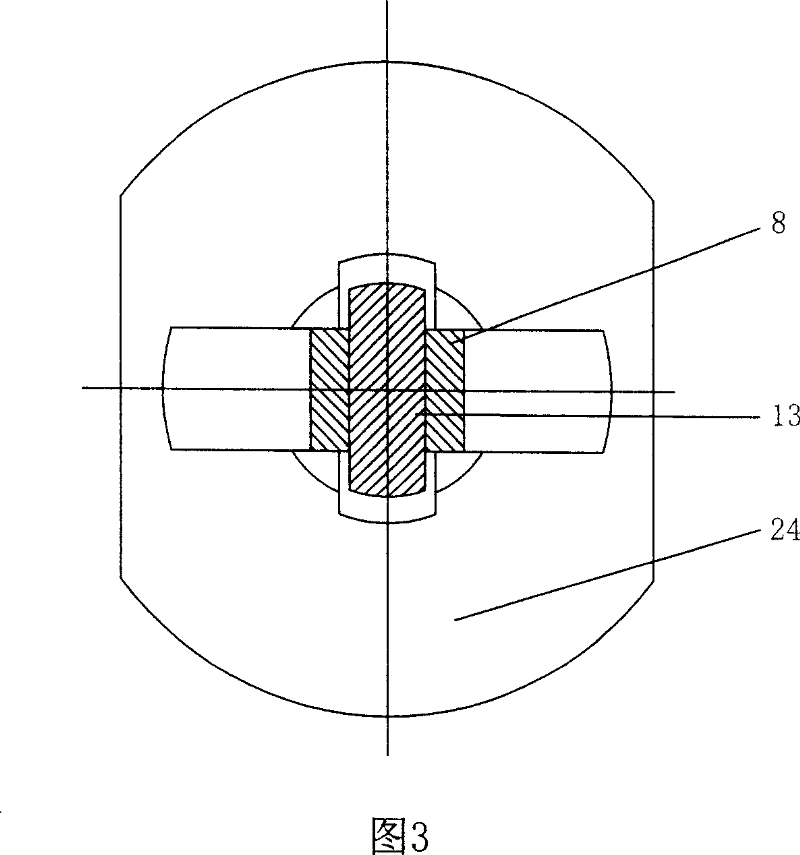

[0029] As shown in Figure 1, the structure of a vacuum cryogenic ball valve of the present invention includes a jacket part, a sealing part and a transmission part. The main feature is that the jacket part includes an inlet flange 30 with a thermal bridge, and an outlet flange with a thermal bridge The flange 19, the inlet flange 30 with a thermal bridge and the outlet flange 19 with a thermal bridge are connected with a housing 14 and a housing end cover 17; the sealing structure part is included in the jacket, and the two ends are respectively fixed on The valve body 16 on the inlet flange 30 and the outlet flange 19 is fixed on the elastic valve seat 6 at the inlet end of the valve body 16 through studs and nuts 4, 5, and two sealing seats 23 with gaskets embedded on both sides, One of them is connected with the elastic valve seat 6, and the other is connected with the valve body 16; The slider 8 is set in the upper groove of the sphere 24, and the slider 8 also has a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com